A good barbell rack is essential for all kinds of exercises: weighted squats, bench presses, seated presses, calf raises, weight holds, and so on. For those who do not really like working out in gyms, performing all kinds of exercises becomes problematic. The main problem is the barbell rack. It is this equipment that is often so lacking to conduct effective home workouts. But if it is so important, then why not do it yourself with your own hands.

Why do you need to make a stand yourself?

Why do you need to make a stand yourself, if you can find a decent stand that will be of high quality and practical in online stores or sports stores? First of all, a do-it-yourself barbell stand will cost three or even four times less than a store-bought one. All you need is to have all the tools and be able to use them.

Secondly, your own stand will suit all personal parameters. There will be nothing superfluous in it, and the design can suit any conditions of your own apartment.

Making a rod

If the decision to make a barbell has been made, you need to decide on the material that will be the basis for the barbell - this is the most important point. The base for the bar must be strong; you can use metal or wood.

A metal bar will add extra weight; if this is not desired, a wooden bar base can be used. It is important that the diameter of the bar is at least 4 centimeters, otherwise it will be difficult to grasp the barbell.

Layout

So, the decision has been made - the barbell rack will be homemade. Before starting work, you need to think through everything carefully. For greater accuracy, it is best to make a drawing. The barbell stand must be proportional. Load-bearing structures must support the entire weight; for this, everything must be calculated and plotted on the drawing. In addition, the drawing will help you avoid buying too much. Since materials are usually bought by eye with a reserve, and this is all money. What is important for a homemade stand is low price. So it is better to first draw up a plan in which the future stand should be described.

Working muscles

The load is evenly distributed between the long back muscles, quadriceps, buttocks, hamstrings and calves. The abdominal muscles, deltoids, and latissimus muscles work as stabilizers. It is sometimes believed that the long back muscles also stabilize in the squat, but the actual situation depends on technique. If an athlete is long-legged and has a long thigh, the natural forward tilt of the back will be compensated by the work of the long back muscles.

Materials for work

You don't need a lot of materials for a stand. It will still be cheaper than in the store. So, for work, first of all, you will need two types of square-shaped profile pipes (types of rolled metal). In order to change the height and width of the rack itself, you need to insert one pipe into another, so one must be smaller than the other. The mechanism is simple: another protrudes from one pipe, and its position can be adjusted, thereby lowering or raising the level of the rod.

In order for the structure to withstand the entire load, a profile pipe of one type 40 by 40 millimeters and a cross section of 2 millimeters will be sufficient. Its length is 5 meters. The second (retractable pipe) should be 30 by 30 millimeters, 2 millimeters in cross section and 3 meters long.

Another important part is the neck holder. It will require two 6-mm sheets of steel 50 by 200 millimeters.

To make the bars, you will need a small pipe measuring 30 centimeters. Since there will be two handles, it is best to take two pipes of 15 centimeters each.

You will need a couple more bolts (act as the regulator itself). They should not be too thin, otherwise the heavy weight will simply bite them. The most optimal thickness of such bolts is 8 millimeters. Since the entire structure is made of metal, it will seriously scratch the floor and rattle. To cause less damage to the apartment and not disturb the neighbors, you need to stock up on rubber stands. These are pieces of rubber 5 millimeters thick. This device makes the entire structure more stable and, therefore, reliable.

Varieties and features of each option

There are several types of bench presses, which differ in both design features and functionality. They are horizontal and inclined adjustable. In addition, simple models of inclined benches for bench presses are often found in gyms. In such exercise machines, the inclined backrest is fixed at a certain angle, which allows you to perform a variety of strength exercises in a reclining position. However, the downside is that they can only be used for a limited number of strength training sessions. In addition, the backrest, fixed at a slight angle, will not allow you to perform the classic version of the bench press with a barbell on such a sports equipment.

Horizontal

According to their design features, horizontal benches are either folding or ordinary (non-collapsible). Such simulators belong to the stationary type of sports equipment. Horizontal benches are often equipped with special stands, clamps, and attachments. Thanks to this, they allow you to use a variety of equipment during training.

As a rule, the horizontal version of the bench press has a low level of functionality. However, such benches allow you to comprehensively use a lot of additional equipment and equipment during training. For example, on such a simulator, if it is equipped with a special block for the legs, you can develop and train muscle groups that are located in the hips and buttocks. In addition, the presence of a leg block allows you to perform twisting exercises, during which the muscle groups located in the abdominal area are actively worked.

