The textile industry has stepped far forward, and now housewives no longer have an urgent need to sew things on their own. This makes life much easier, but many craftswomen sometimes want to please themselves and loved ones with a set of sheets made of beautiful fabric, not factory-made, but hand-made. However, they cannot dare to do this. Often it is dissatisfaction with their own skills that prevents them from taking control of the matter, and then people turn to the studio. But today we will try to prove that sewing bed linen on your own is a feasible task, especially if you know how to make the necessary measurements, how much fabric is needed for bed linen, and what sequence of actions must be followed.

Sewing a bedding set from your favorite fabric is easy if you follow the instructions

Fabric calculation

Fabric consumption for a bedding set

Before sewing bed linen with your own hands, it is first of all important to carry out a number of manipulations: the most important thing is to take accurate measurements. They will help you correctly calculate the fabric for individual tailoring.

If you want to make a high-quality set of bed linen, approach the process with all care. Don’t skimp on the quality, and most importantly, the quantity of fabric (it’s better to have an extra scrap left than to collect pieces with scraps).

Layout for cutting a set on fabric 220 cm wide

In stores you often find ready-made sets of canvas with already calculated length and width (for standard sets this is approximately 2 - 2.5 meters). Consider the likelihood of shrinkage (especially after machine washing - about 5%), as well as the features individual to each individual material.

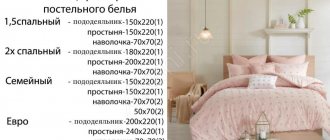

Table for calculating fabric yardage for bedding sets

Detailed step-by-step instructions for beginners. Part 1 (choosing a design, taking measurements, creating a pattern, calculating fabric consumption, preparing fabric for cutting and cutting)

The importance of healthy sleep cannot be overstated. We sleep for almost a third of our lives. During sleep, our body rests and recovers. Good sleep improves your mood, gives vital strength and vigor for the whole day. With regular lack of sleep, a person’s immune system weakens, frequent headaches appear, feelings of irritation and sudden mood swings arise, the risk of heart disease increases, apathy and depression sets in, performance decreases, the aging process accelerates, memory, attention and vision deteriorate.

One of the factors influencing the quality of sleep is good bedding made from natural fabrics. Today, manufacturers offer a wide range of bedding sets, differing in design, size, colors, materials, quality of tailoring and price. However, a standard factory product does not always meet our requirements. In this case, the ideal option would be to sew your own bed linen. A set of bed linen sewn by the golden hands of a caring housewife will be valued much higher than those bought in a store, and sleeping on it will be much more pleasant.

The benefits of making your own bed linen

1. Color

With all the variety of ready-made bed linen, there are much more colors of fabrics from which you can sew it yourself. Plain, in various colors and shades, matched exactly to the color scheme of the bedroom, with various designs, prints and patterns, with images on a variety of topics, two-color, with appliqués and other decorative elements - this is not a complete list of options possible when sewing yourself.

2. Size and completeness (number of items)

The size of bed linen directly depends on the size of the bed, pillow and blanket. In the industrial production of bed linen, standard sizes are used. Below is a table of standard finished bed linen sizes (excluding seam allowances).

Table of standard sizes of finished bed linen

If the bed and bedding have non-standard sizes, then custom tailoring easily solves the problem. In addition, sheets and pillowcases wear out faster than duvet covers, so when sewing a set yourself, you can adjust the number of necessary items yourself, whereas in ready-made sets the quantity is standard.

3. Fabric composition, quality of tailoring, consumables and accessories

It is no secret that some unscrupulous manufacturers sacrifice quality in pursuit of profit. When sewing bed linen, low-quality, sometimes synthetic, fabrics are used; to save time and consumables, the technology of sewing and processing seams is violated, low-quality products are not rejected. This leads to rapid wear and tear of the bed linen and, as a result, after a short time you have to incur additional costs for purchasing a new set.

When you sew your own bed linen, you are the one who chooses the fabric and threads, knowing exactly their composition, strength and density. Only you, and no one else, independently control the quality of tailoring and, if you make a mistake, you can easily correct it.

Today the market offers a huge selection of fabrics for sewing bed linen. Natural cotton and silk fabrics are considered classics for comfortable sleep: - chintz - soft, thin fabric, not particularly strong and durable, but well suited for sewing children's bedding or a set for a newborn; — calico is a dense, slightly rough material that, as a rule, does not lose color over time, but becomes softer during use, without losing its strength and wear resistance; - satin - soft and pleasant to the touch fabric with a slight sheen and good hygroscopic properties; - cambric - wears out quickly, but is light, soft, thin and flowing fabric; - flannel - soft and pleasant to the touch fabric is ideal for sewing children's bedding or a set for a newborn; — linen is a durable and safe fabric that does not cause allergic reactions in the body; - poplin - smooth, practically wrinkle-free, thin fabric of increased strength; - bamboo fabric - soft and smooth, absorbs and quickly evaporates moisture, has antibacterial properties; — silk is a beautiful-looking, smooth, hypoallergenic, highly breathable fabric.

