The invention of particle boards gave us not only a high-quality universal material, but also a profitable way to dispose of particle board waste.

Laminated chipboard (LDSP) differs from conventional chipboard (chipboard) by the presence of a film that protects the surface from damage and increases the wear resistance of the material.

The process of applying a protective film is called lamination, which is why sellers call chipboard laminate, although this is not entirely true.

Next we will tell you:

- what kind of material is this and what does it look like;

- about the types and characteristics of laminated particle boards;

- how laminated chipboard differs from laminate, which material is better to use in different areas;

- who makes the best laminated particle board;

- how much does laminated chipboard cost?

Laminated chipboard: decoding the concept, differences from chipboard

The materials of chipboard and laminated chipboard are similar to each other, the only difference is in the lamination of the top layer. In simple terms, laminated chipboard is a board made of wood and wood chips, bonded with formaldehyde resin.

The surface of the material is treated with a layer of polymers, it protects the material from moisture, makes it durable and smooth.

In turn, the polymer film consists of special paper, which is impregnated with resin. After applying the film, lamination of the material occurs.

Lamination of chipboard to turn it into laminated chipboard

Lamination of the material is done hot or cold. The difference between them is that with cold lamination the material is fixed by a laminator without heating, and with hot lamination it is heated to the desired temperature.

The chipboard lamination process itself is divided into 4 stages:

1. Prepare the boards for lamination. The moisture content of the material should be no more than 8%, its surface should be as leveled as possible. The density of the chipboard sheet should not be more than or less than 0.7 g/cm³. Preparation will make the chipboard sheet durable and smooth. Next, the material is polished, and its roughness should not be more than 63 microns. Chipboard before lamination looks like in the photo.

2. Prepare the film for lamination. The material has three layers: a dense rough layer to ensure the strength of the coating, a layer with a pattern and a fixative. The density of the fixative must be at least 40 g/cm³. When preparing the film, all layers are treated with a substance containing resin. Next, the film is wound on special spools, which help preserve its properties before lamination.

3. The next stage of production is lamination. The material is placed under the base of the laminator, and the film is glued to it using hot or cold lamination. The process looks like in the photo.

4. The result is a finished chipboard material . It has a smooth structure, high strength, and a beautiful pattern. The slabs are packaged and shipped for sale or storage in a warehouse. Before cutting into typical sheets, laminated chipboards have this appearance. Let's look at the photo.

History of origin

Chipboard was first used in the post-war period, when a huge amount of resources was required to restore destroyed buildings. The high cost of natural wood has prompted furniture manufacturers to look for alternative options. Numerous experiments in this area led to the invention of a material that consisted of almost 90% waste materials and waste from the wood processing industry.

Previously, wood shavings were burned along with other waste, but later found a new purpose. Over time, the production of chipboard has improved and today this material occupies a leading position in the furniture industry.

Pros and cons of laminated chipboard

Laminated chipboard, as a material for the production of furniture and renovation of premises, has its own characteristics and disadvantages. Before using raw materials, it is important to know everything about them. It is worth understanding that laminated chipboard is not natural wood, the material has differences and lasts less. But, if you bought high-quality slabs, there should be no problems with them.

The advantages of using laminated chipboard include:

- A large assortment. You can order furniture, both “wood-like” and original colors.

- Affordable price. Compared to natural wood or MDF, laminated chipboard has an affordable price. This is explained by the fact that the cost of the material is lower than that of analogues, and cheap raw materials are used for its production.

- High rates of sound insulation and heat absorption.

- Strength and stability. Furniture made from chipboard is not afraid of temperature changes and mechanical damage.

- Easy to care for. The furniture is not afraid of household chemicals; it can be cared for using ordinary furniture products.

- Versatility. Laminated chipboard is suitable both for making furniture yourself and for ordering it in production.

The disadvantages of laminated chipboard as a material for furniture production include:

- Weak resistance to humidity. Laminated chipboard does not withstand steam and large amounts of moisture. Under their influence, the slab increases in size by at least 30%, swells and begins to collapse. This can be prevented if you buy laminated chipboard sheets that are resistant to moisture, but this drawback cannot be completely eliminated.

