If you regularly encounter problems with high shelves, if you have to use chairs and stands that are not always reliable to remove necessary items or wipe dust in hard-to-reach places, then it’s probably time for you to think about how to get a step-stool or a compact folding ladder. Because getting a full metal stepladder out of the closet every time is not always a convenient option. Moreover, you can start making a step-stool yourself, rather than buying this design in a hardware store, hardware department or supermarket. This item will fit optimally into the interior, take up minimal space, and serve as a constant helper in the household. All you have to do is choose the model you like, purchase the necessary materials, stock up on tools, and be patient – start making a practical and beautiful thing.

Transformable step stool

Stages of assembling transformer parts with your own hands

Before attaching all the elements, it is advisable to carry out preliminary assembly to make sure that all parts of the product fit perfectly together. Next you need to do the final assembly using wood glue, dowels, screws, screws and dowels. Each type of transformer has its own installation features. Let's take a closer look at them.

Elements of a classic steppe chair.

The transforming chair is assembled in the following order:

- The finished and carefully polished parts of the back and high sides of the chair are fixed with self-tapping screws.

- The seat and steps are attached to the grooves of the small side walls. The joints are additionally fixed with glue and self-tapping screws.

- The resulting parts of the chair are held together with a piano ring.

Assembly diagram of a transformable chair.

Steps to assemble a step stool with your own hands:

- For greater stability, the ends of the stool legs should be sawn with a slope of 10 degrees.

- Using dowels, you need to connect the middle legs and ends of the drawers. The steps are cut at an angle of 80 degrees.

- The high chair legs are attached to the top drawers with self-tapping screws.

- Secure the drawers to the top step with self-tapping screws.

- Reinforce the middle legs with a dowel and dowel and attach to the front and back sides.

- Using screws, attach the small legs to the crossbar, then to the front side beam and install the step.

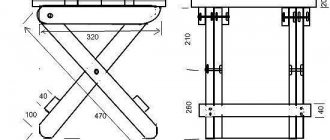

Assembly diagram for a stair stool.

DIY transformer scales:

- The side ends of the chair are attached in pairs to the crossbars using self-tapping screws.

- The steps are attached to the stool using a piano ring.

Stages of assembling a stair stool with a screw module:

- Align the inside corners of the middle and bottom steps. Drill 38mm holes in opposite corners. Secure your leg.

- Using self-tapping screws and wood glue, assemble the remaining pieces of the product.

Step-by-step assembly of a stair stool with a screw module.

High step stool

Another design variation

- We cut out blanks for the chair and steps according to the patterns. The design consists of several elements: four legs; two crossbars at the bottom; two crossbars at the top. And also - drawers (connecting strips between the legs): two upper, lower. And also: two plywood overlays located on the sides; top step.

- For the steps you should prepare blanks: four middle legs;

two crossbars; two small legs; three front and one rear tsars; two steps. Dimensions in millimeters

- For a high stepladder in the form of a stool, we cut out and prepare the parts according to the drawing. We carefully sand each of the workpieces until smooth. And in order for the stool to gain stability, its legs will be positioned in a parallel manner and at a slope of 10 degrees.

- We will also make sure that the ends of the plywood overlay and crossbars do not move away. If you chose dowels to fasten the middle legs, drill grooves for them (dowels need to be placed in the holes).

- We cut the end of the drawer at 80 degrees. When cutting out the step from below, we make two cutouts so that it coincides with the legs of smaller dimensions. We connect the large legs with the upper crossbars with screws. We do the same procedure with the drawers and the top step.

- We install the stool with steps in the way they will look when assembled, and screw the structure guide. If no shortcomings are observed, we disassemble the stepladder-stool again, and then reconnect the parts, but using gluing. And when they are noticeable, there will be an opportunity to correct them. We use clamps to compress the workpieces and securely glue them.

In the same way, according to the drawing, you can assemble a ladder chair

Watch the video on the topic:

The benefits of making it yourself

Making a wooden staircase with your own hands gives the master a number of advantages, the main of which are:

- Assembling a chair yourself will cost much less than buying a ready-made one at a furniture store;

- the ability to select exactly the optimal design option for the stated purposes under specific conditions of use;

- saving space by simultaneously combining two functions in one sample;

- satisfaction from a product assembled independently, the operation of which also brings quite tangible benefits.

Note! From many everyday examples, it is known that hand-made furniture is always treated with much more care than purchased samples.

Because of this, they usually last much longer than store-bought items.

