The back of the cabinet is designed not only to protect things from dust. It adds stability to the furniture, creates completeness, and also performs a decorative function, complementing the design of the room. It will be useful for home craftsmen to learn about the types of fasteners, materials and secrets of installing the back wall of a cabinet. Experts will express their opinions and answer readers' questions.

Example of fastening the rear wall of an OSB cabinet

What is the back wall of the cabinet made of?

The back wall of the cabinet is made of fibreboard (fibreboard), laminated chipboard (chipboard).

One sheet may not be enough to cover the entire back surface.

Some people suggest nailing the back of the cabinets.

The fiber panel consists of wood fibers, synthetic resins, fillers and water.

Is different:

- for general and special purposes;

- by hardness: superhard, hard, semi-hard, soft;

- by thickness.

Under load, the wardrobe may become deformed.

The use of a stapler is also not recommended.

Sheets can be smooth on one or both sides, painted, covered with laminated film, or artificial veneer. They also differ in the degree of reaction to moisture, fire resistance, and exposure to sunlight. The most commonly used hard types are fine fraction (MDF) or chipboard and the harder, modern HDF material made from coniferous wood.

To overcome the problems, you can construct the compartment from sections, each of which would require one sheet.

It is best to use self-tapping screws with a washer.

Chipboard is a mixture of sawdust and resins, which under the influence of high temperatures and pressures turns into a homogeneous and durable material.

Repairing the back of the toilet is not an idle question.

If chipboard is used, then holes are first drilled to prevent the board from splitting, and then self-tapping screws are screwed in.

Plastic

Modern plastics are practical materials that vary in type and manufacturing technology. The plastic coating is applied to the MDF board and then used in the manufacture of furniture. There is a huge selection of plastics, different in composition: Fenix, TSS CLEAF, acrylic, HPL.

Phoenix

Fenix is a new generation of plastic, it is double-sided, matte, pleasant to the touch. Phoenix is almost impossible to damage. An ordinary scratch is smoothed out with a warm iron, and it disappears right before your eyes. Fenix is also called “nanoplastic”.

Main application: for facades, hanging shelves and racks, countertops, kitchen apron. A tabletop made of nanoplastic can withstand significant thermal loads.

Expert opinion Daniil Dmitrievich Korzhavin Designer of stylish home furniture

Fingerprints remain on the dark surface, which are difficult to erase later. No traces are visible on light-colored parts.

The disadvantages of Phoenix include the expensive cost of the material and the presence of mostly calm, neutral shades in the palette.

Acrylic

- Acrylic plastic is a unique natural material made from plant extracts. Features of acrylic:

- The color range is limited.

- The coating can be glossy or matte.

- The gloss shows everything as if in a mirror reflection.

- Fingerprints are not visible on matte surfaces.

The flexibility of acrylic plastic makes it possible to make radius facades and other curved parts for furniture from it. Acrylic panels are also installed on the kitchen apron.

HPL

HPL plastic is the most common material that has stood the test of time and has proven itself to be practical and durable. It is produced by pressing several layers of heat-resistant paper impregnated with special solutions. After applying the MDF board, the strength of the plastic coating increases.

The advantage of HPL plastic is the variety of colors and textures:

- glossy and matte;

- smooth and textured;

- plain;

- with a metallic or chameleon tint;

- fantasy;

- with drawings and patterns.

TSS CLEAF

TSS CLEAF panels are created using Italian technology. A multi-layer coating of tarred paper is applied to the MDF base. Under the influence of the press, a textured convex texture is achieved, reminiscent of a wooden surface.

The multi-layered and tarred outer coating gives it special strength. The panels are difficult to scratch and cause other damage. The color range of TSS CLEAF is wood and fancy shades from white to black. The plate is inserted into sliding doors, used for facades, countertops, and decorative panels.

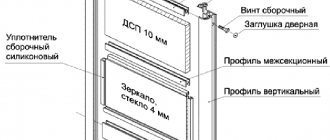

laminated chipboard

Back panels for cabinets made of laminated chipboard are more reliable than fiberboard. They are more durable, mounted to size and have a decorative coating, so they have a more aesthetic appearance. This coating can imitate wood texture or be smooth.

Chipboard is a regular polished chipboard with a lamination section attached. Covering the material with laminating film can be done using three technologies: lamination, lamination, smooth lamination.

To produce this material, a hot press is used, the temperature of which is 160-220 degrees. Several layers of prepared paper and a mixture of different resins are applied to the chipboard, which, when heated, turn into a durable film and reliably protect the surface of the material.

Laminated particle board is available in various thicknesses. There are three options: 10, 16 and 18 mm.

Advantages

- High strength and durability.

- Wide range of colors, allowing you to choose a shade that matches the color of the case.

- Can be installed in confined spaces.

