Not all people have spacious apartments that can accommodate a large bed, a wardrobe, and other necessary pieces of furniture. Often a double bed takes up almost all the free space in the bedroom, so it is impossible to place other furniture there. Of course, this option will not please anyone, so some people strive to make a bed with their own hands, which will be compact, comfortable, and unique. Owners of small apartments usually choose folding beds that can be easily assembled and disassembled. Let's find out how to make such a design with your own hands.

Owners of small apartments usually choose folding beds that can be easily assembled and disassembled.

Types and types of mechanisms

Today, furniture production has a large number of types and types of mechanisms. The photo below shows only some of them (the most common):

Click-clack

| Album | Sofa mechanisms Click-clack |

| Album | Sofa mechanisms Click-clack |

The click-clack mechanism has three positions, one for lying down and two for sitting. Usually installed on modern lamella-type models.

Meralax

| Album | Meralax sofa mechanism |

| Album | Meralax sofa mechanism |

Meralax is one of the reliable French clamshell layout mechanisms. It has an orthopedic effect in two versions - lamella and metal weaving.

Dolphin

| Album | Dolphin mechanism |

| Album | Dolphin mechanism |

The “dolphin” mechanism is exactly the option that combines compactness and convenience. The seat is attached to the side parts of the frame, pulling the mechanism out of the niche “towards you” to the upper horizontal position by the transverse bar and we get a full-fledged sleeping place.

This is the simplest of all existing mechanisms. When made of high quality, it is stable and durable, but, as a rule, the metal from which it is made leaves much to be desired.

Accordion

The “accordion” mechanism is one of the most popular mechanisms for transforming sofas; it has three layout positions.

One part is fixed, the other two have moving parts that are secured with locks.

Now it is installed mainly on modern models of upholstered furniture.

The most common mechanism is installed on a sofa book. It is quite simple in layout and has a number of advantages over other models. The entire structure is made of thick metal and high-quality rivets.

You can also familiarize yourself with other types of sofa transformation mechanisms in the article Review of sofa transformation mechanisms.

The models presented in the photo have their own individual characteristics. Here, not only the angle of inclination plays a role, affecting the lowering and raising of the weight, but also the material from which they are made.

Many manufacturers use thin-walled metal and very low quality rivets for these mechanisms, which is why the furniture becomes unusable in a very short time.

If it is not possible to replace broken mechanisms with new ones, you can make repairs at home. Of course, it won’t always be possible to do everything as it should, but it is quite possible to extend and give a “second” life to the furniture.

DIY repair of a French folding bed

Have you not yet read the contents of the French folding bed repair ? The main idea of this page is that most French folding beds cannot be repaired. But still, in some cases, you can repair a folding bed yourself, if you have skillful hands. There are no contradictions between these pages. It is difficult to predict how a not-new folding bed will behave after repair and how long it will last, so we do not undertake to give guarantees or bear responsibility for the further performance of the mechanism. But you can try to fix some common defects yourself. These types of folding bed repairs include:

- Breakage of the rivet connecting the moving parts of the mechanism frame.

- Raising the foot part of the mechanism when pressing on the middle part of the French folding bed.

Rivet breakage

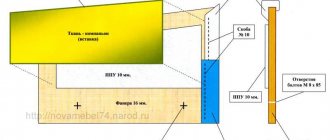

If a rivet breaks, repairing a clamshell is reduced to replacing the rivet with a bolt. Breakage of the rivet connecting the moving parts of the frame of a French folding bed occurs quite often and is a consequence of the lack of lubrication of the rubbing parts of the frame or such a natural process as wear. The rivet can be replaced with a screw or bolt with an M 8 thread. When using a thinner axis, for example an M 6 bolt, a large backlash will form between the bolt and the hole in the part, which will change the geometry of the frame. The advice is quite banal, but in practice it is often M 6 that is installed. When replacing the rivet, it is necessary to take into account that the nut or protruding parts of the bolt may interfere with the folding and unfolding of the mechanism.

The foot part rises when you press on the middle of the folding bed

The defect is due to a malfunction of the part that holds the French mechanism in a horizontal position when unfolded. If a mechanism with such a defect is used for a long time, repairing the folding bed will not give a positive result; over time, the horizontal position lock will work.

The causes of the defect may be:

- Failure to comply with the installation width of the sofa. When the installation size is increased, the movable part to which the long side spring is attached does not engage with the horizontal position lock of the mechanism. Standards for installation sizes of French folding beds can be found on the page table of standards and sizes of French folding beds .