Safety precautions

When making a wooden stepladder, you must adhere to safety precautions and the following rules:

- no need to run your hands over the unsanded surface of the wood - you can drive a splinter under the skin;

- It is better to wear safety glasses to avoid splinters getting into your eyes;

- Be careful when working with cutting tools, watch your fingers.

After completing the work on making the stepladder, you need to check it for reliability and stability. To do this, it is recommended to test the stepladder in different positions.

When performing various types of work with a stepladder, it is recommended to adhere to the following safety rules:

- check the stability of the structure before work;

- when performing work at a height of more than 1.3 m, use a special belt for insurance;

- it is advisable to have someone provide support from below and provide the necessary tools;

- Do not place a stepladder on the steps of a flight of stairs;

- there is no need to try to reach objects that are located more than 1 m from the top of the stairs;

- It is undesirable to use it when working with welding, pneumatic, and electrical equipment alone.

If you have some skills and tools, you can purchase material and make your own stepladder from wood. It will not be difficult to make a simple wooden structure; it will require ordinary tools and no special skills are required.

Making a transformer will require a jigsaw and the ability to work with wood.

Tools and consumables

We will need the following tools:

- hacksaw for metal (optional - circular);

- jigsaw (preferably electric);

- screwdriver;

- grinding wheel and rim for cleaning wood;

- hammer;

- Bulgarian;

- self-tapping screws;

- brushes and paint (optionally, paint, stain) for final finishing.

Experts recommend using multilayer plywood (at least twelve millimeters thick) as the main material. If the base is thicker, then, undoubtedly, the product will become stronger, but its “weight category” will increase. And we are for a compact and not too bulky design. A small clarification: when you plan to work not only indoors, but also outdoors, you need to choose a moisture-resistant version of the plywood sheet.

You can sit down and relax

How to do it?

Simple

Making a simple step stool looks like this. It is necessary to cut and saw off all the necessary parts. Now we need to start making the seat.

- You need to take 2 wide boards and attach them tightly to each other. If desired, they can be glued. To make the product more durable, two bars need to be attached to the back side.

- The support posts should be connected. They can be attached using self-tapping screws: fasten 2 transverse bars to the guides, strengthen 1 of them diagonally.

- To make the sides (legs) of a chair, you need to cut off the inner contour of the side using a drill or jigsaw.

- Next, you should make a ladder: place it at an angle and secure the steps parallel to the ground.

- Like the sides, you need to make a back for the chair.

- Next, you need to take the middle step, which was located in the chamfer, and screw it with self-tapping screws.

Now all the necessary elements can be collected. It is necessary to attach the guides of the support post and the string of the ladder to the seat. Make and attach a step and seat. When the ladder and the support post are connected, you need to secure the slats with the first end under the seat and the other between the support posts.

Using a piano loop, you need to fasten the 2 parts of the step stool together. The structure must be primed and painted with varnish in 3 layers. If desired, the step stool can be painted or painted.

Transformable chair

Transformer chairs can consist of 3 steps, and if the product is folded, it will look like a regular chair. First you need to draw a drawing sample for the blanks. Then prepare the following elements:

- front sides (2 x 29 x 42 centimeters) – 2 pieces;

- rear sides (2 x 32.6 x 86 centimeters) – 2 pieces;

- backrest strips (2 x 7 x 42 centimeters) – 3 pieces;

- rear seat (2 x 16.7 x 41 centimeters);

- front seat (2 x 10 x 41 centimeters);

- steps (2 x 13 x 37 centimeters) - 3 pieces;

- planks (2 x 3 x 9.6 centimeters) - 6 pieces.

Manufacturing.

- It is necessary to thoroughly polish all the elements of the future product. Using a router, you should process the pointed ends.

- The back for the chair can be made from planks. And then, using self-tapping screws, attach it to the sides.

- Using grooves, you need to connect the steps and the seat to the sidewalls. When you need to assemble the structure, all joints need to be lubricated with glue and reinforced with screws. They need to be screwed into the prepared guide holes.

- You need to take a piano loop and connect the 2 parts of the product.

There is another model of a transformable chair - this is a ladder chair. For this design you need to prepare the following elements:

- seat (29 x 37 centimeters);

- walls that will be located on the sides (29 x 63 centimeters);

- bases (29 x 33 centimeters and 21 x 29 centimeters) - 2 pieces;

- cross bars (2.6 x 7 x 37 centimeters) - 4 pieces;

- support strips (2 x 2.6 x 7 centimeters) - 2 pieces;

- side walls (21 x 24 centimeters);

- wall located behind the module (24 x 26 centimeters).

