Features of the material

Epoxy resin is a multi-component chemical substance. These oligomers, which contain epoxy groups, form cross-linked polymers when mixed with a hardener. In its pure form it looks like a clear liquid. It has many shades - from white to wine red. It was first developed in France by chemist Pierre Castan in 1936, and in 1938 he filed the first patent application.

In a short time the material became in demand. It began to be used in industry: aircraft manufacturing, automobile manufacturing, construction, in the production of radio electronics, electrical engineering, and in other industries, including space. In everyday life, raw materials are used for various purposes; they are used to make crafts, decorations, and are used for the production and repair of furniture.

One of the main features of the substance is that it is not used in its pure form. Its properties appear after combining with a hardener, the type of which determines characteristics such as strength, density, rigidity, and elasticity. The components are mixed at room temperature, the proportions depend on the manufacturer, usually indicated in the instructions for use.

Cured resin is considered harmless, but in a liquid state it can cause serious harm to health, cause damage to the respiratory system, and skin burns. When working with raw materials, you should use personal protective equipment: gloves, respirator, goggles, painting overalls.

Composite table - a river of glass and wood

You will also need boards

The requirements are approximately the same, that is, it is important that they are even in thickness along their entire length. In order to make a selection on the boards for glass, we use a milling machine

Of course, before this we would like to mark it in pencil, as we would like to see everything.

Then we make a template using the boards. The template will be necessary for the glazier, to whom we will order our glass for the center of the table.

We can’t guess the exact sizes and shapes, so be prepared to adjust the boards to fit the finished glass. We use the same router, placing glass along the surface and selecting the most obvious flaws.

Well, now all that remains is to make the legs. Take a look at the previous version of the table. You can make it from a square pipe. Well, we paint everything with varnish, basing and securing the boards (tabletop) on the frame.

We lay the glass last. Yes, there will be a gap here and small crumbs and the like will get in there... But this is such a feature and it’s up to you to decide what to do and what to do. Some people can put up with it, others can fill it with sealant, although other problems will appear here...

The final appearance of the river table made of wood and glass will be something like this. Very good. As for the features with epoxy, this is a cheaper option, since glass is much cheaper than epoxy resin.

Now a few examples of tables from professionals.

Advantages and disadvantages

The table made of epoxy resin amazes with its original, sophisticated look. The finished product is obtained by applying a synthetic substance to a wooden base. The demand for the material in furniture production is explained not only by its aesthetic, but also by its practical characteristics. Among the main advantages of a dining table or coffee table are:

- long service life;

- resistance to mechanical damage;

- good wear resistance;

- moisture resistance;

- high strength;

- exclusivity of each individual item;

- using various dyes you can get any shade;

- the ability to use different materials for decoration.

The disadvantages of furniture products include:

- the cost of copyright works is quite high;

- increased demands on production technology, a small mistake leads to irreparable defects;

- upon contact with fire, releases harmful substances.

To prevent the release of toxins, the kitchen table should be additionally coated with a layer of varnish.

Popular techniques

Not everyone can make furniture from synthetic resin at home. The master must have a developed imagination. He will also need to familiarize himself with the most relevant techniques in our time.

Continuous coating

The main advantage of this technique is creativity. This manufacturing method involves three stages:

- Creating the foundation;

- Decoration;

- Filling the product with epoxy resin.

All work must be done extremely carefully. The coating is usually made transparent so that the base pattern is visible.

Countertops created using a similar technology are used for dressing tables and coffee tables, since they are not able to withstand any more significant load.

River

This modification is now in trend. It involves gluing two pieces of wood with an epoxy insert stylized as a river between them.

- These countertops can be of any configuration. The most popular options are circle, oval, rectangle.

- These structures can be placed not only in the living room, but also in the kitchen.

- The most popular styles for a table with a river are country and Provence.

From cuts

Furniture with wood cuts looks luxurious and unusual. Resin helps highlight the natural beauty of the saw cuts and allows you to create real works of mosaic art. The work is labor-intensive and requires good imagination.

