In the twenty-first century, which can rightly be called the digital age, a computer is one of the most popular gadgets in the home. Therefore, the location of this electronic accessory should be ergonomic and quite convenient. You can purchase a computer desk in one of thousands of online stores or make it yourself using only photos, diagrams and simple drawings with dimensions. Our article will tell you about the second option - which models are suitable for what and how to assemble them yourself.

DIY straight work surfaces for your computer

For the convenience of working with office equipment, there are many types of tables. They differ in design, type and size. Straight-shaped products are classics and occupy an important place in furniture production.

Stylish DIY accessory

Creating a fashionable work area for your desktop computer is not an easy task, but it is completely doable. The main difficulty lies in turning curved parts of the correct geometric shape. You can, of course, limit yourself to straight lines, but the effect will not be as expected.

First of all, you need to cut out the base and sides, and then adjust the radius of the transverse parts to fit them. If you do everything step by step, then there should be no difficulties. Pay special attention to the retractable keyboard stand. It is better to mount the runners under it, and not on the side, so it can withstand a significant load. At your choice, equip the product with additional rows of shelves for storing papers and other small items.

Gaming table for personal computer

The work surface, specially designed for gamers, allows you to spend time playing in comfort. With minimal effort, it provides the player with access to all the necessary tools. Most existing models are created by professionals, but if you really want to, you can make a gaming computer table with your own hands. A little skill and imagination will allow you to design a universal product that will satisfy exactly your needs. Use metal pipes as supports. Attach the wooden parts to them not directly, but using protrusions to which you mount the shelves. As a result, you should have a multifunctional piece of furniture.

Features of a circular saw

Knowledge of these features is extremely important; you must take into account the operating modes of the saw, know the type of loads and take all possible measures to strengthen the most important components. Only with this approach can long-term and safe operation of a homemade machine be achieved.

What are the common features of woodworking machinery?

High speed saw teeth. This ensures the quality of sawing. But high speeds of the saw blade cause serious injuries; during the manufacture of the machine, great attention must be paid to safety precautions. All devices available on industrial copies must be installed without fail. Do not think that some of them are superfluous, and you will be able to modernize factory samples for the better. All safety rules are written in the blood of injured people, do not repeat tragic mistakes.

Strength of all nodes

This means the inability to withstand significant static loads, although this is very important. The table can easily absorb large forces of this type, but at the same time vibrate under the influence of even relatively minor dynamic multidirectional loads. This condition does not have a negative impact on safety, but noticeably deteriorates the quality of the cut.

Marks of teeth are noticeable on the surface of lumber, it is difficult to maintain specified linear dimensions, etc.

Fire and electrical safety. Absolutely all electrical devices, motors, starters and other special fittings must be installed in strict accordance with the requirements of the PUE. You need to know that dry sawdust not only burns well, but also forms an explosive mixture at a certain concentration in the air. By the way, burning sawdust is difficult to extinguish; it floats on the water and continues to burn.

There is no need to make the simplest machine at the expense of safety devices; strictly follow the recommendations of the designers. Decide what you need, a woodworking machine or fresh problems?

For a miniature room

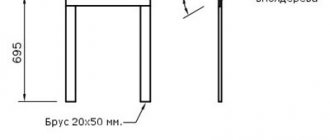

The option is designed specifically for use in limited areas. Depending on the type of room, it may have a different configuration. There are models with a retractable and stationary tabletop. Below is a diagram for creating the simplest table.

Large PC table with bureau

Such furniture will become indispensable for an office in which a lot of documentation is stored. Simple design, does not provide a pull-out shelf designed for a keyboard and other attributes. The photo shows the steps for making a bureau and other elements yourself.

Working studio

The product has impressive dimensions. But if your activity is closely related to computer technology, then a studio table will be the best option, since it has almost everything for work. Desire, as well as a minimum set of materials, will allow you to make such a piece of furniture yourself.