- Initially, incorrect installation of the French folding bed in the sofa. In this case, this defect appears from the very beginning of operation and may be associated with non-compliance with the installation height of the mechanism from the floor.

- Frame lubrication. Lubrication helps the movable part of the clamshell frame slide past the stop, which fixes the mechanism in a horizontal position. To prevent the occurrence of a defect, lubricate the mechanism in this part carefully, do not allow oil to get on the latch.

- Wear of a mechanism part. With each slip , the parts that should engage are worn away . If you use a mechanism with such a defect for a long time, repairing the folding bed is hardly possible.

- Deformation of the frame part holding the unfolded mechanism in a horizontal position.

Before you start repairing, a little about “safety precautions”. When repairing a folding bed yourself, if you have no experience, use someone else’s help to control the position of the mechanism in the sofa. When bending the clamp, the key abruptly flies off the part being bent. To avoid injuring your hands, wear gloves when performing repairs.

To eliminate the defect, remove the mattress (the mattress does not interfere, but without a mattress the mechanism is easier), place the folding bed in the sofa and turn the sofa onto its back. In this position it will be easier for you to bend the latch. If you have a corner model of upholstered furniture, first disconnect the sofa from the rest. Set the mechanism to the middle position, approximately 45 degrees relative to the sofa. In this position, at the bottom, under the lower part of the back of the sofa, there is a movable connection with a latch that you have to bend.

The easiest way to do this is to use either a small adjustable wrench or a hammer. Repairing a clamshell with a wrench is more humane. Make a gap between the jaws of the wrench slightly larger than the thickness of the latch, that is, about 3-4 mm, then put the wrench on the latch, finally connect the jaws so that the gap between the jaws of the wrench and the latch is minimal, and bend the latch toward you like a lever.

After this, an acute angle is formed between the clamp and the plane of the part, instead of an obtuse or right angle. In this case, the movable part of the assembly, resembling a boomerang in shape, to which the end of a long side spring is attached, when trying to slide past the latch outward, will go inside the corner and be securely fixed in this position.

If the repair of the folding bed did not produce a positive effect, the only option to solve your problem is to replace the mechanism.

Repair of the “sofa book” mechanism

Before starting repairs, you need to determine the extent and cause of the breakdown. As a rule, it is mainly the rivets of the guide strip that are bolted to the sofa frame that break here. They fly out completely or wear appears, leading to an increase in gaps.

For work we will need tools:

- Drill or screwdriver

- Rivets

- Hammer

- Anvil or any other massive stand

It is necessary to firmly fix the mechanism on the table surface, for example, using clamps. Using a drill, we drill out the broken rivet, starting with a small drill and gradually moving to the desired size.

To select the required drill diameter, the size of the rivet and its thickness, we measure it with a caliper. We insert it into the hole, with the cap down, and the part that will be riveted should face up.

If it is not possible to repair the mechanism using rivets, the bar can be secured using a bolt and nut.

Here it is very important to choose the right length so that the bolt does not rest against the frame from the inside, because cutting it off after installation will not be very convenient!

Repair of the sofa mechanism “Click clack”

Today, the quality of operation of “Click Klyak” mechanisms leaves much to be desired. Manufacturers do not pay much attention to strength, counting on a large frame area (the larger the area, the more stable the product).

The body bends in places where the weight is localized, since it is made of sheet iron, and this breaks the transformation lock itself.

At home, making repairs can be very problematic; only complete replacement is possible.

In order for the mechanism to serve for a long time, it is necessary to lubricate the rubbing joints in a timely manner.

In the figure below they are shown by arrows.

A common cause of breakdown and rapid failure of the mechanism is incorrectly tightened fastening bolts between the wooden frame and the mechanism.

During operation, large gaps appear, which lead to distortions and wear.

Repair of a sofa roll-out mechanism

The roll-out mechanism of a sofa is one of the most durable and reliable structures, but, as it turns out, it can also become unusable in a very short time.

The reason for this fragility is the poor quality of the layout elements, in particular the rollers. For reliable disassembly and assembly of the mechanism, the rollers must rotate easily and slide unhindered across the surface.

Watch the video of how a home mechanic changes the guide roller of a sofa with a Dolphin mechanism:

This article described only the main causes and options for breakdowns of sofa transformation mechanisms, which almost any owner can do without special training.

