Varieties of four-hinged furniture hinges for cabinets

The list of functional capabilities of furniture hinges is very large; they can be installed on cabinets made of various materials and of different, non-standard designs. Conventionally, all furniture hinges for cabinets can be divided into the following types.

According to the position of the door relative to the side wall

Regarding how the facade will cover the sides of the cabinet, three types of furniture hinges can be distinguished.

| Overhead furniture hinges - the door completely covers the end of the side of the cabinet |

| Inset (internal) furniture hinges – the end of the cabinet body is completely open. |

| Semi-overlay furniture hinges - the end of the body at the place where the canopy is attached is half hidden by the facade. |

By type of façade and body material

Separately, we can distinguish another type of furniture hinges with installation on glass facades and with a frame made of metal profiles.

By installation method

There are three types of furniture hinges, depending on the design and installation features with subsequent adjustment. The differences are obvious at the junction of the hinge body and the strike plate.

| Slide-on - the hinge body is inserted with a slot to look like an installed strike plate and is fixed in the desired position. |

| Clip-on – the hinge body is inserted into the groove of the installed strike plate, fixed by pressing, and adjusted with a fastening screw. |

| Key-hole - the hinge body with a hole is placed on the installed striker and is inserted under it with a translational movement until it reaches a fixed position. |

By bowl diameter

Most four-hinge furniture hinges have a bowl with a diameter of 35 mm. There are so-called “mini-loops”, in a more compact design, with a bowl diameter of 22-25mm.

With different opening angles

| A more complex design of the furniture hinge body can provide a larger opening angle, up to 165-170 degrees versus the standard 90-105 degrees. These types of furniture hinges are called “transformers”. |

Also in everyday life you can find the names “crocodile” and “crab”.

Furniture hinges with closer

You can read more about furniture hinges for cabinets with closers here. The mechanism itself for smoothly “pulling” the facade into the closed state can be built into the mechanism or overhead. In the first case, you should immediately buy furniture hinges with a closer, in the second, you can purchase it separately and install it on existing hinges (if the manufacturer has provided such an upgrade option).

Furniture hinges for corner cabinets

The design of the cabinet box can be corner or end, with various features and non-standard solutions. Furniture hinges for corner cabinets allow you to equip the facade with almost any type of furniture with an angle increment of 5 degrees.

In some design cases, the installation of a hinge requires the provision of special strips to make the angle “correct”, close to 30, 45, 60, 90 or 170 degrees.

Let us highlight the main types of furniture hinges for corner and end cabinets in tabular form, including those that are used to open facades attached to false panels and to each other, “accordion-style”.

| Adit (straight) loop for false panels. |

| For corner kitchen cabinets with 45 degree fronts. |

| For a beveled (end) kitchen cabinet with a -45 degree front. |

| For corner cabinets with fronts at 30 degrees. |

| For a beveled (end) cabinet with a facade at -30 degrees. |

| Carousel hinge for L-shaped accordion cabinet door. |

Basic requirements for furniture

When determining how to properly hang cabinets in the kitchen, you must consider the following requirements:

- Cabinets should be located at a height that provides the most convenient access to dishes and kitchen utensils on the top shelf.

- Their location should not interfere with the ventilation system or spoil the aesthetic appearance of the kitchen with incorrect location geometry.

- The rigidity and reliability of the fastening must ensure long-term operation of the cabinets under high loads.

The main condition when installing hanging cabinets is to ensure accessibility to the top shelf. You can roughly set the height of the suspension in the following way: stand against the wall and raise your hands - at the point where your fingertips touch the wall, the top of the cabinet should be, in this case the shelves located below will be easily accessible.

Consider the height of hanging furniture based on your height, as well as the height of family members

There are also general recommendations for determining the height of the top shelf depending on height: if a person is 155 - 160 cm tall, it is 175 cm, if a person is 160 - 175 cm tall - the shelf height is 185 cm, if a person is 175 - 190 cm tall, the height is 175 cm installations 200 cm.

Depending on the furniture fittings, there are several ways to attach wall cabinets:

How to choose corner hinges

To select corner hinges for furniture doors, you need to determine:

- type of loop;

- required opening angle.

