Some mirror models have special hooks on which they can be attached. In this case, you will need to make a hole directly in the wall, insert a nail into it, on which the mirror will hang. But sometimes, in order to mount the product on a wall or any object, you need to drill a hole in the mirror at home.

The difficulty of performing such work lies in the fragility of the material. Work must be carried out with extreme caution so as not to damage the product. If you do not follow this rule, the mirror will crack or even break completely.

In essence, the product is glass, which has a special coating on one side. That is why it is necessary to work with a mirror surface in the same way. So how to drill a mirror at home? Let's look further.

Principles of working with a mirror

When processing fragile mirror surfaces, you must follow some important rules:

- First you need to place the mirror on a perfectly flat horizontal surface. For these purposes, you can use plastic, chipboard or plywood. The product must fit tightly to the surface.

- It is recommended to additionally degrease the surface to be treated. This can be done using acetone.

- How to drill a hole in a mirror? If the work is performed with a high-quality drill, you need to set the equipment to the slowest operating mode. There is no need to rush or put pressure on the instrument.

- Experts advise not to drill completely. You need to stop halfway, turn the mirror over and continue drilling from the back side.

detailed instructions

How to drill a mirror? Drill glass using a pen tip according to these instructions:

- The mirror must be placed on a flat and solid base. For this you can use sweaty plastic, plywood, chipboard.

- Using a marker, draw a drawing of the location of the hole and its diameter.

- To work with the perk, it is better to use a screwdriver. It is connected to the network and installed on the glass, according to the markings.

After this, using a spray bottle, you need to constantly spray water on the mirror so that it does not overheat during the drilling process. Start work at the lowest speed, gradually increasing it to medium mode. While working, you need to constantly lift the drill so that liquid can get inside the hole.

The process must be continued until the drill appears on the other side of the mirror surface. Then you need to turn the product over and repeat the steps above. When the feather drill appears on the other side, the mirror will have a smooth, neat hole.

Small holes for dowels

In the bathroom it is impossible to do without a mirror, shelves or hooks. If the tiles have already been laid, the question arises of how to properly hang all the accessories so as not to spoil the repair or split the tiles. For such purposes, a special drill is used that can carefully make a hole in the tile without damaging it.

There are several types of ceramic tiles, which you need to pay attention to when selecting tools and drills. Experienced experts advise beginners to use a hand drill to make a hole in porcelain tiles. It will be easier this way, because all the power of rotation and pressure will be in the hands of the master.

To get the hole right the first time, without damaging the tile, you need to follow a certain sequence of actions:

- stick adhesive tape or adhesive tape onto the tiles

- measure the distance and mark with a pencil the place where you need to drill

- insert the required attachment into the drill

- work at low speeds so as not to provoke a chip

- when the thickness of the tile is drilled, you need to change the drill (set for concrete)

- then a hole is made in accordance with the size of the dowel

In this way, all the tiles that need to be drilled for the dowel are processed. The main thing is not to rush and constantly cool the drill, otherwise, due to overheating, the tile will break, and if it is mounted on a low-quality compound, it will fall off.

Rules for working with drilling tools

How to drill a mirror at home using a quality tool? If the work is carried out using a special gimlet, you need to use a drill. In this case, the power of the equipment must be regulated. This tool is not always at hand, so you can use a simple screwdriver.

Markings must be made on the glass. It is not enough to simply draw a cross at the drilling site. It is necessary to draw a regular square, inside of which there will be a circle. This is the diameter of the future hole.

Sometimes during the drilling process the tool slides along the surface, and this can lead to damage to the product. To avoid this situation, you first need to make a small wooden blank. A hole is made inside it and attached to the mirror surface with tape. This little trick helps keep the drill in one position. To prevent the tool and the mirror surface itself from overheating during operation, it is necessary to take short pauses. At this point, it is recommended to slightly cool the mirror and drill.

What tools might you need?

