Many, having lived in a new private house, begin to realize that they chose the wrong material for its construction. This leads to a search for solutions that can help radically change the interior space and exterior decoration of the cottage. Imitation of timber helps to quickly solve this problem - it looks great in the interior, wood has always helped create coziness and comfort. The article will discuss what properties the material has, how to choose a color-matching finish and completely transform your living space.

Imitation timber helps completely transform your living space Source homify.com.mx

Types of imitation timber for interior decoration

Nowadays, manufacturers use coniferous wood, less often larch, to make imitation timber. In terms of external aesthetics, the material is very similar to ordinary wooden blocks, but it has a larger width (up to 180 mm) and a small thickness. You can verify this by looking at the photo below.

Such characteristics allow you to use material economically and not eat up precious cm of room space.

The interior decoration of a house made of timber comes in two types.

Monolithic

Monolithic - this type of DIY finishing of a log house got its name due to the density and uniformity of the base cladding created with its help. It is used for walls, floors, ceilings of private houses, as in the interior in the photo below.

The main advantage of monolithic finishing is its high protective properties for the base, which is completely hidden under the cladding.

But its installation is somewhat complicated, and without certain skills, doing it yourself can be problematic;

Combined

Combined - if you started building a timber house with your own hands, you should think about combined interior decoration of rooms with imitation timber. This design has an unrivaled look, as evidenced by the photo below.

But it is used for incomplete finishing of the room, but for creating original combinations with wallpaper, ceramic tiles or textiles.

In cases where both types of imitation timber are used, it is mandatory to select decorative components that give the interior of the room logical completeness, integrity, and individual character.

This refers to all kinds of moldings, mansoles, cornices, balusters, decorative overlays, balustrades, and wood corners.

How to choose the right one

While it’s easy to figure out the dimensions of the panels, it’s important not to rush in terms of selecting their other parameters. The material for the manufacture of panels is selected based on the purpose of its use and the specific microclimate in the room:

- made of larch - suitable for any interior space. Indicated for people suffering from asthma and problems with the respiratory system;

- made of oak demonstrate high resistance to moisture and mechanical stress, ideal for use in a child’s room, gym, kitchen;

- made of coniferous wood are characterized by a high resin content, therefore they should not be used in rooms with elevated temperatures (kitchen, bathhouse, bathroom).

What is this finish?

To imitate timber, a board with a beveled edge is used, very reminiscent of the lining familiar to everyone. Even the method of connecting individual parts will be similar - the tongue-and-groove system.

To produce such imitation boards, wood of different species is used. This significantly affects the pattern that adorns the outside of the boards. When choosing, you need to pay attention to this.

Most often, there are longitudinal grooves on the back side of the product. They are designed to allow air circulation. If the board is not completely dry or there are temperature changes in the room, these longitudinal cuts will help relieve tension in the board.

The shape of the board remains virtually unchanged, but the size can be from 65 to 200 millimeters in width and 2 or 4 meters in length. Interior work, as a rule, is carried out with boards no wider than 100 millimeters. A wider one will be too monumental, and a narrow one will not look so beautiful and visually reduces the room. However, here the choice remains with the owner of the house.

Pros and cons of finishing with imitation timber

Sheathing with imitation timber has both positive and negative aspects.

The advantages include the following:

- high sound insulation properties;

- low thermal conductivity;

- reliability and durability;

- uniqueness, originality of the drawing;

- feeling of coziness and comfort;

- relatively simple installation;

- saving money and time.

Not a single finishing material has yet had only positive qualities, and imitation timber for interior decoration is no exception.

Therefore, when making a choice in favor of this material, you need to be prepared for the following disadvantages:

- the need to constantly renew the protective layer - treat the wood with antiseptics, paint and/or varnish;

- increase the fire resistance of wood by applying special protective agents.

Features of finishing and stages of installation work

If you are planning to decorate your home with the lumber in question, then you should take into account many features during installation. These nuances are distinctive for external and internal work.

