When installing furniture connecting elements, it is convenient to use a drill, which uses a special drill, with which you can evenly select the waste material and make a hole to the required depth.

Furniture hinges, attached after processing the base with such a tool, “sit” evenly and securely.

Equipping a drill with a drill suitable for the selected hinges is the main task when working with cabinet furniture doors.

Furniture hinges, attached after processing the base with such a tool, “sit” evenly and securely. It is important to choose the correct drill diameter depending on the parameters of the hinge bowls.

A drill for furniture hinges is a special milling attachment that allows you to work with wooden and plastic bases of sufficient width.

You should select milling elements in specialized stores.

What is it and how does it work?

A drill for furniture hinges is a special milling attachment that allows you to work with wooden and plastic bases of sufficient width. With its help, you can make the desired hole in a solid panel, MDF, chipboard or laminated chipboard.

With its help, you can make the desired hole in a solid panel, MDF, chipboard or laminated chipboard.

You can find both standard and non-standard drills with a quality certificate and a guarantee from well-known manufacturers.

The nozzle is a base with a bridge and three teeth. The middle spike is installed in the center of the future circle, which is outlined using a prepared gauge, and the rest make a round hole of the required diameter. Typically the depth of the final cut is about 9mm.

The nozzle is a base with a bridge and three teeth.

Elements that are too cheap are an indicator of a low-quality product, so it’s worth considering options with prices below the market average.

Furniture hinges for which a drill is used are mainly four-hinged. The hole for each is made almost instantly. When working, the drill is held slightly inclined, and not straight, so that the waste material is selected to the desired depth and evenly.

Typically the depth of the final cut is about 9mm.

This cutter is reliable and will last a long time.

Adjusting furniture hinges on swinging facades

Overlay loop diagram

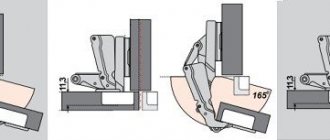

- Horizontal adjustment of the hinges is made using an adjusting screw (see diagram). It is enough to loosen it a little and level the façade. If necessary, experiment with slightly tightening and loosening until the door is perfectly aligned.

- To adjust back and forth, slightly unscrew the fixing screw on the overhead hinge and, again, using a trial method, align the front until a satisfactory result.

- Vertical adjustment is made using the upper and lower screws on the installation pad. Here it is also enough to loosen or tighten them.

As you can see, nothing is impossible for a person with hands and a head. Marking, drilling, installing and adjusting hinges will not cause much trouble if you practice first.

Accuracy and extreme precision of actions are the guarantee of long-term operation of swing facades.

Always yours, Timur Denisov

FURNITURE CATALOG : All furniture in Moscow and the Moscow region > Select category

If you found this article useful, please like it! The author will be pleased :-)

An integral part of furniture assembly is the installation of hinges. It is on them that the front doors are hung. To do this, it is necessary to drill neat and precise holes of a sufficiently large diameter with a slight depth. Forstner drills do the job best.

Kinds

When installing hinges on cabinet furniture, two types of drills are used, differing in size:

- 35 mm;

- 26 mm.

The hole for each is made almost instantly.

It is important to choose the correct drill diameter depending on the parameters of the hinge bowls.

The diameter is selected in accordance with standard hinges or with a reduced bowl. Each type of fastening has its own drill.

With its help, you can make the desired hole in a solid panel, MDF, chipboard or laminated chipboard.

The nozzle is a base with a bridge and three teeth.

A universal drill with interchangeable attachments is suitable for installing furniture hinges.

When working, the drill is held slightly inclined, and not straight, so that the waste material is selected to the desired depth and evenly.

The middle spike is installed in the center of the future circle, which is outlined using a prepared gauge.

Milling machines use automatic calibration and attachments, but at home you cannot do without a special hand-held power tool.

The diameter is selected in accordance with standard hinges or with a reduced bowl.

Each type of fastening has its own drill.

How to make a hole for hinges in chipboard: installation of a furniture hinge

A situation often arises when it is necessary to install a furniture hinge into a chipboard board, for example, when installing a chipboard door. This task involves drilling a hole for a hinge in the chipboard. In this article we will look at what you can use to prepare such a hole and how to install a loop in it.

So, in our case, when making a cabinet from chipboard, a mistake was made - the groove for the hinge was drilled too low, as a result, after installing the hinge in the prepared place, the internal horizontal door cannot open completely. As a result, it is necessary to move the groove slightly upward to eliminate this drawback.