Height adjustable

An original idea for creating a work area for a computer. It is practically impossible to find such a model on the open market. The adjustable surface of the tabletop allows all family members to use the furniture comfortably. Creating such an item is not easy, you will need welding, metal, wood and other industrial style elements, but the effort will be fully justified.

Simple

The easiest PC table to make can be made with your own hands from scrap materials, for example, for the needs of a country house. The product will most likely be universal and can serve as a regular dining or writing desk. The bottom drawer can be used as storage for papers and stationery, or converted into a shelf for a keyboard.

Mechanic's workbench

This device is distinguished by its functionality and durability.

On the working surface of the bench, you can fix workpieces intended for processing, and the pull-out shelves are very practical for storing technical equipment.

Mechanic's workbench

The height of the structure is adjustable.

The main elements of a workbench of this type include the bench (its base) and the lid (working surface).

Components of a carpentry workbench

The benchtop of a bench is usually made from hardwood. However, pine is used for the underlayment.

The thickness of the cover measures approximately 60–80 mm and 500 mm in width. The parameters of the workbench depend on the main purposes of making the workbench.

The understand can be collapsible or stationary. Since the device is easy to assemble and disassemble, it is convenient to use during transportation.

Collapsible workbench

If the workbench base is made of metal, then planks are additionally attached to its base to protect it from various defects. For this purpose, the tabletop is covered with linoleum. This method will prevent small elements from falling into the cracks on the desktop.

It is recommended to install high sides on the workbench lid so that small parts being processed do not roll off the surface. A protective partition will isolate the workplace and prevent chips from flying out during metalworking.

The sides will prevent small parts from rolling off

A workbench for your home requires at least several shelves and drawers.

You can fill the space under the countertop of the device with a variety of cabinets in which it will be convenient to store building materials.

For the convenience of working at the workbench, you will need to install sockets, especially if you frequently use power tools.

In large production, it is better to use roller workbenches. This will allow you to freely move them to the desired place.

Workbench on wheels

Table equipped with an extension

This option is more suitable for people of average and tall height. It is comfortable to work at the monitor while sitting in a large chair. The system unit with wires is placed below in the legs, which are made from old book shelves. The LCD screen is placed on stainless steel supports, slightly above the tabletop. The product is additionally equipped with LED lighting, which gives it a futuristic look.

Simple accessory with shelf

A simple, ergonomic option with sectors measuring 0.5 by 1 m. It is made from planed wood or improvised materials (old furniture, pallets). For manufacturing you will need a circular saw, a chisel, an angle grinder and other small tools.

Backlit

High-quality lighting will be the highlight of any design. Furniture equipped with an LED strip appears to float in the air, creating a feeling of lightness. The accessory will fit perfectly and decorate a small room.

Use of building materials

- Planed timber is considered a universal building material for making a desktop. The size of the legs of the structure is usually 7x10 cm.

Workbench legs made of planed beams

- An old unnecessary door can serve as a workbench cover. The thickness of the boards used for the tabletop should be about 5-6 cm.

- Before making the device, you need to decide what type of workbench will be - stationary or collapsible. Based on this, the fastening is selected (bolts, screws, nuts, nails).

- It is advisable that the workbench has several vices. One can be installed on the side and the other on the front. Vices are convenient because they fix products intended for processing. The universal width of the vise jaws is 5 cm.

Attaching a vice to a workbench

Sketches of computer desks with the most popular sizes - photo gallery

Below you will see drawings of the most popular models of tables for personal computers. The diagrams visually show how to create an ergonomic and practical product from a minimum number of parts that will decorate any room.

Area of application of wood

Lining is made from larch, which will retain all the unique properties of this wood and will have excellent decorative functions. Larch is also used in the manufacture of Durisol building blocks - this is a new unique technology for constructing walls in modern house construction. Houses made from these blocks are distinguished by wear resistance, excellent noise and heat insulation characteristics. Today, Canadian larch in America is used for constructing various types of roads, as well as for the construction of buildings in the Arctic zone. Siberian larch is one of the best materials for the construction of ships, boats and boats, since the physical properties of this wood are very high for use in the aquatic environment. This material has beautiful noble shades, and that is why larch is often used for interior decoration, both in public and residential buildings. This finish is unique because it is not afraid of biological and atmospheric influences, and products made from this material will not be afraid of rotting and can withstand long-term general loads. A structure made entirely of larch can last 200 years or more. Wooden architecture has always been popular in Rus', and today in the Urals and Siberia you can see ancient wooden houses made of larch, which have survived to this day.