Types of loops

Corner hinges for furniture can be:

internal or inset, installed when the door front is located inside the cabinet;

Furniture hinge for the door located inside the cabinet

invoices. Such hinges are installed on the fronts, which in the open position completely cover the side of the cabinet body.

Furniture hinge for external cabinet door

All types of corner-type furniture hinges have a number of features:

allow adjustment in three main directions. To do this, special adjustment bolts are installed on each hinge, by rotating which you can align the cabinet door vertically, horizontally and set the optimal rebate size;

How to adjust hinges after installation

can be equipped with a built-in or separate closer, allowing the door to close smoothly. A hinge with a closer, thanks to the functions of the device, can last a longer period of time.

Furniture hinges, complemented by a built-in closer

The type of furniture hinge should be determined based on the location of the cabinet door and the availability of additional options.

Determining the opening angle

The standard opening angle for furniture hinges is considered to be 95º-110º. If it is necessary to increase or decrease the opening angle of the cabinet door, then the installation of corner furniture hinges is required.

Each corner loop is marked with the sign:

- plus if the opening angle exceeds the standard. For example, an angular hinge 45+ means that the door can be opened to 135º;

- minus if, with the hinge installed, the door opens at an angle of less than 90º. For example, a -45 hinge helps the door open 45º.

On sale you can find corner hinges in increments of 5º. If an opening angle not a multiple of 5º is required, then when installing the hinge, additional pads are installed that allow you to independently change the angle specified by the parameters.

Device for determining the angle of a furniture hinge

To determine which hinge is required to install corner cabinet doors, use a special scale called a Pythagorean protractor.

The principle of working with the scale is extremely simple:

- the flat part of the protractor is attached to the cabinet box on the side where the hinge is supposed to be installed;

- The scale on the tool will tell you at what angle you need to purchase the loop. In this case, the optimal angle value will be located level with the lower side part of the cabinet box.

Rack with attachment

An example of a rail on which furniture is hung

A fairly common method of attaching wall cabinets lately, which includes two main components: a mounting rail in the form of a perforated metal strip with bent edges and a metal hinge in a plastic case with a hook for hanging from the rail.

The mounting rail (can be up to 3000 mm long) is attached to the wall using dowels with self-tapping screws at the required height; the hangers are fixed inside the hanging cabinet in the upper corners so that their hooks protrude beyond the dimensions of the rear wall. Structurally, the hinges provide adjustment of the hooks in height and forward and backward using built-in screws.

Peculiarities:

- Hanging upper cabinets using a rail can be done by one person without assistance in a shorter time.

- The design simplifies the work when hanging several closely spaced cabinets: they can be moved towards each other along the mounting rail and connected with bolts.

- Adjustment in the hinges allows you to change the height of the cabinets and the distance from the wall up to 20 mm.

The design features of the mounting rail provide the possibility of attaching it to hang furniture at many points, which lightens the load on the walls. This is a valuable quality when hanging furniture on plasterboard, gas silicate, or slag concrete; in this case, using a slats is the best option.

- The design of the slats does not allow the top of the cabinet to fit tightly against the wall, which is a positive factor when lowering the bottom of the cabinets onto the apron and a disadvantage if the cabinets are located above the finish of the work area.

- Wall-mounted kitchen cabinets can be easily removed and moved along the mounting rail.

Overview of species

With the expansion of the range of available furniture products, hinges for its installation have also received a certain development. Universal non-mortise models can be installed without milling. They are focused on wood-based panel materials, which usually have a decorative coating - where removing part of the surface is a serious problem.

Hinges that do not require insertion are usually classified according to the type of design and purpose of the product.

By design

The structural features of furniture fittings are the main feature by which they are usually divided into categories. The most popular options for hinges that do not require insertion are worth considering in more detail.

Eight-joint cups. They are considered a universal option used when assembling furniture. They have a wide selection of standard sizes.

These are the main options for furniture hinges, which do not require additional insertion into the facade during installation.

But even home craftsmen who do not have special training can fix such elements on cabinet doors or their bodies.

By purpose

The classification of all existing hinges installed without insertion also takes into account the purpose of such products. Among them are the following.

Furniture hinges. With their help, framed and frameless facades and other swing elements are mounted, in which it is quite difficult to make a hole without damage.

