For example, what do you associate with the word “dacha”? Some with hard work in the garden, and some with a hammock under a shady tree. And I immediately imagine a country table on the open veranda, with an abundance of fresh herbs and kebabs. At the dacha, it can be said to be a cult place, where food mystically becomes much tastier.

Naturally, if you make a table for your dacha with your own hands, it is also a source of pride . You can always say to guests: “Well, how do you like the table? I did it myself” and tell an interesting story of his labor feat. This article provides several examples of how to make a country table; you can choose the appropriate option.

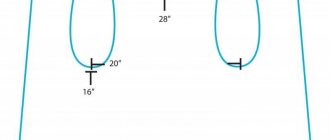

Note . Most of the diagrams in the photo are taken from English-language sites, and they have everything there, as you know, in inches; to convert to centimeters, simply multiply the indicated dimensions (excluding degrees) by 2.54.

Drawing with dimensions

To make a table with your own hands, you will need to draw up a drawing. This way you will prevent errors during the work process and make furniture much faster. This drawing should contain the following designations :

- length of the product;

- width;

- depth;

- height.

Also in the drawing it should be noted the materials of their manufacture. For furniture designed for 8-10 people, the optimal tabletop size will be 80 by 120 cm .

Important : the dimensions of the table for the dacha are calculated based on the needs of the users and the availability of free space in the dacha area.

If there is a lot of free space, you can assemble a spacious country table with benches . The advantages of this design include:

- capacity;

- sustainability;

- ease of use.

Some people prefer tables with an ice chest . Such designs are convenient. In the summer heat, you can cool drinks in them. This model is practically no different from the product with benches. Only in the middle of the tabletop is an ice box made. Instead of an ice chest, you can build a table with flowers. You will have a beautiful flower bed in the middle of the tabletop.

If there is not much free space on your garden plot, you should opt for a folding furniture model. It is different:

- compact size and ergonomics;

- light weight;

- different transformation options.

Important: to make a tabletop, you should choose a board 3-5 cm thick.

Preparatory work

I propose to consider one option for self-assembling a round wooden table.

It is simple enough that even a beginner can assemble such a structure. After re-reading the assembly features and the progress of work, you will decide for yourself whether it is worth making a similar table, or whether you will somehow modernize the proposed design.

You will need a set of tools consisting of:

[adv2]

- roulette;

- pencil or marker;

- jigsaw;

- screwdriver;

- drills;

- set with drills;

- construction compass;

- clamps;

- grinding machine;

- sandpaper, etc.

Prepare everything in advance so that at the most crucial moment it doesn’t turn out that something is missing or missing.

Materials required:

- pine boards for making a lid (table top);

- wooden blocks for the legs;

- self-tapping screws;

- wood glue;

- corners (metal);

- varnish;

- wood processing products;

- paint if you are going to paint the table.

Only when everything is collected and prepared can you begin to implement your planned project.

Don’t be afraid, but also be prepared to devote a lot of time to the round table. Especially if you are doing this for the first time.

What type of wood is it made from?

Before you start building a country table, carefully select the wood. Since the service life of the product, its wear resistance and appearance will depend on its technical characteristics. Most often, outdoor furniture is made from:

tika _

Furniture made from this breed will delight its owners: reliability, aesthetics, and resistance to negative environmental factors. Teak products become stronger and more attractive every year. Such furniture will fit into any landscape design and will become the main decoration of the dacha;- oak _

Oak tables amaze with their noble appearance, elegance and durability. But keep in mind, despite the strength and reliability of wood, before assembling a piece of furniture, the wood must be treated with special antiseptics. Then insects will not appear in the product, and it will not rot; - coniferous species . This material is affordable. Products made from pine will not be as durable, but they will be different: safety, ease of use, environmental friendliness and presentability. A pine table does not require special care and attention;

- linden, alder . These tree species, in addition to their original texture and texture, have high technical characteristics. They are easy to process and can withstand high loads.

As for the advantages of wooden outdoor furniture made from any type of wood, these include:

resistance to damage;- long service life;

- elegance;

- simplicity in convenience.

The disadvantages of wooden products include:

- possibility of ignition;

- insect damage;

- likelihood of rotting.

Advice : to increase the wood’s resistance to all negative factors, it must be treated with special means.

Also, most people consider the disadvantages of wooden country tables to be their heavy weight . But such products are installed outdoors once a year. At the request of the owners, they can be put away in the summer kitchen or any household for the winter. construction.

Attention: when placing a wooden table outdoors, you need to consider the space for water drainage.

How to paint garden furniture

Since the garden table will be located in the open air, it will be exposed to increased moisture and sudden temperature changes.

The tree will also be susceptible to attack by pests. You can extend the life of your country table using various impregnations, paints, and varnish .

It is recommended to paint the table not only to add aesthetics, but also to extend its service life.

To do this, you should use special paint for exterior use .

Advice . Life in the country can be made even more comfortable by making a gazebo table or folding table.

Manufacturing and assembly

The main components of the table are:

- supporting frame;

- table top;

- support strips.

