Good day to all! It is fair to say that shelves are the main element of filling any closet, since they can accommodate a large number of different things and clothes. Therefore, today we will discuss with you the fastening of shelves in the closet.

The fasteners in question are suitable for various structures, including sliding wardrobes, structures made of chipboard and wood, for mounting to a wall, etc. Many people are interested in how to attach shelves in a built-in closet. Today we will try to answer this and many other questions for you.

If you have anything to add or have questions, you can always write in the comments. And off we go!

Types of fastenings for different shelves

There are three main types of shelves used in modern furniture:

- Wooden. The material is chipboard or MDF. The most common type.

- Glass. Manufactured from tempered glass through special thermochemical treatment. As a result, additional strength is provided, which allows them to be used in furniture production.

- Mesh or wire. They are a wire frame in the form of boxes or baskets.

Today, shelves are made from almost any material, including glass.

There are additional modifications to the shelves, such as folding, pull-out or height-adjustable. However, no specially designed type of fittings (with the exception of retractable ones) are used for their installation.

Shelves can have various modifications, including retractable mechanisms.

Materials used

There is a fairly extensive list of materials from which you can assemble or purchase ready-made furniture.

But it would be fair to include the following among the main furniture materials:

- Chipboard (from laminated chipboard);

- MDF;

- wooden boards;

- array;

- plywood;

- furniture panels;

- drywall;

- metal;

- plastic;

- glass, etc.

The last two options are more relevant for bathrooms, since the materials are as moisture resistant as possible. But glass shelves require appropriate fittings, that is, shelf holders.

Practice shows that pelican shelf holders are excellent for glass shelves. There is another option, what is another name for this mount. This is a toucan. We have already written about this, so just follow the link.

Holder for glass shelf in cabinet

There are two most common types of glass shelf holders.

Special holders have been developed for glass ones.

Classic, support

In general, they represent a pin design and are structurally divided into two parts: countersunk and supporting. The first part is usually mounted into the wall. Support – designed directly to hold the plane of the shelf. It is made in the form of a platform: simple, coated, with a plastic gasket or an installed suction cup. Allows you to remove shelves without using tools.

Various modifications of classic holders may look different.

"Pelican": plug-in, with lock

This type of fastening can have different designs, but fundamentally it also consists of two parts: secret and receiving. The hidden part allows you to install fasteners on the cabinet wall, and the receiving part contains a groove where the glass is inserted and secured with a clamp. Installation requires a screwdriver or a special wrench.

Pelican holders look like this.

Attaching mesh shelves

Such shelves are often used in kitchen cabinets or wardrobes. If in the kitchen they are used, as a rule, for storing (drying) dishes, then fastening the shelves in the built-in wardrobe may require special reinforcement (in addition to the standard one or the one that comes included), since in this case mesh shelves are most often used for storage shoes

Such shelves are used in kitchens to store dishes. This imposes its own requirements due to the heavy load and increased size. In general, the mount is a stop with a pin part for mounting and a groove for placing the frame wire.

As a rule, they are attached to a supporting part.

Why is sagging dangerous?

In addition to the unpleasant external effect, sagging is also dangerous because at some critical moment the sagging shelf may simply break in half, and books and other objects placed on it will damage the lower elements if they fall. And in this case, the stability of the side walls of the furniture will be greatly shaken and, most likely, the cabinet will simply fall apart, crushing - at best - the furniture standing nearby, at worst - the owners or pets.

The bookcase must be securely attached to the wall with its entire structure in order to prevent it from falling and causing damage to property and health of people and animals.

To prevent this, deflections should be dealt with at the first manifestations.

Installing shelves in a closet: types of fasteners

Furniture fastening fittings vary both in purpose and in the nature of the connection provided.

Fasteners for shelves differ in purpose and nature of the connection. According to the purpose of the fastener, there are:

- Frame.

- Mounting.

- Power.

