table for a sewing machine

Happy owners of sewing machines cannot always enjoy their happiness to the fullest. It gets boring every time you take the typewriter out of the closet and set it on a table - a dining table or a desk, well, if not on a coffee table. But don’t rush to buy a special table; this article clearly shows that it’s a sewing table with your own hands . Limited space or budget or lack of experience will not be a hindrance. Here are the most affordable, low-cost options for tables for a sewing machine , as well as several examples of how to make a cutting table . Having your own sewing corner in an apartment is the dream of every housewife, but in modern small-sized apartments such a dream is unlikely to be realized. This article offers solutions for small spaces and modest budgets. Moreover, the tables were not made by professionals; most of the authors are very far from carpentry. This means that you will also definitely find here exactly your version of a table for sewing equipment .

Cutting table for home

For those who sew at home, a cutting table is also needed. But given the dimensions of the apartment, it should be foldable, something like in this photo.

Although there are many solutions for folding tables, you can buy an inexpensive and convenient table at any furniture store.

It’s not worth getting a separate table with a large non-folding tabletop at home. If you rarely sew, then a smooth and even floor may well help you out.

Expert opinion

Mikhailov Ivan Maksimovich

Furniture maker. Work experience 3 years.

But household members will quickly fall in love with such a table and fill it with various things. It is much more convenient to use such a universal sewing table.

You can install a machine on it and use it for cutting at the same time. And there will be enough spacious drawers to put all your sewing supplies there.

How to choose a sewing table

Which table to choose for a sewing machine. Is it possible to make a sewing table with your own hands?

Extendable tailor's mannequin

Learn more about how a sliding mannequin works. How to use such a mannequin, and what are its advantages and disadvantages.

Knife for cutting fabric What is the difference between a round knife for cutting fabric and tailor's scissors? How to use OLFA circular knives, sharpen the blade, etc.

How to sharpen scissors at home

Sharpening of scissors, especially those used by hairdressers and tailors, should be done on a special machine and always by an experienced craftsman. But often there is a need to urgently sharpen scissors at home, without wasting time going to the workshop. Is it possible to sharpen scissors yourself?

How to choose zigzig scissors

If the purpose of tailor's cutting scissors is clear, then this is what zigzag scissors are needed for, especially if you have an overlocker and is it necessary to buy them at all? These are the questions the studio technologist will try to answer.

Do you have a sewing machine and love to sew? Then this site is for you. Professional craftsmen will tell you how to perform minor repairs on your sewing and knitting machine.

Experienced technologists will share the secrets of tailoring. Review articles will tell you which sewing or knitting machine to buy, a dummy iron and many other useful tips you will find on our website.

Thank you for viewing the entire page. Copying and reprinting articles from the Sewing Master website without the consent of the author is prohibited.

Copyrights are protected by law.

The sewing table is a reliable assistant for working on the machine. It greatly facilitates the sewing process, making it more comfortable and productive. The necessary accessories will always be at hand, and all sewing operations will be performed in one place.

A table for sewing work creates comfortable conditions for the creative process (photo: berkem.ru)

You can make a table for your sewing machine with your own hands or buy a ready-made one in a store.

Do-it-yourself round table for a summer house

If you like stylish furniture, a round garden table will look great on your deck or patio. For example, such as in this photo, you can immediately feel the atmosphere of relaxation and psychological comfort. Under the tabletop, you can use a lid from an old table, of any shape, and cut out a circle. Or take several boards and attach a sheet of plywood on top. In general, this is not a problem, the main thing is to make the legs and attach them to the tabletop. You can see how this is done in the step-by-step photos.

Photo source www.wikihow.com/Build-a-Round-TableBy the way, the photo shows that you need to drill a hole in the center of the tabletop. To determine where this center is, use a measuring tape to draw several arcs (use a fixed value, secure the end of the centimeter to the edge of the tabletop, and mark the arc that you get when moving the tape with a pencil). The center will be at the intersection of the arcs.