Corner furniture for PC

This variety is designed to optimally fill the space in the corner of the room. Many existing models will create an ideal area for working with office equipment. Below we will look at the most interesting, in our opinion, projects of corner computer desks with drawings and dimensions.

What is it like?

The corner of the room will be a good place to place furniture for office equipment. Such accessories have a larger surface area. In terms of functionality, this product is much superior to its competitor with a straight tabletop. If you are looking for the most rational and optimal option for a miniature room, then making a corner piece of furniture yourself is a good solution. Just follow the instructions and you will be the owner of universal furniture that will satisfy all your needs.

Types of designs

Devices are divided into the following types:

Mobile.

It is a small table with a vice and weighs up to 30 kg.

It is better to make the lower supports of this design from metal material, as this gives the workbench additional stability.

Mobile workbench example

This device is designed for repairing small wooden pieces.

Stationary.

A fairly simple device to make. Most often used for processing large wooden products.

Scheme of a stationary workbench

Composite.

Elements of this design are connected by fastening bolts.

The convenience of this desktop lies in the interchangeability of individual elements.

Composite workbench

Making a composite workbench is fraught with some complexity.

Table with high top in corner

Very often the corner space is the only place where you can put a computer accessory. Knowing the dimensions, it is possible to make it yourself. Use galvanized or water pipes as supports. This table is made high so that it is possible to work, so to speak, “on the go.”

Recommendations for selection and processing

It is recommended to process a wooden tabletop:

- Bio-impregnation. It consists of beeswax and natural oils of plant origin. Thanks to this, the product becomes resistant to moisture, it is not afraid of mold and mildew, detergents (household chemicals) used in the kitchen.

- It is also recommended to use wood oil as a treatment, which may come into contact with food.

- The classic option is a combination of varnish and colored glaze.

The surface does not absorb foreign odors and is not exposed to grease.

When choosing, you should listen to these recommendations:

- It is best to choose a tabletop made from 100% wood.

- Oak and larch are considered the most wear-resistant, but pine has an affordable price.

- The treatment increases wear resistance.

- Tabletops made of spruce, beech, birch or elm are light.

- The interior remains harmonious; the wooden product must fit into it.

- It is optimal if the depth of the tabletop is increased.

- It is necessary to purchase products only from trusted manufacturers.

- By reducing the thickness, you can save money.

- There is a joint between the two canvases, which can easily be made invisible to the eye.

Large selection of textures and shades from beige to noble brown.

Homemade corner table

When no store-bought model suits you, or you don’t have the necessary budget, then the best option would be to create an accessory yourself. You don’t need any special skills for this, just learn how to drill, grind, saw and have good patience. Photos with step-by-step instructions and drawings of computer desks with dimensions of parts will facilitate the manufacturing process.

Varieties

More than 20 varieties of larch have been identified. Of these, 14 grow in Russia. In our country, Siberian larch and Daurian larch are mainly represented, which are among the most common varieties.

Siberian larch (also called Sukachev larch) occupies about 13-15% among other varieties. It can be recognized by the branches extending from the trunk at right angles. Their ends smoothly rise upward. The tree is quite unpretentious and grows in an urban environment. It almost entirely has properties beneficial to humans (bark, needles, and resin).

Daurian larch is the most common tree. This is one of the most frost-resistant varieties. It grows on many soils, but not on excessively swampy ones with a large excess of moisture.

In addition to Siberian and Daurian, European and Japanese (kaempfera) are also widespread.