Interior finishing with imitation timber includes finishing of walls and ceiling. Floors are not treated with this material. The walls and ceiling are made according to an identical principle.

Stages of installation work when finishing the walls and ceilings of IB inside the house:

- Installation of sheathing. Wooden blocks, often 40x40 in size, serve as the basis for the imitation. It is possible to use a galvanized profile when finishing with imitation timber inside the house. A photo of the frame shows how it is attached perpendicular to the future cladding with lumber, and the distance between the boards should be up to 60 cm (on the walls), up to 40 cm (on the ceiling).

- Laying insulation. Insulating material (foam plastic, glass wool) is immersed in the cavity between the sheathing and is controlled by slats, which are also attached to the sheathing. A film is laid over everything.

- Installation. The direction of the pseudobeam boards can be chosen in any direction, both horizontal and vertical. But, most often, horizontal masonry imitation timber is used. Interior finishing, photo of high-quality installation - this is the installation strictly horizontally, as level as possible, of the first plate of imitation timber, like laying a foundation. This procedure is carried out only using a level. Next, the panels are applied and snapped together easily using a tongue-and-groove locking system. This system is additionally fixed using clamps. Each subsequent row should be done with offset seams. Interior finishing with imitation timber using wide plates provides additional fastening with self-tapping screws in some places, because hidden clamps may not withstand the volumetric load.

A well-heated house does not need insulation inside, as this can affect the formation of condensation later.

The photo shows the last stage - installation. Here you can clearly and visually see the quality harvest, row by row.

Stages of installation work for complete external cladding of a house with imitation timber:

- Preparing the walls. Window sills, cornices, lanterns and other protruding objects that could interfere with the work process are removed from the outer surface of the entire house. They clear the entire area of debris, fill cracks and eliminate defects.

- Laying a vapor barrier. Sheets of waterproofing, parchment or other similar material are overlapped on the walls (that is, the ends of the new sheet will be 15 cm over the ends of the old one). The resulting seams are glued together with tape or a similar method.

- Installation of sheathing. Wooden blocks are vertically attached to the house using self-tapping screws or nails if the house is wooden; frame dowels are used if the base is concrete or brick. The fastening step is no more than 1 meter. The resulting frame is treated with antiseptic agents.

- Laying insulation. When finishing exteriors, insulation (ecowool, polystyrene foam) is required to preserve heat throughout the house. Pieces of material are placed between the sheathing and secured with dowels.

- Attaching the moisture-proof membrane. Materials like isospan protect the building from wind and external moisture. The parts are connected using double-sided tape and stapled to the insulation layer with the frame.

- Installation of counter-lattice. An additional frame is necessary to ensure ventilation of the outer skin. Wooden blocks measuring 5x5 are attached to the lower frame with self-tapping screws.

- Installation of cladding. The beginning of fastening can be started either from the top or from the bottom. Particular attention should be paid to the first panel, which should be installed strictly horizontally. The panel should be positioned with the side facing up where the tenon is located. This is an important feature in which water will not be able to get into the groove during operation. The next row of boards is placed with a groove on the tenons; fixation with screws or nails is carried out through the board. There should be 3 cm indentations at the bottom and top of the entire wall masonry for ventilation of the imitation.

- The final stage. The entire resulting “lining” is treated with antiseptic primer, and all elements removed before starting work are attached.

The photo shows the result of correct installation of the sheathing with the insulation already laid out. The frame is ready for the final stage

Design

Finishing for imitation timber can be of two types: monolithic and combined. It depends on the design idea.

Monolithic finishing is a complete covering of the room with imitation timber. In this case, they can cover the walls, floor and ceiling. The panels fit together very tightly, forming a single composition.

Combined finishing includes various materials. The basis is an imitation of timber, and certain areas of the room can be covered, for example, with tiles or wallpaper. The main thing is to ensure that the finishing is done in the same style and color scheme.

You can also implement original design solutions by combining different types of wood.

Regardless of the type of finish, along with imitation timber you need to purchase additional decorative elements.

