Hi all! Almost immediately after their appearance, sliding wardrobes began to rapidly gain popularity and displace classic designs. At the same time, the coupe was improved and improved. One of the innovations was the hanging system for sliding wardrobes, which will be the subject of our conversation today.

This system is used for sliding doors and is distinguished by the presence of a top-hung design. In simple terms, the top of the door is used to place the tracks, not the bottom.

Is this good and how justified would it be to buy such a system for a closet? Today we will try to find the answers to these questions. And you can help me by leaving comments.

Hinged doors for wardrobes

The sliding wardrobe is the most modern type of storage product. It allows you to save surrounding space and organize the storage of things most efficiently. The convenience and service life of the cabinet depends on the quality of the door leaf and especially the chosen method of opening the doors.

The hanging system for sliding wardrobes is a set of sliding doors equipped with top-supporting or bottom-supporting rollers.

Installation features

There are two ways to install suspended systems:

- on the ceiling or on the top lid of a cabinet - usually used for sliding wardrobes, sliding interior partitions, wardrobe doors;

- on the wall above the doorway - used for installing interior doors or doors to a dressing room.

If the upper (load-bearing) guide is mounted not on a solid wall, but on a cabinet lid or on a light partition, then care must be taken to ensure the proper strength and rigidity of the material in order to avoid its deflections or other deformations under the weight of heavy doors. The top rail and rollers are usually masked with a decorative trim to maintain the overall aesthetics of the structure.

Characteristics of the suspension system

The hanging system for sliding wardrobes looks good in classic sliding wardrobes, corner and non-standard shapes.

The furniture market offers cabinets with bottom-support and top-support sliding systems. The lower support provides for a mortise or overhead installation method. It allows you to install the canvas to the floor.

The system includes closers that allow you to close the doors carefully.

The suspended design consists of rollers and a guide made of aluminum profile with a special coating. It also has closers that ensure smooth movement of the doors without much effort.

The mechanism includes an aluminum profile with a special coating.

Cabinets with top rails are slightly more expensive. In a top guide system, the mechanism is open. Mandatory design of the upper part of the canvas is required. Usually during manufacturing decorative elements are used to close the mechanism.

This system allows rational use of living space.

Important! Installation with top rails is more complex. Fastening must be done by professionals or if you have certain skills when installing it yourself.

There are several types of suspension systems:

- Roller. The roller is located inside a rail-type guide. Top or bottom roller mounting;

- Frame. The profile is made of steel or aluminum. Aluminum profile is more resistant to abrasion and more durable. Its use is preferable, but it costs more;

- No frame. The system may become deformed due to temperature changes or high humidity levels in the room. The service life is shorter than other types. Cheaper option;

- Radial. They are usually used in products of non-standard configuration.

Door leaf materials

Hanging systems for heavy and large doors are used in combination with almost any materials from which door leaves can be made:

- with solid natural wood of various species;

- with decorative MDF boards from Alvic, Fundermax, Cleaf and other manufacturers;

- with laminated chipboards;

- with glass sheets of various thicknesses.

MDF and laminated chipboards are the most common solutions for door leaves due to the affordability of these materials. Experts advise using a slab with a thickness of at least 25 mm for the manufacture of heavy doors. Such material resists bending loads much better, leaving the racks and upper horizons of the structure straight.

You need to be careful when choosing a hanging system that matches the weight of the future door. One standard sheet of this thickness weighs about 60 kg. Accordingly, two or three doors in total create a load equal to 120 or 180 kg . It is necessary that the weight of the doors does not exceed the design load for the suspension system.

A striking trend in recent years has been the use of various types of glass for the manufacture of door panels. Glass can be completely transparent, translucent, frosted, decorated with a sandblasted pattern or images, with pasted tinting and other decor. The glass sheet is enclosed in a lightweight aluminum frame or a frameless method is used, attaching carriages with rollers directly to the edge of the glass. The choice of fastening method depends on the design and engineering solution of the facade.

The contents of the closet are no longer hidden, so it is especially important to keep things in immaculate order. In modern closets, special filling is used for this - systems of hangers, frames, drawers and baskets for linen, clothes, shoes, and accessories. There are even drawers with glass elements - fronts and sides, which are in perfect harmony with the glass facade of the cabinet.

Types of hinged doors

- Hinged door. The canvas is suspended on the upper fittings and fixed on the lower one;

- Support door. The wings are supported by the lower rollers, and the upper fittings are used to fix and support the door. They are easier to install and cost less, but the sashes may have play relative to the line of movement.

- Combined. The shutters are fixed on both profiles (there is no play). The design is the most reliable and expensive.

The design has proven its versatility, which is why it is used in the manufacture of sliding wardrobe doors, which can be installed in any room of the apartment.

Do-it-yourself dressing room: how to arrange it, examples of filling

Plus, you will have to think additionally about the design of the upper part of the door, since an open mechanism will be used here. Manufacturers usually solve this problem by installing decorative elements.

