What is a furniture panel?

Furniture board is a wood board. It is made by gluing together wooden blocks. To assemble sheet natural material, lamellas with a width of 10-70 mm are used. This technology has great advantages. It is possible to solve one of the difficult problems of natural wood - curvature. By gluing the lamellas, the internal stress is reduced and the material is not deformable. The result is large-format solid-lamella wooden products.

Different types of wood are used as material for furniture panels: spruce, birch, pine, alder, ash, beech. In some cases, fruit tree species are used.

Content:

- Production Features

- What is the difference between a solid-lamella furniture panel and a spliced one?

- Advantages

- Main settings

- Varieties

- What is common and what is the difference between furniture board, plywood and chipboard

- Storage conditions

A furniture panel is a composite material made by gluing together individual bars selected in size, color and texture. The production technology makes it possible to neutralize internal stresses in the material and reduce the risk of deformation during operation. Glued solids serve as the basis for wooden structures (doors, window sills, stairs) and are used in finishing, decorating residential premises, making furniture, etc.

Material advantages

Furniture panels are very popular today. The high demand can easily be explained by a large number of advantages, including:

Health safety

The main advantage of furniture board is the eco-friendly materials from which it is made. Only natural wood species are used for its production. The gluing technology does not require aggressive chemical ingredients. Thanks to this, the material does not emit toxic substances during operation. It can even be used to decorate a children's room.

Practicality and durability

When the canvas is created, the lamellas are laid so that the wood fibers are located in different directions. This increases strength indicators by 50-70%.

Beautiful appearance

During production, the natural grain of the wood is completely preserved. The texture and shade of each type of wood is beautiful in its own way. A wide selection of patterns and colors allows you to create interiors in different styles.

Moisture resistance

Solid wood is much more difficult to dry than small lamellas individually. Therefore, the percentage of moisture in furniture panels is low. Some types of slabs can be used to furnish the bathroom and kitchen. The main condition is that the lamellas must be connected with a special glue, treated with special wax or glue.

Resistance to mold and mildew

The outer surface of the wood slab is treated with an antiseptic. Mold and fungi do not grow on it. The result is a long service life of the material.

No cracks

Due to the multi-directional nature of the fibers, furniture panels are resistant to cracking. Solid wood often suffers from this problem because the grain of the wood is oriented in one direction.

Easy processing

The slabs are easy to sand and cut. Working with them is not difficult. In addition, the surface can be easily restored after damage.

Varieties (review)

Classification of materials

can be carried out according to a variety of criteria. Among the most important differences is the raw material. These can be stacked panels made of laminated chipboard and solid wood. Depending on the type of finish, the material can be laminated or veneered. The moisture-resistant version is glued together, and then treated with moisture-proof materials, and occasionally covered with shrink film. Based on the gluing method, we distinguish furniture panels into 2 categories:

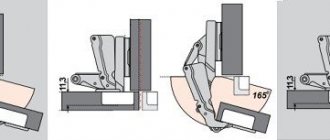

- Solid-lamella - in it, laminated veneer lumber is fastened along its length, with each of the planks running from one edge to the other and being a solid piece of wood. The main advantage of this method is the beauty and strength of the created module, since it looks homogeneous. Shields can be decorated with glazing, because they look like a solid mass.

- Spliced - in this gluing method, a lamellar connection is made along the width and length, and there are much more seams; microscopic spikes are occasionally used for the closest possible contact of all components. This method has certain disadvantages, which are associated with the structure (its diversity) and lack of homogeneity. But at the same time, the spliced shield has increased bending strength and is suitable for creating load-bearing types of structures.

Furniture panels made of wood can be made with different methods of end processing. Options that are created by means of a round milled version or one that is selected by a groove are usually offered to be chosen when creating individual panels. For further processing, boards made from hardwood - oak, maple - are ideal, while soft pine needles are usually used for elements that are as simple in shape as possible. Classification of panels according to decorative properties is quite popular in the production of furniture. Here we will highlight several options that fully determine the uniformity of coloring and placement of fibers relative to each other.