These can be corners, moldings, giving individuality and completeness.

They can be made not only in the color of wood, but also in any other shade: white, black, chrome and others. These parts are presented in a wide range on the construction market.

Combination solutions

IB sheathing may not cover the entire surface of the walls and ceiling. There are options for combining different materials. Such work begins with laying the IB and only then is plastering, laying out decorative stone or other facing materials carried out.

- Finishing with timber the entire surface of the house.

Finishing with timber and plaster. Double cladding gives an aesthetic, “striped” result. The building is visually lengthened.

- Finishing with timber and stone.

In this case, you also get a “striped” look, but richer and more majestic.

The photo shows a magnificent combination of decorative stone with wooden plates simulating timber. Their chaotic arrangement adds chic to the entire interior composition.

Installation

Before you begin installing imitation timber, you need to draw up a clear work plan. First of all, you should study the technology of installing panels and perform preparatory work. The base must be leveled, and the materials themselves must be impregnated with an antiseptic solution. After this, the sheathing is installed, measurements are calculated and the material is selected.

Installation should be carried out strictly following the instructions. After this, the panels are covered with protective agents.

We invite you to familiarize yourself with our range of materials

Imitation timber - Prima grade

Wood Larch Width 140 mm Thickness 20 mm Length 4 m Qty.

in pack 4 things. 2800 rub/m2

Preparation

You can sheathe a room with your own hands; to do this, you need to know the general rules and follow the technology exactly. To begin with, finishing work cannot be carried out until the cottage, cottage or country house shrinks.

If the house is frame, finishing can be done immediately after construction.

- Before installation, it is necessary to thoroughly clean the surface and level it.

- Waterproofing is carried out using mastic. For vapor barrier, the film is laid overlapping, properly attached and secured with tape.

- After this, the frame is made. The lathing made of wood must be treated with an antiseptic.

- To create thermal insulation for a room, you can use special materials, for example, mineral wool or expanded polystyrene. The layer is fixed, covered with polyethylene and treated with mounting tape.

It should be taken into account that in houses made of natural timber, thermal insulation is not necessary, but in buildings made of concrete one cannot do without it.

Attaching false beams to the ceiling

Work on the construction and renovation of a property begins with careful planning of upcoming events and with the preparation of diagrams and drawings. Thanks to this, you can determine as accurately as possible the amount of building materials and the list of tools.

To find out the area of the ceiling, its width is multiplied by its length. The result obtained is divided by the area of one false beam and the number of panels required for cladding is obtained. It is not difficult to calculate how many fasteners you need: the number of fasteners required to fix one board is multiplied by the number of slats. The diagram should contain information on where to start installation. You need to buy materials in reserve.

List of materials and tools:

- false beam;

- metal profiles or wooden slats for the frame or sheathing;

- mounting nails;

- self-tapping screws 60-90 millimeters long;

- dowels;

- screwdriver plus attachments;

- hand saw;

- hammer;

- perforator;

- tape measure, cord, pencil;

- wood antiseptic.

Material selection

Imitation timber is selected, first of all, depending on the type of wood, its class and the size of the panels.

There are several types of material. The “Extra” and “Premium” varieties are considered the highest quality, but they also have the highest price. Cheaper in cost are grades A, B and C.

When choosing panels, you need to take into account the uniformity of the wood texture and its color, the absence of defects on the material, the presence of knots on the surface, a certain amount of which is acceptable on budget-level panels.

When purchasing, you need to take into account not only the price category and quality of the material, but also the needs of the consumer. For example, it is not advisable to buy “Extra” class panels for finishing a bathhouse or balcony.

But in rooms where a luxurious design is planned, their use would be quite appropriate.

As for size, the range of offers on the market is very wide. Experts give some advice on this matter. For example, the large size of the panels can visually reduce the height and size of the room.

The best option may be elements with a width of 100-150 millimeters. Smaller ones will resemble cheap lining.

When choosing the length, it is necessary to take into account the surface area and decor of the room.