To prevent the glass surface from cracking and falling apart during processing, you need to know what you can use to drill a mirror at home. Typically, work is carried out using the following devices:

- Solid feather shaped drill bit. Helps produce a hole with a diameter of no more than 12 mm. Despite the quality of the product, without certain skills it is difficult to make a smooth hole without defects.

- A diamond-coated drill is designed specifically for glass processing; the equipment helps to work as safely and accurately as possible.

- A tube-shaped drill will be needed if you need to get a large diameter hole.

- If the master uses a brass drill for work, you need to remember that it heats up quickly. You need to constantly add water to the drilling site.

- The diamond-coated tubular bit helps make large holes with high precision. The drill must be constantly cooled.

How to drill through tempered glass

Before modern construction tools and consumables appeared, a lot of ways were invented to make a hole in glass. The most popular is to use a regular drill, which is first heated red-hot on a burner or gas stove flame, and then hardened in wax. Then everything is done exactly as described above.

Also, to solve the problem, you can use a copper tube mounted directly in the drill chuck. In this case, it is necessary to secure pieces of cardboard with an existing hole on both sides of the glass, and it is better to place the sheet itself on a rubber base to reduce vibrations. In this case, the composition of the “coolant” also changes - corundum powder should be added to the water.

Hole drilling method

Since the mirror has served as an indispensable piece of furniture since time immemorial, it should not be surprising that there are a great variety of ways in which you can make a hole in the glass. Below we will give you the most popular and easy-to-follow methods.

Using a special drill

The secret of such a special drill for mirrors is the coating of diamond dust on its gimlets. One of the huge advantages of such devices is their durability. They will serve you for many years.

If you have such a tool, we will tell you more about how to use it:

- You need a drill that allows for regulation of the number of revolutions. If you don’t have such a drill, don’t use a regular one! The mirror will most likely crack. Better take a screwdriver.

- When using such a drill, markings for future holes are placed in the shape of a square - it must correspond to the diameter of the drill.

- Drilling cannot be done non-stop. Periodically give yourself and the product a break - it is very important that the mirror and instrument do not overheat.

We use a glass cutter

For this method of drilling a hole in a mirror, you will have to disassemble the glass cutter, since we will only need one part - a diamond roller. The disadvantage of this method is that it is troublesome. First, you will have to make a special rod in order to secure this very roller:

- We take out its diamond roller from the glass cutter.

- We prepare a metal rod in which the diamond roller can be secured.

- The rivets will help you secure the roller to the rod.

- Thus, we get a drill we created with our own hands. We insert it into the drill and begin the drilling process.

Using a regular tool

If you have never had the opportunity in your life to purchase a special diamond-coated tool, it doesn’t matter. Such tools are often absent from our everyday life as unnecessary. Making a hole in glass using a regular drill requires care and patience, but it is quite doable:

- Place the mirror on a surface without roughness and degrease it.

- We take plasticine and make some kind of water container or bath out of it. Pour liquid in there. You can just use water, but turpentine is often used.

- Let's start drilling. It is important to do this without using force or pressure!

Feather

- On the mirror, as always, located on a hard, flat surface, we make markings.

- Take the screwdriver, turn it on, and fix the perk to the center point of the hole.

- It is advisable to either take breaks to cool the glass, or use a spray bottle to spray liquid on it.

- Stop drilling at the moment when the tip of the drill appears on the back side of the mirror.

- We turn the mirror product over and do the same steps on the reverse side.

Crown (tubular)

Another type of diamond-coated gimlets. Usually the manufacturer of such tools is China, but this should not scare you. They do an excellent job of carving glass and are quite capable of cutting right through it:

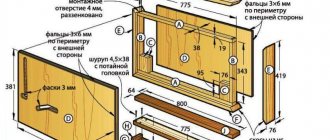

- We take a piece of plywood, which will serve as a template for us in the future. We drill a hole in it that you would like to make in your mirror.

- We apply the resulting template to the mirror. We fix it.

- Let's start drilling.

- Again, we don’t drill all the way. We turn the product over and recreate the process again.