The table assembly process is carried out in the following sequence:

Before you start assembling furniture, each board is pre- sanded, leveled, and burrs are removed from their surfaces .- Next, according to the applied markings, we connect the tabletop to the base with self-tapping screws.

- After this, we fasten the legs with bolts.

- Next, the product is treated with special impregnations that prevent damage to the array.

A round table will look very attractive on a summer cottage. For this you need to prepare:

- base;

- racks;

- table top;

- base for table top.

The assembly stage will consist of the following sequence:

The base is assembled by fastening the crosspiece together with glue and self-tapping screws.- All irregularities are processed with a grinding machine.

- we attach 4 racks to the base , which will act as legs of the product.

- Using a jigsaw, cut the edges of the boards fastened together for the tabletop evenly in a circle.

- Assembling the base . To do this, we fasten the tabletop boards together and connect everything to the bottom of the table.

- To make the product decorative, the screw caps are covered with wood putty .

Remains of boards - put to use

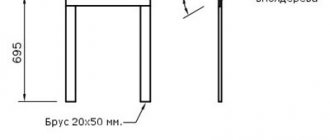

After almost every construction of a dacha or after its renovation, a lot of pieces of wooden boards, as well as wooden beams, remain. The following design involves the use of boards 25 mm thick and 50x15 mm wide. First of all, you should decide on the size of the table by making a frame for it. The table is not wide, only 60 cm, so it can be installed on a veranda that is longer than wide. The length of the table is about one and a half meters, with a height from the floor (standard) of about 85 cm.

Assembling the frame, attaching the legs to it

First of all, the frame is assembled. To do this, take 2 boards and cut them to a length of 140 cm, with a tabletop width of 0.6 meters. The transverse boards should have a length of 5 cm less, that is, 55 cm. So, 2 blanks of 1.4 m each and 2 blanks of 0.55 m each are fastened in the form of a rectangle, with dimensions of 140x60 cm. At the same time, it is necessary to check the presence of corners in 90 degrees. Self-tapping screws are used as fastening elements, with pre-drilled holes.

For the legs, 4 blanks are cut of such length that the final height of the table is no more than 85 cm. The legs are attached to the inside of the frame in the corners, using 4 self-tapping screws (2 on each side).

Making jumpers for the shelf

The jumpers between the legs can be fixed at half the height from the ground or slightly higher. The higher they are installed, the less they will interfere. The installed jumpers will give the structure a certain rigidity. In addition, by connecting them together, you can make a wand that will never be superfluous.

The frame is ready

If everything is done correctly, the frame will be quite stable and rigid. After this, the frame is carefully sanded.

Then the formation of the tabletop begins, for which boards of various types of trees are suitable. The main thing is that the boards have the same thickness. To create an original pattern, the boards are alternated. It is permissible to cover some of the boards with stain, which will help create a very attractive surface.

Making a table top

To fasten the tabletop boards, it is better to use finishing nails, which are achieved with a metal attachment. After attaching them, the boards are also carefully sanded. Painting is the final stage, on which not only the quality of the coating depends, but also the decorative appearance. In the photo below you can see what not to do, turning your work into wasted work. It’s better to take it, sand it and cover the table with a lighter varnish, achieving a more attractive appearance.

Homemade table for the cottage is ready

Affordable, lightweight plastic

This lightweight, inexpensive material is great for cases where furniture is not often taken outside. Plastic is not suitable for constant outdoor use, because its structure is destroyed under the influence of direct sunlight. Although if you place the furniture in the gazebo, this problem is solved.

The main operational advantage of a plastic table is its extreme lightness. Even a woman or teenager can move such furniture. If the design is also collapsible, then it is easy to store. The disadvantages of plastic are a short service life, rapid loss of aesthetics (for example, white material quickly turns yellow when used outdoors).

A table made with your own hands from plastic can be easily damaged by dropping a knife or any heavy object on it. If it is not individual elements that are assembled from plastic, but the entire structure, then the product may be unstable. This table will easily tip over, so it should only be placed on a solid, level base.

Sleek, durable metal

Metal is often used in the production of outdoor furniture because products made from it can last for decades (but only if high-quality metal is used and not recycled materials). Modern forging technologies give wide scope for imagination. A forged table will look especially impressive in a courtyard with ornate metal gates, wickets, fences, and gazebos. Such products seem exquisite, weightless, elegant.

But you can make a simpler design with your own hands using standard sheets of metal and a profile. Aesthetically, such furniture is inferior to forged furniture, but it has the main advantages of outdoor metal products, namely durability and stability. Metal furniture is not afraid of cold, heat, wind, it can be used outdoors all year round.

Metal also has certain disadvantages. In particular, it is susceptible to corrosion and therefore requires special treatment to prevent rust. It can get very hot in hot weather and cool in cold weather, which creates some discomfort when using it. Metal has significant weight and is one of the most expensive materials for furniture production. Aluminum has the most affordable price, but it is inferior to steel and cast iron in strength.