Furniture hinges are the most compact of the options presented. Their recommended loads rarely exceed 20 kg.

Repair

Over time, furniture hinges may fall out of their installation sockets.

There is no need to immediately throw out the cabinet or change it. First you need to remove the loop and carefully widen the hole (10 mm deep). Next, you need to lubricate the wooden dowel with wood glue (or PVA) and drive it into the resulting hole.

We do everything carefully so as not to pierce the material through. After the glue has completely dried, we cut off the protruding part of the dowel with a hacksaw. We tighten the screws that secure the loops directly into the dowels.

What are they?

Ombre loops come in overhead and inset cylindrical types. Overlays are installed on the ends of the sashes in cases where the facades are thin, and installation of mortise elements that are less noticeable on furniture is not possible. The cylindrical hinge is convenient because it can be hidden inside both the end part and the folding part of the product. The fittings are often coated with zinc, which reliably protects metal structures from corrosion, and they can also be made of zinc alloy.

The cylindrical loop has design features. It is a rotating device and cannot withstand heavy loads, so it is not used for large structures. However, the metal part will be hidden when the table is unfolded, which will provide an attractive appearance to the product. Cylindrical hinges can be used for different facades: chipboard, MDF, solid wood.

Product sizes may vary. It is designated by markings, for example, D12, D14, D16, D24. Quite often the option with a diameter of 14 mm is used, since this value is optimal for the thickness of the fabric from which the doors of folding tables are made.

Materials for sliding doors

The most popular materials for the manufacture of sliding door systems today are:

- Tree

- Fiberboard or MDF

- Glass

Tree

The traditional material for the manufacture of not only doors, but also furniture in general, is wood. At the same time, both the entire panel (s) of the sliding door system and the frame for combination with other materials can be made from wood:

- Glass

- Plastic

- Paper

- Textile

- Mirror

The easy flexibility of wood to process allows it to be used for interior decoration in almost any style. Want a charming country room? Use unplaned wooden boards! Do you like classic style interiors? Choose a wooden door leaf with strict shapes. Are you striving to create an interior in a shabby chic or art deco style? Give preference to carved wood with forged elements or inlay. Are you a supporter of the East? Use canvases with a wooden frame and rice paper inserts.

Fiberboard/MDF

Since wood is not the cheapest material, it can easily be replaced by materials such as fiberboard or MDF. In appearance, they are almost impossible to distinguish from natural wood, but the cost is an order of magnitude lower than that of similar products made from natural wood.

Glass

Glass sliding doors are an excellent option for creating an interior in minimalist, futuristic or hi-tech styles. Due to the property of glass to transmit light, glass interior sliding doors do not create a feeling of total enclosure of space. Moreover, by choosing the degree of color and opacity of the glass for the door leaf, you can select the degree of transparency (and, as a result, integration with the neighboring room) of the interior doors.

Types of furniture hinges

Nowadays, on store shelves, consumers encounter a wide range of products in this area. Mounts may vary in:

- structural features,

- installation method,

- intended purpose.

The fittings create a certain style. Thanks to it, the design level of any household item is determined.

By paying attention to such points, you can choose the most functional options that satisfy a specific request. Depending on the method of application to the base, the components have different names. One of the most important parts of the fittings are the hinges.

One of the most important parts of the fittings are the hinges.

Overhead and semi-invoice

One of the most common among specialists are overhead four-hinged structures. This option is used when the door completely covers the walls of the box on which it is installed. It is popular for installation on any furniture: kitchen, dressing room, office. The product makes it possible to completely close the cabinet by tightly pressing the movable front panels to the base.

The mechanism allows you to open the door 90 degrees. It also supports the sashes in the chosen position and prevents misalignment.

If the side of the niche is covered simultaneously by two door panels, semi-overlay parts are used. Their distinguishing feature is the bending of the base. Thanks to this feature, it is possible to obtain a small gap between the components of the facade placed on the same area.

Most often, this type of hinge is included in kitchen sets.

Inverse and piano

Inverse fastenings allow opening 180º, forming a single line with the side of the box. Such components are most often used to equip built-in spaces.

This option is used for bedside tables and cabinets. It allows you to securely fasten the side part.