Using sand and molten metal

The most ancient method described here. It arose in those dark times when drills had not yet blessed us with their appearance. To implement this method, you will have to take care of preparing items from this list:

- Any soft metal. Tin is ideal.

- A small amount of fine sand. It should not contain, for example, shells or stones.

- Burner for melting metal. A gas stove will also work.

- Container for melting metal. Use what you are willing to throw away without regret.

- Alcohol.

How to drill glass using this method:

- Pour sand in a heap onto a previously degreased mirror surface. The sand should be slightly damp.

- We find a suitable sharp object and make a small funnel in the sand. The funnel should match the size of the hole you want to make.

- Using a torch, we melt the metal and pour it into the funnel we created.

- We wait until the metal cools down.

- We brush away the sand and fish out the frozen metal from the hole. Voila - we have a smooth hole!

We understand the features of the material

Before asking yourself the question of how to drill glass at home, you should at least get acquainted in general terms with the characteristics and features of this material.

The glass production process is quite complex. It is performed at industrial enterprises equipped with special equipment. The main stage of this process is the preparation of a melt, which includes several components. Such a melt for glass is subjected to sudden supercooling, and the crystallization process is not completely completed.

To prepare the melt, the mixture of components that make up the future glass is subjected to significant heating - up to 2500°. Depending on the chemical basis of the melt, glasses are distinguished:

- oxide category;

- sulfide;

- fluoride type.

Oxide glass (aka silicate) is used to make bottles.

Glass, which can also be opaque, is divided into various types depending on the main characteristics of the material. So, glass is distinguished:

- quartz, which is obtained by melting quartzite, also known as “rock crystal” (this material can be of natural origin and is found mainly in places where quartz deposits have been exposed to lightning);

- optical type, used for the manufacture of basic elements of optical instruments (lenses, prisms, etc.);

- highly resistant to aggressive chemicals and elevated temperatures;

- industrial use (the most extensive category of glass, also used in everyday life).

The question of how to drill a hole in glass most often arises when using the latter type of product. Industrial products, in turn, are also divided into several categories:

- potassium-sodium type (such glasses, characterized by a clean and light internal structure, have a relatively low melting point, so they are often used for the manufacture of glass products of complex shapes);

- potassium-calcium type (glass of this type has a surface without a pronounced shine, is highly hard and difficult to melt);

- lead type (such glasses have a pronounced shine, which makes them very similar to crystal, high fragility with a fairly high plasticity of the internal structure, significant specific gravity and a higher price when compared with the cost of products of other types);

- borosilicate (they are highly resistant to temperature changes and mechanical stress and are quite expensive).

In most cases, drilling of window or display glass is required

There is also a classification of glass according to purpose. Thus, various types of glass are used for:

- glazing of windows and other translucent structures;

- manufacturing of containers;

- reducing radiation levels;

- fiberglass production;

- protecting smartphone screens;

- making dishes;

- production of thermometers capable of measuring temperature in the range from –200° to +650°;

- manufacturing laboratory glassware (such glasses are characterized by high thermal stability);

- production of medical products (ampoules, tubes, containers for medicines);

- fireplace screens and ovens (in such cases, heat-resistant glass is used);

- manufacturing of electric lamps (in this case, so-called electric bulb glasses are used);

- production of incandescent lamps, X-ray tubes, ignitrons (this requires vacuum glass);

- creation of elements of optical instruments - cameras, microscopes, telescopes, etc.;

- manufacturing thin-walled chemical containers and other products that require high resistance to chemical and thermal effects (for this, quartzoid glasses, also known as Vicor, are used).

Drilling thick glass is best done on a machine

Features of drilling Glass / Mirrors

The peculiarity of drilling glass/mirror is that the material is drilled from both sides with a constant supply of water to the drilling site, i.e. the master begins to drill a hole in the glass from one side, reaches the middle of the thickness of the material and then drills from the back side at the same point, at low speeds, preventing the glass from overheating.