4. Design

There are several options for sewing the components of a bedding set.

a) Bed sheet: - the classic model of the sheet is a straight sheet, processed along the edges. This model is well suited for all types of beds due to its versatility, since the margin at the edges makes it easy to tuck in the sheet. However, this option wrinkles and slides off during sleep; — a sheet with an elastic band or a fitted sheet is suitable for those who like to actively toss and turn in their sleep. Thanks to the elastic band, which can be sewn either around the entire perimeter of the sheet or only at its corners, the sheet is securely fixed to the mattress. However, this model is not suitable for sofas, and its size must exactly match the size of the mattress.

b) Pillowcase: - a classic version of the “envelope” pillowcase, with a flap or a wrap on the side or bottom, external or internal, without additional fasteners, easy to use and sew; — an Oxford pillowcase or one with “ears” has margins along the edges, which makes it look interesting, elegant and original; - a pillowcase with ties on one side is mainly used for decorative pillows, but can also be used for bedding; - a pillowcase with buttons on the side along the length or width, as well as in the middle, secures the pillow well and can become an original decorative element; - a pillowcase with a zipper on the edge (along the length or width) or in the middle, with or without a valve, is considered the most convenient way to secure a pillow in a pillowcase.

c) Duvet cover: - a duvet cover with a square, diamond-shaped or rectangular cutout in the center of the outer side that does not completely protect the blanket from contamination; - a duvet cover with a side cutout along the length or the short side, with or without a flap, without a fastener, fastened with buttons or a zipper is more practical to use.

5. Beginner to sewing

If you are just learning to sew, then sewing a bedding set is a great way to acquire initial cutting and sewing skills. The sewing process is quite exciting and not at all difficult.

6. Benefit in price

It is difficult to say how much more profitable sewing is compared to buying, since pricing is influenced by many factors, for example: - a clothing factory buys materials, tools and equipment in bulk, which undoubtedly costs it less than retail purchasing everything necessary for home sewing; — at the factory, a whole staff of employees works on one set of bed linen and they need to pay wages, while we spend only our free time on sewing; — not all garment factories work directly with the end consumer; accordingly, the initial cost of a factory set increases by the size of the intermediary’s markup.

Step-by-step instructions for sewing bed linen with your own hands

I. Choose (come up with) a design

After studying all the possible options, it’s time to turn on your imagination and come up with your ideal and unique bedding design for tailoring.

I will sew a two-color custom-sized set for a single (teenage) bed, consisting of: two fitted sheets with corner elastic bands, four pillowcases with a side hidden zipper with a flap for two pillows, and one duvet cover also with a side secret zipper with a flap.

II. Taking measurements

The process of sewing any product begins with taking measurements, the main purpose of which is to determine the dimensions of the finished product for further calculation of fabric consumption and construction of a pattern. The quality, appearance and correct fit of the finished product depend on the accuracy with which the measurements are taken. Measurements are taken and recorded in centimeters with rounding accuracy, in the case of bed linen, up to 1 centimeter upward. For example, if when taking a measurement the value is 17.52 cm, its value is rounded to 18 cm, and 17.22 cm is rounded to 18 cm.

To take measurements we will need: - a sheet of paper, a notebook or notepad for notes; - a pen or (better) a simple pencil with an eraser; - measuring tape (sewing (tailor's) centimeter); - bedding items that we will measure (mattress, pillow, blanket).

Prepare a table for taking measurements in advance, as shown below, and fill in the empty cells during the measurement process. A ready-made table for taking measurements can be downloaded under the article in the “Download additional material” section (the download link is available only to registered users).

* Increase for loose fit

necessary to give the product volume, ease of making the bed, and also to ensure that the fabric and seams during the operation of the product do not receive additional load, stretch or tear. Its size depends on additional elements on the mattress (bulges, piping along the edge, the presence of a mattress cover, zippers, etc.), the thickness of the pillow and blanket.