And to complete the shortcomings, I would also like to focus on the more complex installation of the top-support suspension system than the bottom-support system. But if professionals get down to business, you, as a simple buyer of a finished cabinet, will not have to worry about this. And if you decide to assemble everything yourself, you will have to be patient, read additional literature and watch training videos.

Whatever you say, suspension systems objectively have more advantages than disadvantages. This is an excellent solution for a sliding wardrobe, which creates comfortable and aesthetically attractive conditions for gaining access to the contents of the wardrobe, as well as for closing it as needed.

Under no circumstances should you buy a cheap design. Otherwise, it will quickly fail and bring much more problems than comfort and convenience.

Whether to use a suspension system or not is up to each individual.

What can you say about this? Do you consider them a practical and convenient option, or do you have other considerations and preferences?

Thank you for your attention! Subscribe to our website, leave comments and ask relevant questions!

Source: vmk-mebel.ru

Step-by-step mounting instructions

Let's consider the installation of the most common hanging system based on the lower profile for sliding wardrobes.

The loss of running carriages is prevented due to the strong fixation of the array in the doorway and the shape of the profile.

Sequence of actions when attaching:

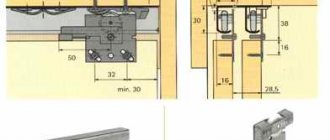

- install the upper fittings (guide profile). When fastening there should be no gap between the ends of the profile and the side walls. For fixation, you can use screws with countersunk heads or self-tapping screws;

- adjust the movement of the roller;

- install the lower guide profile;

- install the door travel limiter corner.

The suspension system allows each door to withstand loads of up to one hundred kilograms.

Roller mechanisms

Photo: part of the wardrobe parts

The roller model for opening doors in furniture has a simplified design and is easy to install, so you can assemble it yourself. The structure of such a mechanism includes an upper guide bar and a roller device. It is installed at the top of the door. The guide piece is fixed above the opening, or directly to the ceiling.

Roller mechanism parts

The roller structure has an upper and lower profile, fixed inside the frame using self-tapping screws. Two blades with rollers move in different directions from these guides. The main load is transferred to the lower profile, so when installing it, special responsibility must be observed.

Types of rollers

Several types of roller mechanisms are used in the furniture industry. They differ in design and principle of operation.

By type of guides

Currently, on the furniture market you can find high-quality furniture models with a convenient sliding system; the entire mechanism of operation of the guides for cabinet doors is based on a special profile, in the grooves of which wheels ride, mounted on the door frame.

Such furniture differs in the type of guides used, which ensure smooth movement of the rollers during operation of the storage product. Depending on the placement and design features, guides are of the following types:

- Lower and upper (taking into account the specifics of installation).

- Single, double (taking into account the number of doors in the closet).

The type of guides affects their cost and also shapes the pricing policy of furniture.

Coplanar mechanism

It was developed by the Italian brand Bartoluzzi Sistemi. A similar mechanism is found not only in compartment furniture, but also in other products of the furniture industry.

Doors with such rollers move along different guides, which are cleverly hidden and do not stand out against the general background due to the specifics of the mechanism. When opened, the blades move forward and then move to the side.

The disadvantage of the system is the limitation on the weight of the canvases. It cannot be more than 55 kg.

The best models of the hanging system

There are products from many manufacturers on the market. The best models are:

- Aristo is a high-strength profile with a wide range of colors. Estimated service life up to 30 years;

- Versal – perfect dimensional accuracy of profiles, easy installation. Estimated period of use is up to 18 years;

- Komandor - with increased tensile strength and a more advanced design of the lower roller.

HfTTich, Hafle and Marbella profiles are also popular.

Thus, an atmosphere of comfort is created when using sliding wardrobes due to the silent movement of the doors.

Important! It is not recommended for specialists to buy cheap models. The design is not particularly reliable and can quickly fail. There will be more problems instead of convenience and efficiency of use.

Sliding wardrobes are compact, multi-functional, large capacity, and easy to use. They replace numerous cabinets with doors. The hanging system is an ideal solution for attaching door leaves. Convenient and aesthetically attractive conditions are created for access to the contents of the cabinet and for its smooth closing.

Advantages and disadvantages

Sliding mechanisms in sliding wardrobes have a simple design, because... consist of simple and understandable components that are easy to replace. The advantages of the system include:

- Presentable design that looks original in any room.

- Movement along one plane, which means there is no need to leave a lot of space in front of the cabinet.

- All parts of the system are simple and inexpensive. If some components fail, they can easily be replaced with other, new ones.

- Opening the door is simple and easy. This allows you to install small cabinets in children's rooms.

- The doors of wardrobes are versatile, so this furniture looks great in any part of the house, including the kitchen, bedroom or living room.

One of the negative aspects of sliding systems is the gradual formation of gaps between the walls and doors, which negatively affects the appearance of the furniture. When using the system, it is necessary to prevent the roller mechanisms from becoming clogged with dirt, since the smooth operation will be impaired.