The piano mechanism is an obsolete type of product. It is very simple and understandable even to an inexperienced master, but still cannot boast of reliability. The design consists of two identical metal strips connected by steel wire in the middle. Most often this type is found on samples from past years. But sometimes it is still used today, for example, in making a kitchen corner with folding seats.

This view is considered obsolete. That is why it is rarely used and included in modern designs.

Internal and corner

The internal structure is taken when it is necessary to place doors inside a niche. That is, the sash does not overlap the ends of the walls, but is located directly between them inside.

The hinge is often included in pencil cases and cabinets that have heavy doors.

In most cases, it is necessary to provide a rectangular opening. But sometimes you need to attach the facade at an angle that differs from the standard by several degrees in one direction or another. In this case, special fasteners are used, which are marked accordingly:

- “plus” if an opening with a value above 110º is expected;

- “minus” when the opening level is below 90º.

Most often, such hinges are purchased for corner cabinets.

The hinge accepts any angle and provides the system with the necessary strength. It is also possible to supplement the system with closers.

Note! Products in this group on the market have a pitch of 5º. If the obtained value is not a multiple of this indicator, then additional overlays are used. These devices allow you to set the correct parameters yourself

These devices allow you to set the correct parameters yourself.

Card loops

Representatives of this group are in many ways reminiscent of their piano counterparts. It also consists of two metal plates that are connected by one hinge. Most often, this thing is used in furniture design to give things an antique effect. Card elements are often made in the form of various figures with wavy, rounded or pointed edges.

With its help, retro-style interior items are most often added.

Gallery and card shops

The adit components allow you to attach the sash not to the sidewall, but to the blank wall of the cabinet located in front. Often this type of accessory is also called “blind” because they attach the door to the adjacent false panel.

If the fittings are of high quality, then with its help it will be possible to secure a door of any weight and size.

Card auxiliary ones are used to attach folding elements. This part is installed on the cabinet from the ends, which makes it possible to move the sash 180º.

The holder can also be used as part of folding parts of furniture.

How to choose a milling fixture

Experts note that it helps speed up the work process several times. Moreover, the prepared niche turns out much smoother and neater than when using hand tools. When reading reviews, you need to immediately find out whether both of these parameters are provided or not

There are different types of locking devices, but they do not replace each other - so this point is worth paying special attention to. Vertical, also known as submersible, the device allows you to select grooves of arbitrary depth

At home, it is better to use a specialized router. At the same time, it does not require particularly high power; on the contrary, it will only unjustifiably increase the weight of the machine. But the option of adjusting the rotation speed of the cutter is very valuable for amateurs. It will help you complete all planned work more accurately.

Important: in a good machine, such a switch is placed in a safe place (even when working, you can stretch your hand there without fear) and allows you to regulate the speed of rotation smoothly, and not stepwise

Read also: Conductors for drilling holes in furniture

Another significant factor is how far the cutter can extend beyond the clamp. Usually this indicator is illustrated by numbers in the model name, and is expressed in millimeters. But it’s still worth reading the technical documentation to eliminate errors as much as possible. In addition, you need to look at whether it will be convenient to use the router.

This is determined by:

network cable length;

location of knobs and other controls;

list of functions performed.

Before purchasing, you should start the machine. If it is of high quality, the head should move completely freely. The slightest distortions and backlashes are unacceptable. The less noise the better. Also worth looking at:

Is there a wide view of the working surface?

is there any additional lighting provided?

Are there auxiliary attachments, holders, etc.

Installation stages

Installation of hinges on facades is carried out in 4 stages:

- first create markup;

- then make holes using a drill;

- then installation is carried out, as well as assembly of parts of the fittings;

- At the last stage, the doors are installed.

Stages of self-assembly of furniture, rules for deciphering drawings The most important and difficult stage is considered to be adjusting the position of the door relative to the furniture body. If the work is done incorrectly, the sash will quickly sag and the cabinet (or any other product) will fail.

Creating markup

To install furniture hinges correctly, you must initially make even markings that correspond to the parameters of the hardware plate. Otherwise, there will be problems with opening and closing doors. The marking of furniture hinges is done as follows:

- The distance between the canopies should be at least 50 cm. At this stage, the number of hinges required is determined.