If you plan to sew standard size bed linen according to the measurements indicated on the tags, you should not trust the manufacturers and skip the process of taking measurements, since the actual size differs from the declared one, at least by the amount of increase for a loose fit.

a) Taking measurements of the mattress

We measure the length, width and height of the mattress, and record the results in a table. When taking measurements, make sure that the measuring tape runs exactly in a straight line, perpendicular to the edges of the mattress from which the measurement begins. In my case, the size of the mattress is 200x90x20 cm. I use a mattress cover with a convex pattern, which has a small thickness and a decorative edging along the edges 1 cm wide, so I add 3 cm for a loose fit. on each side in length and width.

b) Taking pillow measurements

The pillow, in addition to its length and width, has a thickness, which is quite problematic to measure separately, so it is better to take measurements along the circumference, straightening the pillow well, without pressing the measuring tape too hard.

We divide the results obtained in half, rounding up. I got 2 circles with a length of 96 and 136 cm. Accordingly, the size of the pillow is 48x68 cm. Taking into account the fact that when taking measurements we did not allow the pillow to be “tightened”, we add 1 cm for a loose fit on each side in length and width . We record the results obtained in a table.

c) Taking measurements of the blanket

Let's start measuring the blanket, taking measurements of length and width. Try to spread the blanket evenly on the bed.

In my case, the actual size of the blanket is 150x205 cm, although the manufacturer's tag indicates 155x215 cm.

It is worth noting that the blanket can be summer, demi-season or winter, and have different fillings, which affects its thickness. We adjust the thickness by using allowances for a loose fit. I have a winter blanket made of bamboo fiber, which is quite thick, so I add 3 cm to the loose fit on each side in length and width. We record the results obtained in a table.

III. Construction of a pattern (drawing)

After taking measurements, a pattern for the future product is created. Since bed linen does not have complex structural elements, the pattern will be drawn directly on the fabric before cutting, and to calculate the fabric consumption I will draw a drawing, that is, a pattern in reduced dimensions of 1:10 cm.

To construct a drawing we will need: - a table with measurements taken; — A4 paper; - a simple pencil with an eraser; - ruler and square; - calculator; - stationery scissors.

a) Drawing of the sheet

— build a rectangle with a width and length equal to the width and length of the mattress, in mm; — on each side we make an increase for a loose fit, in mm;

- on each side add a measurement equal to the height of the mattress, in mm. If you are sewing a classic sheet, then you should increase the height of the mattress only in width + add 5-10 cm to the fold of the sheet.

— in the “addition for decorative elements” column of the table with measurements, write down the added height of the mattress

b) Pillowcase drawing

The classic version of the “envelope” pillowcase without a fastener is sewn from one rectangular piece with 2 folds. In this case, the length of the rectangle = the length of the pillow x 2 + the size of the valve (equal to 1/2 the length of the pillow), and the width of the rectangle = the width of the pillow. To the resulting rectangle you need to add an increase on each side for a loose fit.

My pillowcases will be made from 2 fabrics of different colors with a small decorative flap of 2.5 cm, under which a zipper will be hidden. To construct a drawing of a pillowcase with a zipper: - draw a rectangle with a width and length equal to the width and length of the pillow, in mm; — on each side we make an increase for a loose fit, in mm;

- draw the bottom part of the pillowcase - a rectangle with a width and length equal to the width and length of the pillow + allowance for a loose fit + valve width x 2

— in the “addition for decorative elements” column of the table with measurements, write down the added valve size

c) Duvet cover drawing

A classic duvet cover without a fastener is sewn from one rectangular piece with a fold. In this case, the length of the rectangle is equal to the length of the blanket, and the width = the width of the blanket x 2. To the resulting rectangle, you need to add an increase on each side for a loose fit. For ease of tucking the blanket, a side hole is made along the length or width, equal to approximately 1/2-1/3 of the width of the blanket.

My duvet cover will be sewn from 2 rectangular pieces of fabric of different colors with a small decorative flap of 2.5 cm, under which a zipper will be hidden. To construct a drawing of a duvet cover with a zipper: - draw a rectangle with a length and width equal to the length and width of the blanket, in mm; — on each side we make an increase for a loose fit, in mm;

- draw the bottom part of the duvet cover - a rectangle with a length and width equal to the length and width of the blanket + allowance for a loose fit + flap width x 2

— in the “addition for decorative elements” column of the table with measurements, write down the added valve size

Next, you need to decide on the seams that will be used when sewing bed linen in order to calculate seam allowances. Now many sewing factories use an overlocker to process seams, while the seam allowance is 0.5-1 cm. This saves the consumption of fabric and time for sewing, but has a negative impact on the quality of the products. After several washes in the washing machine at high temperatures and spinning, the seams may begin to unravel and the threads at the edges may begin to fray. Even more unsuitable for sewing zigzag seams on a household sewing machine.

For processing free edges, a hem seam with an allowance of 2 cm is best suited, and for sewing two parts together, a hemming seam with an allowance of 1 cm on one part and 2 cm on the second. When sewing a classic duvet cover, you can use a double seam with an allowance of 1.5 cm.