Error in choosing the location for the groove for the hinge

Return to content

Tools and materials

During the installation of furniture hinges for chipboard, we will need the following tools:

1. Forstner drill with a diameter corresponding to the loop (in our case 35 mm). The drill is a cutter for making a groove for hinges. These drills sometimes come with stops (designed for chipboard thicknesses of 16, 22, 25 mm), which allow you not to worry about how deep you should go;

2. drill;

3. screwdriver.

The materials we need are the hinge itself and the screws for fastening it.

Internal furniture hinge for flush mounting, right angle

Screws

Return to content

Step 1: How to make a hole for a hinge in chipboard?

First, place a Forstner drill on the drill.

If you have a drill without a stop, then take a test piece of chipboard and drill a groove for the hinge in several steps, each time trying on how far the hinge goes. The essence of this action is to decide how much you need to deepen the drill so as not to drill a through hole and so that the entire loop fits into the groove.

Test drilling

Trying on a loop

Now that we've got the hang of it, it's time to tackle the door itself. First, let's mark the center of the hole. This is where we will install the center of the drill.

Marking the hole for the hinge

If you have a hinge torn out of a chipboard and you don’t know what to do, then the easiest option to repair the torn hinge is to move the hinge, i.e. drill a new hole, since often the places where the hinge is attached with screws turn into dust and no longer hold the door properly. The remaining old hole can be filled or sealed.

So let's start drilling.

Drilling a groove for a hinge

Return to content

Step 2: installing a hinge on a chipboard door

The grooves are prepared, all that remains is to insert the hinges into them and screw them in with screws.

Door hinge installation

Thus, we moved the hinge higher, the inner cabinet door now opens easily.

Installed loop

Return to content

Video

The video below clearly shows how to make a hole for hinges in chipboard.

Advantages and disadvantages

Furniture hinges require precision during installation, so the ability to make exactly the recess that is needed is the main advantage of a Forstner drill. This provides a special stop that prevents penetration into the hole beyond a fixed length. The drill is limited by teeth that do not allow it to deviate from the specified location. The hole turns out perfectly clean, thanks to which the loop cup fits very tightly.

A universal drill with interchangeable attachments is suitable for installing furniture hinges.

At home, you can’t do without a special hand-held power tool.

The only drawback of a Forstner drill when working with solid wood can be its low quality, which is typical for non-factory production. Therefore, it is necessary to choose a product from an official supplier and obtain a guarantee.

Furniture hinges require precision during installation, so it is possible to make exactly such a recess.

Depending on the type of panel, the cutter can become very hot, burning the edges and the material removed from the recess. Therefore, when working with such a base, it is recommended to take breaks to cool the drill, doing 3-4 approaches. This usually happens with MDF panels. When working with laminated chipboard and chipboard, hard alloy elements allow you to make holes for hinges quickly and without much effort.

The drill is limited by teeth that do not allow it to deviate from the specified location.

Varieties

When talking about a drill for furniture hinges, in most cases this term refers to its main variety - a Forstner drill.

It is this that is distinguished by the most complex design with three points and requires special care from the master.

Forstner drills are also divided into 3 types:

- the first is original designs that are created using milling and “finished” by hand;

- the second has a cast working part and is suitable for machine operation;

- the third type of drill is formed by casting, and high-speed steel cutters are fixed by welding.

A type of drill for furniture hinges is also centering or centering, it is also self-centering. The specificity of this nozzle is the ability to accurately center and, as a result, drill an absolutely even hole for the screw and tighten it. Drills are made of high-speed steel and are tightened with a screw.

There are also separate attachments suitable for non-standard furniture hinges: card, bar, mezzanine, card, secretarial, blind, heel and 8-hinged.

How to choose?

Equipping a drill with a drill suitable for the selected hinges is the main task when working with cabinet furniture doors. In order for the hole to be precisely adjusted in radius and depth, you need to take a cutter of the required diameter.

| Four-joint hinges with 35 mm bowl | With such parameters, the drill must be appropriate. |

| Non-standard fastenings | Requires a suitable nozzle diameter. |

| Forstner drills | Suitable for wooden and plastic panels with a thickness of 16 mm. |

The hole turns out perfectly clean, thanks to which the loop cup fits very tightly.

The product must be from an official supplier and obtain a guarantee.

You should select milling elements in specialized stores. There you can find both standard and non-standard drills with a quality certificate and a guarantee from well-known manufacturers. Elements that are too cheap are an indicator of a low-quality product, so it’s worth considering options with prices below the market average. This cutter is reliable and will last a long time.

Depending on the type of panel, the cutter can become very hot, burning the edges and the material removed from the recess.