Net

Nets consisting of separate, interconnected links, both in American and French clamshells, are a thing of the past. No armor is installed under the mesh; the mesh sag quite quickly. Lifting the mesh has a short-term effect and does not solve the sagging problem. Currently, transformation mechanisms with mesh are practically not produced. The exception is French folding beds with a welded grille, but this is a completely different type of configuration for the bed mechanism.

Warning

You should always remember that only a trained specialist with the necessary set of tools can carry out a major repair of the sofa folding mechanism. He will always be able to accurately determine and eliminate the cause of the breakdown at a high quality level.

Without the proper experience, such repairs can lead to even greater malfunctions, therefore, if a problem is discovered, very carefully study the cause of the breakdown of your favorite sofa, evaluate the complexity of the design and your strengths, and also, if you still decide to repair the sofa mechanisms yourself , approach the process itself very responsibly.

Pros and cons of a homemade folding bed

An important advantage is the budget cost of the product. You will not have to overpay for a unique design, taxes and duties. Of course, the material also needs to be purchased, but in most cases, this is less of a waste than for a finished product.

A homemade folding bed will be cheaper.

The second advantage is the ability to make furniture according to individual measurements and design. Depending on the skills of the craftsman, the folding bed can be simple and functional or original, with complex decor.

You can make a cot in any color.

And another advantage is the guarantee of the quality of the materials used. There are few disadvantages, and for an experienced master they are completely insignificant. You will have to spend time on manufacturing; you will need a certain set of tools that may not be in the house.

What is a lamella

Before you begin, you need to familiarize yourself with the description of the features of the lamellas in more detail. Lamels are wooden structures that have a curved shape. Their characteristic features include a high level of elasticity and elasticity. It is thanks to these features that the mattress can be securely fixed.

Such wood products are laid out at a distance of 2-5 centimeters. This allows slatted beds to be used by both thin and overweight people. The thickness of one plank reaches ten millimeters, and the width does not exceed thirty. However, cheap beds can use boards 4-5 millimeters thick.

Main causes of breakdowns

Sometimes people find that the board in their bed is broken. There are several main reasons why a wooden plank can break:

- Exceeding permissible loads. Wooden slats have certain load limits that should not be exceeded. However, some people still overload them, which later leads to breakdowns. Therefore, it is recommended to familiarize yourself with the permissible loads of the slatted bed in advance.

- Marriage. Sometimes manufacturers install low-quality products made from defective wood. This often happens when using overdried wood, which quickly breaks even under light loads.

- Long-term operation. Slats may break if used for more than ten years.

Awning

All companies use polypropylene fabric to make awnings. The sizes of awnings from different manufacturers vary both length and width. Because of these differences, when installing a new awning from one manufacturer on the frame of a French folding bed from another manufacturer, the awning will either be overtightened, which can lead to deformation of the frame, or it will be weakly tensioned and will not efficiently perform its function of distributing the load between the battens. The most common defect of the awning is its rupture at the points of attachment to the frame in the head part (near the back of the sofa). Most often, the awning breaks when using a guest French cot with an awning and 4 lats as a daily sleeping place.

How to choose new ones

Sometimes it is not possible to repair old products and you have to replace them with new ones. Before purchasing new boards, you will have to understand the specifics of the purchase.

Size

When making sofa grilles, lamellas are used, which may differ in size. Therefore, before purchasing, you should familiarize yourself with the main types of such products:

- Wide. These designs are purchased if you need to replace the slats on large sofas where bonnells with springs are installed. The width of such boards does not exceed seven centimeters.

- Narrow. They are considered a universal material, as they are suitable for any mattress. Experts advise buying narrow slats for beds that have spring mattresses. This will increase the strength of the structure. The width of narrow lamella materials is 4-5 millimeters. The thickness of such planks is small and reaches only three millimeters.

Quantity

Having decided on the dimensions, you need to figure out the optimal number of slats. Some people don't know how many boards they need to buy to strengthen the base of the bed.

Experts recommend buying a lot of lamellas, since the strength of the product depends on this.

To determine the required number of slats, take into account the dimensions of the bed. For example, for double structures, at least thirty planks are purchased. For single beds, 15-20 pieces are enough. However, some manufacturers install more than thirty slats to make the sofa more elastic and resistant to stress.

