At one time, the term “panel” appeared in construction, which was used to describe a thin sheet of wood or plywood placed inside a frame. And so, at one fine moment, the same principle formed the basis for the manufacture of door panels, which is why such doors began to be called paneled. panel doors are the most popular , and all thanks to their durability in use and the ability to use a variety of patterns and volumetric elements on such structures (an important aspect for people who care about their interior).

What is a panel?

First you need to understand the history of the name of the product, which served as the starting point. The panel is a thin insert in the door leaf; it is thinner than the frame itself. It can often be seen on interior doors. It is a thin sheet that is inserted inside the canvas. Can be made from any material.

Thanks to the panel, it is possible to avoid ordinary boring products, achieving originality and decorativeness by giving them unusual shapes. This sheet decorates the door and creates an accent on itself or its fragments. This technique allows you to create a product that is stylistically designed and matches the rest of the interior. The canvas can display three-dimensional elements , textured patterns, etc. The design depends on the wishes of the customer and the imagination of the manufacturer.

Finishing of interior door leaves

Paneled doors provide two main finishing options:

- continuous - with the same design of all elements;

- contrasting - with deliberate highlighting of panels due to color, texture or material.

The wooden surfaces of the canvases are treated with antiseptics and fire retardants, they are tinted and primed, and then painted. Wood boards are laminated or covered with veneer made from valuable wood species, and glass is frosted, decorated with sandblasting patterns or other available methods. There are many options, so the flight of fancy in finishing paneled doors is unlimited.

Stained glass windows look prestigious as a paneled insert in an interior door. An equally impressive decorative painting applied on both sides of the glass will help replace an expensive designer product. It is capable of creating a full-fledged imitation of stained glass.

Application of panel doors

Such doors are used everywhere and have no restrictions in their scope. These models can be seen both in offices, public places of various institutions, and in residential buildings.

Paneled doors are used to design interior openings and entrance doors. , materials and functional characteristics play a fundamental role . Interior models with panels are made of lighter materials, for example, it could be plywood or MDF sheet. Entrance structures are often made of metal or hard wood.

Features of finishing of paneled door leaf

One of the first stages of finishing the panel is treatment with antiseptics ( probably everyone knows what this is Often, certain chemical solutions are added to antiseptics to give the product fire-resistant properties. In addition, some manufacturers also add pigments to the above-mentioned substances, which help change the original color of the wood. They make it brighter and more saturated, and, accordingly, more attractive to the buyer. We can say that this is one of the new techniques, since previously varnishes and stains were used for these purposes. Many manufacturers allow a pre-order service, thanks to which the buyer can choose a specific pigment himself. However, you should know that with this technology, the pigment penetrates only into the upper balls of the material, and therefore a scratch or other mechanical damage will easily lead to the appearance of the lower natural color.

The final stage of finishing is treatment with acrylic varnish. This material is characterized by a high level of environmental friendliness and minimal impact on the color of the wood. For those door panels that have glass elements, there is another finishing method, namely stained glass painting. At the request of the client, it is possible to apply drawings of different complexity and color, which makes the door a real work of art.

Paneled doors have two most popular types of finishes:

- Solid (when the frame and panels are made in the same color scheme);

- Contrasting (when the frame and panels have different tones, but the overall appearance of the door does not lose its aesthetics).

When choosing such a door for your home, you should pay special attention to the finishing. A glossy finish is more practical against minor stains or scuffs, but it also smoothes out the grain of the wood. And with a matte finish, the slightest stains or scratches will clearly appear.

Design

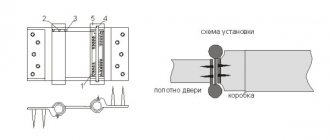

What the door panel is essentially has already become clear. Now we need to figure out how it is attached. That is, to understand the design as a whole. The panel is inserted into the frame, which is made of solid wood, then fixed inside using special grooves. To prevent its movement in the frame, glue or thin glazing beads it in place.

Paneled structures have their own classification, the criterion being the shape of the insert. The panel is:

- Flat. A thin sheet of material is used that has no protrusions or cutters, that is, absolutely smooth.

- Volumetric. It contains volumetric shaped elements with milling around the perimeter. This design is classic and often used.

- Typeset. The base consists of several lamellas that are joined together using a tongue-and-groove method.

There are the following varieties that need to be distinguished:

- Figareinaya. A figarea is an internal insert with thick edges that gradually become thinner towards the edge of the piece. This panel is attached using longitudinal grooves and fixed with wood glue.

- Floating Thanks to the gaps left around the perimeter, destruction of the material is prevented. Depending on the microclimate in the room, the insert can change in size. Attached with glazing beads.

Operation and care of panel doors

Any door requires careful and correct treatment. Paneled doors are no exception. In order for the door to maintain its presentable appearance and functionality for a long time, it requires proper care.

Panel doors should be installed in rooms with a temperature range of 18–24 °C. Air humidity is also an important factor affecting the safety of the door. For panel doors, a relative humidity of 55% is considered optimal.

Glass inserts in doors can be washed using special glass cleaners

To avoid delamination of the door leaf, in rooms with high humidity and temperature (bathroom, kitchen) the door should be kept open. Of course, you can close it while taking a shower, but after water procedures it is worth ensuring air flow into the room.