The larger the diameter of the hole that needs to be drilled, the longer the drilling process will be and the greater the risk that the material will burst.

Making holes using a glass cutter

It is convenient to use a glass cutter as a tool for making holes in glass when the latter has a large diameter. Without an additional device, it is very difficult to describe a circle while holding a glass cutter with your hand. Therefore, a special compass has been developed, the moving part of which is the cutter itself, and the fixed part is made in the form of a suction cup, which is installed strictly in the center of the future hole. They are connected to each other by a rigid ruler.

If you don’t have such a compass, a simpler option is to use a cutter to outline a round template with the diameter of the required hole. The whole process of cutting a circle goes like this:

Types of glass cutters

- Degrease the working area of the glass with alcohol and wipe it dry;

- The template is glued to the glass using double-sided tape;

- Using a glass cutter, carefully cut along the template several times;

- The template is pasted onto the opposite surface of the glass and the previous point is repeated;

- The resulting internal diameter is cut with two perpendicular lines, dividing it into four equal segments;

- Gently tapping, squeeze out the cut element.

Application of glass cutter

To be able to make a hole in the product in this way, you will have to disassemble the glass cutter. The fact is that you need to work with a diamond roller. To understand how to drill a mirror at home, you need to carefully study the sequence of actions with a glass cutter:

- You need to remove the diamond roller from this device.

- The steel rod should be carefully prepared for use. To do this, you need to make a small slot in it.

- You need to insert a roller into the hole and check the reliability of the fastener.

This way you can make a high-quality drill yourself. It is attached to the drill and work begins.

How to drill a hole in a mirror yourself at home

- So how to drill glass?

- lesson - drill a hole in glass with your own hands

- Drilling glass with a drill

- Is it possible to replace the drill with something?

Sometimes even the simplest procedures (for example, how to drill glass) can cause confusion among inexperienced people. Indeed, working with such a fragile material requires advanced skills that you are unlikely to obtain when cutting glass.

In the article we will talk about how this should be done so as not to damage the surface of the glass.

What you need to know about glass?

Let's start with the obvious - mirrors and glass are extremely fragile materials. Is it possible to drill mirrors? Yes, it is possible, but working with them requires great care and delicacy, but at the same time determination. You should take into account that the usual tools that you may have used when working, for example, with wood, are definitely not your help. From their brute force, the mirror can easily burst and crack. Here we need special tools, which we will tell you about later.

Materials and tools

The more complete set of materials and tools you have at hand, the greater the likelihood of successfully completing the task.

- Acetone or alcohol to degrease the surface.

- A flat surface on which you can place the mirror for work. Check that the table (chair, bedside table) does not rock.

- Special drills.

- Glass cutter (not always required, but preferably available).

- Drill (screwdriver).

- Water (turpentine).

- Safety glasses, gloves.

Hole with a regular drill

If it is not possible to purchase a special gimlet coated with diamond, or a drill that was purchased in a supermarket turned out to be of poor quality without coating, then in this situation, to drill a mirror surface, you can use a regular drill, which is used to drill through metal.

How to make a hole in a mirror at home:

- The fragile object is placed on a flat surface and then degreased.

- We make a kind of bath from plasticine on the top side and pour liquid into it.

Important! For this purpose, you can use ordinary water, but turpentine is best suited.

- We set the drill to low speed and, without making any effort, begin to slowly drill.

Recommendations from the experts

The most common problem is the appearance of chips and cracks. The solution is to use diamond drilling techniques. However, this does not completely exclude the destruction of edges. Additional protection can be turpentine or honey in a plasticine funnel, or thick tape.

Transparent tape Source o-manager.ru

The hole should be located away from the edges of the workpiece. If the canvas is thin, then 1.5 mm is maintained. For window and similar sheets, the indentation increases to 2.5 mm or more.

It is generally not recommended to drill tempered and reinforced glass in a home workshop, as it is highly fragile. But the solution may be to use a countertop cooler. The required liquid is a solution of aluminum alum in vinegar essence. A simpler option is a mixture of camphor and turpentine.