Hem

used when hemming the free edge of products. The trimmed edge is folded to the wrong side by 1 cm, then folded again by 1 cm and stitched at a distance of 0.2 cm from the folded edge. As a result, the hem seam is 3 layers thick.

Covering (linen) seam

used when sewing two parts together. First, the parts are laid out so that the edge of the lower part protrudes by 1 cm and the first line is laid at a distance of 1 cm from the edge of the upper part. Then the edge of the lower part is bent by 1 cm, bent a second time by 1 cm, the seam is opened and the second line is laid at a distance of 0.2 cm from the fold. As a result, the sewing seam turns out to be 4 layers of fabric thick.

Double seam

used when sewing two parts together. The parts are folded with the wrong side inward. The first line is laid at a distance of 0.7 cm from the edge. The parts are turned inside out and at a distance of 0.8 cm from the edge (fold points) a second line is laid so that the raw edges of the product remain inside the seam. The finished seam is pressed onto one side, forming a thickness of 5 layers of fabric. (double stitching will not be used for the bedding I have in mind).

Having decided on the types of seams and allowances for them, we fill out the last column of the table with measurements and record the amount of seam allowance in the drawings.

Thus, we received the dimensions of bed linen with allowances for loose fit and decorative elements, as well as seam allowances: - fitted sheet - 250x140 cm; - lower part of the pillowcase - 54x78 cm; - upper part of the pillowcase - 52x74 cm; - lower part of the duvet cover - 160x219 cm; — the top part of the duvet cover is 158x215 cm.

A drawing of a classic bedding set with seam allowances will look like this:

From the finished drawings we cut out a number of parts equal to the number of items in the bedding set. In my version: - for 2 sheets - 2 parts; - for 4 pillowcases - 4 pieces each of the upper and lower parts; - for 1 duvet cover - 1 piece each for the top and bottom.

Now you need to shape the corners of the sheet. To do this, in the drawing, from the edges in the corners horizontally, we put aside a value equal to the height of the mattress, and vertically - the value of the height of the mattress + 1 cm. Thus, at the corners of the sheet we got 4 rectangles measuring 20x21 cm with ready-made seam allowances of 1 and 2 cm Cut out the resulting rectangles.

IV. Fabric consumption calculation

Linen fabric differs not only in composition, but also in the width of the rolls. Typically, store shelves offer fabrics with a width of 150 to 220 cm; wider ones are less common - up to 300 cm. Moreover, the price of wider fabric does not always increase in proportion to the increase in footage. Therefore, proper layout of the pattern on the fabric and accurate calculation of fabric consumption can significantly save money on sewing bed linen.

When laying out a pattern on fabric, it is necessary to take into account some features of the structure and color of the fabrics: - the length of the fabric consists of longitudinal threads (warp threads), and the width - of transverse threads (weft threads). For bed linen, the coincidence of the longitudinal and transverse threads of the fabric with the length and width of the product does not matter. When laying out a pattern on fabric, you only need to ensure that the parts of one product, for example, the upper and lower parts of the pillowcase, have the same direction of the threads;

- if the fabric has a characteristically pronounced pattern, the pattern should be positioned in such a way that the pattern does not move when sewing the seams;

There is another important point when calculating fabric consumption. All fabrics tend to shrink (reduce in size) when soaked, washed or steamed. Based on the amount of shrinkage, fabrics are divided into three groups: 1) non-shrinkable - shrinkage along the warp and weft up to 1.5%; 2) low-shrinkage - warp shrinkage up to 3.5%, weft shrinkage up to 2%; 3) shrinkage - shrinkage on the warp up to 5%, on the weft up to 2%. Depending on the composition, the presence of natural and synthetic fibers, the fabric can shrink significantly more. For example, cotton fabrics can shrink 5-10%. It is better to check the shrinkage percentage not on the Internet, but with the seller, immediately before purchasing the fabric. It is necessary to increase the estimated cut length by the amount of shrinkage!

According to my standards, in order not to make additional seams in the middle of the products, fabric with a width of 160 or 220 cm is suitable. I take colored paper of the same width on a scale of 1:10 and begin to lay out patterns on it to determine the required length of the fabric cut.

The process of laying out a pattern on fabric is a bit like putting together a puzzle. The patterns are laid out, rearranged, and swapped until their optimal placement is found.

For a two-color bedding set, with a fabric width of 160 cm, I need 2 pieces of different colors, 569 and 577 cm long. +% for fabric shrinkage. Taking into account possible weft shrinkage, a width of 160 cm is not enough, and you may have to buy fabric 180 cm wide!

