Many people, in order to save money, when buying furniture, decide to assemble it themselves, so as not to pay for the services of an assembler if they come for a separate fee. In fact, it is very easy to assemble modern interior items, following the included instructions and having at least minimal skills in working with the tool.

However, there are still some nuances. For example, installing furniture hinges with your own hands is a fairly simple task, but one that requires attention and accuracy, because how well the doors of cabinets and cabinets will close will largely depend on correct installation.

Installing furniture hinges yourself

How to make holes for furniture hinges with a router

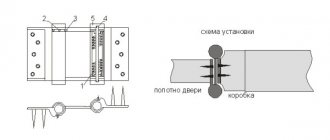

Overhead hinges are located at a certain distance from the edge of the panel.

To select a blind hole for a cup with a hand router, it is more convenient to use a device (template) with a stop bar, which facilitates positioning on the furniture board.

Drawing of a template for inserting a furniture hinge.

The template is designed for inserting a standard loop with a cup with a diameter of 35 mm. For products with other installation dimensions, you should calculate the diameter of the hole and determine the position of the stop according to the distance from the middle of the loop to the edge of the panel.

Cut out the pieces of the fixture from plywood and secure the strip with glue and small nails.

To make a hole, secure the template to a furniture panel, resting the bottom bar against the end. Set the routing depth on the tool to 11.5 mm and cut the recess in several passes.

Templates from DOOR-TOOL

The DOOR TOOL template is a modern template for inserting door hinges that should be in the arsenal of every wood door installation professional. This tool allows you to work with replaceable inserts for different types of fittings, therefore it is widely in demand for installation work.

Differences between DOOR TOOL templates

To insert hinges you will need the following set of devices:

- universal template for inserting DOOR TOOL hinges (one of the models, Mini Plus, Mini Plus Air, Max Plus, Max Plus Air, Telescope or Telescope Air);

- manual edge router;

- racks for stable installation of the door leaf in a vertical position;

- clamps for mounting the template on the door leaf;

- measuring and marking tools;

- door card hinges with self-tapping screws for their installation;

- drill and screwdriver (or screwdriver) for installing screws.

- corner chisel.

The template for inserting hinges can be used both for making grooves on the door leaf and for installing a hinge on the door frame.

The DOOR-TOOL Max Plus template allows you to embed card loops as standard. There are various types of inserts for locks and lock mates

The copy template is a template holder designed for attaching replaceable metal template inserts.

It has an elongated base and two stops that allow you to mark the insertion point without a tape measure (the distance from the edge to the insertion point is 15-20 cm), which saves time and simplifies the work of the master. In addition, there are special recesses on the sides for reliable fixation of the device using clamps.

With this set you can cut door hinges and locks faster and more accurately than with a router with a stop. To insert hinges, two bases are usually used, connected to each other by a ruler; the bases have replaceable inserts for different sizes of hinges and locks; it is possible to use one base for inserting, but this is less convenient and requires measurements.

The base is made of acrylic (plexiglass) and moisture-resistant laminated plywood 15 mm. The bases are adjusted very simply by moving the lower stop and the plastic part, the ruler is made in such a way that it is easy to use. The bases are intended for use together with a router on which a copying ring is installed at the calculation: cutter diameter + 4 mm (example: if the cutter is 14 mm, then the copying ring is 18 mm.)

Instructions for inserting a lock into an interior door

The following stages of work are implied:

- securing the door in a horizontal position;

- performing preparatory work on marking a wooden door. Usually the lock is installed at a height of about 90-110 mm from the floor level, which ensures ease of opening;

- installation of the DOOR-TOOL template in accordance with the markings;

- preparation and installation of a manual router on interior doors;

- excavation of the lock opening, groove for the bar and other elements depending on the design of the lock;

- fine-tuning the grooves (if necessary, remove wood residues using a chisel);

- installation of fittings.

Advantages:

- the presence of different template options for different tasks in different price categories;

- it is possible to use it with any milling cutter, provided that a cutter with an upper bearing is used;

- metal inserts.

Minuses:

- you will have to buy additional mod inserts for different models of locks and hinges;

- card loops of 100 mm have different deviations in size, you need to buy different inserts;

- the cost of the insert is 550 rubles (compared to similar models of competitors from 230 rubles).

The cost of a stencil template starts from 2090 rubles. and telescopic models 8200 rub. These are quite affordable prices for builders and hobbyists. The price increases depending on the functionality and possibility of using the vacuum cleaner.

The universal template for inserting hinges and locks Ш-004 DOOR-TOOL Max Plus is enough for work and its price is 3300 rubles. The basic kit includes a steel insert for inserting a 100 mm card door hinge; other inserts are sold separately for different sizes. You will have to purchase an individual set of tools for inserting door hardware.