Sewing machine table - functions

The table contains the machine and all the accessories necessary for sewing a product (threads, needles, scissors, sets of presser feet, thimbles, fabrics, etc.). It makes it possible to make the workplace as comfortable as possible. As a result, the speed and quality of sewing increases.

Types of bases for a sewing machine

Tables for sewing on a machine vary in size, design, material and design. Choosing a suitable base depends on the needs and size of the room.

- attached (increases the sewing area);

- corner transforming table (accommodates all sewing accessories; when unfolded, it takes up a large area);

- table-book (suitable for small rooms);

- collapsible (convenient for transportation, if necessary, disassembled into parts and folded);

- a cabinet with sections (has a small tabletop);

- with drawers (takes up minimal space, holds all the necessary materials and tools for sewing);

- folding (suitable for small rooms);

- expansion (helps to sew voluminous products, expanding the working area).

Additional Information! Some models of sewing devices come complete with small side tables that increase the sewing area and make the seamstress's work easier. For example, the Singer 8280 machine is equipped with a removable arm platform

Industrial models

The Beloshveyka model range is represented by tables for sewing machines of different sizes and functionality. For example, “Seamstress 3” is intended for home use. The model does not require much space, is inexpensive (from 6 thousand rubles) and has good capacity. Can be equipped with bedside tables, drawers and shelves.

The Comfort series tables are positioned as semi-professional, but are also suitable for sewing at home. For needlewomen, the “Comfort 1” model is suitable. The table consists of a table top, a bedside table, a needle bed, trays for sewing accessories, a measuring ruler and a device for storing and putting on spools.

The main rules when buying a table for a sewing machine

To purchase a workplace to accommodate the machine and sewing accessories, it is necessary to take into account the purpose of its use, the size of the room, the dimensions of the machine and the material of manufacture. Depending on how often you plan to sew, choose the volume of the table and the number of additional drawers, shelves, bedside tables, racks, etc.

Buying a sewing table depends on the size of the machine and the size of the room (photo: damadoma.ru)

Expert opinion

Mikhailov Ivan Maksimovich

Furniture maker. Work experience 3 years.

When purchasing, they also pay attention to the cost. If it is not possible to purchase a sewing table, you can replace it with a computer one, adapting it to suit your needs.

Videos and articles with photos and reviews of models will help you choose the right purchase. It is important that the table is made from high-quality raw materials.

Wood fittings are considered the most reliable and durable.

Why is it more profitable to make furniture yourself?

A self-made table for a sewing machine will save your budget, since the raw materials for its creation will cost less than buying a ready-made base. When making furniture, you can choose the color, size, shape, design yourself and make a unique product. If you make a table from natural materials, it will turn out to be reliable, durable and strong.

Additional Information! In order not to get confused in the abundance of sewing accessories, you can stick pictures with captions on the boxes

How to make a sewing table

To make a table for a sewing machine with your own hands, drawings and tools must be prepared in advance.

- hammer;

- Screwdriver Set;

- pliers;

- screwdriver;

- wood varnish (polyurethane);

- jigsaw;

- sandpaper;

- building level;

- brush or roller;

- edge tape;

- construction pencil.

Work begins by selecting a drawing, according to which the parts are cut out on paper, indicating the dimensions. It is used as a guide when purchasing building materials. To make a folding table with drawers you will need approximately a sheet of plywood, MDF or chipboard.

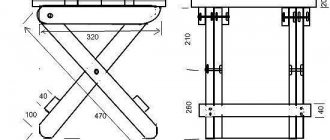

Drawing of a sewing table (photo: novamett.ru)

How to make a table for a seamstress with your own hands:

- Use a pencil to mark the parts on the board, taking into account the edges, cut out with a jigsaw, make holes for fastenings (when using natural wood, the surface is sanded, and chipboard and MDF are covered with edging tape).

- Assemble the housing.

- Connect the tabletop, side parts and support strips using self-tapping screws.

- Using a hammer and nails, attach the back wall, attach the legs to the cabinet using pruners (use a building level to check the result).