Manufacturing.

- It is necessary to determine the drawing of the future product, prepare the drawing tool and all the elements that will be attached to the wooden blanks for sawing out parts of the upcoming structure.

- It is necessary to thoroughly sand each part, and also remove all sharp edges and corners.

- Now you can assemble the product. Fasten the side parts in pairs using self-tapping screws and attach the crossbars.

- You need to take a piano loop and use it to connect the stool and steps.

Pros and cons of homemade design

It is necessary to highlight the pros and cons of assembling the structure with your own hands.

The advantages are as follows:

- designing a staircase chair at home will be much cheaper than buying it in a store;

- you can save time, because you can’t always find a suitable chair in the store;

- everyone will be happy to make a design for themselves that will be useful;

- common advantages of all models: compactness, ergonomics, versatility, ease of use.

Disadvantages: you need to calculate all the indicators very well, otherwise the step may break.

Finishing of the product

To make a step stool comfortable to use with your own hands, you will need to perform surface treatment. Requires grinding, priming and puttying of elements. Plastic or wooden plugs that match the design are used as plugs for self-tapping screws.

The product must be decorated; decorative finishing is done with paint and then with translucent varnish. It is recommended to apply at least 3 layers. After each protective coating, the product is thoroughly dried.

To create a bright decor, you can use paint in contrasting shades for the seat and back. Translucent varnishes are optimal for products with a classic design or decorated in the English style. A stepladder chair for Provence style rooms must be painted with a white color. Designs for a country-style apartment do not require careful processing and can be rough; you only need to emphasize the beauty of the wood with the help of clear varnish.

Types of structures

Different types of products differ mainly in their design, according to which they can have the following designs:

- chair-ladder with steps smoothly rising outward (without backrest);

- modular block in the form of a stool;

- a chair with a ladder, but with a backrest for sitting;

- a high stool equipped with retractable steps.

Additional Information. All types of prefabricated products can also differ in the material from which they are made (they can be metal, plastic or wood).

The main requirement for the models is high structural strength, reliable fastening of individual components and good stability of the platform itself. All samples can be fixed or collapsible depending on how they are stored in non-functional form.

Stationary

A fixed or non-removable ladder is made so that the product does not shrink to a compact shape, but remains in its original state. The most popular types of stationary chairs that can be turned into a comfortable and fairly high staircase are:

- after simple manipulations, the transformable chair turns into a three-step staircase;

- a stool, which is a structure with a retractable part that moves along special guides;

- staircase in the form of a chair with a small back;

- a small stool with steps that spiral out from under the base (seat).

Non-folding products are inconvenient because they take up too much space in the room, but they are more functional than folding ladders.

Folding

The seats can, if desired, be quickly converted into a fairly compact form and then converted back into a stool or a comfortable ladder. When folded, the chair takes up minimal space and is used only when necessary.

The most famous examples of folding seats that can be converted into a step design are:

- a transforming stool that easily folds and turns into a compact whole;

- bar counter with steps, which when folded turns into a small structure.

Important! The hinge mechanism used in folding models must include a reliable latch with a safety lock, eliminating the possibility of its spontaneous return to its original state.

In a situation where it is planned to manufacture a prefabricated staircase with a folding back, a special hinge mechanism (piano ring) will be required to fix it. With its help, you can easily lower the top of the folding chair, creating additional support.

What is

A transformable chair is a wooden product that looks like a regular chair, but can turn into a stepladder. The product has many advantages:

- takes up little space;

- does not require additional support, it is easy to move;

- able to withstand heavy weight while maintaining stability;

- you can make it yourself at home using available materials;

- Easily transforms into a staircase.

The design of such a chair consists of the following parts:

- front, rear sidewalls;

- backrest slats;

- sitting;

- steps.

Similar transforming chairs have been used in everyday life for a long time. Initially, they were used in libraries, as they made it easy to reach even the highest shelves. Soon after this, the idea spread to the people, step stools began to be found everywhere. At the same time, the appearance of the products can be completely different: the chair can be made of inexpensive wood or decorated with decorative and carved elements. Everything depends only on the carpenter’s imagination.

Drawing of transformers and dimensions of parts

When making a transforming ladder with your own hands, you can use standard dimensions (indicated in millimeters) of blanks:

Drawing of a transformable chair.

1. To assemble the transformable chair we will need:

- two front sides, 20 * 270 * 400;

- two back sides, 20*325*850;

- three slats for the back of the chair, 20 * 50 * 400;

- rear seat, 20 * 165 * 400;

- front seat, 20 * 90 * 400;

- three passes, 20 * 120 * 360;

- six strips, 20 * 20 * 95.

