The ceiling is not only a part of the room that limits it from above, it plays an important role - it determines the overall appearance of the room and makes it cozy. If designed correctly, it can visually increase or decrease the space and divide it into functional zones. The mood of the household and the impression that the guests have when visiting largely depends on the chosen decoration, which can both darken or give a solemn look to the interior.

It is necessary to finish the ceiling very carefully, since it is always in sight and the slightest flaw or defect will be noticeable. The construction market offers a huge selection of building materials, the use of which will allow the surface to match any design. The ceiling panels, which occupy a huge niche, deserve special attention. They are popular and are an excellent alternative to old-fashioned wallpaper, plaster, and drywall.

Plastic panels

Plastic is often used for finishing work inside and outside buildings. This is due to its excellent performance properties coupled with a low price. Plastic panels differ from other finishing materials for ceilings in the thickness of the strips.

For indoor decoration, thinner sheets are used. They also have niches located inside between the stiffening ribs, making the structure lighter, and also have spikes for fastening, so that they can be firmly secured to each other and to the frame. The blanks are attached to a pre-made frame of supporting profiles.

Advantages of PVC panels

Plastic panels have many advantages, we will provide the main ones:

- Such panels resist moisture well;

- Simple installation process;

- Due to them, you can create good noise protection for the ceiling;

- The ceiling area will not need to be trimmed or applied with any special compounds in advance.

The aesthetic appearance of these panels may vary - some manufacturers produce material similar to wood or painted in different colors.

This allows them to be used in different rooms: loggias, bathrooms, offices or other public institutions. For a children's room, bedroom, kitchen, it is recommended to choose a more natural material for the ceiling, which will be good from an environmental point of view.

Current design ideas

Plastic panels or products made from other materials are successfully used for arranging various rooms.

MDF panels. The models are created from wood waste using the hot pressing method; the material contains no toxic impurities. Safe products are even used for cladding a children's room; the appearance of the material is improved by a decorative film decorated with an unusual pattern or imitating various textures.

If the panels are laminated, they can be easily wiped with a damp sponge; installation is carried out using platbands and corners.

Based on wood fiber boards. Cheap fiberboard panels made by hot pressing are superior to MDF models in thickness, and are slightly inferior to them in performance characteristics.

Based on particle boards. The products are made from shavings with sawdust, but the composition contains binders that cannot be called environmentally friendly. Chipboard is afraid of moisture; the model is best used for cladding non-residential premises: hallways and corridors.

Wooden. Aesthetic panels bring nobility and prestige to the interior; the cladding material is expensive wood veneer; an additional effect is created by mirror inserts, natural shades, carved elements and gilding.

Cork. Manufacturers produce these panels mainly in two layers. Pressed cork chips are at the bottom; pieces of cork oak bark are added to the top layer. The panels improve sound and heat insulation, they are durable and are not susceptible to mold.

Plastic. PVC panels can be used in any room: they are environmentally friendly, fireproof, and moisture resistant. Easy installation of wall panels is an important advantage; every craftsman can do the cladding with his own hands.

Bamboo panels are exotic products; they are used to decorate interiors in African, country or ethnic styles.

3D panels. The products have a three-layer structure; on top there is a decorative and reinforcing layer, which gives high strength to the structure.

Glass. This is a popular new product on the market of facing materials; its popularity is explained by its excellent resistance to moisture or other external influences.

How to choose ceiling panels

Here's what is important to pay attention to when planning to purchase plastic panels:

- For thickening and weight of the product. Here we need to take into account the design of the raw materials. The material is made of two walls, with several rows of horizontal ribs inserted between them. The outer side of the panel should be thicker, because loads may be placed on it.

- Number of ribs. The greater their number, the stronger the casing will be. But it’s worth taking a closer look at the location of the ribs. They should be located radially to the panels. When they are tilted, this means that the material was stored incorrectly, for example, the packages were laid in such a way that the upper packages squeezed the lower products. Therefore, the strength of the panels is low.

- The tenon connecting the lock to the groove must have density;

- Cost – don’t assume that you can buy quality products for less money. It is recommended to purchase from the middle price range.