Material

Most often, slats for sofas are made of wood. It is used to make adhesive plywood, which is laid in several layers to create a more durable surface. Products made from plywood are characterized by good elasticity and elasticity. The lamellas can also be made from the following materials:

- Birch. Budget products are made from young birch trees. Such structures are not very durable and therefore are not recommended to be used.

- Beech. To make more reliable bed bases, beech is often used. This wood is flexible and highly durable.

Battens and batten holders

Battens and batten holders are the only parts that can be changed in French clamshells. Information on the relevant pages of the site.

to repair a French folding bed that already served its expected service life, which is from 5 to 7 years. In reality, with daily use, even the strongest and most reliable mechanisms can rarely last more than 10 years. Interchangeability allows you to freely change French folding beds produced by different companies. The guest transformation mechanism with a mesh, with an awning without battens or with an awning and 4 battens, which was originally installed in the sofa, can be replaced with a French folding bed with an awning and 10 battens or with a welded lattice.

The page self-repair of a French folding bed describes some types of work that you may be able to do without resorting to the services of a specialist.

How to repair and replace slats

At the initial stage of repair, it is necessary to get rid of damaged planks. They are carefully removed from the groove, moved to the side and removed from the structure. Some types of lamellas are attached using special holders. In this case, you will have to use pliers or a screwdriver.

Some people use a hammer, but it is not recommended to use it so as not to accidentally damage the structure.

If the slats are broken in the central part of the bed, you can swap them with the outer slats. This is done when one or two planks are broken. If more lamellas are broken, you will have to buy new ones. In this case, it is recommended to buy the same products as before. The purchased products are carefully attached to the bed using clamps. After installation, you need to check the reliability of the fastening and make sure that the slats are not loose.

How to repair a lifting mechanism with your own hands

Sometimes the bed lifting mechanism, which is responsible for transforming the structure, breaks along with the slats. The following signs indicate a breakdown:

- spontaneous lowering of the orthopedic base;

- jamming of the mechanism when lifting or lowering the structure;

- creaking and other extraneous sounds that occur during operation.

If one of the listed symptoms appears, it is necessary to disassemble the lifting mechanism. To do this, the mattress is removed from the bed, after which its base is unscrewed. Then the fasteners are unscrewed, with the help of which the mechanism is screwed to the structure. It is difficult to repair such a product yourself and therefore it is better to take it to a specialist who professionally repairs furniture.

Methods for restoring an old bed

If the bed is too old, you can restore it and make it look like new furniture. During the restoration process, it is necessary to carefully inspect the structure and identify parts that require replacement. Most often, the springs and mattress are changed during restoration. Sometimes people decide to replace worn side panels. To do this, you will have to purchase new panels that are suitable for the restored sofa. If the side parts are not very worn, you can sand them and varnish them. It is recommended to use varnish mixtures that have a mahogany tint.

Benefits of a homemade bed

Before deciding to make a folding bed yourself, you should consider the advantages and features of this design:

- the piece of furniture will have the desired shape, dimensions that will fit the dimensions of the room;

- You will independently monitor the quality of the elements used and assembly;

- this option is much cheaper than buying a finished product;

- a self-made folding bed can be placed anywhere;

- the construction does not require things that are difficult to find on sale.

Before deciding to make a folding bed yourself, you should consider the advantages and features of such a design.

When we purchase furniture in a store, it is difficult for us to assess how high quality and reliable it is. For this reason, it is safer to build it yourself using high-quality materials. This is only possible if you have the appropriate knowledge and skills.

When we purchase furniture in a store, it is difficult for us to assess how high quality and reliable it is.

How to cheaply and quickly make a cot from what you have on hand

Not everyone has nice and large apartments that can comfortably accommodate all guests and relatives. There are a lot of owners of small-sized apartments, so you have to come up with something and get compact sleeping places. In this case, a folding bed helps a lot.

A folding bed is a fairly compact and mobile item. It does not take up much free space and is easy to clean after use. If you do it yourself, you can create a unique item that will have no analogues anywhere. An extra bed can easily and happily accommodate overnight guests without compromising anyone’s comfort.

Self-made furniture: what is the advantage and why is it so relevant today?

Furniture that you make yourself, as well as interior items and everyday things, fit harmoniously into the overall atmosphere of your home or life. In addition, any activity, including handicrafts, has a lot of positive aspects that you should always remember and pay attention to.

- Do-it-yourself things and objects have a huge number of significant advantages, which include the following nuances:

- The item is created in accordance with individual measurements and necessary parameters.