- Varnish the finished table and components.

- Proceed to assemble the drawers, attach the ball guides after applying the varnish.

- Make sure that the boxes fit smoothly into the fastenings (use a building level).

- Lastly, attach the handles and doors.

- Insert drawers.

Additional Information! A self-made cutting table must correspond to the height and length of the arms. Before work, you can calculate the optimal height by sitting at a regular table and placing the machine on it. By placing small sheets of chipboard under the device, you can adjust the height until the most comfortable position is found

Adviсe

If it is not possible to make a cutting table with your own hands, you can remake a simple dining or computer table. It can be supplemented with drawers, racks and shelves for sewing materials, and a recess can be made to accommodate the machine.

You can use an old cabinet to make a DIY sewing table. It is cut, one side is sawn to make shelves, and the second side is turned into a tabletop. The result can be seen in the photo.

A table for a sewing machine made from an old cabinet (photo: novamett.ru)

A sewing table facilitates the creative process, increases the speed and quality of work. It holds all sewing accessories and materials, making it possible to perform the necessary operations in one place.

You can make the base for the machine yourself, buy a ready-made one, or remake it from old furniture. The video below shows a DIY sewing machine table with drawings.

Quite often, seamstresses who work at home store their machines in the closet. It is not very convenient to take out sewing equipment from a secluded place every time and look for where to put it.

Most women sew at home at their desks, dining tables, and even coffee tables. But you won’t work for long in such conditions. Your back and neck will immediately begin to hurt.

To make your work comfortable and enjoyable, you should get a special sewing table. It can be purchased ready-made in a store or made with your own hands.

To save personal savings, most people prefer the second option. Moreover, you can make a sewing table from different materials. It will not only be convenient and practical, but also attractive in appearance. A well-made piece of furniture will harmoniously fit into the interior of the room and emphasize its individuality.

Why is it more profitable to make furniture yourself?

Many may have a question: why waste time making a sewing table with your own hands when you can just buy a ready-made one? If you carry out a simple calculation, it turns out that most of the cost of the product is the cost of someone else’s labor and the rental of retail space. The main advantage follows from this - saving the family budget. The costs will only go to materials and accessories, which is 3-4 times cheaper than buying a ready-made table. With the money you save, you can take creative training courses, which will be a profitable investment.

There are many options on the market for work desks designed specifically for tailors.

When installing the tabletop, make sure that the fastening is carried out exactly according to the marks corresponding to the drawing.

A sewing table created with your own hands becomes not just a unique thing, but also a reliable assistant in the creative process. How much should this small bedside table fit: sewing accessories, sets of threads of different colors and thicknesses for each type of fabric, cutting tools, ribbons, appliqués and other accessories. In this case, the size, color, material, design of the tabletop and cabinet will be recreated at the request of the owner. Whether the table will be a strict workplace or a real art object is up to you to decide.

If you know how to use a tape measure, a screwdriver and a jigsaw, this is a reason to think about making a sewing table with your own hands.

The modern market is overflowing with furniture made from chipboard, but not everyone is eager to use furniture made from sawdust. When making furniture with your own hands, you can choose environmentally friendly materials. The price of the issue is also beyond doubt: the cost of a furniture panel made of pine will not exceed the cost of a finished table with a folding tabletop. Varnished wooden furniture does not emit toxic substances and fills the room with the delicate aroma of pine forest. In addition, natural materials are characterized by durability, strength of fastenings and the possibility of restoration.

The main advantage follows - saving the family budget.

Coat the finished product and components with varnish.

Peculiarities

The advantages of a sewing table include:

- comfort and convenience when working . The competent design of the product will prevent swelling of the legs during work and will relieve stress from the neck and spine;

- easy and simple workplace transformation . Almost all models of sewing tables have interesting designs. During operation, they easily unfold, and when assembled they represent an ordinary cabinet, suitable for the overall interior of the room;

- mobility . If you equip the sewing table with wheels, it can be moved to the place you need. For example, while sewing, the product can be placed by the window, where there is a lot of daylight, and then hidden in a secluded corner of the room;

- capacity . Almost all models have good capacity. Some tables are designed not only to accommodate a sewing machine, but also to accommodate a small overlocker, which every seamstress needs.