- Formaldehyde content. Impregnation of laminated chipboard contains formaldehyde resin, which over time turns into a volatile substance and evaporates. When formaldehyde gets into the air, it can cause diseases in humans and animals. The film that covers the chipboard reduces the likelihood of evaporation, but does not completely prevent it.

- Fragility. Repeated screwing in of self-tapping screws leads to the slab crumbling and deteriorating. If the furniture has been assembled once, then when moving it can be assembled and disassembled no more than 3 times. After this, it will begin to lose its strength and crumble.

When choosing laminated chipboard, carefully look at the quality of the material, read about the manufacturer and do not be tempted by low prices. Cheap laminated chipboard material may contain high levels of formaldehyde and will become a serious problem in everyday life.

In addition, it is not advisable to place furniture made of chipboard in the bedroom and children's room in order to reduce the likelihood of poisoning.

Leading manufacturers on the market monitor the quality of their products and their composition. If you buy furniture or materials from chipboard, then there should be no problems with its use. Regardless of the manufacturer, when purchasing material, check for quality certificates and carefully read the composition of the slabs.

A few final words

Making furniture requires not only sufficient experience, good tools and design, but also high-quality safe material. You can purchase high-quality laminated chipboard that meets all the requirements of European standards only from trusted manufacturers and suppliers. Foreign manufacturers offer high-quality material, but you should not overpay just for a well-known brand, because domestic companies produce laminated boards that are not inferior in characteristics to imported analogues, but are cheaper.

Save time: selected articles delivered to your inbox every week

Scope of application of laminated chipboard

The scope of application of laminated chipboard is growing. Natural wood is used less frequently in the production of furniture and renovation of premises due to its scarcity and high cost.

High quality laminated chipboard material can replace natural wood and reduce production costs.

The main areas of application of materials include:

- Production of various furniture in factories and workshops;

- Independent production of furniture;

- Manufacturing of interior doors;

- Production of partitions and screens of various formats;

- Creation of rough floors and substrates for decorative materials. Typically, third grade chipboard is used for this purpose, which does not go through the lamination process and is not processed.

It is important to know! When cutting slabs to the desired size, all machined edges should be tightly sealed. Open shavings are not allowed because the risk of formaldehyde evaporation increases.

Thanks to the variety of colors and sheet thicknesses, laminated chipboard can be used to implement any design projects.

How laminated chipboard is used depending on the thickness of the sheets, see the table.

Flaws

1. The presence of formaldehyde resins. The composition that binds small wood shavings releases a certain amount of formaldehyde into the air, which is not entirely safe for health. Despite the insignificant amount emitted by laminated chipboard, some types of this material are not recommended for use in the manufacture of furniture for a children's room.

2. Impossibility of fine processing. Due to its hard and heterogeneous structure, laminated chipboard cannot be subjected to fine processing - milling. It is impossible to make curly and elegant parts from it.

3. Susceptibility to swelling. With the exception of moisture-resistant types of laminated chipboard, this material swells when exposed to moisture. However, the PVC edge on the end elements performs a protective function and prevents moisture from entering the material. Swelling occurs only with prolonged contact with water.

Kitchen furniture made from laminated chipboard: features of production and operation

The laminated layer allows the use of chipboard in conditions of high humidity. In addition, the material is a budget-friendly way to get modern designer furniture with the necessary functionality.

For the production of furniture frames, a plate no thinner than 20 mm should be used. The color of the slabs can be any; their surface is usually glossy or matte.

Self-production of furniture allows you to combine color schemes or use the classic “wood” look. When purchasing a ready-made kitchen, the buyer selects a set from the available models.

It is possible to order the production of kitchen furniture according to your own design, but this will cost an order of magnitude more than ready-made furniture.

You can make furniture from laminated chipboard with your own hands, this is especially true for kitchens of non-standard size. Furniture companies usually charge 60% more money for such orders than for a standard one.

This is necessary for the production of furniture from laminated chipboard with your own hands.

It’s possible to make a kitchen out of wood slabs with your own hands. This is what a simple kitchen set looks like, designed in a regular drawing program and created with your own hands. See photo below.

If you are not a furniture company, you can use the demo version of the drawing and design program for free. But the peculiarity of the demo is that you cannot exit the program and turn off the computer while you are using it.