For a two-color bedding set, with a fabric width of 220 cm, I need 2 pieces of different colors, 408 and 410 cm long. +% for fabric shrinkage. There is also a small amount of fabric left for shrinkage along the width of the upper parts. The valves of the lower parts of the pillowcases and duvet cover, if the fabric shrinks in width, may have to be moved to the other side; accordingly, the width of the valve (5 cm) will need to be added to the length of the cut (410 + 5 = 415 cm).

V. Selecting fabric and consumables, preparing fabric for cutting

To sew a two-color bed linen set, consisting of 2 fitted sheets with an elastic band, 4 pillowcases and 1 duvet cover with zippers, I chose: - 2 pieces of calico 220 cm wide, 430 and 440 cm long (with taking into account possible shrinkage of 5%); - elastic band (elastic band) size 4x300 cm; — 5 hidden zippers, 50 cm long, in the color of a lighter fabric; — 2 spools of reinforced (lavsan-linen) threads in the color of the fabric, which have high elasticity, strength and wear resistance, as well as 1 spool of white threads for basting parts.

Before cutting, the fabric must be prepared:

a) Carry out decatification or WTO (wet heat treatment) - wash in the mode recommended by the manufacturer and iron, preferably with steam. During ironing, the surface of the fabric is carefully examined to identify defects (mechanical damage, knots, uneven coloring, etc.). During WTO, the fabric shrinks, which we cannot foresee in advance and take into account when creating the pattern. After the WTO, the actual size of the fabric turned out to be: - light fabric width - 215 cm (taking into account the edge, which I will not cut off), with the manufacturer initially stating 220 cm and length - 432 cm, although I bought fabric 430 cm long. By the way, the increase in the length of the fabric during the WTO process occurred not because the material stretched, but because the seller measured inaccurately and cut 8 cm more (it’s good that he made a big mistake!); — dark fabric with a width of 214 cm (taking into account the edge, which I will not cut off), with a length initially declared by the manufacturer of 220 cm, and a length of 438 cm, with an original length of 440 cm. They say that calico practically does not shrink. It turns out that it does! Moreover, different pieces of fabric of the same composition, in my case, gave different percentages of shrinkage. I won’t buy more material, this amount is enough for me. I foresaw the likelihood of this situation in advance in my calculations. Now you just need to make adjustments to the drawings of the lower parts of the pillowcases and duvet cover, moving the valves (taking into account the seam allowance) to the other side. As an option, you can completely abandon the valves, leaving only hidden zippers, but sleeping on such underwear, in my opinion, will not be comfortable.

[center] [center]

b) Determine the front and back sides of the fabric. Sometimes this can be quite problematic. There are several ways to determine the front side of linen fabric: - the front side of multi-colored fabric is usually brighter, and the pattern itself is richer and clearer; - in smooth fabrics, the backing is more fluffy, which is determined both tactilely and visually; — minor defects (thickening or elongation of threads, knots, stamps, etc.) are displayed on the wrong side; - some plain fabrics have colored threads on the edge on the front side, which are practically invisible from the back; — most fabrics have punctures along the edges, which are made in production from the wrong side to the front. On the front side they are convex, and on the back side they are concave. This can be determined visually, or by running your finger along the edge of the fabric, feeling the bulges from the punctures; - the fabric can be double-faced.

I have a plain fabric that does not differ in color on both sides, there are no punctures on the edge, so I choose the wrong side based on the presence of defects. I mark the wrong side in several places so that after cutting I don’t mix anything up. Marks are made using any device for cutting fabric (chalk, water-soluble pencil or fabric marker, soap, aspirin tablet). I sometimes use masking tape if the fabric is not fuzzy, knitted or delicate.

Never use a ballpoint or ink pen, simple or colored pencils, felt-tip pens, markers or other stationery to mark fabric. The mark will be printed on the front side and cannot be washed off.

c) Align the cross section of the fabric if necessary. According to production technology, the transverse thread must run strictly perpendicular to the lobe thread. Accordingly, by pulling out the transverse threads, you can align the sections of the fabric. However, manufacturers sometimes violate production technology, and the transverse threads are skewed. You can try to straighten the cut by pulling the fabric diagonally, or you can use a square: fold the fabric in half lengthwise (face inward), align the edges, apply the square to the edge, draw a perpendicular line and cut off the uneven edge. It is better to cut fabric with special tailor's scissors, and the lower end of the scissors should not come off the table surface. Under no circumstances should you cut fabric while it is in weight - warping cannot be avoided!

The fabric is ready for cutting.