A book model is also suitable for small apartments.

. This table has two sections that rest on supports. Inside the cabinet there will be a compartment for the machine and many shelves for storing tools, fabrics, and patterns.

Before you start making your own sewing table, you should think it through carefully. Decide in advance on:

- manufacturing materials . It can be: natural solid wood, chipboard, MDF, plywood;

- product dimensions . It is especially worth paying attention to the dimensions of the working surface for cutting. If you make patterns while standing, the height of the product should be 85 cm;

- availability of accessories . All seamstresses love it when there is space on the work surface for: accessories, threads, fabric.

Improved book table

A sewing table-book with a compartment for the machine is much more convenient, since its body is flush with the working surface. There are simple compartments where equipment must be placed manually, then sliding open areas with slats, and there are compartments with an elevator - a special lifting mechanism.

When lowered, the machine is completely hidden in the table, that is, there is no need to look for a place to store it. There are mechanical elevators, and less common ones with an electric drive. The disadvantages and advantages of such a table are exactly the same as those of the simple version of the book table. But the cost, of course, is somewhat more expensive.

Materials

You can make a table for a sewing machine from different materials:

- NDE . This material is affordable and easy to use. But the finished product will need to be sanded, dried and coated with paints and varnishes;

- Chipboard or laminated chipboard . Due to their coating, these materials do not emit harmful substances;

- MDF . This material is environmentally friendly and moisture resistant;

- furniture panels . They are distinguished by a wide color palette and smooth surface;

- natural wood . The array has a beautiful texture, naturalness and durability.

Tips and tricks

The surface of the table top for cutting fabric should be well sanded, but not slippery. Otherwise, working with light flowing materials will be inconvenient: they will simply begin to slide off the table.

It is important to consider the size of the sewing machine itself and the mobility of the design. The joints of the plates do not interfere with cutting, provided that the ends of the sheets are well processed and fit smoothly together

During assembly, it is advisable to use a level to determine height differences and level the structure

The joints of the plates do not interfere with cutting, provided that the ends of the sheets are well processed and fit smoothly together. During assembly, it is advisable to use a level to determine height differences and level the structure.

How to do it?

Expert opinion

Mikhailov Ivan Maksimovich

Furniture maker. Work experience 3 years.

Now you can start making parts. Using an electric jigsaw, all parts of the furniture item are cut out according to the drawing.

If you do not know how to work with a jigsaw, you can order detailing of the product from a specialized company . There you can also buy lumber (MDF, chipboard and others).

Boxes with guide elements are manufactured in the following sequence:

- The necessary elements are cut out of plywood , fastened with screws and guides are attached to them. The guides can be either removed from old furniture or bought new ones at any hardware store.

- After assembling the drawers, markings are made on the inside of the cabinet . The remaining guides are attached to these places. Now you can insert the drawers into the table and check how easily and conveniently they open and close.

- If everything has been assembled correctly, we proceed to making the front panels for the previously assembled drawers.

- The front panels are attached using screws from the inside.

- Now let's start assembling the tabletop .

- It is cut out with an electric jigsaw according to the drawn drawing. Or you can buy a ready-made element of the product in the store.

- We apply the plate to the body of the product and make markings . Holes in the countertop are drilled to half its thickness. Their diameter should be equal to the diameter of the wooden pins.

- Now carefully coat the pins with glue and install them in the grooves . We wait until the glue dries and the pins stick firmly.

- The pins must be painted to make it easier to install the countertop. Since the paint will leave a mark on the place where you will need to drill holes.

- Installing the countertop.

- wheels are attached to the lower ends of the side panels using metal bases. This way, you can easily and simply move furniture from one place to another.