2. Assembling the transformer ladder:

From the pipe

If there are fragments of a profile pipe left from welding any metal structure, you can put them to use - build a step-ladder chair with your own hands.

- Using a grinder, we cut the profile into parts so that the base can be welded. We will weld the frame at an angle of 45 - for comfort in climbing stairs.

- We make the frame of the bench at an angle of 90 degrees (see picture below).

- We cover the finished frame from the profile pipe with black paint (it is better to do this twice, drying each layer thoroughly).

- We construct steps with a seat from a plank pallet (from under blocks or bricks). We cut out the elements using a jigsaw in accordance with the dimensions of the welded structure.

- We fasten the parts from the board with self-tapping screws, covering the steps with the seat with furniture varnish (2 layers are desirable). Ready to use!

Stages of production from a profile pipe

Photo gallery

Manufacturing process

A do-it-yourself wooden ladder stool, assembled according to a pre-drawn sketch, can become an indispensable seat in the house and comfortable for home use. To manufacture it, you will need to stock up on all the necessary components (including special models). Most often, the material chosen is wood or plywood, which is easy not only for conventional processing, but also for finishing.

Tools and materials

To work you will need a set of tools:

- Universal jigsaw.

- Drill with a set of drills.

- Lumberjack and carpenter's plane.

- Clamps, chisel and hacksaw.

You should prepare consumables, which should include dowels, dowels for fastening, wood glue, as well as self-tapping screws. You can use boards, plywood or MDF blanks as the main working material. Before preparing drawings of a wooden folding ladder, you need to decide on the configuration of the future product.

The thickness of the material used is selected so that the finished product can withstand the weight of a person (at least 20 mm).

Purpose of the model

Any universal design that can easily be converted from a chair to a stepladder is always in demand not only in a city apartment, but also in a private home or country house. The need for it may arise in any living space where you need to reach mezzanines or ceiling lights.

It is practically irreplaceable in cases where there is a need to reach the cornice structure, as well as high shelves with books or deposits of household utensils.

Operating rules

The main goal of orthopedic developments is the prevention and treatment of diseases of the musculoskeletal system. This chair was no exception.

The positive result after its use gives grounds for orthopedic doctors to recommend the knee chair to their patients.

An orthopedic knee chair is recommended both for healthy people who want to maintain their supporting apparatus into old age, and for patients with medical prescriptions.

Of course, it will not solve your problems, but if used correctly, it will greatly alleviate your posture problems.

In order for you to sit comfortably on such a chair, it is important to correctly adjust its height, namely the distance between the knee support and the seat itself.

Correct posture helps restore the natural curves of the spinal column in mild to moderate scoliosis, completely preventing its development in the future.

Also, do not forget to periodically get up from it and do a short walk, warm-up or physical exercise to improve blood flow in the lower extremities.

Kneeling chairs often take some getting used to. Start with 10-15 minutes a day, gradually increasing the time you sit on it. If you feel discomfort when sitting on this chair, and you can’t get used to it, give up this idea. Listen to your body.

Many owners of this wonderful invention recommend alternating its use with conventional orthopedic chairs so that the frequency of loads in the sitting position changes.

Advice from professionals

Before you make your own step stool, you need to treat all surfaces so that the structure is easy to use. All elements need to be sanded, primed, and puttied. Plastic or wooden plugs can serve as plugs for self-tapping screws. It is better to use a wooden transforming chair for work. There is no need to allocate a specific place for the chair to store it.

The structure can be decoratively decorated or varnished. It is better to apply 3 layers of varnish and leave the chair to dry thoroughly after each coat. If you want to create a bright decor, then you need to use paints that have contrasting shades; they are suitable for the seat and back. If the room is decorated in Provence style, then it is better to paint the step stool in white.

If the room has a country style, then in this case it is not necessary to carefully process the product; it can be coated with clear varnish.

In the next video you will find a master class on making a wooden chair that transforms into a comfortable stepladder.

In the household, you often need to do something at height: nailing a nail, getting things from the top shelf, or hanging curtains. At the same time, space in most apartments is limited; there is nowhere to store bulky stairs. In this case, a step-stool, which is not much different from a regular one, can be an excellent solution. If necessary, such a chair can be quickly unfolded; it comes in different sizes and shapes, so it will easily fit into any interior.