- Radial is the optimal option in terms of uniformity, with the lamellas laid parallel, and the color is natural and does not have a sharp transition. In the structure, the fibers lie radially, and the deviation in width should in no case be more than 2 cm.

- Natural - for this class of shields, a characteristic feature is the uniformity of the structure, but the presence of light “eyes” is acceptable, the diameter of which is no more than 0.3 cm. There are no strict requirements for the direction of the fibers.

- Select is a class where the sewn surface can be heterogeneous in lamella size and color. Wood fibers are usually placed in different directions. Select panels have quite noticeable defects, such as knots and curling.

- Rustic is the most variegated option, and sometimes it is made from several types of wood. Despite the far from being the best quality, this option is especially loved by Russian designers. The finished slab looks like laid parquet; usually it should be coated with wax or paintwork for protection to create a beautiful decorative solution.

This is not an official classification, but it is used in sales as well as in production. Buyers must be guided by this data so as not to waste time from the very beginning searching for those options that practically do not meet the established objectives.

How to take into account the material of shields

From oak

Furniture panels made of oak, quite an elite wood, are aimed at creating countertops and furniture. The pattern on the panel surface can be variegated or uniform - each option has certain advantages and disadvantages. The main advantage of oak panels was their high density, ranging from 730-780 kg per cubic meter. At the same time, they are durable, solid and massive.

From fiberboard

In this case, production is carried out using classical technology, but using a more valuable base material - natural hardwood, which significantly improves the performance properties of the shield. One or both sides can be smooth. The hot pressing method using resins ensures high strength of the connection of the elements. But if formaldehyde is added, such a shield can no longer be called furniture.

Made from linden, alder and larch

These types of natural wood have a beautiful pattern, and they are also very durable and strong. Linden has the advantage of having natural antiseptics, which make the material resistant to decay and other biological damage. Larch is not afraid of contact with moisture. Alder is quite beautiful, very dense and hard. Panels made from wood of such species are often used in interior decoration.

From spruce and pine

Such softwood boards are quite inexpensive. Moreover, they are light in weight and moisture resistant, since the material contains resins. The density is quite low, no more than 525 kg per cubic meter.

Made from bamboo

The material is truly exotic, and therefore it is produced in limited quantities. It is also appreciated by people who adore Asian aesthetics. Bamboo panels are quite flexible, and they can be used to make structures with complex geometries. Due to their rarity, they are very expensive, but they look unusual, which means they are always in use.

Made from MDF and chipboard

Classic chipboard and MDF boards can also be classified as panels. But the raw materials for creation are not always environmentally friendly. Physical and mechanical strength is also much inferior to analogues made from solid wood. MDF boards are a more elite material, and therefore they are more highly valued.

Production technology

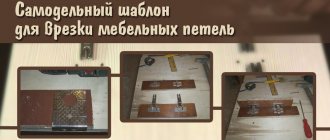

Let's try to figure out composite furniture board - what it is and how it is made. The production process consists of several stages:

- Raw wood is cut into boards.

- The resulting boards are dried until the moisture content drops to 6-8%.

- The boards are “cut” - cut into lamellas.

- Then the lamellas are assembled into a sheet and glued together.

- The layer obtained from the bars is pressed.

- After pressing, the material is processed by planing on all sides.

- The layer is cut to the required size and trimmed to length.

- The resulting shields are polished on a machine. Packed in film.

Types of furniture panels

Which furniture panel is better? How to choose a furniture panel from a wide variety of options? To answer these questions, you must first understand what types of furniture panels there are.

The first sign by which the material is divided into types is the assembly technology. According to this parameter, there are 2 types of shields:

- Solid lamella.

- Spliced.

Solid lamella

Such slabs are made from long bars. They are glued together into a single web with only the sides. The pattern of the lamellas is selected so as to visually give the impression of a single array. The price of all-lamella material depends on its length. The longer the shield, the higher the price per 1m3. This can be explained simply: to produce long slabs you will need expensive material - tall tree trunks without defects. A furniture board of this size will be expensive. The all-lamella type of material can be used anywhere: for the manufacture of window sills, countertops, and decor.