To create projects you can use the following programs:

- IKEA Home Planner;

- Google Sketchup;

- Sweet Home 3D;

- Roomtodo;

- other analogues.

The user chooses which program is convenient to work in. Next, you will need to correctly cut the chipboard and decorate the raw edges. See the video for examples and basics of cutting material.

It’s easier to order cutting of the material from specialized companies that cut and process laminated chipboards. Their responsibilities also include edge processing.

Furniture fittings are bought in stores; there are thousands of product options. It won’t be difficult to assemble furniture parts into a complete set. Do-it-yourself furniture made from laminated chipboard is 50-70% cheaper than ordering from furniture stores, even taking into account the fact that you need to cut sheets and buy accessories.

When choosing laminated chipboard for furniture in a children's room and bedroom, pay special attention to its quality. Children and adults are quite susceptible to formaldehyde; it is better to keep its content in furniture as little as possible.

Tips for choosing

When choosing laminated chipboard, you need to remember that the material has a laminating film that reliably hides its internal composition. In order not to fall into illiquid goods hidden under a shiny shell, when choosing, you need to know the criteria for evaluating the material. Not all types of slabs are suitable for making furniture. Therefore, when choosing a material, you need to use the following knowledge about assessing product quality:

- no need to buy material at prices lower than analogues. There is definitely a reason for this: the price is reduced due to a promotion to attract the attention of customers in order to increase consumer demand;

- a defective product is offered without explanation for a price reduction (such a product is suitable for construction work), but not for the manufacture of high-quality cabinet furniture;

- the decorative film should not have scratches or cracks;

The main advantage of laminated chipboard is its protection from aggressive environmental influences: high humidity, the influence of pathogens and fungi, rotting, high resistance to temperature influences, long service life. If the choice is made carelessly and the material has flaws, the protective properties of the material will be impaired over time. This will lead to a reduction in service life and disappointment in the purchase.

Basic colors of laminated chipboard

The main color schemes of the material include:

- Bleached oak. This is the color of office furniture. Thanks to the shade, it is possible to create a laconic and discreet design.

- Sonoma Oak. A discreet and light shade for office and home furniture.

- Shimo ash (light shade). Calm color with a pronounced structure.

- Milk oak. The shade has no woody touches and is warm.

- Atlanta oak. A beautiful shade with light spots on the background.

- Italian walnut. The color is suitable for a warm interior.

- Guarneri nut. This shade is called universal because the color is suitable for light and dark interiors at the same time.

- Beech Bavaria. The color can be both dark and light.

- Wenge. The shade is considered a classic in interiors.

These are the basic shades of laminated chipboard that are available from manufacturers. Additionally, you can look at the palette of each company and choose what you like. Palette of basic colors in the photo

Compatibility with other materials

Laminated chipboard is a universal material used for the production of all types of furniture: cabinets, walls, hallways, kitchens. It has a pleasant appearance and laconicism, which allows it to be combined with completely different types of materials. Most often, laminated chipboard complements MDF, from which facades are made, and fiberboard, presented in the form of the back wall of the product.

In the production of cabinets, the most relevant additions are in the form of large mirror panels, emphasizing the elegance and beauty of modern furniture.

Often cabinets are supplemented with plastic panels with various designs applied through photo printing.

Laminated chipboard looks great in tandem with glass display cases, which can be presented in the form of transparent, frosted or shaded glass.

Major chipboard manufacturers on the market

The production of laminated chipboard is a profitable business for many companies. On the market you can find material of domestic and foreign origin.

Color solutions, quality and cost are very different. It is worth talking about industry leaders in order to navigate the assortment and choose the most profitable product option.

Active in the market since 1961. Branches in Russia are a subsidiary of BAZIK, the main production is located in Austria. The company produces laminated chipboards according to European standards. The manufacturer can offer a wide selection of colors, coniferous wood products without additives and reasonable prices.

It is possible to get European quality at Russian prices. The company has representative offices in 7 European countries and is not going to stop at the heights it has achieved.

Laminated chipboard from the brand "LAMARTY"

Lamarti is a plywood factory in Syktyvkar with a line of laminated chipboards in 120 decorative options. The brand constantly updates its collections, which allows you to choose both classic shades of material and find something exclusive.

