The opening mechanism of x cabinets is the most vulnerable point in the design of kitchen furniture. Therefore, choosing reliable and durable hinges is no less important than choosing other high-quality materials for the kitchen.

What kind of hinges are needed for kitchen cabinets? The choice depends on their purpose, method of fastening and design.

A furniture hinge is attached to the body and door, which serves as a means of connecting two structural parts and as a mechanism for free opening/closing at a specific angle.

You can see the types discussed below in an accessible, understandable and visual way in the video review:

Corner furniture hinges

Door hinges are the main element of furniture cabinets of any size and any purpose. They come in various types, differing from each other in design features and purpose.

The most popular are the four-joint ones because they are durable and last a long time. They are divided into two types: straight (with an angle of 90 degrees) and angular (all other non-standard angles). Corner furniture hinges are used in sets when assembling corner cabinets.

Areas of use

The use of furniture hinges without mortise may be determined by the type of product design or the materials used. These can be thin doors in frames made of chipboard or plywood, or other options in which drilling holes is somewhat difficult. Special non-mortise hinges are produced for glass elements; you don’t even need to drill holes for them. For aluminum structures, fittings are often supplied immediately complete with the furniture profile.

The use of such fasteners is most in demand when assembling cabinet furniture, built-in and conventional, free-standing. Options without drilling are mounted like clamps, securing the blade in a kind of groove. They are in demand when assembling display cabinets with a large glazing area.

Types of loops

All furniture hinges are semi-mechanical parts for opening and closing facades. Taking into account the purpose and installation method, they are divided into:

- internal

- semi-invoice

- invoices

- card

- piano

- inverse

- corner

- heel

- pendulum

- ombre

- gallery

- secretory

- mezzanine

Furniture fittings can also be made of different materials and differ in opening angle. There are many different mechanisms on the market, including those designed for furniture and interior doors. Having similarity in appearance and method of functioning, products can withstand different loads. Therefore, for interior doors, what is best can be suggested by the specialist who will carry out the installation.

What are they?

Ombre loops come in overhead and inset cylindrical types. Overlays are installed on the ends of the sashes in cases where the facades are thin, and installation of mortise elements that are less noticeable on furniture is not possible. The cylindrical hinge is convenient because it can be hidden inside both the end part and the folding part of the product. The fittings are often coated with zinc, which reliably protects metal structures from corrosion, and they can also be made of zinc alloy.

The cylindrical loop has design features. It is a rotating device and cannot withstand heavy loads, so it is not used for large structures. However, the metal part will be hidden when the table is unfolded, which will provide an attractive appearance to the product. Cylindrical hinges can be used for different facades: chipboard, MDF, solid wood.

Product sizes may vary. It is designated by markings, for example, D12, D14, D16, D24. Quite often the option with a diameter of 14 mm is used, since this value is optimal for the thickness of the fabric from which the doors of folding tables are made.

How to install furniture hinges

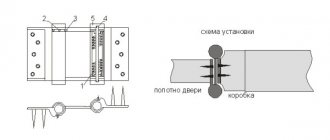

The bowl deserves the most attention in the hinge design. From the picture it is clear that it should literally be inserted into the surface. To do this, you need a hole (roughly speaking, an unfinished, not through hole), and a very respectable diameter. It is impossible to make such a hole with a regular drill; you will have to use a special cutter with a standard diameter of 35 mm, but there are other 25-32 mm mounting holes.

Forstner drill with height adjustment

There are different types of drill cutters

The illustration shows two cutters, a standard one and a slightly modified one. It's useful to have both. It is better to start cutting a hole with a regular cutter, but then it will be best to change it to a modified one. The reason is that a standard cutter has a protruding tooth. Beginners may inadvertently drill a through hole with a cutter instead of a hole, and the tooth on the cutter greatly contributes to this.

The hinges must be installed so as to support the door securely and without distortion. Therefore, when attaching furniture hinges, it is important to mark the surfaces of the cabinet and door as accurately as possible, marking the places for cutting holes for hinge bowls and for screwing in self-tapping screws.