Furniture hinges: features and types

A furniture hinge is a semi-mechanical design that makes it possible to open and close part of the furniture body (usually a door), retracting it to a certain angle. It is completely invisible from the outside, but at the same time it is capable of not only holding it in the desired position and helping to open the facade (door), but also preventing it from opening without permission. Typically, hinges are used for the so-called hanging of doors made of various materials - wood, glass, aluminum profile. Also, most hinges are capable of closing on their own. The most common type of hinges is four-hinged . They are highly functional and very reliable, durable and can serve for many years without breaking.

Four-joint furniture hinge

On a note! For the first time, a design that can close on its own appeared only in the twentieth century; it was patented in Italy.

History of furniture hinges

The design of a furniture hinge is represented by the following elements.

- The base or base is the element that is attached to the mounting plate. It has a special screw that makes it possible to adjust its position.

- The cup is a part that, during the installation of hinges, is installed in a hole specially drilled in the facade. It has a round shape.

- Hinges are movable elements equipped with spring mechanisms.

Furniture hinge - structure

Each hinge of this type has a spring that allows the design mechanism to hold the cabinet door closed and prevent it from opening without permission. These hinges can be adjusted in three planes at once, which is very convenient and allows you to adjust them perfectly in almost every case. They are made of steel and have high protection against rust.

On a note! Such loops in Russia are also called cup loops or a more prosaic name - frog.

What is it and how does it work?

Hinges with four hinges can be:

- semi-overhead , which are usually used if you need to attach a pair of sashes to one side at once, which will open in different directions. That is, the facade covers only part of the end;

- overhead , which are suitable for installing the door on any side of the body;

- angular , which must be used if the door must be attached at a strictly defined angle (for example, 45, 90 or more degrees). As a rule, the angle depends on the design features of the cabinet;

- inverse , which make it possible to open the door 180 degrees, that is, when the door is opened, one plane is formed with the base wall;

- inset or internal , which allow you to secure the door inside the cabinet. The loop resembles a half-overlay, but is more curved.

Types of furniture hinges

In fact, there are not only four-hinged hinges, although they are the most common and are most often used during furniture assembly to connect the body with the doors. There are also other varieties that we will now get acquainted with.

Fitting

- The next step will be trying on the lock. It should not dangle in the groove.

- Now trace with a pencil the front lining of the lock inserted into the finished recess.

- Use a chisel to cut away any excess wood from the inside of this outline. This item is considered completed provided that the lock escutcheon exactly coincides with the plane of the door end.

- After this, you can finally insert the lock and secure it with screws through the holes made.

Adjusting the strike plate

- Insert the cylinder, screw it with the bolt from the kit and make sure that the product functions well. The key should turn without effort. If so, you can secure the handle.

- Next you need to apply something to the latches that leaves marks. After closing the door, turn the key so that marks remain.

- Drill holes along these marks and level them with a chisel.

- You have finished cutting the lock into the wooden door. The last thing you need to do is prepare the hole for the strike plate, align it and tighten it with self-tapping screws.

There is nothing impossible; it is easy to embed a lock with your own hands, provided that you strictly follow the instructions. The only difficulty is that the grooves are perfect, however, if you use a router, it will be easier for you.

Inserting locks into interior doors: necessary tools and their purpose

The choice of the tool needed to embed a lock into an interior door depends primarily on the technology with which this process will be carried out. There are two of them - one professional, which involves the use of high-precision modern power tools, and the second, one might say, artisanal, carried out using a hammer and chisel. It is, of course, up to you to choose which one you will stick to. I will only say one thing - in the latter case, the result may upset you. On average, if we talk about tools for cutting locks, you will need the following set.

- A manual milling cutter for inserting locks is used by professionals to ensure high accuracy and quality of selection of landing recesses for the lock plate. Thanks to the high rotation speed of the cutter, it allows you to cut out recesses for the lock without damaging the decorative covering of the door.

- Hammer. What would it be like without him? Most likely, it will be needed to work in tandem with a chisel for the artisanal cutting method. But it can also be useful with a professional approach to business.

- Chisels of different widths. With their help, you will have to cut a mounting hole for the lock bar - this tool is quite clumsy, and the result of working with it depends largely on the hand of the master.

- A drill or screwdriver will be needed to drill holes for the handles and a deep mounting hole for the lock itself.

- Flathead and Phillips screwdrivers. It is with them that it is best to tighten the screws that secure both the lock and the handles themselves - if the screwdriver comes off the screw, the door will most likely be damaged.