Loop insertion order

1. Mark the furniture door based on the recommended distances between the hinges.

2. Using the stopper against the end, place the template on the door and secure it with a clamp.

3. Place the router in the work area, lower the tool body until the cutter touches the surface of the workpiece and clamp the locking lever.

4. Lower the depth gauge to the position support.

5. Count 11.5 mm on the scale and set the stopper position.

6. Tighten the routing depth adjuster lock.

7. Adjust the parameter using a micrometer screw.

8. Release the locking lever.

9. Rotate the positioning support to set the depth of the first pass.

10. Start the router, press the body and fix the position. Smoothly moving the tool along the surface to be processed, cut out the material, starting from the circle and moving to the center.

11. Once you have completed the passage, release the latch. Rotate the support to the next position and repeat the process until the recess is completely exhausted.

Advice. If there is no sawdust removal system, it is recommended to clean the work area with a vacuum cleaner after each pass to avoid milling defects.

12. A neat seat is ready.

13. Insert a loop into the recess, align and mark the location of the screws.

14. Drill for screws, limiting the drilling depth.

15. Screw the hinges with countersunk screws.

After inserting the hinges, proceed to the door hanger, for which mark the location of the mating parts. In our example, the markings for the screws are 37 mm from the end of the chipboard. For other modifications of the fittings, determine the size locally: having assembled the hinge and positioning the front adjustment screw in the middle, lean the door against the side with a gap of 2 mm and place marks through the oblong holes. Complete the work with adjustment operations.

Adjustment screws: 1 - height; 2 - in depth; 3 - in width.

In a similar way, it is easy to calculate and make templates both for installing cup hinges of other sizes and for cutting other holes.

The furniture hinge has a cup on one side that cuts into the door mass. The standard cup diameter is 35 mm. To install the hinge yourself, you need to get a forstner drill and do the following:

Place the door against the cabinet body and mark with a pencil where it joins the shelves. Measure in several places at right angles from the edge of the door 22 mm. Connect the points into one line. Mark the centers of the recesses at a distance of 10 cm from the top and bottom of the door slab. If the points coincide horizontally with the shelves inside the cabinet, move them vertically. With the slab on the floor or workbench, carefully use a forstner drill bit (ø 35 mm) to make recesses

This must be done very carefully so that the drill does not come out. The best option is to purchase a drill with a stop; it will stop at the desired depth. As you drill, insert the cup of the hinge into the groove until, when you press on the transverse bars with holes, they swing

When working with a limiter, this is not necessary. Lower the hinge cups into the openings so that the line of the slats' holes is strictly parallel to the side edge of the door. Secure the hinges with screws. Lean the door against the body so that the hinge arms are against the cabinet wall. Screw the fasteners through the holes in the second half of the hinge. Two hinges are installed on the doors of wall and floor cabinets. In the case of installing a door leaf of a pencil case with a height of more than a meter, three hinges are installed.

When installing double-leaf hinges, you need to determine the thickness of the plates. Usually this size does not exceed 2 - 3 mm. Having determined the attachment points on the end surface of the side pillars of the door frame, attach the hinge halves to the wood and trace the outline of the plate with a pencil.

Detachable hinges can be left or right. Their correct location should be as follows: the plates with the pin are mounted in the cabinet opening with the axis up. The door hinge plates are installed with the sockets facing down.

At the end of the door where the hinge is installed, mark the thickness and length of the plate. Carefully remove excess wood with a chisel. If you own a hand router, then the recesses for the hinges can be made easily and quickly.

Having placed the plate at the installation site, use a pencil to outline the holes for the screws. Having removed the loop, use a drill with a thin drill to make shallow holes (5 mm) at the marking points. Using a screwdriver, you can easily secure the hinges with self-tapping screws on the doors and cabinet body.

Briefly about sizes

The holes in the furniture product are needed to fit the furniture hinge bowl inside, fix it and ensure a reliable connection between the canvas and the fittings.

The diameter of the special drill used is selected based on the size of the purchased and used furniture hinge. Most often on sale you can find hinge bowls with a diameter of 26, 35 and 40 millimeters. Moreover, in the vast majority of cases, furniture fittings manufacturers use a diameter of exactly 35 mm. It is universal in size, optimal for most types of standard furniture that require hinges. But since there are also non-standard solutions, special hinges are also sold for them. And you can purchase appropriate cutters for these hinges.

No special skills are required for insertion. But experience, even the slightest, will not be superfluous.

Additionally, I would like to remind you of a set of tools for a furniture maker, which are considered basic and most necessary. It's definitely worth including a hinge cutter or just a Forstner drill in this set.