Spliced

These shields do not connect solid beams, but several short ones. They are glued together not only on the sides, but also on the ends. To make the fastening as strong as possible, not only glue is used, but also open and closed tenons. The seams where the bars were connected often remain visible. When gluing, the uniformity of the pattern is not maintained. Externally, this assembly resembles parquet. The price of jointed slabs is less than that of solid slabs.

Which furniture panel is better: solid-lamella or spliced?

This question immediately arises when choosing a suitable material. The answer depends on the purpose of the purchase. For example, if you plan to manufacture steps and staircase landings, then it is better to buy spliced furniture panels, the dimensions of which allow this type of work to be carried out. They are stronger in bending and evenly distribute the load across individual sectors. After all, there is such a rule: the more glues, the more reliable the product.

In addition, they can be used where appearance is not so important - internal shelves, side and back walls of furniture. If external presentability is important, then the answer to the question of which furniture panel is better: spliced or solid-lamella is obvious. Solid lamella has the best external characteristics.

Features of application

The choice of furniture panel is related to its future use. The noble texture of solid-lamella slabs is used in interior decoration, the manufacture of stair steps, and doors.

When choosing laminated wood as a finishing material, you need to pay attention to the shape of the lamella pattern. With a radial cut, the fibers are arranged longitudinally, and with a tangential cut, they resemble diverging from the center of a circle.

It is necessary to use furniture board for interior decoration if the humidity of the room does not exceed the norm and the temperature does not fall below 50C.

It is not recommended to cover the finished finish with glossy varnish - it can highlight the seams.

Finger-joined slabs are used in covering surfaces hidden from view, in the manufacture of risers, and stair frames.

Durability, a wide dimensional grid, and reasonable cost make laminated wood indispensable in furniture production. Wardrobes, chests of drawers, bedroom sets, etc. are made from it.

Despite the low humidity level, wooden panels exhibit slight shrinkage, which must be taken into account during installation.

Types by type of wood

The description of furniture panels begins with the type of wood. They are made from almost any type of wood. Much will depend on what type of wood is chosen:

- shade;

- drawing;

- physical properties;

- strength.

Let's consider the most commonly used types of wood from which furniture panels are produced in accordance with GOST.

Pine

. Durable, inexpensive material, density 500 kg/m3. It withstands moisture well and is durable.

E l

. Less hardy material and not so dense - 445 kg/m3. Its advantage is low thermal conductivity. It holds heat well. It is used for finishing interior space and making inexpensive furniture.

Birch.

It is distinguished by the lightest shade of wood and high decorative properties. The main disadvantage is susceptibility to moisture. Density – about 650 kg/m3.

Larch

. The advantage of this type of wood is its low price and good resistance to moisture. The disadvantages are that the design is not the most beautiful and the hardness indicators are not the best. Material density – 660 kg/m3.

Oak

. Belongs to the luxury category of wood. Oak is characterized by an exquisite appearance and the highest strength. Density is 750 kg/m3. Furniture made from such wood can last for decades. If the question arises: “which furniture panel is better?”, then we predict the answer: of course, oak. The disadvantages include the high cost and weight of the furniture board.

Where is it used?

The use of furniture panels has gained popularity in the creation of countertops and tables, as well as cabinets and kitchen facades. In structure they are close to wood. Products can be carved and milled. From thin shields you can make a beautiful carved screen for radiators or a screen.

Thick ones are suitable for making steps for stairs, window sills, shelving and storage systems. The use of the material is no less in demand in the field of interior decoration. The unusual pattern and structure of the spliced material, which resembles parquet, was used here.

Floors with this type of finish can be varnished, waxed and treated with impregnations. Finishing walls or creating partitions can also be done using furniture panels. If you need to make durable and soundproofing ceilings, such glued boards are perfect. Taking into account the recommendations given in the article, you can easily cope with the task of choosing the most suitable material for making interior items or finishing rooms.