You can make this compartment directly under the working surface of the table by cutting a plate to the size of the machine. This compartment is attached to the overall structure with wooden pins and metal corners. This way you will securely secure the machine.

In addition, the sewing table can be equipped with additional elements:

- folding table top . With its help, it will be easy and simple to make patterns from fabric and even install an overlocker.

You can attach an additional folding board using piano hinges. It is not necessary to make legs for it. Since it will rest on the side panel of the product;

- backlit;

- additional niches for storing tools and materials;

- pencil cases;

- folding ironing board.

Any DIYer who knows how to handle power tools and lumber can assemble a functional and practical sewing table on their own.

Procedure:

- Select the product drawing you like, draw out the details to scale and indicate the dimensions. Take the drawing with you to the hardware store to purchase the required amount of materials. As a rule, to make a table for a sewing machine with your own hands, one sheet of MDF or chipboard is enough.

- Mark the sheet, not forgetting the edge. Cut out the parts with an electric jigsaw.

Important! You can order sheet cutting in the workshop. It won't cost much, but everything will be done with millimeter precision.

- Assemble the table. Connect the tabletop, support strips and sides with self-tapping screws. Nail the back wall. Attach the legs to the cabinet with self-tapping screws. Check the correct installation of the legs using a building level.

- Coat the finished product with varnish. Apply each subsequent layer of varnish after the previous one has completely dried.

- Assemble the drawers and attach the fittings.

The DIY sewing table is ready!

Finishing

After manufacturing and assembling the product, it needs to be given an attractive appearance. If the table is assembled from laminated chipboard or MDF, it does not need additional finishing .

If natural solid wood or OSB and plywood were chosen as its production, the product will additionally need to be primed, treated with stain, and painted on top with paint or varnish . This will not only give the furniture an elegant and noble appearance, but will also improve its performance.

Depending on individual preferences and the materials used, you may end up with something similar to this:

Deciding on design and construction

Depending on the size of the room, the dimensions of the sewing equipment and the availability of additional tools for sewing, the following models of sewing tables are distinguished:

Cabinet with sections for storage. The model is easy to manufacture, but has a small countertop area. Suitable for amateur craftsmen.

The costs will only go to materials and accessories, which is 3-4 times cheaper than buying a ready-made table.

Table-book with a compartment for a sewing machine and storage of accessories. It is spacious and multifunctional. Suitable for small spaces.

Design Features

In the modern understanding, a sewing table is a kind of transformer. When folded, it is a compact bedside table, which, if necessary, expands into a full-fledged workplace. The cutting table for a sewing machine is ergonomic and highly functional.

You can completely hide your equipment in it. Inside, the product is equipped with many drawers of different sizes, spool pins, and shelves.

The main task of a sewing table is to make the master’s many hours of work more comfortable.

Having a specialized workplace, a seamstress can easily make cuttings and apply patterns. All tools will be at hand, and the machine will not move during operation.

Expert opinion

Mikhailov Ivan Maksimovich

Furniture maker. Work experience 3 years.

In addition, if there are small children at home, a folding transformer will protect children from sharp and dangerous objects, which is almost impossible when working at a regular desk.

Furniture modification

Making a carpentry workbench with your own hands

Of course, any furniture can be converted and used for home machine sewing. However, here you always have to solve a dilemma: what will be cheaper in terms of financial costs, time spent and nerves - purchasing specialized furniture or modifying universal ones. However, a computer desk is closest in functionality to a tailor's workstation, so alterations will be minimal.

The easiest way is to adapt a base for a modern sewing machine under the once-produced “Seagull” or “Singer” models with a foot drive. Alterations in this case will be minimal and will consist of the following:

- Removing the old countertop;

- Installation of a new plane under a modern electrified model;

- Dismantling the foot drive and replacing the rocking pedal with the base for the electric pedal;

- Retrofitting the bed with drawers, sticks, containers.