This technology is used, as a rule, to create small round tabletops. However, no one forbids making products of a different configuration and size.

Recommendations for working with epoxy resin

Working with the material is quite simple. This does not require special skills or professional tools. The main requirement is adherence to technology. However, to prevent frequent mistakes, you should listen to the advice and recommendations of experts:

- Strict adherence to safety regulations.

- Mandatory use of personal protective equipment.

- If a liquid substance gets on the skin, immediately wipe the affected area of the body with alcohol and wash your hands.

- If epoxy accidentally gets into the eyes or mucous membranes, you must seek help from a medical facility.

- It is recommended to cover the surface on which work is carried out with plastic film. Plain paper will not protect the base from negative consequences.

- You should not work in a room with high humidity and air temperature less than +22 ° C, in this case hardening will occur slowly.

- Moisture must not enter either the individual components or the mixture.

- To prevent the hardened resin from turning yellow over time under the influence of sunlight, you can buy a substance that contains a UV filter.

- It should be remembered that under the influence of low temperatures, the hardened material delaminates.

- If mixed unevenly, spots and uncured areas may appear on the finished product after drying.

- If, after leveling, there are still bubbles in the layer of the mixture, then the surface must be slightly warmed up with a construction hairdryer, without stopping for a long time in one place.

How to choose a resin

Different types of epoxy are used for the job. The choice of a particular brand depends on many factors. First of all, the budget allocated for these purposes is taken into account. Parameters such as transparency and hardening period are also important. Depending on the type of table, its thickness, and the presence of decorative elements, a specific composition is chosen. Let's look at a few common options:

- ED-20. The only advantage is low cost. Experienced craftsmen do not recommend using it for furniture production. It has increased viscosity; after hardening, air bubbles are visible on the surface; over time, the transparent appearance is lost, and the substance turns yellow.

- EpoxyMaster. The composition is characterized by low viscosity. Allows you to work with large objects, pour one layer up to 5 cm thick. This variety has good fluidity, self-leveling, and penetrates hard-to-reach places.

- QTP-1130. A transparent material that is suitable for making a desk or coffee table if the thickness of the fill does not exceed 3 mm.

- PEO – 610KE. Under the influence of sunlight and heat it does not lose its transparency.

- Art-Eco. Manufacturers produce a wide range of different colors. Filling is done only in thin layers. However, when exposed to light, a yellowish tint may appear.

- CHS Epoxy 520. One of the most popular types used in the production of tables. Allows you to fill decorative elements, for example, coins, corks, herbariums.

How to cook

From epoxy resin you can make not only a coffee table or desk, but also a kitchen countertop, bar counter, chair, stool, and other pieces of furniture. Having decided on the type of future product and choosing the appropriate brand of chemical, the novice master always has the question of how to make the solution with his own hands.

Typically, epoxy is sold complete with a hardener, which starts the chemical reaction. These two components must be mixed in the correct proportion. Each manufacturer has different parameters, so before starting work you should read the instructions and carry out all actions strictly according to them.

To mix the ingredients you will need two measuring containers. First you need to measure out the resin. If a color is used, it should be added and thoroughly mixed before adding the hardener, preheated to a temperature of +30-35 ° C, but no more, so as not to spoil the mixture.

A hardener is added to the prepared composition in the ratio specified by the manufacturer. The resulting material is slowly and thoroughly mixed until a homogeneous mass is formed. If there are bubbles, carefully blow them out with a hairdryer. It is worth remembering that the finished mixture has a limited shelf life for pouring.

Features of density

One of the important characteristics of a material is its viscosity. Consistency affects the final result. The choice of thickness depends on many parameters, such as the decor used, the type of work performed. For some purposes, liquid compositions are chosen, for others, viscous ones. There are several states of matter, each of which is used for different purposes:

- Liquid. The finished mass flows easily from the stick. The resin spreads well, penetrates into all hard-to-reach places, fills all the depressions, recesses, corners, and impregnates the wood.

- Semi-liquid. The consistency is thicker and more viscous. Used for filling round tabletops, allowing you to create decor if necessary.

