Furniture screed is a special type of fastener that is used exclusively in furniture production. Such fasteners can not only significantly facilitate the process of assembling furniture, but also become “invisible” after installation. In this article we will look at the different types of fasteners used for assembling wooden cabinet furniture.

Cabinet hanging mechanisms

Initially, furniture was mounted on the wall using nails or screws. The disadvantage of fasteners is their fragility and fragility. The cabinet could collapse at any moment. This is especially dangerous for glass doors on modern headsets. But such canopies are still used today.

Classic hinges

This is a pendant in the form of metal plates 1.5-2 mm thick. They are attached directly to the wall using a regular or L-shaped self-tapping screw (crutch) screwed into a dowel.

There are several types of loops available:

- Simple pendants differ in the location of the mounting hole: at the top and in the center. The most aesthetically pleasing devices are those with a pear-shaped groove in the middle. They are not visible after installation. But this complicates the installation: when hanging a cabinet, you have to aim for a long time to get onto the suspension. Attached to vertical racks, designed for cabinets with a small load. When the groove is located at the top, it is easier to install furniture. The number of holes for self-tapping screws can reach 5, versus 2 for hinges with central fastening. They can withstand furniture with greater load. Screw to the sides of the cabinet.

- The corner canopy is non-adjustable - bolted to the top shelf of the box and to the wall. There are no installation problems, but the suspension is visible from both sides. The shape allows the cabinet to be hung close to the wall or moved away.

- P-shaped - screwed onto the box with self-tapping screws in 2 places: the upper horizon and the vertical post. This allows you to strengthen the structure through screeding. The time required to draw markings is reduced, since the horizontal position of the cabinet can be adjusted.

It is impossible to combine aesthetics and ease of installation of furniture hinges. Either they attach easily and stick out on the wall, or they are not visible, making them difficult to hang.

Mounting strip

Modern suspensions are easy to attach and easily move in the horizontal and vertical plane. The adjustment block is attached to the side panel of the cabinet through 2 through holes. There are mechanisms designed for different capacities. The maximum load on weak suspensions is 35 kg, on reinforced ones - 130. A fixing hook comes out of the block. To attach it, you need a strip that is mounted directly to the wall.

Advantages of adjustable hangers:

- a single strip on which the cabinet is supported is more reliable than a point fastening with screws;

- Possibility of hanging alone;

- adjusting the cabinet relative to the wall and floor;

- no strict requirements for marking - an error of 1.5 cm is allowed;

- Possibility of attaching to a kitchen apron.

Eccentric coupler

This type of fastening element is used when assembling furniture in a factory environment, due to the complexity of drilling holes for its installation.

The main advantage of the eccentric screed is its concealability, which prevents the appearance of the cabinet or other cabinet furniture from being spoiled.

In addition, unlike the previous type of furniture screed, the presence of such elements allows you to carry out the procedure of assembling/disassembling interior items an unlimited number of times without damaging them, which, you see, is very convenient when moving frequently.

Also, using this fastening method, it is possible to fix the parts at an angle relative to each other.

As mentioned above, the installation of eccentrics is carried out in the conditions of factory furniture production, since the sampling depths for their installation are at least 12 millimeters. And this despite the fact that the wall thickness of the laminated particle board has a size of 16 millimeters. Therefore, without the use of special equipment, which is impractical to purchase for a one-time installation of interior items, installation of such fasteners is practically impossible.

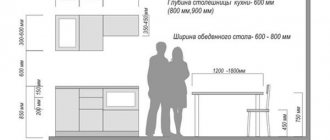

Hanging height

Consider the distance from the countertop to the bottom of the cabinet. Minimum – 45 cm, average – 90 cm. At a height of 110 cm, hang only one shelf.

You can also use the formula:

H=h1+h2+h3-45mm, where the letters are the height:

- H – from the lower stop (table top, floor) to the bar;

- h1 – furniture above which the box is hung;

- h2 – kitchen apron;

- h3 – wall cabinets.

Subtract 45 mm from the resulting sum of all heights - this is the standard indicator of suspension shrinkage.

Focus on the height of people who most often use things from the closet. The optimal distance would be when a person reaches with an outstretched arm to the top shelf and takes the item without the risk of dropping it. But also leave enough space above the countertop.

Standard parameters of a kitchen set

Expert opinion

Bashir Rabadanov

Technologist at the furniture company Woodband

If it is necessary to hang over tall equipment, place the lower part of the cabinet in close proximity to their upper limits, almost close to the ceiling. This applies to refrigerators and ovens.

Find out more about hanging heights for kitchen furniture.

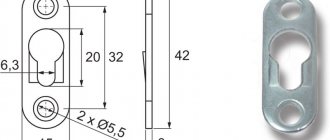

Tabletop fasteners

A special type of furniture tie used to secure two parts of a tabletop together. It is used exclusively in the production of kitchen furniture and requires special milling of surfaces before installation.

Tabletop fasteners

Tabletop fasteners

| Album | Tabletop mount |

Tabletop mount

Tabletop mount

| Album | Tabletop mount |

Step-by-step installation instructions

Attaching hangers and cabinets requires no preparation. When hanging on furniture hinges, you will have to practice your accuracy. In the case of mounting on a bar, everything happens easier and faster. Below are detailed installation instructions.