By the nature of the connection:

- Collapsible.

- Non-separable.

Typically, fastening involves the use of tools such as a drill, forstner cutters, countersinks, screwdrivers, hex keys, chisels, and wood glue. In addition, some types of fasteners require the use of very specific tools, which imposes restrictions on the possibility of their use (Lamello Invis screed).

To attach the shelves you will need certain tools.

Before choosing the type of fastener, you should carefully consider the nature of the cabinet's use, so that later you can ensure trouble-free servicing of individual elements or complete disassembly.

Euroscrews (Euroscrews, confirmats)

Used to connect wooden furniture elements (chipboard, MDF). Such fasteners for a shelf in a closet impose a requirement for a wall thickness of at least 16 mm. Confirmations are manufactured in a certain range of lengths, from 20 to 70mm.

The wall for such fastening should be no thinner than 16 mm. To prepare the mounting hole, special drills with a countersink part at the base are required, as well as special keys to fix it in place. They are relatively easy to assemble, but may not be suitable for all types of furniture, since the screw head remains open. In addition, euroscrews do not allow organizing the longitudinal arrangement of shelves at the same height in the presence of vertical jumpers.

Such fastenings are quite reliable.

Fastenings for shelves in the closet: rastex (minifix)

This fittings belong to the so-called eccentrics, which indirectly indicates their principle of operation. This type of fasteners provides good joint strength, but is difficult to prepare, as it requires great precision in drilling holes. Structurally, it consists of a sleeve for the pin (footer), the pin itself, and a tension sleeve.

This is what Rastex fasteners look like. The footer is installed in the cabinet wall, in a previously prepared place. A pin is screwed into it. For the tightening sleeve, a piece of wood is selected with a milling cutter so that it fits flush into the shelf. A hole for the pin is drilled perpendicular to it, from the end. After the connection is assembled, the bushing pulls the pin and clamps it, thanks to the groove in the sidewall (hence the ex src=»https://severdv.ru/wp-content/uploads/2020/07/sverlenie-dlya-rasteksa.jpg "class="aligncenter" width="1500″ height="1143″[/img] This fastening requires precision drilling skills. Such a connection has two significant drawbacks: it cannot be used in a finished frame, and when marking it should be taken into account that when fixing the shelf can move in the plane.

Conical coupler

In this case, installing shelves in a closet is similar to installing using a minifix. Moreover, their schematic diagram is also quite similar: both have a liner, a tension sleeve and a pin. The only difference is the holding method.

This is what conical screws for fastening look like. If rastex ensures this using a groove in the bushing body, then here the fixation is carried out with a special conical screw, which, screwed into the cavity of the bushing, engages the corresponding hole at the end of the pin and tightens it, thereby creating the necessary tension.

Screw tie

Typically, this fastener is used to lengthen (splice) shelves, in particular in the presence of vertical walls. This solution provides both a fairly convenient installation method and high reliability. Can be considered as additional reinforcement of the frame.

The screw fastener is easy to install and reliable. The concept of this solution is extremely simple: a piece of wood is removed from the edge of the shelf with a milling cutter, forming a recess. A similar one is being formed in another regiment. A hole is drilled into the wall large enough to allow a threaded lag pin or screw to pass through. Specially shaped staples with a hole in the side are inserted into the recesses. The pin is threaded into the brackets and then tightened with nuts on both sides.

Fastenings for shelves in the closet: Rafix

Another representative of the eccentric type, but unlike the minifix, does not require drilling the end channel. The schematic diagram is approximately the same, only the pin is held in place with a special screw.

This is what Rafix furniture fastenings look like. The selection for the sleeve is made at the edge of the shelf, so that after processing with a milling cutter at the end there is an opening sufficient for the passage of the pin, which is installed on the cabinet wall. After this, the shelf with the inserted bushings is put on the pins. Fixation occurs by tightening the bolts. The disadvantages of Rafix include the inconvenience of installation, especially with low shelf heights.