- Thick. This mixture is not suitable for pouring. Used for restoration work, for repairing vertical surfaces, as an adhesive.

Some craftsmen, trying to save money, use chemical additives to increase fluidity. For example, when a regular varnish solvent is added to the mixture in a volume of 5% of the total mass, the fluidity increases by 60%, but the strength of the composition decreases by 35%.

A safer way to reduce viscosity is to heat the components. In this case, the components are heated separately at a temperature not exceeding 50 °C. In some cases, on the contrary, it is necessary to make the substance more viscous. For this purpose, special powder fillers are used, for example, wood flour.

Working conditions

It is necessary to work with resin in a dry (very important!) and warm , well-ventilated room. High air humidity can have a critical effect on the surface of the finished product after hardening. It is highly recommended to use personal protective equipment when working with resin: respirator mask, gloves, safety glasses. We also recommend using work clothes - it is very easy to get dirty with resin, and it is almost impossible to wash it off the fabric.

We offer the following range of protective equipment:

- Not available

Rating 5.00 out of 5

Set of nitrile gloves

From 160 rub. More details

- Disposable polyethylene protective apron

From 60 rub. Choose …

- Open safety glasses

180 rub. Add to cart

- Disposable polyethylene sleeves

From 75 rub. Choose …

- Respirator Jeta Safety J-SET 6500

2399 rub. Choose …

- Respirator Jeta Safety J-SET 5500

2299 rub. Choose …

Methods of using epoxy resin

The material has unique characteristics, and the finished products are exclusive and impeccable. The substance allows you to create objects of almost any shape. The coating holds decorative elements well: corks, coins, shells, stones. Using a variety of attachments, craftsmen create three-dimensional surfaces.

Epoxy can be used in the manufacture of a table either as a restoration material, or as a main or integral part in the manufacture of a new product. In the second option, three main types of furniture can be distinguished:

- Made from epoxy resin. It is made from a pure composition by pouring into a mold. May include decorative embellishments.

- Wood and its derivatives covered with a layer of mixture. In this case, the chemical is used as a protective layer.

- Combined. Wooden fragments alternate with parts cast from resin.

Tabletop without support surface

The structure has no base, it is completely cast from epoxy resin. Characterized by a unique, spectacular appearance. It can be completely transparent, have an interesting color, and include decorative elements. The shape of the object depends on the experience and imagination of the master. The finished product is often decorated with LED and neon lighting.

Even if you make it yourself, the tabletop turns out to be quite expensive. To pour it, it is necessary to build a formwork that will give the resin the intended shape of the object. For this purpose, glass is used, which is very thoroughly cleaned and degreased. When assembling the formwork, special attention is paid to joints, cracks, and other defects.

Having calculated the volume of the mold, we begin to calculate the amount of substance required for the work. Based on the data obtained, a mixture is prepared. Before pouring, the internal surfaces of the formwork are treated with a release agent that will prevent the epoxy from coming into contact with the glass. Then pour the mixture and wait until it hardens.

Tabletop made of resin and various supporting elements

Unlike the previous option, during the production of the product the composition is poured onto the supporting base. It can be standard, telescopic, decorative. In the first case, the support is represented by a central post, consisting of four legs and a drawer. In the second, the height of the table is adjusted using special mechanisms. In the third, the most diverse and original designs are used.

If the countertop is poured without the use of wood, using pure epoxy, then the master is faced with a difficult question related to installing the lid on the supporting elements. To do this, either special recesses are provided, which are formed at the stage of preparing the formwork, or they make the supports and drawers part of the tabletop, bringing their upper parts into the prepared form.

After the epoxy resin is poured and the substance hardens, the entire structure becomes a single whole. However, it is worth considering that ES in its pure form will not be able to withstand heavy loads. To increase the strength of the material, fiberglass is added to it. When attaching metal supports, you can provide for the presence of metal plates with a welded pin inside the cover.