European most often grows in Europe (Central and Western). It should be noted that this variety has about 5 breeds (Horstmann Recurved, Kornik, Puli and others). This is the tallest variety: in the Alps the height reaches 50 m, the trunk diameter is more than 1 m. In Russia, European larch cannot grow to such parameters due to climatic conditions (here the maximum height will be 25 m, but this does not always happen).

Japanese larch got its name from the country where its characteristics were first discovered. Widely grown in Korea. Used for decorative purposes only. Characterized by a height of up to 35 m, in autumn the needles turn bright yellow.

In addition to the varieties mentioned above, there are also Kuril and Olga varieties. Hybrids have also been bred: Amur, Chekanovsky, Lyubarsky, Okhotsk. Nowadays, to improve the territory of a personal plot, you can buy varieties of decorative larch species specially bred by breeders from nurseries. They are considered, unlike wild species, to be dwarf trees (their height does not exceed 2 meters). These are the varieties “Puli”, “Kornik”, “Krejci” and others.

Sketches of corner products

Below are assembly diagrams for the most popular models. Making such interior items yourself will not be particularly difficult.

Material advantages

Molded larch materials have a number of positive qualities:

- strength and moisture resistance;

- resistance to microorganisms and insects;

- aesthetics of products;

- durability;

- not susceptible to cracking or deformation;

- attractive surface texture;

- fire resistance.

Due to the presence of resins in the structure of the tree, larch moldings can be used in all spheres of human activity. And the pleasant aroma of pine needles will bring the feeling of being in nature into your home.

Humidity, temperature fluctuations, shuffling and intensive use do not affect the building material. Over time, it is able to harden and become harder.

The decorative qualities of wood allow the molding to fit into any interior. A warm brown and beige color scheme will make the room bright and attractive.

Work surfaces made from pallets

Building materials are excellent raw materials for creating home furniture. From pallets you can make benches, shelves for books and, in unusual shapes, tabletops.

A simple model of a pallet structure

An original solution to recycle unnecessary boxes and at the same time create something necessary for the home. The U-shape fits into limited space. You can place the system unit on the left side, and disks and documents on the right. The tabletop is covered with thick glass according to the size of the pallet.

Classification of metalwork benches

Locksmith workbenches can be of various types.

There are single and double designs. The type of fixture depends on the number of bedside tables it has.

Basically, the diameter of a mechanic's workbench, which has one bedside table, is 120x80 cm, and from 80 cm in height. This type of single-seat workbench is rightfully recognized as the most convenient.

Single workbench

Workbenches, consisting of several bedside tables, are usually made at large specialized enterprises.

The dimensions of the two-seater workbench are approximately 280 cm in length.

There are also pedestalless devices.

The single-pedestal workbench is made of high-quality metal, the thickness of which reaches 2 mm.

The working surface of this design is most often made of wood or galvanized material. Often these workbenches are equipped with hanging shelves for storing equipment and other devices.

Double backpack with hanging shelves

Single and double benches differ from each other only in the number of bedside tables. The more drawers and cabinets a device has, the more convenient it is to store various tools and building materials.

Today, a reinforced workbench with a metal lid reaching 5 mm in thickness is especially popular. All structural elements are connected to each other with fastening bolts.

How to make a PC desk

If you want to have a good work area for your computer, but no store-bought option suits you, or you don’t have enough money to purchase the models you like, then make it yourself from pallets. Such building material can be easily obtained and given the desired shape. Use the best boards for arranging the tabletop, the rest as needed. Open the finished product with varnish.

A simple option from pallets

To implement the idea you will need three pallets. Two of them will have to be disassembled to make a solid tabletop. From the rest, depending on the project, legs, shelves and other elements are created. It is better to fasten all components with self-tapping screws. When the structure is ready, it is polished and covered with ship's varnish.

Large table made from wooden pallets

It is quite expensive to purchase such a product in a store. Many people resort to pallets to solve this issue. Creating a table with your own hands is not difficult, but you will have to work hard. Boards made from pallets are not always smooth, often chemically treated, and have elements of rust. However, after sanding them and varnishing them, the product comes out as if it came out of a factory assembly line.