Imitation timber can be from 3 to 6 meters in size. The thickness should not exceed 12 millimeters.

Walls finished with panels of shorter length and thickness will not only look more profitable, but will also require less money. A thoughtful and successful combination will create a unique and unique interior of the room.

When choosing a type of wood, you need to study its qualities and characteristics.

- We can give an example of the most popular materials, one of which is larch .

This wood is highly fire resistant, very durable, and also has a very nice shade.

Larch can be used for finishing both indoors and outdoors; it can withstand even unfavorable operating conditions, and in addition, it has healing properties. Finishing with imitation timber from this wood can be carried out even in rooms with high humidity and temperature changes, such as a bathhouse and sauna.

Using linden panels you can perform work on finishing ceilings and walls. It has an even, beautiful color that tends to be preserved even with changes in temperature and humidity.

- As for oak , this tree is one of the most durable. It is resistant to rot and insects, has a large number of shades, but is very difficult to process. In addition, oak materials have a higher price compared to others.

- Aspen , on the contrary, is easy to process and resistant to high humidity. At the same time, it is not particularly durable. If the wood is properly processed and dried, over time it will develop good density and resistance to high temperatures.

However, the material has a huge drawback, which is that it may have rotten fibers inside.

This nuance cannot be detected in a timely manner; it will only reveal itself during operation. The only way out is to replace the low-quality element with a new one.

- Cedar panels have a high price, but at the same time they have excellent quality. They are durable and can easily withstand any adverse impacts.

An important point is the release of medicinal natural resins during operation.

However, it must be said that quite often cedar is counterfeited, and imitation timber based on it is made from low-quality wood, so it is worth purchasing material from trusted suppliers and checking the necessary certificates.

- pine is a fairly popular material due to its very reasonable price . It can be used in any room. The only caveat is the ability to release resin with a sharp increase in temperature.

In the case of completely finishing a house with imitation timber, you can consider combining wood species depending on preferences in price, quality, and also based on the properties and characteristics of the material.

How to calculate material taking into account the size of the house

The calculation for purchasing the required amount of lumber is based on the purpose of the cladding: external or internal. After all, the size for these types is different:

- Width. This figure usually ranges from 110-190 mm. It is better to take wide panels for exterior decoration, narrow panels for interior decoration. Running width – 135 – 140 mm.

- Length. This size comes in 2; 2.5; 3; 5.4; 6 meters.

- Thickness. The parameters of this value can be found in the following sizes: 14, 16, 20, 22, 28, 34 mm.

- Weight. The dry square meter of the product reaches 11 kg.

The imitation timber drawing clearly shows the dimensions of the lumber. The locking system is visible on it; you can see what the groove and tenon look like. Ventilation slots that prevent the formation of condensation during operation are also schematically shown.

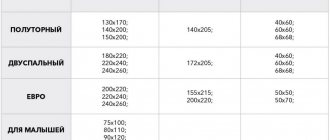

The most popular sizes are presented in the table below. When ordering imitation timber (be sure to look at the photo) with special dimensions, it is better to check the calculation of material consumption with the sellers.

| IB size (thickness, mm X width, mm X length, m), | Number of boards per package, pcs. | Area 1 m3/1 package |

| 20 x 140 x 6 20 x 140 x 5 20 x 140 x 4 20 x 140 x 3 20 x 140 x 2 | 5 | 68,04/4,05 59,98/3,37 50,76/2,7 39,6/2 28,08/1,35 |

| 20 x 190 x 6 20 x 190 x 5 20 x 190 x 4 20 x 190 x 3 20 x 190 x 2 | 3 | 85,47/3,33 71/2,77 60,68/2,22 48,14/1,66 34,04/1,11 |

| 25 x 190 x 6 25 x 190 x 5 25 x 190 x 4 25 x 190 x 3 25 x 190 x 2 | 3 | 67,58/4,15 56,68/3,27 41,23/2,17 40,0/1,95 27,91/1,25 |

Fasteners

It is preferable to secure the imitation timber using clamps. They are suitable for hidden fasteners and do not spoil the visual appearance of the surface with holes. In addition, this option is quite economical due to the low consumption of elements.