Advantages of IKEA stools

The main advantages of such pieces of kitchen furniture from IKEA include:

- Reliability and strength of the structure;

- Compactness (applies to folding stools);

- Ease of assembly and operation;

- Variety of assortment, materials and shades;

- Modern design;

- Possibility of decorating stools with pillows or removable covers;

- Affordable price.

We could go on and on about all the advantages of IKEA stools, but let’s still look at their models, which differ from each other both in design and in the type of materials used for their manufacture.

Varieties

The IKEA step stool has several varieties. The models differ in design and functional features. The number of steps can be from one to three. When there are two of them, the product is used as a ladder and is not transformed. The stool with three steps is equipped with an unfolding mechanism, this makes the furniture more practical. The folded stool is easy to carry and takes up little space in the car.

Rules for choosing a kneeling chair, step-by-step DIY production

Manufacturers offer the following models of stepladders:

- Backvem is a stool-ladder in the classical presentation. There is a special handle on the top step that makes it easier to carry furniture to the right place. The height of the product is up to 50 cm, the width varies from 43 to 45 cm. Ikea’s assortment includes two- and three-stage Bekvem models. The material of manufacture is wood; today the manufacturer offers products in beige color. The main advantage of the model is its ability to withstand any load. Among the disadvantages, consumers highlight the lack of varnish on the wood. At the same time, the surface of the stool is perfectly polished, there are no burrs on it. Due to the fact that wood is sensitive to high humidity, using a stepladder in the bathroom is not recommended.

- Masterby - this model is distinguished by narrower steps and a more sophisticated shape. It is made of plastic, so it is lightweight. At the same time, manufacturers use high-quality material, so there is no need to worry that the stepladder will not withstand heavy loads. Product dimensions - 43x40x50 cm, maximum load - 100 kg. Plastic is not afraid of water, so this stool can be used outdoors, in the bathroom, or on the balcony. Due to its simple design, the Masterby staircase would not be out of place in a living room or bedroom. But this model is suitable for children, it is easy to rearrange, and easier to care for.

Another interesting model is Bolman. This is a single-stage plastic ladder stool, this product is especially suitable for families with small children. The child will be able to easily move the structure to reach the necessary objects. Since the height is small, there is no need to be afraid that the baby will fall and hurt himself.

Backvam

Masterby

Bolmen Wilto

Cost of materials

- pine beam 300 x 4 x 2 cm – 1 pc. = 30 rub.;

- board 234 x 4 x 1 cm – 1 pc. = 15 rub.;

- screws 4 cm – 16 pcs. in stock;

- emery wheels – 2 pcs. in stock;

- bolts ø 6 mm, length 4 cm – 10 pcs. = 10 rub.;

- nuts, washers, groovers (spring washers) - 10 pcs. of each type. = 10 rub.;

- metal tube with internal ø 6 mm, length 19.5 cm = 15 rub.;

- hairpin ø 6 mm, length 31.5 cm in stock.

Total costs were: 80 rubles.

Therapeutic effect

The knee orthopedic chair model allows you to adjust the seat height, adapting to everyone. With a correctly adjusted chair, the load is distributed approximately 60 to 40. Of this, 40 percent of the load goes to the knees and only 60 to the pelvis. This allows you to significantly relax your back muscles and take a comfortable position without tilting your body forward. Those. You will feel comfortable sitting on such a chair with a straight back.

A feature of the kneeling chair is the redirection of the load from the lower part of the spine to the muscles of the legs, while maintaining a vertical position of the back, the shoulders remain straightened.

Doctors and orthopedists advise purchasing such a chair for schoolchildren and students who have to spend a lot of time sitting in class.

Since its inception, when the chair had only a seat and a knee rest, its design has acquired many innovations.

Bar chairs

In kitchens or cafe establishments where there is a bar counter, there is a need to purchase specific furniture. Ordinary chairs in this case will be impractical. The bar models presented in the IKEA chair catalog are distinguished by their unique style and fashionable colors.

They are ideal for any modern style, be it minimalism or hi-tech. You can choose not only chairs, but also stools for the bar. They do not have a back, but at the same time they have a comfortable place to sit.

- IKEA beds - catalog 2022! See TOP 100 photos of the best new products from the IKEA catalog here!

- Ikea interiors - ready-made solutions and current design options (110 photos and videos)

- Ikea chests of drawers - stylish furniture models and beautiful combinations for 2020. 125 photos and videos of examples of using IKEA chests of drawers

Such models are made mainly of wood or metal. They may have mechanisms that allow them to be folded and stored. The chairs have a special lock that allows you to adjust the seat height.