- Set of feather drills for wood. They are mounted on a drill or screwdriver and are used to drill mounting holes. We'll tell you how this is done a little later.

- Roulette. There is no need to talk about its purpose; everyone already knows what it serves.

That's all you need to solve the question of how to embed a lock into a wooden door? You can also talk about tools that are rarely used in this matter, but it’s probably not worth it, since without some experience you can do a lot of irreparable things with them.

You can clearly see the process of installing a lock on an interior door in the video below.

Inserting hinges yourself

We determine where the door opens and check the ease of opening. We lay the doors on their side; ideally, for ease of work, make corner stops for the door so that the door holds on its own, this will make the work much easier. We step back, put marks with a pencil 20 cm from the edge of the door , apply a hinge and put marks. We take it, screw the hinge to the door with screws, and make sure that the hinge holds well. We take a construction knife and carefully and with little effort trace the outline of the door hinge, as shown in the photo, then with great effort we draw the outline of the door hinge, and carry out the same operation with the second hinge. As a result, we get a clearly cut outline. Learn about new modern ways to quickly insert locks and hinges, using special templates and carriages that significantly help speed up work and improve quality. Details about the devices and templates used when installing doors by professional craftsmen.

The insertion of the loops can be done by eye using a chisel. Of course, you can do it more quickly using a hand router. Don’t think that a router is something big and industrial, it’s a completely acceptable tool that will require at least a couple of diameters for different types of locks. The milling cutter will greatly facilitate and speed up the process of cutting in door hinges; with it, you can clearly guess the depth of the cutting, and it is very helpful if you come across knots and uneven wood fibers.

Price

The cost of installing a lock on an interior door is constantly changing (they can change throughout the year). This, first of all, depends on the company that will do the cutting. If you take a wooden door, then the prices for inserting locks into it range from 1000 to 3000 rubles.

An insert into a PVC door costs a little more, from 1500 to 3000 rubles (and this is not a guarantee of 100% quality).

To install a lock in a door, you first need to buy this lock. To choose the right lock, you need to know two parameters: the width and thickness of the vertical bar of the door. If the thickness is less than 40 cm, then there is no point in embedding the lock.

Locks come with handles and without handles. If the choice fell on the first option, then first the lock is cut into the door, the next step is installing the handle. Stores also sell latch handles. And although they are structurally quite simple, cutting them in is not so easy - this process requires experience and the necessary set of tools.

Well, the choice has been made. Let's move on to installing the lock.

Installation of the locking mechanism

The door lock is usually cut into the center of the left or right door strip, so you need to measure 1 meter from the floor surface and mark the place where the door handle will be located. Drill a hole for the lock mechanism. The diameter of the drill must be equal to the thickness of the lock, the length of the lock must correspond in size to the depth of the hole. Using a chisel, we knock out a platform for installing the support plate for the lock. Drill a hole for the handle. We install the lock and mark the place for the screws. We make holes and secure the lock with self-tapping screws.

Handle attachment

To attach the handles on both sides of the door, you need to install the linings and secure them with self-tapping screws. We check the operation of the lock and handles. The process of installing the handle is not complicated, but it can only be used for doors that are made of wood. A lock can be embedded into a wooden door absolutely anywhere, but doors made of steel or MDF require a completely different approach.

To insert a lock into an MDF door, you will need experience and theoretical knowledge, since such a door has an additional wooden beam, which is located at a distance of 1 meter from the floor. The rest of the door is completely hollow. Without knowing this feature, you can try to embed the lock above or below this beam, which will damage the door. Therefore, it is better to entrust this to experienced craftsmen.

To install a lock in metal doors, you need to contact a highly specialized company, such as ours. Trying to do everything yourself will lead to wasting your time, breaking the lock, and damaging the door. We don't think you need such expenses.

Lock mortise process

Using

a router

The lock can be inserted using a router. For insertion, a submersible universal milling cutter is used. Most people associate the word “milling machine” with some kind of large machine, but it is a small and convenient manual machine. It allows you to make grooves, grooves, align edges, cut profiles, and all this without the use of special and expensive equipment.

Briefly, the lock installation process looks like this:

- We mark the place for the castle.

- We make a recess with a router.

- We drill holes, remove excess wood, clearing the area for the lock.

- We install the lock and handles.

Without

a router

If a router is not available, then you can install the lock without it. Although, when inserting a latch lock, you will still need a cutter.

Fashionable interior trends dictate their conditions, thanks to which people began to change both entrance and interior door leaves more often. At the same time, their replacement is associated with certain costs, the lion's share of which goes to pay the workers who will install the door. An obvious solution to the problem would be to install it yourself, but this requires skills and special tools. For example, to carefully cut into a locking device you will need a cutter; we will talk about this in more detail later.