Installation stages

Installation of hinges on facades is carried out in 4 stages:

- first create markup;

- then make holes using a drill;

- then installation is carried out, as well as assembly of parts of the fittings;

- At the last stage, the doors are installed.

Stages of self-assembly of furniture, rules for deciphering drawings The most important and difficult stage is considered to be adjusting the position of the door relative to the furniture body. If the work is done incorrectly, the sash will quickly sag and the cabinet (or any other product) will fail.

Creating markup

To install furniture hinges correctly, you must initially make even markings that correspond to the parameters of the hardware plate. Otherwise, there will be problems with opening and closing doors. The marking of furniture hinges is done as follows:

- The distance between the canopies should be at least 50 cm. At this stage, the number of hinges required is determined.

- Start marking the center of the canopy holes. At the same time, they retreat from the edge of the door by 2–2.5 cm.

- Marks are applied taking into account the width of the door. At the intersection points, holes are made with self-tapping screws. At this stage it is worth using a template for marking furniture hinges.

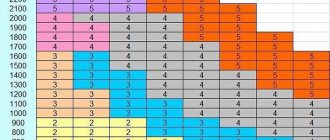

Despite the fact that templates for furniture hinges are made of durable materials, they must be handled very carefully. It is strictly forbidden to drill through them, otherwise the service life will be reduced. To determine the number of loops needed, it is worth studying the recommendations presented in the table.

| Door weight, kg | Facade height, mm | Recommended number of loops |

| 4-5 | up to 500 | 2 |

| 6-9 | 500-1000 | 2 |

| 10-13 | 1000-1500 | 3 |

| 14-18 | 1500-2000 | 4 |

| 19-22 | 2000-2500 | 5 |

Hole preparation

The next step will be preparing the holes. To make the notches correctly, you need to accurately follow the markings already made. To carry out this operation, a drill with a special drill and a milling cutter are used. The holes are made like this:

- First you need to lay the door on a flat surface.

- Fix a cutter for furniture hinges of a suitable diameter in a drill. The depth of the hole should not exceed 1.25 cm.

- During the drilling process, the drill must be positioned strictly perpendicular to the surface of the door.

- During the process of forming the hole, you need to carefully ensure that the cutter or drill does not drill through the door.

Nuances of making furniture drawings, review of useful programs

When the main holes for the screws are ready, you can move on to the next stage. Inserting canopies in accordance with the markings and formed recesses is much easier and of better quality.

Hinge Attachment

The hinges are attached in the following sequence:

- The part of the loop that will be directly attached to the facade is placed in the bowl.

- The hinges are carefully positioned in the recesses to ensure optimal placement.

- Using a construction angle and a level, achieve an even position of the loop in the cup.

- If you need to correct the hole to lay the canopy evenly under the level, use a furniture cutter to install the hinges.

- Using a screwdriver, screw the screws into the holes on the hinge itself.

After fixing the screws, you need to check the strength of the canopy. It is recommended to try to loosen the hinge in the cup and move it relative to the surface of the facade. If no changes are observed, then the fittings are secured well.

Hanging the door

The most difficult stage in this work is the installation of the door. To simplify the task, if possible, it is worth laying the furniture body so that the doors are attached to the hinges in a horizontal position. Algorithm for installing doors:

- In the inside of the furniture body it is necessary to make the same markings as on the door. To install the hinges, you also need a furniture bit.

- Next, secure the platform to secure the canopy using self-tapping screws.

- Connect the two parts of the canopy.

- Finally, adjust the position of the fittings relative to the door and furniture body. This can be done using a screwdriver and a level.

Making upholstered furniture with your own hands, tips for beginners

Hanging the door is not the final stage of work. Even after the initial adjustment, additional measures must be taken to align the position of all components.

Hinge installation angles

The installation angle is the angle between the door and the side wall of the furniture box when closed. Typically the installation angle is 90°. Standard angles in hinge production are 90 degrees, but there are plus 30° and plus 45°, as well as minus 30° and minus 40 degrees.

