When making a kitchen set, the master is faced with the need to carefully plan the dimensions. This work, at first glance, seems very difficult. In fact, knowing a few basic operating principles and understanding how to get started can make planning your kitchen unit a breeze.

A well-made kitchen set will provide the housewife with comfort for many years. Source derevyannie-doma.com

Buy ready-made furniture or make it yourself

The industry offers customers a large variety of kitchen sets. It is often possible to choose a ready-made option that takes into account the owner’s wishes. However, there are those who prefer to make furniture themselves. On the one hand, this will save a significant amount of money, on the other hand, it will require a significant investment of time and labor. Most often, the reasons why an owner wants to use a self-made kitchen are the following:

- The kitchen has a non-standard shape. If you buy ready-made furniture, it will require a long, complex and expensive adjustment.

- It is much more convenient for the owner to use furniture that was made just for her. In this case, both the physical characteristics of a person and aesthetic preferences can be taken into account. When, for example, cutting out a corner kitchen, you need to take into account the traditions accepted in the family and established habits.

- Kitchen sets are an expensive purchase. If the furniture is poorly installed or organized, it will have to be used for many years. Sometimes it’s easier to think through and make a kitchen set yourself than to look for the most suitable one.

- Some families are very limited in their financial resources. Sometimes self-made kitchen furniture is the only option available.

Having the opportunity to independently plan the installation of furniture and make it, the owner will receive exactly what he needs and at the same time save his money.

The plan must accurately indicate the dimensions of the furniture Source derevyannie-doma.com

Manual cutting

The algorithm for working with laminated chipboard is as follows:

- Draw the dimensions of the slab on paper. Reduce each side of the slab by 10 mm.

- Determine the characteristics by which future elements for furniture production can be grouped. These may be the same dimensions, if there are many such elements, or only the same width (height), the same structure of the laminated surface pattern and other characteristics. In the list of elements, group them according to the same characteristics.

- When drawing, place large elements first (on top). Leave a gap of 4 mm between the elements - this is the width of the saw.

- Next, arrange the remaining elements, also leaving a gap of 4 mm.

Video description

How to calculate a kitchen.

When drawing up drawings of kitchen furniture, you must not forget about the need to use a cutting table. The most convenient place for it is between the stove and the refrigerator. When designing a kitchen, it is important to ensure that the housewife spends minimal effort when doing the work. One of the most profitable solutions is to install a corner kitchen unit.

The height of the furniture should be comfortable for the hostess Source derevyannie-doma.com

Planning procedure

When planning, it is important to collect all the necessary information in advance. The diagram needs to show the exact shape of the kitchen space, the dimensions of each wall, the location of communications, ventilation, window and door openings.

The diagram prepared in this way will become the basis for further planning. It contains drawings of each cabinet. After this, you need to determine the location of various household appliances. Their dimensions must be accurately measured before indicating their place on the drawing.

The dimensions in the drawing must be accurately calculated Source derevyannie-doma.com

The next step is to indicate the location of the remaining items and furniture in this room. In this case, you need to think about installing tabletops, chairs or stools. The kitchen must have the required number of cabinets. There should be enough space for everything the housewife needs.

In the video you can find out where it is convenient to start making a kitchen:

Video description

Where to start making a kitchen.

You need to think about the height of the furniture. Usually the first floor is no higher than 90 cm from the floor. For the second tier, you need to provide another 90 cm. It is convenient when the depth of the cabinets on the first level is 50 cm. For wall furniture, it should not be more than 30-40 cm. When determining the depth, the thickness of the facade is not taken into account - here we are talking only about the useful volume .

A carefully designed drawing will help you make high-quality furniture Source vstroyke.com

There are no strict requirements for the width of cabinets. In practice, it is determined taking into account the size of the kitchen space. Usually it does not exceed 100 cm. For corner cabinets on the lower level, the limit is 90 cm, for cabinets with 2 tiers - up to 60 cm.

After planning has been done, you need to consider your options for purchasing standard furniture. In this case, you will not have to adjust them. If it turns out that furniture of special dimensions is required, then it will need to be customized on your own.

Example of a corner hanging cabinet Source vstroyke.com

Technique 1. Cutting along the guide

We install a guide (rail) on the workpiece, set the sawing depth and make the cut. As you can see for yourself, even on the outside of our chipboard workpiece there are no chips or explosions. The cut itself was smooth with no signs of scoring or side waves. Why such difference?

What is the merit of the guide?

When we saw with a disk, we inevitably move the saw, the so-called “iron movement” is obtained. That is, when we move our hand, we constantly move the saw to the right and left. A guide that has a hard edge allows you to avoid this.

Accordingly, when we guide the saw along the guide, it does not move and the saw blade itself works smoothly, without changing its position. The result is an ideal line parallel to the guide.