The fastening also depends on the base material.

For example, on wooden surfaces it is convenient to use self-tapping screws or nail the elements. On concrete, brick or block bases it is worth using dowels and screws.

Please note that the position of all fixed parts should be checked using a building level: in this case, the surface will be smooth and even.

Safety precautions

Decorating the inside of a house with imitation timber requires compliance with the rules: “Safety in Construction”. All work related to cladding is performed in special clothing, gloves and safety glasses.

Safety in using jigsaws and other similar cutting tools is observed based on their operating instructions, which must be carefully studied before starting work.

The safety glasses presented are required to protect against splinters getting into your eyes and soft tissues. This brand and form is just one of the options that you can use

What is imitation timber

Imitation timber (IB) is a wooden cladding material, externally similar to natural timber during manufacture. This type of finishing is used for external and internal finishing of buildings.

Building an environmentally friendly house from natural wood is a very expensive pleasure.

For this purpose, professionals have invented equally environmentally friendly wooden panels that are applied to the façade of a building or the interior walls of a room, creating the impression of being built from natural wood.

Professional exterior cladding of the house with imitation timber turned an ordinary country house into an elite mansion. The picture shows that the installation followed all the rules, so there are no defects. The entire surface is varnished to protect against unpleasant external conditions.

Necessary tools for work

To perform high-quality finishing with imitation timber, you need the following basic tools: jigsaw, stapler, building level, hammer, screwdriver, pencil.

In addition to the tools listed, you will need additional materials:

- 40x40 bars to create a body on which the panels will subsequently be attached;

- hardware: screws, clamps, dowels;

- insulation;

- vapor barrier film;

- double sided tape;

- varnish;

- insect repellent.

Here is the basic set of necessary tools for installing imitation timber. If necessary and desired, you can supplement it with your own acceptable items, and also replace the jigsaw with a grinder, for example

Size selection

This type of finishing material does not have strictly regulated dimensions. The most common products are those whose width ranges from 110 to 190 mm, and thickness from 18 to 34 mm (although there are modifications with the same thickness as lining: 14 and 16 mm).

The most popular panel thickness for interior decoration is 18-22 mm and width up to 110 mm.

If we talk about the standard version of ordinary or profiled timber, from which houses for permanent residence are built, then it has a cross-section of 150x150 mm. Therefore, the interior decoration of a house made of timber (in terms of cladding frame interior partitions) should be carried out using panels of the same width as the dimensions of the main building material.

With the choice of length, not everything is clear. There is no point in purchasing the entire batch with the same length, especially in the maximum size of six meters. Considering the length of the partitions, when covering walls inside a house, the most common panel sizes are up to four meters. It is better to calculate and select the dimensions of the molded lumber so that there are as few scraps as possible.

If the length is not enough for the entire wall, then the joints can be hidden behind furniture or hidden with a fillet.

To finish the ceiling, you need to use whole panels, if possible without splicing them along the length. And they should be located in the direction from the window (if the room is corner, then in accordance with the laying of the floorboard).

Calculation of the amount of imitation timber must be carried out not only for each room, but also for each type of surface. This will allow you to optimize the cost of materials and the cost of work in general for the interior decoration of the house.

Features of application

Decorative bars for the interior are manufactured in a factory; when finished, they are completely ready for assembly. Installation can be carried out in the shortest possible time, without having the skills of a carpenter. The lamellas are lightweight and easy to mount even on an inconveniently located surface. The cost of the material is lower than natural timber, its purchase will be inexpensive. The color of wood and its texture have a beneficial effect on a person’s psychological state. Which is also important.

False beam fastening scheme Source fas-deck.ru

See also: Catalog of timber house projects presented at the Low-Rise Country exhibition.