When there is little experience in installing the material, then it is better to use an expensive option that will be easier to install.

Calculation and preparation

Aesthetic panels on the ceiling are mounted using two methods: directly on the surface using an adhesive composition and on a specially constructed frame using fasteners. In the second method, there is no need to prepare the ceiling. Sound and thermal insulation can be attached to the ceiling space.

Tools required for work:

- Hammer, tape measure;

- Hammer or drill;

- Construction gun for fastening panels;

- Metal scissors;

- Screwdriver;

- A small-toothed hacksaw or electric jigsaw.

Before purchasing panels for the ceiling, you should calculate the area of the room; to do this, you need to multiply its length by its width. The resulting number is divided by the area of 1 panel - this definition is written on the packaging.

It is recommended to add 15% to the calculated amount and round towards the larger number. This way the segments are counted. You also need to calculate the number of parts for the sheathing.

However, it’s not so difficult with them, if you can’t get the profiles, you can still buy them, but panels of the same type may not be available in the store. In addition, the material from different batches differs slightly in shades. If a wooden sheathing is installed, it must be impregnated with antiseptics.

Installation methods

You can decorate the ceiling with panels of various types. Before starting work, all your actions must be carefully planned. It should be noted that products may differ in thickness, width, appearance of the front part, and fastening features. There are several ways to attach structures to the ceiling:

- Cassette suspension. Decorative modules and various profiles are mounted simply and quickly on pre-prepared guide rails;

- Rack mounting. Installation is carried out on a special frame. Rack profiles are adjusted to size. Lean it against the ceiling and snap it into place with the tire fasteners;

- Gluing. The method is suitable for lightweight polystyrene, laminated, extruded boards. For fastening, it is better to choose special compounds, but simple PVA or Moment glue will do. You can create the effect of a seamless ceiling by treating the joints with silicone sealant;

- Tongue-groove system. With the help of a locking connection, the elements are easily and reliably joined, creating a smooth surface. They are mounted on a wooden sheathing. Installation does not require leveling the walls. The mounting method is suitable for plastic and MDF models.

Frame installation

The first thing to do is find out the lowest corner in the room. To do this, the height of the ceiling is measured at the corners. In that corner there is a 5 cm deviation from the ceiling. From this point, using a laser level along the perimeter of the walls, lines are drawn on which the profile guides will be fixed.

- Now you need to cut and secure the profile to the ceiling. It is cut to the width of the room and mounted orthogonally from the wall of the room.

- Here you need to take into account that PVC panels are installed along the room. That is, orthogonal to the wall with the window.

- After all, this way you can prevent the joints between the panels from being visible. When the room is large, first markings for hangers are drawn on the ceiling.

They are mounted and secured to the base of the ceiling with self-tapping screws on plastic dowels. Then the profiles are installed clearly horizontally. The frame must be assembled in one horizontal plane. Here the ceiling profiles with their edges should fit into the guide profiles. At this stage, the frame is already prepared.

Peculiarities

The use of panels for finishing allows you to quickly update the ceiling in a house or apartment, while the costs associated with repair work will be minimal. The finishing material consists of slabs of various sizes. Based on the method of fastening, they can be divided into two main groups:

- The elements are mounted directly to the ceiling. The connection to the surface occurs by gluing the plates to it. Such options include foam plastic, polystyrene, and individual PVC strips.

- Installation is carried out on a pre-prepared frame and sheathing. This group includes aluminum, MDF, metal, and plastic panels.

Panel ceilings are found everywhere. This is due to the fact that using building materials, you can give the room the necessary style, combine the type of ceiling with the selected floor covering and wall decoration, and merge with the overall interior of the room.

Installation of plastic panels

You need to start by installing a starting profile. It is attached directly to the wall, and secured to the frame with small self-tapping screws at intervals of 15-20 cm.

- This component is fixed along the entire length of the wall. Next, the first panel is cut and secured to the frame. Fastening is carried out in the groove of the panel.

- Thus, the head of the screw will not peek out, since it will be covered by the tenon of the second panel. In the same way, the second panel is inserted into the groove with a tenon.