Varieties

The modern furniture market offers a wide selection of ways to organize a workplace for needlewomen. Sewing tables are available in several types:

- Classical. Designed for household or industrial sewing machines and accessories. All studios, as well as large factories, are equipped with it. The sewing machine is securely fastened to the work surface. This table does not fold, but is adjustable in height, which is very convenient for those who are tall.

- Multifunctional. Often made angular, it includes several main and additional modules. Some models can be compactly folded into one large cabinet. Such a sewing table often has many sections, compartments, and drawers. It looks like a full-fledged workplace. Most models have an organized cutting surface.

- With built-in lighting. Such products are presented in a wide variety of models. The main advantage is the presence of built-in lamps that provide proper illumination of the work surface.

- Table transformer. When unfolded, it is a spacious workplace with many compartments for storing necessary small items; when folded, it is a regular folding table that can be used as a desk.

- Book. A budget and simplest table for needlework, consisting of three or more sections, one of which is stationary, and the rest are folded out as needed. Often, such models are equipped with compartments for storing a sewing machine and accessories. The main advantage is the ability to adjust the height of the table.

- Angular. Larger model with a spacious work surface. Allows you to cut, sew and do all the necessary work without changing position.

- Professional table for cutting and drawing patterns. It is often more convenient for seamstresses to work at large tables, which simultaneously house a sewing machine and a cutting surface. The model is suitable for those who constantly sew.

- Cabinet with sections for storage. The most budget option. Actually, this is an ordinary bedside table, which has drawers and shelves for the dimensions of sewing equipment. They are often accompanied by a folding tabletop, screwed to the cabinet on hinges. The main advantage of this model is its compact size.

Of course, for a hobby in the form of tailoring, any table with or without a drawer is suitable, but if sewing becomes the main profession, it is advisable to give preference to special products that are height adjustable and have a large working surface area. Because only correct and comfortable body position during long-term work will preserve the health of the spine.

The times of shortages are long gone, and if you wish, you can buy whatever your heart desires in a modern store. Despite this, some people continue to create their own clothes.

In order for the sewing process to proceed in the most comfortable conditions, it is recommended to use a special table. Ready-made furniture for cutting can be very, very expensive, and therefore it will be much more economical if you make a table for your sewing machine yourself.

Features of manufacturing a table for cutting chipboard

Some home craftsmen often work with chipboards, so they need a special table for carrying out operations. Making it at home is more difficult, since you will need the most durable and even tabletop that can withstand significant loads.

The table top is the most important part of the cutting table. All needlewomen know that working comfortably with fabric and scissors is possible only on a smooth surface.

Practicing craftsmen recommend not making a table for cutting chipboard with your own hands, but purchasing two simple strong tables and connecting them with ties.

In spacious rooms, it is advisable to equip a permanent corner work area near the window.

What should a sewing table be like?

It is important that the furniture made for the sewing machine is spacious enough so that the person using it can easily place on the surface all the devices he needs for sewing: the machine itself, the material, the overlocker, and so on.

Nowadays, a folding cutting table is considered the most comfortable. If desired, they can only be used halfway.

It’s good if there is space for additional accessories, including: accessories, threads, fabrics. Of course, you will have to put in a little more effort, but the result will certainly please you.

It will be quite comfortable to work at a ready-made table, even if you do sewing regularly.

To make the table more practical, it is better to make the left side so that when finished it acts as an extension of the base on which the machine is located. On the right side, the furniture may not be laid out straight, but at a certain angle in relation to the person using it.

This part is most often used to organize patterns, ironing accessories, a laptop and other things that are needed for work.

It is important that the cutting table is easy to use, in other words, that it allows you to have all the necessary devices and tools at hand.

If there is not enough space in the house to install a large cutting table, then it is better to give preference to a folding model that resembles a bedside table. This is a very convenient option, which involves a pair of sections resting on swinging doors.

Inside the cabinet is equipped with a special compartment, which is used to place a sewing machine. Numerous shelves can easily accommodate tools, patterns and fabrics.

