Types of entrance gates for suburban areas

The material and design for the gate are chosen based on the budget.

The model is selected taking into account the type of structure, dimensions, while paying attention to the weight of the gates and the material of the supporting pillars. It is important to use automation, which will increase the cost, but will add comfort to maintenance.

According to the method of opening gates there are:

- with manual movement of the blade;

- with automatic drive.

Manual opening is appropriate if the gate leaves weigh little and move easily. Otherwise, you will need to connect electricity and invite a specialist. There are modern options with a solar-powered engine. The sash material does not play a role in the installation of automation. The disadvantage of the electric drive is its high cost.

The automation of modern gates and gates for a private home can be of a linear, lever type; in such systems, the mechanisms are hidden in the rod. They produce open paired sets without a rod nut. The linear group also includes hydraulic drives powered by a liquid pump.

Elbow-type electric drives are produced when the parts of the mechanism are folded. There are underground devices that are not visible on the surface of the driveway. Drives for domestic gates operate on 230 volts; the system maintains a constant voltage of 24 volts.

Classification by opening method

Hanging gates made of metal profiles

Swinging structures are used most often, because they are the cheapest to make. The canvases open outwards or into the yard; sometimes pendulum hinges are installed to open in two directions. For them, linear (worm) and elbow types are installed, operating from a rod. Swing gates will require two mechanical or hydraulic drives for each leaf.

Sliding gates are called sliding gates if the design uses two doors that move in different directions. They are most often used in industry, but are also placed at the entrance to cottages and mansions. An underground opening mechanism can be used for them.

There are types of sliding gates:

- hanging;

- console;

- on the rail.

Rail varieties move using rollers at the bottom of the canvas. The wheels run along a guide profile embedded in the base of the gate. The second type is cantilever, when the rollers move along a beam mounted on a nearby fence. The suspended type involves the presence of a purlin, which is mounted above the entrance opening; the wheels of the canvas move along it.

Advantages and disadvantages

Sliding gates on rollers

The advantages of a swing system include ease of installation, reliability and low cost. To open swing doors, you need a place in front or behind the passage area. When opening from the outside, the sidewalk is taken into account so as not to disturb pedestrians. Internal opening requires taking into account the space for the entering car so that it is possible to close the door while the car is standing.

Suspended versions of gates to the house are durable and can withstand wind loads. The disadvantage is that such opening methods limit the height of the passage. But in the private sector this is not so important, because the dimensions are adjusted to a certain type of car.

Opening on a rail requires regular cleaning of the profile from snow and leaves, but such systems do not need space for opening, since the sash moves along the fence. The most effective are the cantilever varieties, which do not require a foundation to install a guide profile at the bottom of the opening. The console is located outside the vehicle passage and does not limit the height.

Photo gallery

We bring to your attention various options for gate design in 14 photos.

And some more great ideas in the video:

Materials for production

Forged gates with metal filling are considered the most expensive.

Solid metal for gates to a private house with a wicket is chosen for durability, rigidity, strength and safety. Blind doors are decorated with decorative elements. Corrugated sheeting, another metal profile stylized as wood, or stone are inserted into the iron frame.

Unusual examples of street gates can be made from wood. The material is light, environmentally friendly. The disadvantage is the high risk of fire, susceptibility to rotting, and destruction by bugs. Before installation, it requires treatment with special preparations.

The design of forged doors has an interesting look, it uses ideas of various geometric and floral patterns. The disadvantage is the high cost, since forging belongs to the manual category of work.

Beautiful gates to the yard are obtained by combining wood, metal, corrugated sheets with forging. Combined options are cheaper, but their appearance only benefits. Steel looks good together with sectional or solid polycarbonate.

Installing additional accessories

For greater ease of use, you can add gate latches - by which they will be held open and a mechanical stop for the closed position of the gate.

To install automation on swing gates, you need the following minimum set:

- Control drive for each leaf separately,

- Control block,

- Remote Control.

To properly install automatic gate opening and closing, you can invite a specialist in electrical work or do this yourself.

Additional accessories also include photocells, video surveillance systems, intercom and the like.

Swing gates are a practical, inexpensive and aesthetically worthy solution for any private home, office, or institution. Since the lining and decor can be completely different, any buyer can easily choose a gate model to suit his taste and needs.

Sectional garage doors: types, sizes, installation, advantages

How the price of garage doors is determined

Gate with wicket

Wooden gates made of picket fence with a wicket - a budget option for fencing.

A wicket in the gate leaf is made to combine the passage and passage of vehicles in one opening, to reduce the size of the entrance group. This simple option saves material on separate posts for the gate and sewing the fabric. Additionally, a square pipe is purchased to make the frame and diagonal.

There are two options for gates:

- The picket-type design includes two horizontal slats and a diagonal brace for strength. Such an amplifier is directed upward to the recessed part of the gate from the hinge side.

- A more complex model is represented by a rectangular frame made of wood or iron. The canvas is made from slats, small timber, and sewn up with profile metal. The braces are placed from the center to the corners or they are used to connect two sides of the corner.

The gate in the gate always has a top crossbar and a threshold, so the movement of a tall person is fraught with inconvenience. The width of the passage is limited; there is no possibility of unhindered transportation of a cart with cargo.

Question about attractiveness

It is customary to use common design trends when decorating gates. The degree of decorativeness largely depends on the location of the house. If it is built on a protected area, you can supplement the poles with street lamps, and decorate the doors with overlay elements with interesting designs and patterns.

Modern directions

Characteristic features of the Loft style:

- Manufacturing of gates from sheet metal, lumber;

- The presence of simple lines;

- Lack of elegant patterns;

- Construction of brick pillars.

When choosing a color to paint, you need to pay attention to dark tones. They are best suited to the specified design direction.