- Possibility of fastening in different ways: euroscrews, angles, eccentrics.

- it is very resistant to moisture and scratches.

Flaws

The only drawback may be the high cost of this material.

The price for installing laminated chipboard walls often reaches the cost of finishing the walls of the room.

Plywood

Plywood is one of the best but expensive materials for the back of furniture. It has a smooth surface that does not require additional grinding. The production process uses heat treatment and drying. Thus, the product retains its presentable appearance for a long time, does not dry out or become deformed.

Plywood is made from different types of wood, but the most popular raw material is birch.

Advantages

It has a uniform and durable structure, so it is used to make smooth, high-quality veneer. After giving the required thickness, the veneer sheets are glued together to form the well-known plywood. Sheets of this material for the back walls of cabinets are traditionally made with a thickness of 3 mm.

Types of fasteners

To hang a cabinet on the wall you will need reliable fasteners; hardware stores offer several types of these. They make furniture installation and dismantling simple and convenient.

It is worth paying attention to:

- mounting strips;

- furniture corners;

- special fittings with adjustment.

Mounting strips

A fastening element in the form of a longitudinal metal strip with holes ranging from 5 cm to 3 m in length. Fastening cabinets to a mounting strip is easier to do than to other types of fasteners, since you do not need to hold the entire structure suspended in order to mark the places for drilling holes. First, a rail is attached to the wall, its position is leveled using a level, and then furniture is hung on it.

Mounting for a wall cabinet has the following advantages:

- One person can handle the installation;

- high precision of furniture placement;

- Possibility of adjustment after hanging;

- notches allow you to set the length;

- there is no need for a leveling border;

- simplifies installation and dismantling.

Flaws:

- high cost of the set;

- due to the loose fit of the cabinet to the wall, a visually noticeable gap is formed;

- small objects lying above may fall into the space behind the furniture;

- high requirement for evenness of walls.

Furniture corners

The simplest fastening element in its structure is a small metal strip, bent in half, with holes on both sides. It is used for installation, fastening of wall cabinets, connecting them together.

During installation, you will have to use the help of a second person to help hold the cabinet while marking. You can attach corners to uneven walls or drywall. The disadvantage of a furniture corner is that you cannot adjust the position of objects, so the accuracy of drilling holes is very important.

Special fittings with adjustment

Externally, this hardware is a small plastic box with the heads of adjusting screws protruding outward and several holes for fixing. Some models of fittings are completely metal, which increases their reliability. In metal products, there are metal inserts around the holes that strengthen the mechanism.

How to make a wall with your own hands

The back wall of the cabinet is a simple part that does not require special care, so it can be done with your own hands. The main thing is to choose the right raw materials and decide on the method of fastening.

Next, you need to prepare several fragments from the selected sheet of material (you may end up with one). It all depends on how many furniture modules are needed to prepare the back side.

On a note! Cutting plywood, chipboard, fiberboard and other materials must be done strictly with a jigsaw. The fact is that when sawing with a hacksaw or a hand tool, uneven breaks occur and curved edges are formed. And this is not only not aesthetically pleasing, but also dangerous from the point of view of the further functioning of the structure.

There is an unpleasant smell from the back of the cabinet, what should I do?

In this situation, you can try 2 options:

- Treat the entire frame with Smelloff universal odor neutralizer. This product is safe for people and pets.

- If the first option does not help, you should replace the back panel with a new one.

How to remove nails from the back wall?

- If the nail head is exposed, you can pull it out using side cutters or a small nailer.

- If it is deep in the wall, first remove the plug with a wooden punch and then remove the nail with pliers. This method damages the material and will have to be replaced in the future.

- When the back of the fiberboard is overlapped, the best way to remove the nails is to carefully drive a flathead screwdriver between the fiberboard and the cabinet body, gently prying the wall away. The nail heads will be visible and you can remove them using the first method.

How to strengthen the back wall?

To strengthen the structure, it is enough to attach two narrow boards crossed to the back, which will cross the entire surface of the cabinet.

Facades

A wardrobe for a balcony can be with doors and drawers (cabinet fronts) or without them (open cabinet type).

The facade is the front part of the cabinet, its “face”. Doors should be beautiful, easy to use, not interfere with the passage of people and open in limited space.

The main types of facades for a cabinet (stand) on a balcony are: roller shutters (lifting mechanism), hinged doors made of laminated chipboard and hinged aluminum facades in white or brown. Doors made of laminated chipboard are installed only on cabinets made of chipboard. Roller shutters and aluminum facades can be installed on cabinets made of any material – both moisture-resistant and non-moisture-resistant.

A few words about cutting laminated chipboard

Cutting laminated chipboard panels at home is very difficult. And it’s not even that a lot of fine dust is generated (for the safety of workers, the workshop at a furniture factory is usually equipped with an exhaust hood). When cutting laminated chipboard with a hand tool, it is impossible to avoid chipping the laminate. To ensure a clean cut, the parts must be cut on specialized machines (a circular saw with one blade is also not enough).