Folding pallet model

If your room is small, your budget is limited, and a table is extremely necessary, then you can make it out of pallets and fold it out. One part of the accessory is fixed on the wall, and the other has legs. Using door hinges, a mechanism is created that, if necessary, folds and unfolds the table. This surface is convenient to use for working with a laptop and PC.

Types of vices

Before choosing a workbench, you need to find out what kind of vices exist for these devices.

The vice is designed for fastening workpieces to the structure. To ensure the efficiency of the work process, special grooves with wedges are installed on the workbench lid, thanks to which the bars are attached.

The properties of the vice depend on the specifics of the work.

The following types of fasteners are distinguished:

Chair vice.

The vice gets its name because it is attached to a chair-shaped base. They are designed to perform heavy duty work. They are used very rarely.

Chair vice

Hand vice.

They, in turn, come in three types:

– instrumental;

– rotary;

– non-rotating.

For rotary and fixed vices, the width of the jaws is approximately 80 mm.

Hand vice

Universal vice.

They are used for fastening small workpieces.

The universal vice is fixed to the workbench tabletop using mounting bolts.

Universal vice

Special vice.

They are convenient because they can be easily rotated in any plane and adjusted both vertically and horizontally. This allows you to position and fix the element for processing at your own discretion.

Special vice

Photo selection of tables made from pallets

Below are photographs of the most popular DIY models.

Coating process

Proper treatment of a wooden surface is the key to its long service life. This rule especially applies to kitchen countertops. In addition to the fact that you need to choose the right treatment product, it is also important to properly prepare the surface, apply protection and dry. The following describes the process of how to coat surfaces using oil compositions as an example.

The coating process follows certain rules.

Preparation of the product

The main thing you need to pay attention to when choosing a coating is its quality. A good protective agent will protect the wooden surface from mechanical damage and moisture and give it a shiny, renewed look.

The coating must be of high quality to provide the furniture with protection and a well-groomed appearance.

The product must also be prepared. Before treating a wooden countertop in the kitchen, the composition must be thoroughly mixed for 5 minutes.

The product must be mixed well.

Preparing the wooden surface

The first step will be to clean the countertop from all kinds of dirt and greasy marks. Next it is dried.

Before coating, the surface must be cleaned of dirt.

On a note! The wood moisture content should be no more than 12% according to DIN EN 13183-2.

To ensure that the oil adheres well and is absorbed, the wood is sanded, starting with coarser abrasives, gradually moving to finer ones. Also, after each abrasive, the coating is cleaned. You may need to putty it to remove deeper scratches. A special restoration kit based on wax is ideal.

The wood should be sanded so that the coating lays more evenly.

Application

The composition is applied with a brush or cloth, and the latter should not leave lint on the surface. It will take about 12 hours for the first layer to dry. Then you can apply the next one, and so on. The number of layers will directly depend on how the product is applied. Using a brush, two treatments are enough; a fabric coating will require up to 4 layers.

Use a brush or cloth for application.

When the product is well absorbed, the entire treated area is thoroughly wiped with a soft and clean cloth.

After the product has been absorbed, wipe the surface with a cloth.

Drying

Drying time varies from several hours to several days. Naturally based oils or mixtures containing acrylic require a longer drying period. They can also increase strength gradually. It is important not to use a freshly treated countertop for a while.

After applying the coating, it is important to let the furniture dry.

Original solutions

A non-standard approach to creating a furniture accessory will help you create a truly unique piece of furniture. Below you can get some ideas.

Dresser

A computer tabletop can be combined with such a necessary furniture accessory as a chest of drawers. It is safe for children and takes up no more space than a standard TV stand.

Unusual modding on a coffee table

In this option, an additional pull-out shelf is equipped under the tabletop in which you can store a laptop. It is very convenient and incredibly practical. If you want a similar accessory for yourself, read the detailed step-by-step instructions.

Furniture with built-in PC

An interesting idea on how to hide a computer. The equipment is placed inside the table, so it is not visible from the outside. Looks compact and versatile.