Gates made in the high-tech style should symbolize severity, a harmonious combination of plastic and metal. It is necessary to achieve significant accents on the vision of modernity and manufacturability, and therefore, when decorating gates, ornate patterns, intricate designs, and translucent elements will have to be excluded.

Provence or Modern

The half-forgotten Provence style can be used when decorating gates. The design is characterized by a harmonious combination of wood and stone, so a good solution would be to use lumber. A reliable frame and large, wide hinges are made of metal. When painting, it is best to use light shades:

- Light blue;

- Rich green;

- Olive;

- Lavender;

- Turquoise;

- Cream;

- Champagne;

- White.

Provence symbolizes antiquity and therefore the gate must be skillfully aged. A stone fence will effectively complement the style direction.

The Modern design direction is quite complex, but many owners of country houses try to use a non-trivial style when decorating gates. In the manufacturing process of products, the following elements are allowed:

- multi-colored;

- metal;

- forged;

- openwork;

- ornate;

- smooth.

A harmonious combination of decor will create an interesting design.

Standard gate sizes for a private home

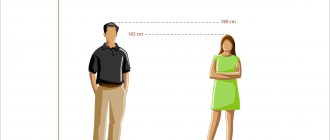

For a passenger car to pass, a width of 2.4 m is sufficient, but a special vehicle, truck, or firefighting equipment with dimensions exceeding 2.5 m can enter a private yard. It is necessary to design the gate width starting from three meters.

The gate to a private property is not always in a straight line if you need to turn when entering. The width in this case depends on the turning radius. Sometimes the size between the outer edges of the road and the gate is equal to or greater than the turning radius. Then the car has a margin on both sides, driving perpendicularly.

In another case, such a gap is less than the turning radius, then the car enters at an angle. There is a danger of the rear end skidding and hitting the curb. In this case, the width is taken at the level of 3.5 - 5.0 m. If this does not save the situation, the gate is buried 1 - 1.5 meters into the yard.

Main stages of construction

Installation of support posts for a fence

Preparation for work includes determining the location in the fence, developing a sketch or drawing, and marking the position on the ground.

Basic installation consists of the following processes:

- installation of poles;

- welding of gate and wicket frames;

- filling of canvases, installation of a wicket structure;

- hanging sashes on racks, installing automation, locks, constipations.

The pillars are dug in at 0.9 - 1.2 m, and the bottom is filled with crushed stone. The gate frame is boiled on the ground, choosing a flat place. The racks are checked with a plumb line, and the right angles in the canvases are checked. At this stage, electricity is supplied for the drive. The lining is fixed with self-tapping screws, and a wicket frame with the canvas is placed in the canvases.

The lower part of the canopy is welded to the racks, the top is attached to the frame, and the location of both parts is checked on the same axis. They hang the gate leaves on hinges or put them on rollers, check the quality of work and the opening of the gate. After this, bolts are welded on and locks are installed.

Installation of supports

1. Careful measurement and calculation of the area.

Before you start installing support pillars, you need to carefully measure and calculate the area. To do this, it is advisable to clear the landscape as much as possible, remove debris, grass and anything else that may interfere with the marking.

2. Mark the location of future structures.

It is convenient to mark the location of future structures using pieces of reinforcement or electrodes. It is important to measure it several times to make sure that the supports are positioned correctly - once they are installed, you will not be able to move anything.

3. We dig the supports into the ground.

To install support pillars, they need to be dug into the ground. This must be done taking into account the length of the supports - the depth of the pit for the support is at least equal to the length of its above-ground part, but it is better if it is a little larger. The dimensions of the hole for the support are made taking into account the size of the support itself; the width of the hole in the ground should be slightly larger than the material.

The support for sliding gates, as a rule, has a metal rod inside (pipe, channel), and the outside is lined with brick, which can then be decorated with anything.

4. We concrete the support.

Be that as it may, in order to obtain a solid base for support, it must be thoroughly concreted. This is not difficult to do, just follow a few requirements:

- Firstly, pour 5-7 cm of cement mortar under the lower (underground) edge of the pipe - this will prevent the possibility of premature corrosion of the metal;

- Secondly, the lower part of the core can be additionally equipped with a cross made of reinforcement or thin corners - they will provide a solid foundation for the future support of the gate.

You can prepare the concrete for pouring yourself. This will require cement, usually M200, sand, crushed stone and water. The ratio of sand to cement is standard: three to one. You will need as much crushed stone as sand; you should not skimp on this material - it is this material that ensures the durability of the hardened mortar and prevents it from cracking.

The concreted supports will be ready for further work in about a week - during this time the solution will completely strengthen and harden.

5. Cover the support with bricks.

Next, the support is covered with bricks, evenly installing metal tabs - they are needed to secure the sashes.

Important

when laying bricks, take into account whether the gate will open inward or outward and where the automatic mechanism will be located - for this, even during the laying process, it is necessary to provide special niches and recesses.

Installation Tips

Pouring the foundation into the gate formwork

Gate posts can be hammered in to simplify installation and reduce installation time. The hole for the metal pole is made with a garden drill to half the design depth (0.5 - 0.6 m). A support is installed at the bottom and hammered with a hammer head (a steel pipe with a heel and handles) or a heavy sledgehammer. This method is suitable for light gates; for heavy ones, standard concreting is used.

The parts for the gate are prepared in advance, they are made exactly to size, paired elements are cut identical. The metal for the diagonals is cut locally, so it should be at hand. Cuttings of a profile pipe, angle, or channel are suitable for this.

Finished sashes can be sewn only on the street side, or the sewing can also be applied from the yard. The material is placed without gaps; sometimes a slight overlap is required, for example, for polycarbonate. Locks can be welded to the frame or canvas; in another option, bolts with nuts and washers, and metal screws are used.