If the horizontal bench is equipped with special handrails, then it can be used both to perform strength elements with a barbell, and to repeat exercises aimed at working muscle groups in the abdominal area (lower abs). A mandatory condition when performing strength exercises with a barbell on a horizontal bench is the support of a partner. However, if it is equipped with special racks for the barbell, then you can perform lifts with heavy weights yourself.

The average width between the racks on a horizontal bench should be about 110 cm. If, for example, the distance is smaller or larger, it will be inconvenient for a person to use the barbell during training.

Regular

Folding

Inclined adjustable

The inclined bench for the bench press is equipped with a special seat with a backrest. In this case, the user can independently change the angle of its inclination at any time. Also, such an adjustable bench press bench can be additionally equipped with racks with hinge-type fastenings and locking tongues. In addition, manufacturers equip such benches with a special chain, which limits a person’s movements during strength exercises.

The advantage of an adjustable inclined bench is that it allows you to perform a variety of elements both lying and sitting. Therefore, it is ideal for exercises with barbells and dumbbells. A special feature of this shop is the ability to:

- using various sports equipment (barbells, dumbbells);

- performing bench presses at different angles;

- use not only in gyms, but also in apartments.

For home use, it is preferable to use an incline bench press. This is due to the fact that such equipment is more compact for the home (the back can be disassembled or assembled).

The most optimal length of an adjustable bench is 1.2 meters. In this case, its width should be about 39 cm, and its height no more than 38 cm. The weight of such a simulator on average varies around 30 kg. However, it may vary depending on the design features, as well as the level of equipment of the simulator.

Closer to the point, or How to make a foundation

Almost the entire load goes to the base. It must be very strong and stable. It should also be collapsible so that it takes up less space in the apartment. So, let's start making the base of the future rack. The first step is to cut the metal profile into the required length bars. The base is the part into which a smaller (30 by 30) profile will then be inserted, which will hold the bar. It will look like a big T.

First you need to prepare all the tools. The base will need two bars 700 and 300 millimeters long. To do this, you will need a thicker profile (40 by 40). Two bars need to be welded in the same letter “T” so that 15 centimeters remain from the middle of the longer one in both directions. This design will ensure maximum stability. A hole for a bolt is drilled in a 30-centimeter block - it will adjust the width.

You need to mark the middle of the letter “T”. It is there that the next block 850 millimeters long should be welded. From this bar there will be another one, on which the bar will lie. But under a heavy load, the block can bend, so you need to weld an additional block 550 millimeters long from the base to the middle of the rack. It will serve as additional support. It is welded at an angle so that it connects the vertical and horizontal bars. At the end of the vertical one you need to make a hole for the bolt. It should be no smaller in diameter than the bolt itself.

A similar design is made using the same principle.

Squats for girls

Many people are afraid of “swinging their hips,” but since this issue is not decided by training, but by nutrition, fears can be left outside the gym. Girls who eat “to lose weight” will not build up an impressive mass.

Here is an example of a squat workout “for weight loss”, all exercises are performed for 12-15 repetitions, with strictly 45 seconds of rest between sets:

- Bar squat;

- Romanian deadlift with dumbbells;

- Hamstring curl;

- Gluteal bridge;

- Hip extension in glute crossover

Squats. Execution technique for girls

How to do the rest

Before welding, you need to bend the sheets of steel so that they look like a hook. “Hooks” are welded to bars (30 by 30) 900 mm long. It turns out 2 long bars with a hook at the end. The pipe joint is welded behind the hook - the future beams. The same is done with another profile.

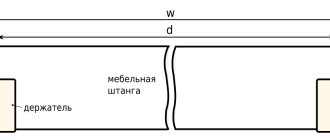

Every 5 cm a hole with a diameter of a bolt is drilled. Thanks to these holes, the barbell rack can adjust its height.

The height can already be adjusted, but how to change the width? To do this you will need a profile (30 by 30) with a length of 1100 millimeters. Holes are also drilled on it with a center-to-center value of 5 centimeters. Its place is in a larger profile (40 by 40), namely in the small block of the base of the letter “T”. Moving out from the base, it can adjust the width of the rack or bars.