Shelf holder

The simplest, yet no less effective option for attaching shelves. Structurally, it differs between mortise and hinged. Mortise involves a pin part with which it is installed inside the wall. Hinged - attached with screws or glue.

Shelf holders can be mortise or hinged. With this method, the shelf is freely placed on supports (under its own weight), which, if necessary, allows it to be easily dismantled. Structurally, a typical shelf holder in a closet can be equipped with a platform supplemented with spacers or a special protrusion to prevent the shelf from moving towards the door.

The convenience of such holders is that the shelf can be freely dismantled at any time.

Dowel

The same pin, only wooden - the oldest way to connect furniture elements to each other. Structurally, it is a small chop (20-30 cm in length) with corrugation along the side surface. The connected parts of the frame (or shelves) contain inlet and counter coaxial holes, so that the pin installed in the end of the shelf fits into the hole on the cabinet wall.

The wooden dowel has the shape of a small chop with corrugation on the side surface. In principle, just installing the dowels is enough. Nevertheless, for the reliability of the connection, as well as to strengthen the frame, the adjacent ends are additionally glued (sometimes confirmats are also screwed in). The obvious disadvantage of this type of fastening is the difficulty of dismantling. As a rule, such fasteners for shelves in a closet are used in non-demountable structures.

The disadvantage of such fastening is the difficulty of dismantling the shelves.

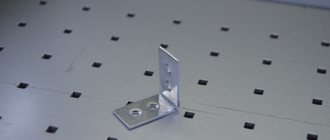

Corners

Also a simple and at the same time reliable type of fastening hardware. They differ both in design (in details) and in the material of manufacture. Of course, it is best to install metal corners, as they are stronger and more durable. However, they have a significant drawback - appearance.

Corners are simple and reliable fittings for attaching shelves. Since the installation of corners, whether to the wall or to the shelf, is carried out using screws, this may not always be acceptable. In such cases, the installation of shelves in the closet is carried out using open or closed plastic corners. The closed-type fastener has a special cover that hides the unsightly interior part.

However, recently metal corners have also begun to be equipped with decorative covers.

General rules

Making a wardrobe with your own hands provides many advantages. So, this is not only a significant saving on the family budget, but also an opportunity for imagination and experimentation. In order for the finished product to be comfortable and practical, at the design stage you should be guided by the following tips:

- The number of compartments inside the cabinet must match the number of doors. But this rule does not apply to wide doors, behind which you can install 2 compartments with shelves at once.

- It is convenient to store laundry in cells with a height of 35-40 cm, books - 20-35 cm.

- The optimal opening for long clothes is 150-160 cm, for short ones – up to 100 cm.

- Large items, suitcases, and travel bags are best placed on the top shelf. The height of the opening must be at least 45 cm.

- According to generally accepted standards, the depth of the wardrobe is 60 cm, which is exactly the size of the factory model. If the wardrobe is made independently, it is better to make it at least 65 cm. The fact is that the door mechanism “eats” 10 cm, so only 50 cm remains for clothes with hangers.

- If you plan to install a volumetric handle on the box, then it needs to be recessed a little so that the protruding part does not touch the doors. An excellent alternative to such handles would be the finger grooves on the front panel of the drawer.

- When making drawers with your own hands, it is better to use ball-bearing full extension guides. They are distinguished by their durability, strength and convenience.

- Large cells larger than 80 cm must be reinforced with a partition, otherwise they will bend under the weight of things.

- Rods for clothes longer than 100 cm are also recommended to be additionally reinforced with a vertical rod, the lower end of which rests on the floor, and the upper end on the top shelf. Thanks to this, you don’t have to worry about the heavy weight of your clothes.

- It is better to install the lighting in the cabinet in the remote roof canopy, and not inside the structure, otherwise the light will only fall on the top shelf.