Types of furniture panels

When talking about what types of shields there are, it is necessary to mention their grade. Wood products are classified according to the presence of various defects: knots, cracks, deformations, biocontamination. The condition of the core and its shade are also taken into account. According to this classification, products are divided into varieties:

- Extra

. Furniture board of the “Extra” grade is the most expensive. There are practically no defects on it. There is no sapwood, knots, resin pockets, cracks or other imperfections. The panel pattern is carefully assembled from different lamellas so that it resembles solid wood. - Grade A.

Furniture panels of category A are also distinguished by a high level of quality. Several knots are allowed: per 1 m2 – 2 dark or 4 light. Their diameter can vary from 0 to 3 mm. Also, per 1 m2 there may be 1 small non-through crack and 1 curl. - Grade B.

2-3 knots are allowed per 1 m2. Possible sapwood - up to 10%, minor dents, small blind cracks. - Variety

C. This category includes wood products with a large number of flaws: cracks, captive knots, blind cracks, dents, curls, sapwood - up to 75%.

The markings are quite clear. But it happens that there are designations like: AB furniture board. What does this mean? It's simple: the grade is determined by two sides: A/A, A/B, A/C, B/B, B/C, C/C.

What sizes are there?

Furniture panels can be made to order. But there are standard sizes of furniture boards. Widths vary from 200, 300, 400 mm and up to 1200 mm. The length of the slabs can be from 1000 to 3000 mm. The thickness of the material starts from 14 mm and ends at 50 mm. Permissible deviations in size: thickness +0.2 mm, width +1 mm, length +1 mm.

Facing

Furniture panels are used not only for finishing, but also for the construction of walls and ceilings. They give the structure the necessary rigidity. Due to their high strength, boards are used for cladding; panels and ceilings are made from them.

Which material is better?

When choosing between wood products, you may be faced with a difficult question: “what is better – furniture board or chipboard?”, “what is stronger: furniture board or plywood?” The choice depends on the purpose of the purchase and financial capabilities:

Plywood.

Veneer sheets glued together in several layers. The strength of the material is comparable to natural solid wood. Plywood holds fasteners well and is highly wear-resistant. The scope of application is limitless. But due to its high strength and environmental friendliness, it is most often used for the production of children's furniture: high chairs, tables, cribs, chairs, cabinets, chests of drawers.

Chipboard.

The material is produced by pressing shavings and sawdust. Bulk elements are combined into a slab with formaldehyde resins. Stability is the main quality of chipboard. Thanks to him, wood panels are used in the manufacture of kitchen furniture. The main disadvantage is the short service life, no more than 10 years.

MDF.

Wood shavings and sawdust are pressed under high pressure. The boards are more environmentally friendly than chipboard. Adhesives of natural origin are used to glue the board components together. The products withstand high temperatures, humidity, and steam. For this reason, the material is often used for the production of kitchen furniture, bathroom and bedroom sets. The durability is low, like chipboard - about 10 years. Another disadvantage is that it does not hold fasteners and screws well.

As you can see, furniture panels are superior in many respects compared to other wood-based panels. Possessing all the advantages of natural solid wood, they have a long service life, are not too expensive in price, and are distinguished by high aesthetic properties.

Comparative characteristics of spliced and solid-lamella technology

Strength

Both options allow you to create high-strength, stable structures with a long service life.

Appearance

Products made from solid lamellas look expensive and solid. However, high-quality “parquet” made from planks of disparate textures has been valued for a long time and increases the status of the room.

Price

The cost of finger-jointed panels is lower due to simpler manufacturing technology and the possibility of using small elements - wood residues. The price of solid lamella panels depends on the length of the lamellas - the longer they are, the more expensive the product.

However, the cost of both options is affected by the type of wood and grade - for example, pine will cost much less than oak panels, grade AA is higher in price than AB.