For the production of raw materials, the latest generation equipment is used, all lamination processes are automated.

Compared to foreign analogues, Lamarti is a golden mean with affordable prices and high quality products.

The line of this brand has the following advantages:

- Wear resistance;

- Strength;

- Large assortment of colors.

It is not recommended to buy this type of chipboard for bathroom furniture or rooms with high humidity.

Lamartie is inferior to the same Egger by 2 times. Representatives of the furniture company conducted an experiment in which samples of Lamartie and Egger were immersed in a container of water to a depth of 3 cm. The duration of the experiment was 3 hours.

As a result, the Lamartie sample was saturated with water to 8 cm, while the Egger impregnation remained at the immersion level.

Brand Kronospan

The Kronospan company operates in 24 countries around the world and markets a wide range of chipboards. The brand's products are distinguished by antistatic characteristics, a large selection of shades and durability.

The advantages of laminated chipboard from Kronospan include:

- Increased resistance to humidity. You can buy furniture made from this material for the kitchen or bathroom, and it will not lose its aesthetics over time;

- Strength. Disassembly and assembly of furniture is allowed up to 5 times without deformation of the holes for the fittings;

- Furniture service life is up to 20 years;

- Environmental friendliness. The content of harmful substances in the composition is not higher than the lower threshold of the permitted norm;

- Affordable prices.

Laminated chipboard from the Kronospan brand is used for the production of various types of kitchen sets. The formaldehyde content in the material is no more than 10 mg.

High quality, safety, design are the three main requirements that the manufacturer places on its products.

laminated chipboard from

This is a domestic company with affordable prices, a large product line and quality certificates. Branded products are cheaper than their European counterparts, but their characteristics are no worse.

Users consider the main advantages of the material:

- Resistance to mechanical damage and scratches;

- Resistance to humidity. Furniture made from this material can be freely purchased for the kitchen or bathroom;

- Large palette of colors. You can choose the shade of the slab that suits you best for the project;

- The material holds fasteners well when assembling furniture and is less likely to deform;

- Affordable price.

Laminated chipboard furniture from Nevsky Laminate lasts no less than its analogues.

Chipboard "Swiss Krono"

Swiss Krono is a domestic company with a plant in the city of Sharya. The brand offers a large range of materials from classic tones to fantasy shades and exclusive decor.

The brand offers customers:

- 13 types of structures and hundreds of shades of products;

- Certificates of conformity and authenticity for goods;

- The content of harmful substances is within normal limits;

- Long service life;

- Execution of individual orders of exclusive type.

The brand is not as well known on the market as Egger or Lamarti, but this manufacturer should not be discounted. The company's assortment includes decent types of furniture materials.

Laminated chipboard from the BYSPAN brand

- manufacturer of furniture materials from Belarus. The brand is engaged in the production of chipboards, laminated chipboards, and cutting materials according to specified requests.

You can order the required amount of material with delivery. Delivery of an order from Belarus is sometimes cheaper than purchasing goods in Europe or from individual domestic companies.

The brand offers its customers:

- Low content of harmful substances in products;

- Quality control of production and product line without defects;

- More than 120 types of wood shades, different chipboard structures;

- Affordable prices. The cost of goods is much lower than in Europe.

Price

Enterprises that produce this finishing material do not sell it at retail .

Therefore, the cost of laminated chipboard depends not only on the selling price at the factory, but also on the number of intermediaries through which it comes to the buyer.

In addition, color affects the cost of products , which is why the same type and size of slabs with different colors can vary greatly in price.

In addition, the cost of the boards is affected by the degree of formaldehyde emission - a material that causes minimal harm (with emissions of 0-0.5) is, as a rule, significantly more expensive than others.

Another factor affecting the cost is related to the material of the lining layer, which determines the depth of embossing.

At the same time, each manufacturer adheres to its own labeling , the explanation of which must be obtained from the manager or looked for in the catalog.

Therefore, in different places the cost of the same slab may differ by 20–30% .