When making a wardrobe with your own hands, we must not forget that the arrangement of things in it must have a certain sequence. For example, on top are placed the most unnecessary things that need to be taken out least often - hats, bags. In the middle are those that are used most often - outerwear. Below are boxes with shoes, bags, backpacks.

How to attach removable shelves?

Removable shelves are often installed in a cabinet that is already in use. It may also be an initial decision pursuing its own specific goals. In principle, most of the above types of fastenings are suitable for their installation, but not all. The following are commonly used:

- Shelf supports.

- Corners.

- Screw or conical ties.

If you have the necessary tools, Rafix may also be a good solution, but only if the shelf does not need to be removed every other day.

What types of brackets are there?

Shelf brackets vary in shape, material, style and maximum load. Photos of shelf brackets, which can be found in hardware catalogs or on the Internet, allow us to distinguish 3 main forms:

Corner bracket. One of the easiest ways to attach a shelf. Structurally, it consists of two planks connected by a rib or jumper for greater rigidity. The vertical strip is used to attach the support to the wall, and the horizontal part is used to mount the shelf itself.

Rectangular brackets. The method of fixing to the wall is similar to the previous one. A distinctive feature is that the bracket allows you to install 2 shelves under each other at once.

Pelican type mount. The support got its name due to the similarity of the lower part with the beak of a bird. Most often used as a bracket for glass shelves. But it can also be found paired with a shelf made of chipboard or metal.

This type of shelf holder has a collapsible design, dividing the device into moving and fixed parts, a screw pair and a seal. The fixed part is attached to the wall; a pressing element with a rubber or silicone gasket is inserted on top. The shelf is clamped between the two parts using a screw.

Most models can withstand loads of up to 30 kg. At home, it is very rare that the weight of a shelf with its contents exceeds this figure. But for warehouses or retail outlets, it makes more sense to secure shelves using reinforced shelf brackets.

Increased thickness (from 3 mm or more), the addition of additional stops and ribs make the element durable. It can withstand significant loads without deforming.

Shelf holder in the closet: care and operation

As such, there are no special rules relating exclusively to the care of fasteners. Unless the plastic corners and tension sleeves are kept clean. The mode of operation is more important here. For example, a connection with Euroscrews does not tolerate loads in a perpendicular plane.

There are no special requirements for the care of fasteners. Minifixes, conical ties and especially rafixes have a greater degree of resistance. The weakest point of such fasteners is the cutouts for the pin. Therefore, you should not load the shelves more than usual. In addition, it is advisable not to allow excess humidity in the room, as this does not have the best effect on the mechanical properties of wood.

If the shelf is properly attached, it will last a very long time. Based on the large selection of available fasteners and auxiliary accessories, solving problems with installing a new shelf or fixing a broken one should not present much difficulty. Moreover, using original fastenings for shelves in the closet, you can try to optimize the internal space so that everything you might need fits there.

Through fasteners (with drilling) for confirmations

Confirmats are the most common through fasteners for shelves. To install, you will need to drill a hole in the end of the shelf with a diameter of 5 mm and on the front side of the side of the cabinet with a drill with a diameter of 8 mm. It is better to use a special confirmation drill. Since a countersink is still required for the head, the screw itself is flush with the surface of the sidewall. Next, the cap is hidden with a special self-adhesive plug, matched to the color of the chipboard.

A nuance: depending on the thickness of the sidewalls, the length of the confirmat is selected. For standard chipboard and MDF thicknesses of 16-18 mm, a 5x50 euroscrew is used; for thicker board materials, a longer one is used, up to 70 mm.

- Among the advantages of attaching shelves to confirmations, it is worth highlighting the ease of assembly and the low cost of the fasteners themselves.

- The downside is the need to drill through. Not everyone likes the “holey” sides of the cabinet from an aesthetic point of view. Although the self-adhesive plugs are color-matched, they are still visible. Also furniture assembled through repeated assembly and disassembly.