Tools

For installation you will need:

- level – preferably for the entire length of the cabinet;

- pencil;

- knife;

- roulette;

- hammer;

- hammer drill or drill - when hanging on a concrete or brick wall;

- screwdriver;

- screwdriver;

- when installing several cabinets, clamps are needed - clamps that allow you to create the appearance of a monolithic structure.

Already at the stage of collecting tools, think about which awnings to purchase. If you purchased a ready-made cabinet and a complete set of fasteners, then there will be no problems. When purchasing spare parts for hidden installation, check the presence of all bolts, screws, mechanisms, and plugs.

Preparatory work

Before installing suspended structures, calculate the height and draw boundaries. Draw a line along the level with a pencil. Installation of the DIN rail and wiring must be completed so that you do not have to remove the cabinet and redo the entire design.

Align the walls as much as possible at the fastening points, even if you plan to install the box on a plank. When installing furniture at an angle, it should be 90 degrees. Paint the walls, wallpaper or install an apron. After installing the cabinet, it is difficult to perform these operations.

Installation of awnings

The process is the following algorithm of actions:

- Markings for system installation. On the inside of the cabinet, measure 1.3 cm from the side panels and 2.5 cm from the top.

- Drilling with a drill or screwdriver with a pen attachment with a diameter of 25 mm.

- Cleaning chipboard from chips.

- Trying on the suspension - the fixing hook should be located in the center of the opening. This makes it possible to adjust the position of the cabinet.

The final stage is screwing the screws. Before attaching the hanger, check the alignment of the holes in the decorative plug and the side walls of the cabinet. First lean and screw, then screw. This is necessary so as not to damage the furniture.

Metal guide fastener

The material of the wall determines what you need to attach the plank to:

- a self-tapping screw screwed into a dowel - onto aerated concrete and into a foam block;

- screws with a diameter of 5-6 mm - into wood;

- anchor bolts – for brick, concrete.

The profile length varies. There are planks around 19 inches or 50 cm, but most manufacturers produce 2 or 3 meter products. Each tire is cut at a certain distance. They can be easily broken by hand without using a hacksaw if the guide is longer than the cabinet.

After choosing the fastening tool, attach the strip to the drawn line. Using a drill, hammer drill or screwdriver with an appropriate attachment, drill holes in the wall through the prepared holes in the profile. It is enough to make indentations at intervals of 10-30 cm. There is no need to attach screws every 1.5-2 cm.

Installation of cabinets

Lift the box and hook it onto the guide. Use the adjusting screws to secure the desired position. Use the top bolt to level the cabinet horizontally, and use the bottom bolt to reduce or increase the distance from the wall.

To assemble several cabinets into a monolithic structure, you will need clamps. Drill holes for the tie in the places where the clamps are installed. The chipboard can be damaged during this process, so use a smaller drill bit first. On both sides, expand the holes with a nozzle of the desired size, then make a through hole. Another way to avoid damage is to lean a wooden block against the side opposite the drill and press it as tightly as possible with your hand.

Start installation with a corner cabinet. Connect the boxes in pairs with clamps. To maintain the quality of the surface, place a wooden wedge between the clamp and the wall of the box. All that remains is to hang the doors.

When using a sliding system, we recommend that you read the article: “Adjusting wardrobe doors.”

Shelf supports

As you can guess from the name, such fasteners are used to fix shelves (both glass and plastic) of a wardrobe or kitchen cabinet.

Depending on the installation method, shelf holders are divided into open and hidden. The former are mounted directly to the pieces of furniture (after which a shelf is placed on them), while the latter are something like an eccentric coupler.

Shelf holders in the closet, photo:

The fittings that you see in the photo above are intended for attaching shelves in the closet.

Features of hanging on drywall

The low strength of gypsum boards often leads to the cabinet falling to the floor. To prevent possible breakage of awnings, professional kitchen assemblers use 3 main fastening methods:

- Self-tapping screws with a large pitch and a wide head, impregnated with phosphates, expansion anchors. Ordinary screws, nails, bolts will immediately begin to put pressure on the drywall, and it may not withstand this load.

- Embedded beam - used at the stage of major repairs (during the installation of plasterboard sheets). The block is installed in a metal profile, which serves as a frame for drywall. The method is highly reliable. The disadvantage is the need to immediately allocate space for cabinets, or to adjust to the beam in the wall.

- Adjustable hangers using a metal strip. The most modern and popular fastening method.

For heavy cabinets, it is better to choose a place with a stronger wall. The maximum load on one self-tapping screw is 25 kg, the anchor is 35 kg.

Read on for other ways to attach cabinets to drywall.

How to choose and buy fasteners of proper quality

The employees of our online store, specializing in the sale of furniture accessories, are well versed in all the nuances of the products presented on the website and strive to share their knowledge with every potential client. We guarantee:

- Help from an experienced specialist in selecting suitable parts.

- Timely shipment of the ordered batch of goods from a warehouse in Moscow.

- Competitive prices for basic and additional services.

- A wide selection of mechanisms to implement the assigned tasks.

You can order and buy connecting elements from us in two ways: by calling the manager on one of the indicated telephone numbers or by leaving an online request on our resource.