VI. Cutting fabric

For cutting we will need: - a measuring tape, which was used to take measurements from the bedding. It is with this, and not with a ruler, that we will measure the required amount of fabric. Why not a ruler? Because the measuring tape can stretch during use and the value of 1 centimeter on it and on the ruler may not coincide. With large sizes of garments, such as bed linen, seemingly minor differences can significantly affect the size of the finished product; - ruler and square; - crayons or markers for marking fabric; - tailor's pins; - iron; - tailor's scissors.

I don’t have a special cutting table, so I’ll be cutting on the floor. It is more convenient to cut fabric folded in 2 layers lengthwise with the right side inward. With my size of bed linen, the fold will not be in the middle of the fabric, I will make 2 folds: in the middle of the sheet and pillowcases.

When cutting bedding pieces onto fabric, the main difficulty is creating clear fold lines due to the large amount of fabric. To overcome difficulties: - on the wrong side of a piece of fabric along the entire length parallel to the edge (at a distance of approximately 30-40 cm), measure and mark 1/2 the width of the sheet on one side, and 1/2 the width of the pillowcase on the other;

— bend the fabric face inward at the marks and pin it with tailor’s pins; - Use an iron to form clear and even fold lines.

Before cutting out parts from the fabric, carefully check again that the markings are applied correctly.

If you, like me, sew a fitted sheet with an elastic band, do not forget to cut the corners as indicated in the drawing.

After cutting out the parts on the fabric, apply seam allowances to them according to the drawings. In places where an allowance of 1 cm is provided, we mark one line at a distance of 1 cm from the edge, and where an allowance of 2 cm is provided - 2 lines of 1 cm from the edge.

The cutting stage is over, you can start sewing.

VII. Sewing bed linen

The process of sewing bed linen in the article “Do-it-yourself bed linen set Part 2”

Calculation of fabric for children's bedding

Let us illustrate more clearly with an example of sewing children's bedding. Let's take a mattress 90 cm wide and a pillow measuring 60 cm by 60 cm.

We calculate the canvas.

- 1 sheet - you will need approximately 120cm x 2. If you want to tuck the edges under the mattress, add a little more padding around the edges. The pass is calculated based on the height of the mattress.

- Duvet cover - raw materials are calculated based on the size of the blanket under which it is actually sewn. It turns out: for a 1.2 m blanket you will need - two widths + 10 cm allowance + 10 cm for shrinkage + 10 cm so that the blanket is free = 2 m 70 cm + 10 cm seams.

- 2 pillowcases – their size remains the same as the size of the pillows + 10 cm, leave seams sewn and another + 10 for shrinkage. Cut the pillowcase along the material to make the process more economical.

By summing up all the necessary measurements, we will get the exact amount of fabric that will be needed in the process of sewing a bedroom set. It’s better to protect yourself - buy with a reserve in order to avoid troubles later.

Elements of children's bedding - cut to a fabric width of 150 cm

How much fabric do you need to sew a double bedding set?

To sew a standard double set, you will need:

- for duvet cover – 200/200; 180/210; 180/210;

- sheets – 175/210; 200/220; 210/230;

- sewing pillowcases – 50/50; 60/60; 50/70.

Let's calculate the amount of fabric needed.

To sew a duvet cover measuring 180 by 180, fold a piece of fabric in half + 5 cm allowance = 365 cm.

Cutting sheet 200 cm + 5 = 205 cm.

For pillowcases – 125 cm.

In total, you need 6m 95 cm to make the entire set.

Layout of the cut with seam allowances and fabric shrinkage for a double set

Nuances: size and processing of the cutout edges on the duvet cover, sewing in zippers, etc.

Duvet cover with zipper

There are several options for placing the cutout on the duvet cover - in the middle, on the side or at the bottom. To prevent the blanket from falling out, you can sew in a zipper or sew on buttons. The simplest option is to place the slot at the bottom. In this case, when sewing the desired side of the product, it is enough to leave the center unstitched and finish the edges with a hem seam with a closed cut. The standard length of the side cutout is 60 cm.

The zipper is sewn in before the edges of the duvet cover are sewn down. It is placed exactly in the middle, basted so that the fittings are not visible from the front side, and then stitched on a machine using a special foot. Instead of a zipper, you can use buttons.

If you choose the option of locating the hole in the middle part, you need to decide on its shape - circle, square or rhombus. The standard diameter or diagonal is 45 cm, but this figure can be changed up or down depending on the size of the duvet cover and personal preferences. Mark the center of the canvas and draw a frame relative to it. Edge the edges with bias tape. If desired, the set can be decorated with lace, braid, embroidery or appliqué.

How much fabric do you need for a Euro bedding set?

For a luxury set you will need approximately:

- duvet cover - 220/240; 215/225; 200/220;

- sheet – 220 x 240; 220 x 250; 215 x 240;

- pillowcases – 50 x 50; 50 x 70; 60 x 60.