- Start marking the center of the canopy holes. At the same time, they retreat from the edge of the door by 2–2.5 cm.

- Marks are applied taking into account the width of the door. At the intersection points, holes are made with self-tapping screws. At this stage it is worth using a template for marking furniture hinges.

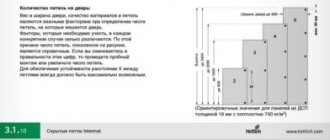

Despite the fact that templates for furniture hinges are made of durable materials, they must be handled very carefully. It is strictly forbidden to drill through them, otherwise the service life will be reduced. To determine the number of loops needed, it is worth studying the recommendations presented in the table.

| Door weight, kg | Facade height, mm | Recommended number of loops |

| 4-5 | up to 500 | 2 |

| 6-9 | 500-1000 | 2 |

| 10-13 | 1000-1500 | 3 |

| 14-18 | 1500-2000 | 4 |

| 19-22 | 2000-2500 | 5 |

Hole preparation

The next step will be preparing the holes. To make the notches correctly, you need to accurately follow the markings already made. To carry out this operation, a drill with a special drill and a milling cutter are used. The holes are made like this:

- First you need to lay the door on a flat surface.

- Fix a cutter for furniture hinges of a suitable diameter in a drill. The depth of the hole should not exceed 1.25 cm.

- During the drilling process, the drill must be positioned strictly perpendicular to the surface of the door.

- During the process of forming the hole, you need to carefully ensure that the cutter or drill does not drill through the door.

Nuances of making furniture drawings, review of useful programs

When the main holes for the screws are ready, you can move on to the next stage. Inserting canopies in accordance with the markings and formed recesses is much easier and of better quality.

Hinge Attachment

The hinges are attached in the following sequence:

- The part of the loop that will be directly attached to the facade is placed in the bowl.

- The hinges are carefully positioned in the recesses to ensure optimal placement.

- Using a construction angle and a level, achieve an even position of the loop in the cup.

- If you need to correct the hole to lay the canopy evenly under the level, use a furniture cutter to install the hinges.

- Using a screwdriver, screw the screws into the holes on the hinge itself.

After fixing the screws, you need to check the strength of the canopy. It is recommended to try to loosen the hinge in the cup and move it relative to the surface of the facade. If no changes are observed, then the fittings are secured well.

Hanging the door

The most difficult stage in this work is the installation of the door. To simplify the task, if possible, it is worth laying the furniture body so that the doors are attached to the hinges in a horizontal position. Algorithm for installing doors:

- In the inside of the furniture body it is necessary to make the same markings as on the door. To install the hinges, you also need a furniture bit.

- Next, secure the platform to secure the canopy using self-tapping screws.

- Connect the two parts of the canopy.

- Finally, adjust the position of the fittings relative to the door and furniture body. This can be done using a screwdriver and a level.

Making upholstered furniture with your own hands, tips for beginners

Hanging the door is not the final stage of work. Even after the initial adjustment, additional measures must be taken to align the position of all components.

Step by step installation process

The considered method of attaching hanging cabinets is used for hook hangers with mounting rails.

- Before carrying out work, remove the front doors, if there are no installed fasteners, cut off fragments of the rear wall in the required places and install hook hinges. The hooks should protrude 3 - 5 mm. from the plane of the back wall of the cabinet.

- Lean the cabinet against the wall at the required height and mark its upper boundary, using a building level, transfer this mark, outlining a line along the perimeter of the entire wall where the cabinets are hung.

- Apply a fragment of the mounting rail to the hanger in the final suspension position and measure the distance from the top of the cabinet to the top of the rail.

- This difference is transferred to the wall by drawing a line for the upper border of the batten, parallel to the first line (usually it is 30 - 50 mm lower.)

- Place the mounting rail on the line and drill through the mounting holes into the wall. It is most practical to first do this at one point and secure the rail with a dowel and a self-tapping screw; during further work it will not need to be constantly supported.

- Next, hammer in the dowels and tighten the screws, completely securing the rail.

The mounting holes in the mounting rail often have a diameter larger than the screw head. This allows you to drill holes through it for the dowel without removing it from the wall; when installing it on self-tapping screws, you will have to put washers on or use special types with wide heads.