Today, imitation timber is widely used in home interiors. Many designers willingly use this material both for decorating large city apartments and for decorating office buildings. Gradually it displaces the lining. This happens because the imitation timber looks richer. The installation of wide panels is much faster, they are easier to assemble, and they also allow you to accurately imitate timber. This effect cannot be achieved using lining.

Imitation timber looks richer than lining trim Source derevyannyy.com

Traditionally, when performing finishing work, the false beam strips are positioned horizontally. This helps to recreate the log structure. It looks good only in rooms with the correct geometry and high ceilings.

A room with the correct geometry Source tarifi.info

It is not necessary to cover all the walls in the interior with bars. They will look beautiful even when they cover only one side of the room. The material goes well with other textures: concrete, glass, metal.

Accent wall designed using imitation timber Source dobrostroy.house

However, it is allowed to experiment and place the bars vertically to each other, and even lay them at an angle. Designers love to try using traditional materials in innovative ways. And this allows you to create completely original interiors that can surprise with their perfection.

Vertical cladding is used where it is necessary to visually raise ceilings Source izhevsk.ru

Vertically located planks visually make the ceilings higher. If you need to decorate a narrow, elongated room with wood, designers advise covering short walls with horizontal planks, and long walls with vertical planks. This technique will make the room both taller and wider.

If ceilings are sheathed, then the slats should be placed parallel to the shortest wall. This will make them taller. When decorating rooms with complex geometry, you need to focus on the layout and create separate functional zones using the arrangement of lamellas.

The arrangement of the slats helps emphasize the geometry of the room Source abcnews.com.ua

Note! Many people strive to buy false timber of the highest quality. It has a perfectly smooth surface without any defects. But sometimes the presence of dark spots and knots adds its own flavor to the interior. This becomes justified when a rural stylistic concept is chosen to decorate the house.

Raised timber with knots and stains on its surface Source dontcallmepenny.com.au

See also: Catalog of companies that specialize in finishing materials.

In which rooms can it be used?

Imitation timber is used for finishing walls and ceilings. This is a textured living material that has a number of advantages. It allows you to create the feeling of a wooden house in the interior of one or all rooms. Wood allows the coating to breathe; some varieties even purify the air.

With the help of cladding you can create a unique design and emphasize a certain style.

False timber is used to decorate the interior space of apartments, country estates, and private cottages. It will perfectly complement the corridor, living room, bedroom, nursery, office. Some breeds can be used in the bathroom, kitchen, balcony, loggia. In general, the material is universal and compatible with absolutely any room.

However, it is worth considering the fact that finishing actually reduces the usable area.

In the kitchen, using imitation timber, you can cover both the walls and the kitchen apron, but additional wood processing will be required. Different colors will highlight the severity or warmth of the space.

In the living room, it is enough to make one accent surface, or decorate a certain area, or you can completely cover all the partitions. It all depends on the preferences of the owners and style.

What is used as raw material

Practice shows that false beams look very different in the interior. This is because it is made from different types of trees. Each has its own texture, its own color, its own pattern. This must be taken into account when purchasing material.

Light false beams make the room visually more spacious Source ttrofimov.ru

If the bars are made from pine, they will be light yellow in color. Over time it will darken a little, but its golden shine will remain. Designers recommend choosing this material for wall decoration in the kitchen and hallway. Pine looks good in the decoration of the attic. There, its light shades help to visually expand the space and fill it with air.

Imitation of pine timber in the bedroom interior Source pilomaterial-stroi.ru

In the interior, bars made of cedar always look royally luxurious. They are used to decorate living rooms, offices, and large reading rooms. This wood has a unique pattern, very beautiful and embossed, it adds restraint to any design.

After processing, the tree drawing is completely preserved Source fcld.access.ly

Therefore, when it is necessary to emphasize the severity of the chosen style, preference is given to wooden finishes made of cedar. It has its own smell, cedar is known for its healing properties, so interiors with cedar cladding have a beneficial effect on human health.

Cedar in the living room interior Source glenoakspathology.com

Larch is a material that perfectly resists moisture. Under its influence, it swells slowly, so wooden trim made from larch is suitable for decorating kitchens, baths, saunas, and saunas.