About custom furniture

When planning the arrangement of furniture in the kitchen, it may turn out that only standard furniture will be used. However, in most cases, shelves and cabinets are required, which you need to adjust to size yourself. This can be done at the request of the owner or due to the presence of certain features of the premises. This, for example, can happen in the following situations:

- Much depends on the placement of communications. Sometimes they are made in such a way that the owner must adapt the furniture arrangement to them.

- Sometimes there are niches in the kitchen. They can be large. In this case, they can be used to place furniture. If they are miniature, then they will have to find another use.

- When planning, you need to take into account how the outlets are located. If necessary, they can be rearranged. Finding them a more comfortable place. The issue of their placement must be resolved before work with furniture begins.

- The presence of non-standard protrusions can affect the configuration of the location of the kitchen unit.

The easiest way to account for niches or projections is to adjust the depth of cabinets and cabinets. This parameter must be changed so that it allows optimal use of the room area.

Kitchen module for oven Source vstroyke.com

How to make a kitchen set will be discussed below. Thus, a thoughtful and rational way of planning includes the following steps:

- Indicating the shape and size of the kitchen space. Here all niches and protrusions must be taken into account, with the exact value recorded.

- The location of window and door openings should be marked on the diagram.

- It is necessary to note all available communication elements. Dimensions provided must be exact and not approximate. Parameters must be obtained from technical documentation, and if necessary, measurements must be carried out independently.

- Next, on the drawings of kitchen furniture, you need to mark the place where household appliances should be located. They often use stands or nightstands, the placement of which must be taken into account when planning. Some owners may choose to place something else in the kitchen at their discretion. An example would be a washing machine. These objects must also be taken into account when planning.

- Taking into account the previous stages, you need to consider where you can get by with standard furniture, and where you will need special furniture. It is necessary to mark on the plan exactly where the regular furniture will be installed.

- Now you need to find where to put non-standard furniture and formulate requirements for its parameters.

At first glance, this procedure seems complicated, but if you neglect any of its stages, it is dangerous for the owner and will result in significant additional costs. To make things easier, you can schedule multiple times. In this case, at each step it is enough to make clarifications until a high-quality plan is obtained.

The video describes in detail the standard sizes of furniture:

Video description

Standard sizes of kitchen furniture.

You can also choose one of the ready-made projects as a basis. Then you need to make adjustments to suit the needs of your kitchen. It is easier to refine a project than to start it from scratch.

Creating a sketch will help you imagine your future kitchen Source stroyday.ru

The kitchen layout allows for a large number of options. However, it must be taken into account that there are not many initial elements for working on the plan. For example, one of the most common are various lockers.

They are divided into two main types: floor-mounted and wall-mounted. The first ones are installed on the floor. They usually have a relatively large capacity. The depth of the internal space allows you to place a lot of useful things here. This type of cabinet is often used to store the heaviest items. The following types of floor models are usually used:

- The most common are conventional cabinets, which are called straight. They contain shelves and drawers.

- To effectively use the corners of the room, specially shaped cabinets are used. They can be equipped with special door designs that provide convenient access to the contents.

- The kitchen set is made in such a way that the pieces of furniture included in it are located end to end. There are end tables at the edges. Unlike other cabinets, they must have an additional special design on the outer side.

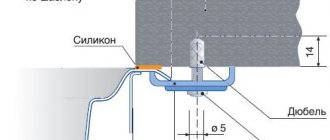

- The sink cabinet differs from others in that it does not have a back wall. It is located under the tap. The tabletop is attached to it along the edges; the attachment point must be sealed so that moisture cannot seep through it.

- A cabinet may be required to accommodate the built-in oven. To work with it, you need to ensure ventilation.

- The use of pencil cases has become widespread. They can be used both for storing and placing household appliances.

First, the drawing indicates the shape and dimensions of the room, the location of communications. Source stroyday.ru

Do-it-yourself wardrobe – Notes from one programmer – LiveJournal

- Room measurements;

- Calculation of the overall size of the cabinet based on measurements;

- Planning the interior space of the cabinet;

- Creation of initial design;

- Improving the project taking into account the chipboard used;

- Calculation of details;

- Cut out the parts on a sheet of chipboard.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

Video description

Lessons Pro100.

Corner kitchen table. For each piece of furniture you need to make a drawing indicating the dimensions. Based on it, a material cutting map is drawn up. Having determined all the needs for it, you can decide how much of it is needed. In this case, you need to buy fittings, materials for making legs, and for decorative elements. For example, a drawing of corner kitchen furniture must contain the exact shape and dimensions of the cabinet and all the necessary fittings.