In our company, parts for a cabinet made of laminated chipboard are manufactured in production, and only assembly is carried out on the balcony. During installation, parts are trimmed if necessary to fit them to existing unevenness or protrusions (for example: a protruding window sill, air conditioner duct, load-bearing beam of a building or crossbar, large floor slope).

The production of parts from laminated chipboard and gluing of PVC edges is carried out on specialized machines.

We do not practice delivering solid laminated chipboards to your home and cutting them on site.

How to strengthen the back wall of a cabinet?

Repairing the back of the toilet is not an idle question. Some people suggest nailing the back of the cabinets.

The advantage of individual models is that they can be disassembled, moved and placed anywhere.

Yes, this method allows you to do it quickly, but fastening the back walls of the cabinets in this way reduces the rigidity of the structure and its strength. In this case, the material of the body and the wall is destroyed, and in the future difficulties arise when disassembling such a product. The use of a stapler is also not recommended. It is best to use self-tapping screws with a washer.

The back wall of the cabinet, the material of which is laminated chipboard, is better in all respects, but also costs five times more.

If chipboard is used, then holes are first drilled to prevent the board from splitting, and then self-tapping screws are screwed in. Increases the rigidity of the entire structure and fixes sheets in selected grooves using a cutter in the end posts, cover and bottom of the product. In this case, it is important that the dimensions of the sheet being fixed match very accurately the dimensions of the room being closed.

Chipboard is a mixture of sawdust and resins.

Fastening is carried out around the perimeter:

- partitions and end walls;

- ceiling on top;

- at the base of the structure;

- to spacious fixed shelves.

They also differ in the degree of reaction to moisture, fire resistance, and exposure to sunlight.

MDF, chipboard and fiberboard - what are the differences and what is better

MDF is a fine fraction of wood from which furniture boards are produced by hot pressing. The material is relatively new and environmentally friendly. Unlike chipboard, it does not use formaldehyde or other adhesive components. Often these raw materials are purchased abroad, where safety standards are very strict. On the positive side, one can also mention the relative ease of processing the material, which allows products to have a more complex shape. The downside is the relatively high cost.

Chipboard is a chipboard made, like MDF, from wood waste and solid wood of relatively cheap species. This material has been known for a long time, since Soviet times, and remains loved by consumers for its durability and low cost. If properly treated, chipboard furniture will last for many years and will not fade or warp.

Fibreboard is a fibreboard produced from finely divided wood powder using the so-called “wet” method. The raw materials are impregnated and rolled out, then dried. The thickness of fiberboard is small, so in furniture this material is used only for the back walls of cabinets and the bottom of drawers.

Decor the back wall of cabinets and shelves with wallpaper

If you initially think that the back of the furniture will be glued “on theme” only in the same places as the walls of the room, then nothing like that! Don't limit yourself to such a banal solution.

The back wall of the cabinet can be decorated with any wallpaper of a similar color. If it is not in stock, look at the shelves for sale in stores and hypermarkets. You need fewer rolls and you don't have to spend much. Geometric patterns look especially impressive and win-win when pasting back walls.

In a classic living room interior, you can choose wallpaper with luxurious Provence or Baroque motifs for covering the open back walls of furniture. This will add atmosphere and a touch of luxury to the overall style of the room.

Fun wallpaper will make the room more cute and cheerful. Especially if the room is on the shady side.

The use of bright and cheerful patterns is appropriate not only in cozy kitchens, but also in bedrooms and children's rooms, wherever you want to enliven the interior and add a good mood to yourself and your loved ones.

Sources

- https://AmiPlus.ru/zona-otdyha/zadnyaya-stenka-mebeli.html

- https://m-strana.ru/articles/zadnyaya-stenka-shkafa-material/

- https://made-box.ru/details/kreplenie-zadnej-stenki-shkafa.html

- https://NuclearFactor.ru/zapahi/zadnyaya-stenka-shkafa-iz-chego-2.html

- https://lkard-lk.ru/dom/iz-chego-sdelana-zadnyaya-stenka-shkafa-vidy-materialov-ih-plyusy-i-minusy

- https://dom-naveka.ru/dom-stroj/chem-obshit-zadnyuyu-stenku-shkafa.html

- https://mebeltorgspb.ru/shkafy/iz-kakogo-materiala-sdelana-zadnyaya-stenka-shkafa.html

- https://12-stuliev.ru/shkafy/zadnyaya-stenka-shkafa.html

- https://VegaMebell.ru/dizajn/krepezh-dlya-zadnej-stenki-shkafa.html

- https://dom.sibmama.ru/drevesn-plity.htm