Pockets located on the doors are most often used to store tools. Experts advise laying out furniture only when necessary, and keeping it assembled the rest of the time.

Types of cabinet designs built into a flight of stairs: 5 options

If you decide that a closet under the stairs is vital for you, then you should decide on its type. The following options for under-staircase cabinets are available:

- Closed cabinets in a traditional design. Inside, you can use completely different filling options: shelves, hooks. All this is closed with ordinary hinged doors. Door sizes can be very different. It is allowed to make blind areas for storing boxes.

- An excellent alternative to cabinets with hinged doors are sliding wardrobes. They save a lot of free space due to the fact that their doors do not swing open, but move along guides. In this case, it is best to make the doors the same height. Otherwise, difficulties may arise with their movement along the guides.

- Open shelving is very convenient to place under steps. Simple shelves are great for storing books or decor. You can install multi-level racks with beveled or rectangular sections.

- Drawers are very convenient to use. Suitable for storing small items that should not be put on public display and are difficult to place in cabinets on shelves. Such boxes can be mounted on a special frame using internal guides.

- Glass display cases are suitable for storing dishes, souvenirs and other decorative items. An ideal option if the staircase structure is located in the living room or dining room. The presence of glass doors on the display case will reliably protect things from dust. And to achieve the maximum decorative effect, you can equip the showcase with LED strip. Such glass showcases will give the interior a feeling of incredible lightness and visually expand the space, making it more functional.

Having decided on the design of the cabinet under the stairs, you should pay attention to the material from which it will be made. The most common materials today are the following:

- Wood, which can be used to create the frame of the product, as well as in the manufacture of individual cabinet elements (drawers, shelves, doors, and so on).

- Chipboard and MDF are materials that are used as an alternative to wood. They are cheaper and can be used to create doors and shelves.

- Metal underlies almost all fasteners. The frame of some models, as well as guides, are made from it. This also includes fasteners for internal filling.

- Mirrors and glass are ideal for decorating a structure. Cabinet doors and shelves can be made from these materials.

In order for the staircase structure to turn into a functional cabinet under the stairs, you need to carefully consider the appearance, as well as select the material for the structure. And then it’s a matter of technology. Making your dream come true will not be a problem.

Focus on photo and video materials, and also make sure that you always have instructions for installing a built-in structure with your own hands at hand. With this approach, you are guaranteed to get excellent results.

A beautiful cabinet under the stairs that you can make yourself

Step-by-step instruction

Before you start, you need to make sure you have the following tools:

Investments in natural materials are always worthwhile.

Step 1. At the first stage, you need to select a drawing of a cabinet for a sewing machine and cut out all the parts on paper indicating the dimensions. With the finished drawing, you should go to the building materials store. To make a folding table with drawers, one sheet of chipboard, MDF or plywood will be enough.

The reliability of furniture assembly is determined by high-quality fittings.

Step 2. Then you need to mark the parts on the board with a construction pencil, taking into account the edges, and cut them out using a jigsaw; mark and make holes for fastenings. If natural wood is used, the surface of the parts must be sanded. Cover chipboard and MDF with edge tape. In order not to cut out the parts yourself, you can order cutting and edging according to the drawing and immediately proceed to the assembly stage.

The latter can be made in a certain style and perform a decorative function.

Step 3. Start assembling the body of the cabinet: connect the tabletop, sides and support strips using self-tapping screws. Attach the back wall using a hammer and nails, making sure that the edges of the wall do not protrude from the sides. Using self-tapping screws, attach the legs to the cabinet and check the result with a building level. If there are deviations from the horizon, correct them. When installing the tabletop, make sure that the fastening is carried out exactly according to the marks corresponding to the drawing.

At the first stage, you need to select a drawing of a cabinet for a sewing machine and cut out all the parts on paper indicating the dimensions.

Step 4. Varnish the finished product and components. You should take special care when cleaning the countertop, as it will become your main work surface. If the varnish coating will be done in several layers, it is necessary to allow time between applications. The varnish will dry completely after 36 hours.