How to choose a milling fixture

Experts note that it helps speed up the work process several times. Moreover, the prepared niche turns out much smoother and neater than when using hand tools. When reading reviews, you need to immediately find out whether both of these parameters are provided or not. There are different types of locking devices, but they do not replace each other - so this point is worth paying special attention to. The vertical, also known as submersible, device allows you to select grooves of arbitrary depth.

Please note: this tool is useful for securing not only locks, but also door hinges. If you want to make the edges of a recess more aesthetically pleasing, an edging (sometimes called edging) device comes to the rescue. Experts prefer to use a combined device. It combines both functions and eliminates the need to move two heavy machines to each site. However, the cost of such equipment will naturally be higher.

At home, it is better to use a specialized router. At the same time, it does not require particularly high power; on the contrary, it will only unjustifiably increase the weight of the machine. But the option of adjusting the rotation speed of the cutter is very valuable for amateurs. It will help you complete all planned work more accurately. Important: in a good machine, such a switch is placed in a safe place (even when working, you can stretch your hand there without fear) and allows you to regulate the speed of rotation smoothly, and not stepwise.

Read also: How to measure amperes with a multimeter on a power supply

Another significant factor is how far the cutter can extend beyond the clamp. Usually this indicator is illustrated by numbers in the model name, and is expressed in millimeters. But it’s still worth reading the technical documentation to eliminate errors as much as possible. In addition, you need to look at whether it will be convenient to use the router.

This is determined by:

network cable length;

location of knobs and other controls;

list of functions performed.

Before purchasing, you should start the machine. If it is of high quality, the head should move completely freely. The slightest distortions and backlashes are unacceptable. The less noise the better. Also worth looking at:

Is there a wide view of the working surface?

is there any additional lighting provided?

Are there auxiliary attachments, holders, etc.

What types of locks are there for interior doors?

Before you start thinking about mortise, you need to decide on the type of lock. There are many of them for interior doors, and each of them has advantages and disadvantages. Often the ordered door comes with various fittings, including a lock. However, this does not mean that you cannot install any other fittings.

Latch lock

The hardware market can offer the following solutions:

For each of the types described above, you can find installation templates. However, despite the fact that they are all different, the basic installation algorithm remains the same, since in terms of fastening and installation, not a single type of lock has brought anything fundamentally new.

Types of manual milling machines

On the modern market, manual milling units are represented by electrical equipment of the following categories:

- devices of a vertical or submersible type, which are mainly used for cutting grooves of various depths and widths (a typical representative of a power tool in this category is a milling cutter for inserting hinges and locks);

- edge milling cutters, which are also called edging cutters (using power tools of this category, decorative processing of the edges of wood products is performed);

- combined type milling machines, used primarily in the professional field (they are called combined because they combine the capabilities of edge and vertical type milling machines);

- special-purpose power tools, the most common types of which are lamella and dowel milling cutters (as the name of the category of such devices implies, they can only be used to solve a specific technological problem).

What is a milling cutter, what advantages does it provide when installing a lock on a door?

A hand router (popularly just a milling cutter) at one time made it possible to make a breakthrough in woodworking, because with such a tool complex wood carvings can be done practically “on the knee”. The advantage of a hand router is its portability. In the daily work of a carpenter, various situations may arise when work needs to be done locally. Previously, you had to either drag the product to the workshop or use a chisel and, accordingly, get a rougher and more approximate result.

Now you can simply take the router with you, bring it into any room, drag it onto the roof or into other hard-to-reach places and perform the necessary actions without wasting extra time. Door installers have made their work much easier by starting to use a hand router.

Using a suitable cutter, you can insert the locking device many times faster, saving an additional 30 minutes of time. This is quite significant, considering that it takes a specialist 2 hours to install a turnkey interior door.

We should not forget that earlier craftsmen, when cutting into a lock, were forced to “pick out” a deep groove under it with a chisel. Anyone who has “handled” a chisel knows how labor-intensive this work can be, how much time it takes, not to mention the risk

After all, a chisel can jump out from careless movement and damage the surface of the door leaf. In this case, on the one hand, the master will discredit himself, and on the other hand, he will suffer financially, because he will pay for the new door out of his own pocket

Types of cutters: which ones are useful when installing a locking device?

Currently, there are a huge number of cutters for hand routers. With their help, an inconspicuous piece of wood in skillful hands turns into a finished product right before your eyes. All cutters can be divided into three large groups.

- Edges. They are used for making various carved elements on the surface of the material; they are also useful in making the edges of products.