We calculate the amount of production fabric.

Duvet cover – bend the fabric so that both pieces are 240 + 5 cm each.

Sheet – 245.

Pillowcases – 115.

In total, it turns out that to make a euro headset it will cost 8 m 45 cm of good quality fabric.

Layout of the cut with seam allowances and fabric shrinkage for the euro set

Several recommendations for choosing material

Bed fabric with a cherry blossom pattern

Sewing a sleeping set with your own hands gives you the opportunity to choose any fabric you want (even the cheapest - as long as you like it). However, it is important to remember that these pillowcases and sheets are for the purpose of sleeping on them; imagine what a dubious pleasure it is to “sleep on kitchen towels.”

Basic requirements for fabric.

- Softness, pleasantness, comfort - it simply needs to be suitable for sleep, as well as accompany its normal course.

- Natural - synthetic - the worst thing you can choose for sewing bed linen. Give preference to breathable, natural materials (silk, calico, cotton) that will retain heat in winter and provide normal ventilation in summer.

Natural fabric for a bedding set is the key to a sound, healthy sleep. They will not harm children's health; easy to handle; affordable.

What you need

Why bother sewing sleep accessories yourself if the times of shortages are over, and in stores you can easily find a bedding set for every taste and budget? It's easy to answer this question:

- You can choose the color and quality of material as you wish. It is more difficult to evaluate these parameters in ready-made kits. For example, it is unknown what the bedding will look like after the first contact with water, powder or iron, but the fabric for sewing can and even should be washed and ironed before cutting. And nothing stops manufacturers from writing whatever they want about the composition of the material on the packaging, raising the price of the set higher because of the supposedly natural fibers.

- The duvet cover is the exact size of the duvet. Ready-made bedding sets are not convenient for everyone. You can sleep on a wide double bed, but cover yourself with a one-and-a-half-length blanket, or lie on a narrow sofa, wrapped in a Euro-size duvet cover. In such cases, the simplest and most economical option is to sew all the components yourself, according to individual measurements.

In addition, you can equip any set with additional products that are not provided in ready-made kits. For example, sew two duvet covers at once if they get dirty faster than sheets and pillowcases, and simply change them as needed, without redoing all the linen.

So, to figure out how to properly sew a duvet cover, you first need to prepare everything you need. This is about:

- matter;

- matching threads;

- scissors;

- a measuring tape and a long ruler;

- pins;

- chalk or a piece of soap for marking fabric;

- sewing machine;

- iron and ironing board.

You also need to take care of a large, flat surface on which it will be convenient to cut the fabric. Considering the size of the duvet cover, it is better to use a wide bed or the floor in the largest room for these purposes.

If you make a mistake when buying threads, the bedding will turn out to be fragile, even if you sew it from the densest and most durable fabric. After several washes, the duvet cover will simply come apart at the seams, reducing all efforts to nothing. And the sewing process itself will be seriously complicated - low-quality threads get tangled, tear and do not fit well on the fabric

Experts recommend giving preference to manufacturers Durafix, PolyStrong and Confil, and paying attention to the markings indicating the composition of the fibers and the thickness of the threads

It is also important to decide on the fabric. Duvet covers, even with daily use, take less stress than sheets and pillowcases. But this does not mean that material of poorer quality is suitable for them.

It will be very disappointing if, after several washes, the duvet cover fades, stretches in the corners or shrinks, no longer matching the size of the blanket

But this does not mean that material of poorer quality is suitable for them. It will be very disappointing if, after several washes, the duvet cover fades, stretches in the corners or shrinks, no longer matching the size of the blanket.

The material that is ideal for bedding sets should absorb moisture well and allow air to pass through. This means being completely natural. Hypoallergenicity, pleasant sensations from touching the fabric and ease of care are also important. Therefore, cotton fabrics are most often used for sewing duvet covers:

- chintz;

- satin;

- calico;

- percale;

- mahra.

In recent years, fabrics that combine the best qualities of natural and synthetic fibers have become popular. For example, polycotton is a mixture of cotton and a small amount of polyester, thanks to which the material becomes more durable and wear-resistant, does not deform, does not shrink and does not require ironing. It is thanks to the combination of different types of raw materials that it becomes possible to sew bed linen from flax, which in its pure form is rarely used for such purposes due to its rigidity. But by mixing linen fibers with cotton or bamboo, you can get fabrics that are pleasant to the touch, breathable and hypoallergenic, under which you will sleep comfortably in both winter and summer.

Threads for bed linen

Modern manufacturers offer a large selection of durable, reliable and good threads

They are also recommended to be given due attention. Correctly selected thread strength, thickness, density, and their color matching to the selected material will ensure the quality of your finished work.