- The frame is hung on the rail and set using adjusting elements in one line along the level at the required distance from the wall. If necessary, they are fastened to each other using self-tapping screws or intersection ties.

- The final stage of installation is hanging the doors and adjusting them.

Areas of use

The use of furniture hinges without mortise may be determined by the type of product design or the materials used. These can be thin doors in frames made of chipboard or plywood, or other options in which drilling holes is somewhat difficult. Special non-mortise hinges are produced for glass elements; you don’t even need to drill holes for them. For aluminum structures, fittings are often supplied immediately complete with the furniture profile.

The use of such fasteners is most in demand when assembling cabinet furniture, built-in and conventional, free-standing. Options without drilling are mounted like clamps, securing the blade in a kind of groove. They are in demand when assembling display cabinets with a large glazing area.

Four-hinge hinges

The most widespread in the production of cabinet products intended for the arrangement of any residential and domestic premises are four-hinged hinge structures, the advantages of which are:

- high strength of individual elements, ensuring reliable operation of the product as a whole;

- a large number of operation cycles, ensuring the operation of the product during its entire service life;

- Possibility of adjusting the door leaf in three planes.

The design of the four-hinged hinge includes:

- cup;

- shoulder;

- installation site;

- additional elements - an adjusting screw and a decorative flange.

As a rule, the cup is installed in a special recess milled in the door. In order to reduce the range of cutters (Fosner drills), most loop specimens have a cup with a diameter of 35.0 millimeters.

Cups with a smaller diameter (26.0 millimeters) have models designed for installation on door leaves that are small in weight and size, as well as on hinged glass doors, such as in sideboards. The lever arm is the body of the adjustment mechanism and is connected to the installation platform, fixed inside the furniture compartment, on its sidewall. Fastening of all elements of hinge fittings is carried out with self-tapping screws or using a screw confirmation.

Installation tool

In this article we will look at how to install overhead type furniture hinges. To work you need to prepare the following tools:

- furniture hinges;

- end mill (diameter 35 mm);

- screwdriver;

- pencil;

- ruler;

- building level;

- self-tapping screws (4x16 mm).

Semi-overlay fittings help to apply two or more facades to the sidewall.

After forming the groove, we begin to secure the hinges.

Types of furniture hinges by design

There are many hinges and canopies used to attach a swing door to the frame of a cabinet or cabinet. Basically, in modern furniture production, four-hinged hinges are used, which allow the facade to be adjusted in three planes at once:

All of them consist of two interconnected parts - a bowl with an elbow and a counter plate. Often the strike plate is called a mounting or mounting plate. This article will focus specifically on four-hinged hinges.

Other types of furniture hinges can be combined into one large group as “bowlless” hinges.

First of all, these are piano hinges, card hinges, pin hinges, and heel hinges, known to everyone for fastening interior doors and facades in old furniture. They are rarely used in modern furniture. For example, piano, card and mortise hinges can be used to attach tabletops to the base, movable legs in book-tables. For ordinary cabinets, brass decorative hinges are used as additional decor.

Overhead hinges that do not require drilling of the facade. They come in handy when the thickness of the material chosen for the facade does not allow installing (embedding) a four-hinged hinge due to the depth of the bowl. The only drawback of such hinges is their rigid fastening, which does not allow adjustment in three planes, like four-hinge hinges.

Hinges for fastening specific facades. For example, prefabricated facades made of aluminum frames of different widths are installed on special hinges - you can purchase them together with the profile

Please note that just like regular four-hinged hinges, they can be overhead and internal, designed for corner cabinets of 45, 135, 180 degrees and facades covering the end of the case

Installation of wall cabinets in the kitchen: choosing a mounting method and following installation technology

Hanging kitchen cabinetry is never a daunting task with an inexpensive household peg-hole drill and matching concrete drill bits. The task became more complicated when traditional Soviet methods of fastening using corners or furniture hinges were replaced by modern ones.

The illiterate use of a mounting rail with a hanger made of low-quality materials and a violation of installation technology led to so many falls of hanging cabinets that even a caste of professionals in hanging them has emerged. In any case, with a reasonable approach to the choice of materials, method of fastening and adherence to technology, hanging different types of furniture remains an easy task for any homeowner deciding how to hang cabinets in the kitchen.