In small objects, craftsmen recommend forming holes in cold water. The object is immersed in a container, the liquid hides it. In this case, the workpiece is fixed.

Often the edges of the hole are uneven, with streaks visible inside - marks from the drill. Defects can be eliminated by grinding. For this purpose, an abrasive material with a small grain fraction is used.

Step-by-step instructions: how to make a hole with your own hands?

The drilling process is carried out as follows:

- Wear special glasses and gloves to avoid injury.

- Place the mirror product on a flat surface. Make sure it fits snugly.

- Degrease the surface of the mirror with alcohol.

- Make the markings.

- Start making the hole. We remind you - set the drill to minimum speed. Do not use force or put pressure on the drill or the product under any circumstances.

- Every 10-15 seconds it is necessary to stop working to avoid overheating. Spray the mirror with water from a spray bottle.

- Always hold the drill at a right angle.

- Do not drill all the way through. Turning the product backside down, continue drilling.

We invite you to watch a video on how to make a hole in a mirror with your own hands:

Using a special drill

To drill holes in the mirror yourself, use special tubular drills coated with diamond:

- In order to drill a mirror at home using a special gimlet, you need to use a drill that has a speed controller. If such a drill is not available, then you can use a screwdriver.

- Marking on a fragile product is not done in the usual way, in which a cross is placed at the central point of the hole, but a square is drawn that describes the diameter of the hole.

Important! If this is your first time facing the need to drill a mirror, then a situation may arise in which the perk makes sliding movements along the surface of a fragile object. To avoid this problem, you can use a small plastic or piece of wood in which a small recess has been pre-drilled with exactly the same drill bit. This blank is secured with tape to the glass to hold the drill while working.

- When drilling, it is necessary to periodically stop the process so that the percussion and glass do not overheat. When the drilling process is stopped, the mirror and drill should be cooled with cool water.

Preparing the material for the drilling process

Many factors are responsible for the successful completion of a glass drilling operation. One of the important ones is proper preparation of the work site and workpiece. For this:

Preparing glass for drilling

- Remove dirt and grease from the glass using turpentine or alcohol;

- The working surface of the table where the operation will take place is covered with an elastic, dense material that prevents slipping;

- A table is selected on which the edges of the glass will not protrude beyond the boundaries of the workplace, but will touch it along the entire perimeter;

- To prevent the tool from sliding on the surface, the drilling point is first covered with masking tape or a piece of electrical tape;

- The drilling center is marked with a marker or ballpoint pen;

If you have no experience in carrying out the work, it makes sense to practice and drill glass at home using waste. This will make it possible to feel with what force you should press on the tool, how it is more convenient to hold it in order to get a positive result and the glass does not crack.

Before you start drilling good glass, try it on unnecessary glass first.

Drill a hole in the mirror for the button

I decided to make a mirror with lighting for the hallway. And it became necessary to place a button to turn on/off this very backlight, and since I have the mirror itself without a frame, and I plan to illuminate it from the inside, the only place for the button was the surface of the mirror itself. It was decided to drill the mirror and install a button in the hole. I watched a bunch of videos on YouTube on how and how to do this, and realized that the main problem is chips, which almost inevitably occur when the drill comes out. In general, having gathered enough information, I got to work.

In my work I used the following tools: a glass drill with a diameter of 3 mm, a glass drill with a diameter of 12 mm, abrasive rollers for metal, a screwdriver and related materials - plasticine and water.

The thickness of the mirror is 4 mm, the diameter of the hole that needs to be drilled is 14 mm. I recorded the whole process on video, and I can say right away that the hole was made almost perfect. So, I hope this video will be useful to someone.

And here are some more photos of the resulting hole:

here is a photo from the front side, microscopic chips are visible, because the photo was taken from a very close distance, specifically to show the edge, in reality they are visible only if you look very closely, from a distance of 20 cm they are not visible at all

and a photo from the back, here the photo was taken a little further, and the hole looks perfect

And the drilling process itself.