The market offers a wide range of different threads: from ordinary cotton to silk or even the finest gold. For sewing, the following will be the best.

- Polyester threads "Durafix".

DURAFIX sewing threads made in Turkey - Professional threads made of high-strength polystrong.

- Capitone threads - suitable for all occasions; weightless but durable, they perfectly hold even dense samples together.

Threads are often marked with the following marks: LH - linen cotton; LL – flax lavsan. The numerical designation indicates the thickness of the thread.

Threads made from synthetic materials (for example, 100% polyester) have much higher parameters than natural products. They are much stronger, less likely to delaminate, and the tension coefficient is also much higher. A high-quality thread is easy to recognize by eye: its structure is even and smooth. The stitching with these threads is neat and smooth.

Patterns for sewing sleeping linen with your own hands

We cut the sheet to cover the entire width of the fabric, and calculate the length using the formula: length of the mattress + 20 cm

We make the length of the duvet cover to cover the entire width of the fabric, and calculate the width of the duvet cover using the formula: the width of your blanket + 6 cm (shrinkage allowance) + 1.5 cm (seam allowance) x 2

Cutting is the second, but not the most important, stage, the stage after taking measurements and establishing the required size of the canvas. Here you are required to apply maximum care, since it is very important not to cut off too much, otherwise it will no longer be possible to correct it. Next, we will give some tips to optimize the sewing process as much as possible and avoid damage to expensive brocade through your own efforts.

A piece of fabric for pillowcases 50 by 70 cm = (50 cm x 2 + 25 cm (at the hem) + 5 cm (seam allowances))

Piece for pillowcases 70 by 70 cm = (70 cm (side) x 2 + 25 cm (at the hem) + 5 cm (seam allowances))

Pillowcase

Many needlewomen have already encountered sewing pillowcases back in school during labor lessons. The principle of sewing is distinguished by elementary actions and the preparation of a whole pattern with a wrap. Usually the sketch looked like this:

Standard pattern for pillowcase

The pillow was placed in the “pocket” of the pillowcase and fixed inside with an overlap in the form of a strip of fabric, the so-called wrap. But there are also more modern options for sewing pillowcases, where the place for threading the pillow can be hidden and located in different parts of the product, for example, on the side.

Master class on sewing a pillowcase with a hidden hole for the pillow:

Pattern of a unique pillowcase

- Lay the fabric out on a flat surface.

- Transfer to the canvas the measurements that will correspond to the size of the pillow.

- You need to form 2 parts that will be identical to the shape and size of the pillow. Don't forget about the seam allowance (+4 cm).

- Finish all cuts with an overlocker.

- Place the pieces right side together and sew them together using a linen stitch.

- The procedure is performed from 3 sides. The fourth will become a hole for the pillow. Here you can sew in a zipper or sew on buttons.

The principle of creating a linen seam

Additionally, you can decorate the pillowcase with ruffles along the perimeter of all side seams. You need to prepare 4 strips of fabric. The width is determined arbitrarily, and the length corresponds to the sides of the pillow +20 cm. Overlap all the cuts on the strips. Using safety pins, attach the padded strips in some places to one of the pillowcase pieces. Sew on the detail.

How to approach the process correctly?

- Before you start cutting, iron the fabric thoroughly (preferably with steaming). This way you can smooth out unnecessary wrinkles, unevenness, and perform initial shrinkage - believe me: this will make the process much easier.

- We mark the necessary notes. It is best to use chalk or a flat piece of white soap (soap). If you don’t have them, aspirin tablets will come in handy. It also distinguishes perfectly and washes without problems.

- To avoid inaccuracies, it is important to duplicate each mark on both edges.

Let's sum it up

This floral set seems too simple, but made with love by your own hands, it will delight you every day

If you resort to sewing a sleeping set yourself, then nothing can limit your creativity, inspired by a flight of fantasy and creativity. The main thing is not to forget about the practical side of the future product, because this underwear should constantly please the eye, but also “calm” the body and give rest during sleep. Choose the material wisely, follow the instructions and you will certainly succeed!

How to sew a duvet cover for 1.5 sleeps, 2 sleeps or for children - sizes

Dimensions

Dimensions

Reasons why it is better to sew a duvet cover with your own hands rather than buy it in a store:

- You have a non-standard blanket.

- You find it difficult to choose ready-made duvet covers because you don't like their fasteners or sizes.

- Are you tired of squeezing your blanket into a duvet cover that's too small or too big?

- You want exclusive bedding.

- You want to save some money.

If at least one of these reasons is yours, feel free to start sewing, remembering to measure seven times and cut once. In fact, there is nothing easier than sewing two rectangles and figuring out what the fastener on the duvet cover will be.