- Grooved. Used for making grooves, recesses, recesses, grooves of any depth on any wooden surfaces.

- Curvy. Designed for creating various carved decorative elements on furniture facades, on the surfaces of door panels and other products.

To install locks in interior door leaves, you will need a groove cutter of suitable length. With its help, cutting the perfect recess in the end part of the door leaf costs nothing. True, it may be difficult to install door hinges, because even grooves need to be cut under them. But if you have an overrunning cutter at hand, no problems will arise.

Working with a router for inserting loops

The main thing is to be very careful when working, since the rotation of the collet is more than 30,000 revolutions and, accordingly, it must be well screwed in and, of course, we follow safety precautions.

Please note that the frame and the router stop are in contact with the surface of the door. There is also vibration, and if measures are not taken, the door leaf can be damaged. To avoid damage to the door leaf, you need to use sliding materials on the surface for the frame and stop; you can, of course, make templates, but this requires skills.

And so let's start selecting the door hinges, take it, set the depth on the stop of the router, for this we use the hinge, install it in a pressed state between the stop and adjust the depth of the depth. It doesn’t really affect what diameter of the collet you use for tapping, you can even use 12mm. – 18 mm. We set the limit stop along the edge, fix it and proceed to deepening. Clearly holding the milling machine and not going beyond the boundaries of the loops. We finish the rest with a chisel, in the end we get a clear seat and screw the hinges.

Additional tools and recommendations for them

To install a lock on an interior door, you must use a tape measure. It helps to accurately measure the required distances. In addition, useful devices will be:

drill with a diameter of 0.2 cm.

In some cases, a hammer drill can be of great benefit. It is needed to level and enlarge the opening. Using a hammer drill, holes are drilled where the anchor dowels will be placed. When purchasing or renting a screwdriver, you should find out whether the necessary attachments are included in the kit. If you have to process hard-to-reach areas, unravel platbands or trims, sometimes you need to prepare an electric jigsaw.

When choosing pencils and markers for marking the canvas, you need to avoid buying products with very hard rods. They will leave traces that will be extremely difficult to get rid of. To more accurately measure all dimensions, you need to use a tape measure with a tape 3 or even 5 m long. A caliper will help you determine how deep you need to cut the lock. To more accurately orient the locks, eliminating distortions, you need to use a bubble level.

But since the locks are usually installed on a small part of the door, you will have to use a steel ruler. It is much stronger than wood and plastic and can withstand even accidental impact from a tool. Using metal test squares, angles are measured. This device is also needed to tune an electric instrument. You definitely need to prepare a set of screwdrivers, especially since it will also be useful when installing hinges.

You should also prepare: a mounting gun for supplying foam, chisels and peaks for the hammer drill, files for a jigsaw.

How to embed a lock into an interior door yourself, watch the video.

Using a template

The procedure in question is also carried out with a special template. You can get it yourself as follows:

- First, the offset of the cutter is measured.

- You can determine the dimensions of the template for insertion using conventional measuring tools.

- 2-3 passes are performed.

- This step produces a finished hole.

After receiving the special element in question, you can embed the hinges using other various tools.

In conclusion, we note that the process of cutting hinges with a router is carried out to obtain a high-quality niche. The features of the tool can significantly speed up the process and reduce the likelihood of serious defects. By using special attachments, you can significantly expand the capabilities of the device.

If you find an error, please select a piece of text and press Ctrl+Enter.

What types of locks are there for MD?

Taking into account the insertion, use and other parameters, locks are:

Flat. They have a rectangular frame and tongue that are separate from the locking latch. They also have a push handle (halve). Such designs are very reliable.

Flat lock

- Round. In such mechanisms, the cylindrical body, latch and tongue are connected. The shape of the handle can be arbitrary. In such devices, the stopper and the cylinder are embedded in the spindle.

- Small flat with a rotary handle. No latch provided;

- round with a knob handle.

Round castle

To install a lock, you need to know the thickness and structural features of the door. Modern MDs are:

- with MDF 3.5 or 4.5 cm wide;

- New type wooden MD with a width of 5 cm;

- Wooden fiberboard door with an old design (with a plank frame).

Installation of the device in the MD can be done without outside help, but to do this you need to know the design features and operation of the lock.

Flat

These locks are the most expensive. They are more difficult to install, but they have good burglary protection. They load the door leaf (DP), so it is better to install them in an existing door.

Only a small flat lock can be installed in MDF panels with a thickness of 35 cm. Also suitable for them are locks with a wide tongue of about 1.5 cm. The width of the end is a maximum of 2.4 cm. This limitation is explained by the fact that only a wooden frame can withstand the load created by the lock.

MDF door