An open door will help reduce indoor humidity

To clean a paneled door from dirt, use an alcohol solution consisting of 90% water and 10% alcohol. The use of cleaning agents and abrasive powders is not allowed - they scratch the door leaf and thereby spoil the appearance of the door.

To remove dust from the door surface, use a soft, damp cloth and then wipe dry.

The paneled door is very susceptible to chemicals. Therefore, when you are planning a repair, it is better to remove the doors and put them in a safe place, but if this is not possible, you can cover them with plastic film.

Do not place even very thin objects under the doors - this may cause the structure to warp.

In order for the door to last a long time, it should be periodically coated with varnish or paint. Before this, the surface of the door must be sanded with fine sandpaper and a thin layer of plaster or water-based paint applied. After the bottom layer has dried, the top, final layer is applied.

Today, acrylic paints and water-based varnishes are especially popular: they are odorless and safe for humans and the environment.

You need to take care not only of the door, but also of the fittings. Use special products to protect metal parts from corrosion, and to avoid unpleasant squeaking, lubricate them twice a year.

You can lubricate door hinges with regular vegetable oil.

Materials

Not only the appearance of paneled doors depends on the material of manufacture, but also the characteristics, margin of safety and reliability, as well as cost.

To make the frame of the door leaf, take a solid wooden beam . Not only wood, but also other materials are suitable for insertion. This already turns out to be a combined type of product.

Wooden versions of products involve the use of soft varieties and more durable valuable species. A pine, cherry or spruce door will not cost very much. Oak, teak, beech, and walnut are considered more valuable and durable. Red and black trees belong to the elite class.

Important! Wood structures can combine several species. Therefore, in order to prevent the destruction of the panel due to changes in temperature and humidity, you need to clarify this nuance with the seller before purchasing.

Inexpensive combined models combine MDF sheets, plywood, chipboard, and pressed paper. Blind inserts are covered with leather or its substitute. Whiter, more interesting products are obtained through the use of glass. It can be regular, matte, colored, embossed, stained glass, with photo printing or oracal, etc.

pros

— The high technical characteristics of panel doors keep their solidity high in the eyes of the buyer, although they are gradually being replaced by more modern types of interior doors. — Wide range of door leaf design options and colors. Since the production of panel doors began earlier than other designs, there is a wide variety of models. — The noise and heat insulation of panel doors is rated as above average, but they are different for each model, so average indicators are taken. — Paneled interior doors are distinguished by the variety of molded products and additional elements (capitals, caps, cornices, rosettes, squares, bases). — The likelihood of a paneled door subsiding is relatively small, because, as a rule, they are not assembled dry - the parts are glued together or glued into one frame with MDF sheets on both sides.

Design

Thanks to the almost unlimited variety of materials used, a paneled door can reflect any style and design . Therefore, choosing the optimal model that meets the requirements of a certain interior style is not so difficult.

For living rooms, kitchens, and living rooms, panel doors with translucent inserts are usually selected. In fact, the ideal solution is to purchase a canvas with glass in the central part. Of course, blind inserts are more suitable for bathrooms and toilets. However, this does not mean that the choice seems boring. A unique interior can be achieved by decorating doorways in one style.

an important role in the process of creating a wide palette of models of any style. Thanks to coatings such as PVC, veneer, laminate, etc., as well as various cutters, a variety of inserts is achieved. They can be straight or curly in shape, contain additional overlays, carvings, volumetric elements, or elaborate relief. Over time, it is possible to replace the boring middle.

If the paneled door has glass, then you can show your imagination and put a design on it, cover it with a film with a pattern, photograph or any other image, and also turn it into a stained glass window. This design knows no boundaries.

Advantages and disadvantages

From all of the above, we can conclude that paneled doors have the following advantages , such as:

- Decorative and aesthetic appearance.

- Thanks to the thin insert, the weight of the canvas is reduced.

- The structure can be disassembled with the replacement and restoration of its elements.

- The durability of the structure is determined by the presence of an insert made of a different material. After all, a solid massif of soft rocks can dry out within a few years.

- Reducing prices by reducing the amount of material and replacing expensive elements with cheaper analogues.

The use of low-quality raw materials and non-compliance with the rules of technology during production are shortcomings that depend on the integrity of the manufacturers and are entirely on their conscience. In general, loin doors are an ideal option and can be installed in any home.

Thus, the panel is the central part of the door, which is distinguished by a number of positive features and often has an aesthetic function, as it is shaped into a variety of shapes, decorated and made from a variety of materials.

Repair and restoration of panel doors

Even the most durable and reliable door may sooner or later require repair or restoration. Every owner can encounter wear on the hinges, skewing of the canvas, loosening or cracking of the panels.

Loose panels can be fixed using glazing beads or glue, and the presence of small gaps and cracks can be hidden using putty and paint. Simply fill the crack, sand it and coat it with varnish or paint to match the door.

Currently, there are many special markers and pencils for removing scratches from the surface of the door leaf

If the damage to the panels is serious, you cannot do without replacing them. The complexity of this process depends on how the panels are secured to your door.

Table: the process of replacing panels depending on their fastening in the door

| Mounting type | Replacement process |

| Fastening with tongues and grooves |

|

| Fastening with glazing beads |

|

As you can see, if the panels are attached using glazing beads, then the replacement process is the least labor-intensive and quick. In this case, there will be no need to remove the door from its hinges.

If you change all the panels in a door, they may differ in color and shape from the previous ones. Thus, you will not only restore the door, but also update its boring appearance.