- You need to secure it in the groove and at the second end of the panel. According to this principle, you need to install everything to the last panel. The last element is not attached to anything.

Also, this panel is often wider and therefore it is cut to the required width. The edge is inserted into the starting profile, which is mounted there in advance, then it is bent and the second edge is inserted with a tenon into the groove of the penultimate plank.

Foam ceiling tiles

Foam tiles are materials for ceiling finishing that have not lost their relevance and popularity. This is due to their low cost, simple fastening and excellent decorative capabilities.

- Often, foam panels come in white with patterns and designs on the front.

- It can be painted in the desired color. In order for the panels to look on the ceiling as a single whole, you need to purchase models without seams.

Installation of foam tiles is done using liquid nails. In this case, there is no need to save money, because the better the glue, the stronger the elements will stick to the ceiling.

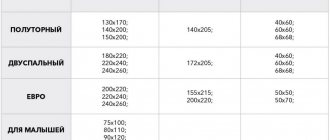

Possible sizes

Depending on the type of panels, lamellas are available in different sizes.

The lining has a length of 3 meters and a width of 10 cm. The reinforced one is slightly larger - 12.5 cm.

The dimensions of plastic panels for ceilings without seams are as follows:

- length 260, 270, 300, 400 or 600 cm;

- width - 10, 20, 25 or 50 cm.

The largest are leafy: length 150-400 and width 80-200 cm.

Peculiarities! The maximum dimensions are used for spacious premises (such as industrial facilities or garages for several cars). In ordinary apartments, plastic lining or panels no longer than 300 cm are installed.

The thickness of all products is within 5-10 mm. For a suspended ceiling, thinner ones are usually used. But you need to be careful with them - this material is less durable.

MDF panels

This material is made from wood chips compressed at high temperatures with resins. Considering that wood is considered a completely ecological material, this type of finishing is very suitable for decorating living rooms.

Manufacturers often produce this material taking into account moisture resistance, which makes it possible to use it in offices and bedrooms, as well as in kitchens and even bathrooms. Such panels have an attractive overall appearance.

Tips for choosing

The variety of types and shapes of panels makes their choice difficult. First of all, you should decide on the material of manufacture. It should match the overall interior of the room, wall and floor decoration. In order for the structure to last for a long time, the choice should be made taking into account the characteristics of each type:

- Plastic plates must be smooth with a clear geometry and uniform distribution of the pattern. To ensure sufficient strength, the element must be squeezed with force with your fingers;

- Wooden products should not have cracks or chips. For each type of wood, small errors are acceptable, which reduces their cost. But it is better to use elements with a clear pattern, without burrs, scratches, or blue stains;

- Foam blocks should be selected only with a smooth, clear, identical pattern over the entire surface. High-quality tiles do not break when dropped or lightly shaken;

- 3D panels have various characteristics and features. When giving preference to this type of finishing, you should take into account the purpose of the room. These can be natural models, fireproof, moisture resistant;

- Aluminum parts must have a minimum thickness of 0.5 cm. If they are thinner, the structure can quickly deform at the initial stage of operation.

Armstrong construction panels

This type of suspended ceiling consists of a frame with honeycombs in the form of squares, and slabs are built into them. Plates for these ceilings come in hygienic, economy segment, moisture-protected, designer and acoustic types.

Even the cheapest options look beautiful in public spaces and their performance characteristics are also of good quality.

Examples of application in the interior of an apartment/house

Classic cassette panels made of natural wood always remain stylish. Even an inexpensive analogue will look beautiful and aristocratic. The slatted finish in light colors will fit perfectly into the Scandinavian style and minimalism. This interior is suitable for a small apartment or a spacious country house.

Acrylic tiles will look good in any room. This is a universal material for the bedroom, toilet, kitchen, hallway. Economical plastic and wooden lining will create a beautiful, smooth ceiling, even on an uneven surface. The white foam finish will fill any room with light and lightness. Using ceiling panels, you can create a surface in a restrained, classic style or assemble a complex multi-level structure with designer lighting.