- Confidence in the reliability and safety of the material as it is chosen independently, which eliminates the content of toxic substances not specified by the manufacturer in the composition on the packaging.

- Art associated with the design and decoration of homemade objects promotes the development of thinking and also improves fine motor skills. Labor done by hand cultivates accuracy, patience and perseverance in a person.

- There is an opportunity to earn extra money by completing custom projects. There is such a thing as a handmade freelancer who can work from anywhere in the world and send finished work via mail.

- By involving your child in work, you can develop his communication skills and increase his self-confidence.

- Self-assembly of products promotes the development of creative skills and develops personality in every possible way. Such work does not get boring and almost never turns into a routine.

Naturally, there are also disadvantages to working on creating products yourself - the cost of raw materials. Sometimes, they can be expensive, which undoubtedly puts a strain on the family budget. In addition, you should prepare for the time investment and show a high degree of perseverance and patience.

Read more about the technique of making a folding bed

So, you need to start making a folding bed with your own hands from the drawings. After all, a do-it-yourself folding bed, the drawings of which are not drawn up or are not prepared according to the rules, will be unsuitable for full use. First make calculations and then start assembling the structure. The sequence of actions here is as follows.

- The materials you will first need are two load-bearing boards corresponding to the length of the mattress.

- Depending on its dimensions, it is necessary to cut boards of the appropriate length. These are the future “boards”. Note that the cross bars should be slightly longer than the width of the mattress. They need to be connected to the load-bearing ones using self-tapping screws.

- Then you need to connect the back wall.

- Next, a shelf is made where the base is attached. The shelf must be secured inside the box using supports.

- Then you need to make a box for the mattress with your own hands. This will be a frame with approximate dimensions of 100x1450x1980 mm. It will need to be attached in the middle of the bottom. For production you will need 2 side and 2 end boards. You need to make folds in advance using self-tapping screws. Afterwards the frame is assembled and the bottom is nailed from a sheet of plywood.

Structures made from such materials last a long time and look attractive.

After all the above operations, done with your own hands, you can begin to make supports. When extending the bed, it is necessary to install supports made of timber with a section of 40 by 100 mm. Using prepared loops, the supports must be attached to the bottom. Next, you need to let the parts dry thoroughly. The folding/unfolding mechanism is chosen at your personal discretion.

It is easy to work with such raw materials even for an inexperienced craftsman.

It is recommended to use a decorative latch for the best fixation of the stock when closed.

At the final stage, it is advisable to decorate the product, since “naked” it will not look as attractive as we would like. For this purpose, you can use blinds that can cover the timber supports. You can also make sliding supports. This is an alternative option.

A do-it-yourself wooden cot is much more profitable than a metal version, since the former is more environmentally friendly and retains heat better.

It is recommended to use a decorative latch for the best fixation of the stock when closed. In this way, you can protect yourself from arbitrarily unfolding the bed, because it is dangerous and uncomfortable to sleep on such a bed. In view of this feature, it is necessary to ensure in advance that the folding/unfolding mechanism works properly.

When everything is collected, you can start working.

Often those who build a bed on their own from materials such as MDF worry that when the bed linen and mattress are unfolded, they will slide off. You need to stock up on 30mm wide straps on both sides for fixation. Before lifting the bed, you should fasten the Velcro.

So, you need to start making a folding bed with your own hands from the drawings.

The folding/unfolding mechanism is chosen at your personal discretion.

If desired, the finished folding bed, made by yourself, can be originally painted or decorated with decorative items. It is only important that the bed matches the interior design. If the room is in a minimalist style, then the folding bed should contain elements of this style.

First make calculations and then start assembling the structure.

After all the operations performed with your own hands, you can begin to make supports.

As you can see, building a bed for sleeping with your own hands is not as difficult as it might seem. A folding bed made by yourself will delight you for many years if all the rules and nuances were taken into account during creation.

Depending on its dimensions, it is necessary to cut boards of the appropriate length.

Such a product can be built for a bedroom or for a room in the country, replacing an old and non-functional sofa. The main thing is to approach work responsibly and follow the sequence of actions. Then it will be possible to produce a durable, durable product. If desired, you can use ready-made sketches, according to which it is much easier and more convenient to build a bed. The most important thing is that the structure fits freely in the room, looks functional, and presentable.

Then you need to make a box for the mattress with your own hands.