But when making furniture or assembly errors, it is necessary to correct the standard installation angle. For this purpose, adjustable and non-adjustable pads are used. Non-adjustable pads are made of plastic with minus or plus 5 degrees. By placing loops on the side wall under the striker plate, you can adjust the angle plus or minus; you can place two or even three such pads. But if you need to adjust to an angle that is not a multiple of 5, then this lining will no longer be suitable.

Types of loops by design

They are hinge units that connect the doors to the cabinet body. Various design solutions make it possible to leave the door leaf open at a certain angle. Based on the method of fastening facades, you can choose the following models:

- Four-jointed.

- Mezzanine.

- Pianos.

- For glass doors.

Quadruple joint

The most common and popular are 4-hinge furniture hinges. They are distinguished by their versatility and high reliability. There are three types of four-hinged hinges, which differ from each other in the method of fastening the shoulder cup to the striker:

Slide-on. The protruding part of the strike plate fits into the shoulder. Fastening is carried out with a fixing screw. The connection has notches on both sides. The length of the arm can be lengthened or shortened by securing the connection with notches.

Clip-on. This system allows you to do without a screw. The parts of the loop are connected by a latch. Such canopies are called quick installation models. The cabinet door can be removed and replaced without tools.

Key-hole. The cup arm is placed with a hole on the counter plate screw. The edges of the opening are inserted under the screw. The mounting hole resembles a keyhole.

Materials for sliding doors

The most popular materials for the manufacture of sliding door systems today are:

- Tree

- Fiberboard or MDF

- Glass

Tree

The traditional material for the manufacture of not only doors, but also furniture in general, is wood. At the same time, both the entire panel (s) of the sliding door system and the frame for combination with other materials can be made from wood:

- Glass

- Plastic

- Paper

- Textile

- Mirror

The easy flexibility of wood to process allows it to be used for interior decoration in almost any style. Want a charming country room? Use unplaned wooden boards! Do you like classic style interiors? Choose a wooden door leaf with strict shapes. Are you striving to create an interior in a shabby chic or art deco style? Give preference to carved wood with forged elements or inlay. Are you a supporter of the East? Use canvases with a wooden frame and rice paper inserts.

Fiberboard/MDF

Since wood is not the cheapest material, it can easily be replaced by materials such as fiberboard or MDF. In appearance, they are almost impossible to distinguish from natural wood, but the cost is an order of magnitude lower than that of similar products made from natural wood.

Glass

Glass sliding doors are an excellent option for creating an interior in minimalist, futuristic or hi-tech styles. Due to the property of glass to transmit light, glass interior sliding doors do not create a feeling of total enclosure of space. Moreover, by choosing the degree of color and opacity of the glass for the door leaf, you can select the degree of transparency (and, as a result, integration with the neighboring room) of the interior doors.

Proper furniture maintenance

To ensure long-term and trouble-free operation of furniture canopies, it is not enough just to install and adjust them. Proper operation and regular lubrication are also important.

Following these recommendations will help maximize the life of your hinges:

- Frequency of adjustment. The first time setting up the canopies is done after installing the furniture. The following adjustments are made depending on the intensity of use of the cabinets. In one case, this will have to be done 4 times a year, in another, once is enough. If distortions or other problems with the sashes are identified, there is no need to wait for scheduled maintenance; the identified violations must be corrected immediately.

- Lubrication. To reduce friction in the moving elements of door hardware, they require periodic lubrication. This is done once a year or if there are any extraneous noises, squeaks or difficulties when opening/closing the doors. For lubrication use machine oil of any type (synthetic or mineral). A few drops of special lubricant (for example, WD-40 or similar) is enough.

Other types of furniture hinges

Card, piano, and hinge hinges are rarely used for installing cabinet doors. They do not have three-level adjustment and do not lock the door in the open and closed position. An additional fastener is needed. Today they are more often used as an additional decorative element. For example, antique.

Mezzanine

For installation of horizontal overhead panels that open upwards.

Mezzanine