We have prepared a table that includes average prices for products from the best chipboard manufacturers:

| Manufacturer | Dimensions (thickness, width, length in mm) | Color and description | Average price per sheet, rubles |

| Egger | 8x2070x2800 | porcelain | 1800 |

| Egger | 8x2070x2800 | black | 1950 |

| Egger | 8x2070x2800 | bog oak | 2100 |

| Egger | 8x2070x2800 | titanium, waterproof, wear-resistant | 2800 |

| Egger | 16x2070x2800 | white | 3300 |

| Egger | 16x2070x2800 | wine | 2100 |

| Egger | 16x2070x2800 | Navarre ash | 2800 |

| Egger | 16x2070x2800 | sand gladstone oak | 2900 |

| Kronspan | 10x2070x2800 | white | 1500 |

| Kronspan | 10x2070x2800 | snow birch | 1600 |

| Kronspan | 10x2070x2800 | fineline mocha | 1200 |

| Kronspan | 16x1830x2500 | white | 1000 |

| Kronspan | 16x1830x2500 | milky oak | 1000 |

| Swiss Crono | 10x1850x2500 | beech, walnut, light oak | 1000 |

| Swiss Crono | 16x1850x2500 | beech, walnut, light oak | 1100 |

| Swiss Crono | 22x1850x2500 | acacia, alder, cedar | 1300 |

| LLC Syktyvkar Plywood Plant | 10x1830x2750 | aqua, burgundy, volcanic | 1900 |

| LLC Syktyvkar Plywood Plant | 16x1830x2750 | serenity, topaz, rose quartz | 2050 |

| LLC Syktyvkar Plywood Plant | 38x1830x2750 | monsoon, lemon, golden sand | 3200 |

| Russian laminate | 10x1830x2750 | beech | 1350 |

| Russian laminate | 10x1830x2750 | pear | 1450 |

| Russian laminate | 16x1830x2750 | oak, alder, mocha | 1450 |

| Russian laminate | 22x1830x2750 | cherry | 1600 |

| Russian laminate | 22x1830x2750 | chateau oak, larch | 1750 |

Chipboard or MDF, which is better to choose?

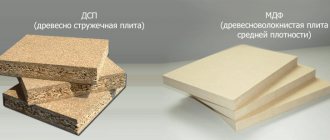

The production of inexpensive furniture often occurs with laminated chipboard and MDF. We will tell you below which material is better to choose for furniture.

1) MDF is made from wood dust and fine wood fractions, and the substance used is ligin and paraffin, which are environmentally friendly substances.

2) MDF does not contain harmful substances, it can be used for furniture in a children's room. Premises for children require special attention to the quality of renovation materials and furniture.

3) Additionally, it is worth noting that MDF has greater resistance to humidity due to the content of paraffin, which repels water.

4) MDF is better milled and can be used where laminated chipboard would be irrelevant. MDF has much greater opportunities for implementing exclusive furniture projects.

5) In turn, laminated chipboard is much cheaper than MDF and is used for the production of furniture in the economy segment.

MDF material has the following advantages compared to laminated chipboard:

- Safety. The raw materials do not emit harmful substances, they do not contain formaldehyde;

- Resistance to humidity. MDF can withstand a higher percentage of humidity than chipboard;

- Variation. Furniture of complex geometric shapes can be made from MDF, which cannot be said about laminated chipboard;

- Quality. It is believed that MDF is of a higher class than chipboard. But this material is also much more expensive.

In turn, laminated chipboard has a larger range of shades and colors than MDF. It costs less and is available to everyone who needs practical furniture.

Almost all headsets from budget options are made from laminated chipboard. This is worth knowing when buying furniture. If you follow safety rules, read the composition of the material and buy products from trusted companies, then the likelihood of harm from chipboard is minimal.

The main differences between MDF and laminated chipboard, comparisons and which material is better to choose, see the video

And.

Glass blocks: which are better and what types of glass blocks are there?

Documentation that defines quality.

If you want to familiarize yourself in more detail with the documentation that regulates the quality of manufactured laminated chipboards, you can refer to the following documents:

- The main document in force in Russia is GOST R 52078-2003;

- International standards for product quality can be found in MS (international standard) EN 14322:2004;

- Companies producing laminated chipboards and furniture have so-called Technical Conditions (TU). Specifications are the most detailed list of production requirements, for example, the composition of an adhesive or a mixture of resins. You can find such documentation on the website of the manufacturer or manufacturer.

To the listNext articlePrevious article