False beams in sauna decoration Source stroyservis-74.ru

Stylistic directions

Wood is ubiquitous and has been used in construction for a long time. All cultures treat this material with respect. Therefore, natural wood finishing is compatible with almost any interior style, from country to high-tech.

However, the most related trends are eco, rustic, Provence . Here a wooden wall can become the main accent of the room.

False beams will look good in a classic interior . The classic color palette includes three main shades: beige, cream, brown. Selecting the appropriate panels is not difficult. For a Scandinavian design, the boards will have to be painted white. For country and ethnic in texture and color, oak, which has a pronounced woody pattern, is best suited.

Whitewashed and aged panels made of oak, ash, pine are appropriate for rustic and other ethnic styles .

For the loft , it is enough to decorate only the ceiling with slats or decorate a specific area. The chalet style is suitable for a country residence. There must be animal skins on the floor and walls. High-tech implies the use of wooden material only as an addition.

Interior color scheme

To preserve the natural texture and color of wood, when processing panels, preference should be given to impregnations, colorless varnishes, and wax. It is better to refuse paint. In this case, the color of the board will directly depend on the type of wood. The most common shades are light brown, brown-red, and coffee.

There are also unusual ones, for example, blue, green, pink.

For clarity, let's look at some options (variety - color scheme):

- oak – from light brown to dark brown;

- beech – white with a yellowish-red tint;

- ash – from dark brown to light yellow;

- alder – red-brown;

- walnut – from light brown to black;

- pine - from pale yellow to reddish yellow;

- larch – from light yellowish to reddish;

- yew – yellowish-white.

Indoor treatment and care

Natural material has some features that require special care indoors. Negative factors include susceptibility to wetting and swelling, and exposure to various microorganisms.

Deformation of timber beams can be prevented by regular treatment with special products.

Varnish coating

Water-based varnishes are well suited for treating wooden lining. They emit absolutely no odor, dry quickly, and do not contain organic solvents. Hydrophobic scuba tanks are also often used.

Impregnation repels water and provides reliable protection against rotting.

Thanks to a thin transparent film, varnishes allow you to preserve the natural color of wood. To give additional strength, polyurethane compounds are used. This coating can be applied with a brush or swab.

Coating with different types of paints

The main feature of this type of protection is the ability of the mixtures to completely hide the surface of the wood and give it a certain color. The following types of covering paints are suitable for indoor timber :

- Alkyd enamels. They have a pungent odor, emit toxic substances, and form a dense film on the surface.

- Water-dispersion paints. Completely environmentally friendly compositions, dry quickly and are quite durable.

- Polyurethane enamels. Toxic in liquid form, but resistant to mechanical damage.

Textured paint

The surface relief can be created using a wooden brush. The object is guided along the wood fibers and the soft components are destroyed. The excess is removed and varnish or paint is applied.

The effect of bleached wood is created in a similar way, but white glaze is added to the coloring composition.

Artificial aging work is carried out mechanically. They deliberately damage the surface in several places, trying to do this as naturally as possible. Then they are painted according to the standard.

When is it worth covering imitation with paints and varnishes?

The procedure for painting imitation timber is necessary to prevent moisture, insects and other reasons that destroy the wood. Therefore, it is necessary to cover with IB paint or varnish, especially if the external walls of the house are covered with it. Transparent and colored paint and varnish mixtures are available for sale. They treat both walls and ceilings in the same way.

Transparent mixtures include drying oil, aquolac, azure and a special composition for impregnation. The advantage of such materials is that they retain the natural color of the base wood. This coating also blocks moisture, collecting it in itself, so the wood lasts as long as possible.

Opaque paints include waterborne paints and acrylic paints. The peculiarity of such coatings is that they have different colors. You can give your cladding any shade you like.

The picture shows the varnish coating of an already assembled imitation timber structure. The procedure is usual: take wood varnish onto a brush and apply it to the surface using standard movements.