Using a conventional drill

If glass processing does not involve mass production, then there is no need to purchase special tools. Its cost is quite high; with prolonged use, the surface of the cutting edge wears out. Here's how to drill a hole in glass using a regular drill press. You will need:

- Drill for working with metal or ceramics. In their manufacture, a hard alloy is used that can withstand long-term use.

- Drill with low speed and drilling machine with adjustable speed.

- Ordinary plasticine.

- Turpentine.

- Alcohol solution.

Drilling instructions:

- The glass is placed on a flat surface. The edges should not extend beyond its limits.

- The area of glass to be treated is degreased.

- After fixing the tool in the chuck, set the minimum speed. Excessively high drill speed may result in deformation of the workpiece. In addition, the degree of tool runout should be low, since variable loads can lead to cracks.

- Plasticine is placed on the surface to be treated, which will eliminate the possibility of the tool slipping. A small hole is created in the central part.

- To reduce the likelihood of cracks, work should be carried out carefully. Too much force causes various defects to appear. The minimum rotation speed should be 250 rpm. If the material is highly resistant to mechanical stress, the value is set to 1000 rpm.

During machining, fine chips are formed; safety glasses should be used when working.

Marking and preparation

The usual method of marking the center of the hole with a cross will not work for marking. To drill glass, you need to draw a square that will describe the hole. Remember that a tubular drill cannot be centered, so you will need a stand that will allow you to guide the tool in a strict vertical line. If there is no such frame, then distortions may occur.

In addition, starting the drilling itself will be quite problematic. It is possible that the drill will slip and scratch the surface of the glass. In this case, you can use a piece of plastic or wood. They are pre-drilled and attached to the surface of the glass with tape, and then using the same drill, a hole is made in the glass itself. If you have enough experience, you can do without plastic. Then you need to make an approach with only one side of the drill, gradually bringing it to the normal.

General rules

Any man who has repeatedly performed household repairs can handle the procedure of drilling a mirror at home. But such a complex task cannot always be solved in a high-quality manner, since there is always a high probability that the material may crack or even break during operation. Therefore, to prevent such a problem, you can use the services of a qualified professional or take the fragile product to a glass repair shop. You can also watch a video on this topic and first practice drilling holes on pieces of glass.

Let's consider the principle of working with a fragile object:

- In order to start drilling a hole on a mirror product, you need to find a perfectly flat surface and place the workpiece on it.

Important! A fragile interior element must fit tightly to the surface and it must wobble.

- After this, you need to degrease the surface. For this purpose, use a solution of acetone or alcohol.

- How to drill a mirror at home? The drill must be set at very low speeds, otherwise you can damage the fragile product.

Important! You should never rush, you need to work with maximum care and do not put pressure on the drill.

- The hole does not need to be drilled all the way through. You should drill to about half the width of the fragile item, then turn the mirror over and continue the drilling process on the back side of the item.

Important! This option helps to avoid chipping on the outer sides of the product. This is very significant, especially if the mirror is drilled at home.

Steps

Method 1 of 2:

Preparation for drilling

1

Buy a set of glass drill bits. The choice of drill bit also depends on the size of the hole you are going to make. Diamond drill bits with round tips are best for holes up to 1.5 cm in diameter, while diamond drill bits with hollow cores are best for holes larger than 1.5 cm in diameter. Typically, two types of drills are suitable for drilling glass: diamond and tungsten carbide. Diamond drill bits are traditionally used for drilling glass; a single diamond bit can drill many holes and rarely breaks glass when used properly. Carbide drill bits have a spade-like tip that can withstand the friction generated when drilling into glass or tile.

2

Choose glass that is not tempered or safety glass. These types of glass can only be drilled using special equipment that is not available to the average craftsman. Make sure the glass you choose is the right size and thickness for you.