It is recommended to purchase not only the required quantity, but also an additional 10%-15% of materials. Having the professional skills to perform such work is important.

One of the options for inserting a sink into the countertop Source stroyday.ru

In the process of work, it is not necessary to act only independently. There is always the opportunity to contact specialized companies to perform some work. This may increase costs, but will guarantee the high quality of the work done. In this case, the owner will receive the following benefits:

- Such companies operate on efficient specialized equipment. This level of quality is difficult to achieve when making it yourself.

- The work gets done much faster.

- The owner is not faced with the need to remove debris left after carpentry work.

- The company that took on the work is responsible for the quality of workmanship. If there is a defect, the furniture will be remade and the customer will be paid compensation for damages.

- When purchasing raw materials, it is important to cut the material correctly. If professionals do this, they will do it optimally, minimizing the generation of waste. This will result in a significant reduction in furniture manufacturing costs.

Thus, when creating a headset yourself, it makes sense to entrust some or all of the work to specialists. This will allow you to achieve the desired result in accordance with the layout of the kitchen. The furniture will be made by professionals with their inherent high quality of work.

Various types of fasteners for kitchen furniture Source stroyday.ru

Rough floor finishing

Subfloors are installed from hardboard quite often; this material is especially suitable for leveling old plank floors if dismantling work is not expected. In addition to resulting in a perfectly flat surface, the fiberboard layer will serve as a good heat insulator, which is especially important for residents of private houses or first-floor apartments in old high-rise buildings.

For laying the subfloor, untreated fiberboard with increased hardness or soft fiberboard is used as a soundproofing pad. Despite the abundance of hydrophobic additives in the production of modern fiberboards, experts advise that they be further processed before installation. Impregnation with hot drying oil in 2-3 layers gives good results. After complete drying, the sheets can be laid.

Fiberboard floor ready for further processing

If the old base for the floor is quite flat, the hardboard is laid directly on it. If there are significant level differences (more than 10 mm), you will have to level the old floor or lay joists. In any case, the surface for laying fiberboard is pre-treated with an antiseptic primer.

We cut hardboard

Many modern enterprises that sell building materials offer their customers cutting fiberboard to individual sizes upon purchase. Special high-precision equipment guarantees that the work of cutting material and processing edges will be done with high quality, without chipping. In this case, your main task will be to accurately take all measurements. If you are so unlucky, you will have to cut the hardboard yourself at home.

In principle, a hand saw with a fine tooth will be suitable for this work. After all, small irregularities formed at the cutting site are of no importance for laying the material as a subfloor. When there is a significant amount of work, cutting fiberboard is much faster and easier using the following devices:

Jigsaw

- a jigsaw or circular saw, preferably with a laser guide;

- saw blades of a special brand, suitable for cutting hardboard;

- trestles with an inclination of 20-25% from the vertical, allowing you to fasten a large-format fiberboard sheet;

- metal ruler

- marker.

If you have to cut fiberboard for the first time, in order not to spoil the material, first practice on a small piece, placing the jigsaw blade to the right of the marking line. Be sure to first familiarize yourself with the techniques of experienced craftsmen, for example, by watching thematic videos, one of which is presented below:

How to lay fiberboard?

If after laying the fiberboard it is planned to lay linoleum, the hardboard is laid with the wrong side down. In other cases, the corrugated surface will provide better adhesion of the fiberboard to the finishing materials, so it is turned upward.

Installation usually begins from the corner opposite the front door. Fiberboards are fastened using special staples, nails or screws, or glued with mastics. Before nailing or gluing, they try to fit the sheets together with a minimum gap to make puttingtying the seams easier.

By the way, there is no need to seal cracks near the walls; on the contrary, be sure to leave technological gaps that will allow the fiberboard to “play” without deformation when expanding with temperature fluctuations.

The easiest way to cut fiberboard when going around a heating pipe is with a regular knife. More accurately, such work can be done using a specially created template made of thick cardboard, using a jigsaw.

After laying fiberboard, if you plan to finish the floor with linoleum or paint, it is necessary to seal the seams. In addition to having high adhesive properties, the mass with which we will putty the fiberboard must certainly be plastic, since fiberboard floors are somewhat springy and are capable of changing their linear dimensions. If you putty the floors with a hard and monolithic putty, then it can either bend and deform the fiberboard sheet, or itself tear at the junction of the seams.

How to assemble

After the components of all units of kitchen furniture have been manufactured, the time comes when it is necessary to begin assembling them. To do this, you need to separate all the blanks into sets corresponding to individual items.

Before continuing work, you need to check the furniture configuration. All necessary elements must be present. It is important to ensure that they correspond to the required dimensions. Assembly must occur sequentially. This will reduce the risk of making a mistake.

Fasteners for hanging furniture Source novamett.ru