DIY home office

During sedentary work, blood stagnates and muscles atrophy. Uncomfortable furniture is the main provocateur of osteochondrosis. There is an opinion that working while standing is much safer. If you are a fan of this idea, you can create a special high computer table for standing work. The design looks solid and has everything you need.

Non-standard modding of the system unit made of natural wood

The universal covering of the device in a futuristic style will help decorate your room. Unusual shapes and dim lighting will make the equipment the highlight of the interior. I like the idea, try making something similar.

Combining parts

The main properties of a workbench for the home:

The surface of the device is made of wood. For these purposes, dry planks with a thickness of 5–6 cm are selected. It is best to use wood that has been pre-treated with drying oil. Otherwise, the workbench tabletop will not last long.

Edged board for workbench

A vice is attached to the cover of the structure, which will fix the items being repaired.

It is preferable to make large vices from wood, and small ones from metal. If the length of the workbench exceeds 1 m, several vices of various sizes can be installed on its working surface.

Vise design

The legs of a carpentry workbench are made from boards of other wood species (maple, linden, pine). They are connected to each other by strips located longitudinally. This ensures reliability of the design.

The space under the workbench tabletop can be used rationally by installing pull-out drawers or shelves for storing work tools.

Workbench with built-in drawers

Recesses are made on the surface of the structure in which heavy items for repair will be fixed.

It is recommended to drill a hole on the back of the tabletop for repairing small parts.

Table stand

Any desk or coffee table can be refined and reformatted into a computer table if you install such a stand. The design is height adjustable and adapts to the needs of the owner. This is an ideal budget option for creating a full-fledged work area.

If you decide to make furniture yourself, then follow these tips:

- • Study well the issue and drawings of the most popular office desks.

- • Properly calculate the amount of materials needed.

- • Before you begin, make a detailed project in which you indicate all the nuances.

- • Carry out the work step by step and slowly. Pay special attention to cutting curved parts - if you doubt your abilities, entrust the cutting to a professional carpenter.

- • Treat the finished product with durable varnish.

With a little effort and some patience, you can create an original sketch. In this article we told you how to make a computer desk with your own hands.

Workbench design

The height of the device must be correlated with your own height. With an average height of a person (170 cm), it is rational to make a workbench with a height of 90 cm. It will be very convenient to work at such a table.

The configuration of a workbench for a home is selected taking into account the work that is planned to be performed on it. In the usual sense, a workbench should have stops, recesses on the working surface for various parts, and a vice.

When designing a structure, it is necessary to take into account which hand of the master is the leading one - left or right.

Simple single workbench project

The dimensions of the workbench largely depend on the size of the room. The following standard desktop dimensions are established: 2×1 m.

It is better to place the structure near the window. It is necessary to provide additional lighting sources. You need to leave space for sockets near the workbench.

If possible, place the workbench near a window

Alternative options

A good alternative to varnish for a kitchen countertop is to impregnate the wood with vegetable oils. Typically, mixtures of tung, linseed, and citrus oils are used.

A good alternative to varnish for a kitchen countertop is to impregnate the wood with vegetable oils.

The main advantages of oil impregnation compared to varnishing:

Environmentally friendly. Oils do not contain harmful substances that are necessary for film formation.

Oils do not contain harmful substances that are necessary for film formation.

Ease of use. Small scratches here are practically not noticeable and do not spoil the appearance. In case of serious damage to the surface, the damaged part can be sanded and then coated with oil again. Moreover, you can do this yourself. When restoring a varnish coating, it is necessary to treat the entire surface completely.

Small scratches here are practically not noticeable and do not spoil the appearance. In case of serious damage to the surface, the damaged part can be sanded and then re-coated with oil.

Oil impregnation does not change color and does not look noticeable, preserving the natural appearance of the wood. Oils can dry completely or partially. In the first case, they form a durable film; in the second, they can be erased from the surface of the wood over time.

Oil impregnation does not change color and does not look noticeable, maintaining the natural appearance of the wood.