3

Cut the required piece of glass yourself or use this service when purchasing glass and sand its edges

4

Mark the location of your holes on the glass, being careful to place them as far from the edge of the glass as possible. Never drill closer than 2 cm to the edge

5

Place the glass on a completely flat surface, where it will rest on its entire plane. If you have the opportunity, place a rubber mat or other fairly hard, elastic material under it, but the glass must lie absolutely flat.

6

If possible, immerse the glass in water or constantly spray it with water to remove the smallest glass particles flying while drilling. If you choose to use oil to cut glass instead, use a small amount.

Method 2 of 2:

Drilling a hole

- 1

Insert a small drill bit into a variable speed drill.

Make sure it is securely fastened. It is best to start working with a 2-3 mm drill.

- 2

Center the drill on your intended drilling point and start drilling.

Use constant pressure while pressing down on the drill while drilling, and try to maintain a constant, slow drilling speed.

- 3

When you get close to the other side of the glass, flip it over.

Often, when drilling through, the drill breaks off a piece of glass on its back side, so it is better to turn the glass over in advance and finish drilling by drilling a counter hole on the other side.

- 4

Replace the small drill bit with a larger drill bit to make the hole larger.

The first hole is only a basting hole. It will guide larger drills as the hole is enlarged to the desired size.

- 5

Drill the hole to the desired size using each subsequent drill bit in sequence.

When using larger drills, less pressure on the drill and a lower rotation speed are required.

Adviсe

- Use a set of drill bits, starting with the smallest one, and work through each other drill size in order to minimize pressure on the glass as you reach the desired hole diameter.

- The glass must lie absolutely flat, otherwise it will break.

- Keep the glass cool while drilling. This will prevent the drill bits and glass from breaking.

- Using a drill press can help regulate the pressure applied to the drill bit.

- No need to drill at fast speed. Glass is a very hard and abrasive material, and you can quickly ruin your drill bits.

- While it's best to use water, glass cutting oil can also help when drilling holes in glass, just don't use too much of it.

Warnings

Glass is a fragile and sharp material

Handle it with care and wear gloves, a guard and safety glasses when drilling. Glass shards can seriously damage your eyes, so you should wear safety glasses that properly protect your eyes.

- Variable Speed Drill

- Glass drills

- Durable, flat work surface

- Water container or spray bottle

- Safety glasses, gloves, respirator.

Tips for working from home

When drilling at home, it is recommended:

- Diamond drills and glass surfaces have a common enemy - high temperature. To avoid overheating, stop and periodically pour water on the mirror.

- Get better at practicing your skills on scrap pieces of glass.

- Watch a video on how to drill glass.

- Turpentine is an excellent tool that will help you avoid cracks in glass.

- Do not use force or pressure when working with mirrors. Work concentratedly, carefully, but don’t be nervous and try to do everything with a “light hand.”

Good luck with decorating your interior! Go for it!

Features of mirrors

A mirror is a very fragile material. So is it possible to make a hole in it? It is possible, but you will need caution, accuracy, and, at the same time, determination. And yet, the usual tools that you safely used when working with wood or stone are definitely not suitable here. They will easily “bring” the fragile material to scratches, or even cracks and chips. So you will need a special set of tools and an individual approach.

You can make a hole in the mirror yourself using tools.

Basic recommendations when working with mirrors (glass) look like this:

- Before you start working with a large mirror, test your competence in this matter on a small piece of mirror or thick glass.

- A smooth surface, without any roughness, is the key to successful manipulations with mirrors.

- When working with a drill, set it to minimum speed, otherwise you will be in for a “surprise” in the form of cracks or chips along the edges of the hole.

- Before you start drilling, degrease the mirror surface thoroughly. Regular alcohol is perfect for this.

- Never make a hole all the way through in one sitting. After making a small indentation, stop, turn the mirror over, and continue working on the other side.

- Pause every 10 seconds. Remember: the mirror should not heat up.

- While drilling, be sure to spray the reflective surface with water for additional cooling.

- Instead of water, you can use turpentine. This composition will be the best assistant when drilling at home, thanks to it you can avoid the appearance of cracks.