Wooden table with filling and epoxy resin

Wooden furniture itself has a very interesting and beautiful appearance and can decorate any interior. But the flight of design ideas is limitless. The unique properties of epoxy inspire craftsmen, who use all the achievements of science in their work, to create unsurpassed products.

If you add decorative filling when making a table, you will get an exclusive product. Various materials are used as investments: marble chips, semi-precious stones, pebbles, pinwheels, shells, pieces of wood eaten by bark beetles. But true masterpieces are obtained when using memorable souvenirs.

Original furniture can consist of a wide variety of attachments. Products with 3D images and paintings look interesting. Experienced designers do not lose sight of such a structural element as legs. If metal supports are coated with paints based on polyester and epoxy resins, then wooden ones are additionally decorated.

Slab and resin table

Slabs are used in the production of unique furniture. These are longitudinal cuts that are made from a single tree trunk. Most often, the slabs are represented by oak, elm, and poplar. Such cuts allow you to fully reveal the full potential of wood and its structure. Blanks for work can be ordered and purchased at any sawmill.

In the manufacture of furniture, saw cuts of different sizes and shapes and their combinations are used. The tabletop can consist of either one slab located in the center, or include two or more evenly distributed elements. The finished product will always have an original appearance, since the texture and pattern, like fingerprints, are unique and inimitable.

Massive tables, countertops, cabinets, bar counters, and small coffee tables are made from slab. To work with the material, you will need carpentry equipment and special skills. If there are none, then it is better to seek help from specialists who will cut the wood to the required size.

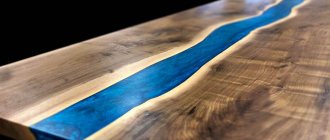

River table

In fact, this is a variation of the previous option. In this case, two slabs are laid in such a way that a space is formed between them that looks like a river bed. Thanks to its characteristic appearance, the item got its name. However, solid wood and various wood boards can also be used for work.

Blue epoxy resin is poured between the laid elements, sometimes it is completely transparent and has a green tint. It all depends on the author's intention. Some craftsmen add phosphorus to the mixture, making the product glow at night. Artificial fish, driftwood, and other interesting elements are also used as decoration.

Design possibilities

Thanks to resin coloring, you can get hundreds of color nuances from transparent to deep and rich tones, as you wish, as well as achieve the effect of various landscapes, from mountain to sea, which is very popular now.

Under the filling, you can place any components of your choice: pebbles, shells, interesting twigs and leaves, various types of sand, marble chips, dried flowers, as well as memorable little things and souvenirs.

The special beauty of the furniture is given by dilapidated pieces of wood, withered, eaten away by bark beetles, larvae and voids formed over time. By filling such natural flaws with epoxy, you can achieve unrealistic special effects.

And by adding additional decor in the form of coarse sand into the gaps, alternating layers of resin with chips and sawdust, we will create the impression of frozen time.

It is also easy to create modern motifs using polymer resin by placing metal objects, semi-precious stones, glitter, and foil into the tabletop. In addition, when painting exposed parts of wood with metallic paints, we will get fantastic effects and shimmers.

Self-made table technology

The work of manufacturing parts and assembling the table begins with the selection of suitable materials. Using the example of the following master class, you can see how easy it is to make a small coffee table with your own hands. By spending a minimum of available materials and time, you can get real designer furniture.

Fabrication of the supporting structure

One of the important stages in the work process. In order for the future table to be strong and stable, you will need to prepare two wooden circles of different diameters - one for support, the second for the tabletop. Their thickness should be at least 1 cm. The connecting element will be a plastic pipe. You will also need epoxy-based glue to attach the stand, the resin itself for pouring, and a furniture border. You can use any material you wish as a decorative filler. Metal beer caps will look original and stylish under a layer of filling.

Now the structure needs to be assembled. Place the smaller circle on the floor, mark the center and glue the pipe. We also determine the center on the underside of the lid, lubricate the attachment point with glue and place the tabletop on the upper end of the stand. Degrease and prime the surface of the table.

Preparation of formwork and filling

First, we do the first fitting - we lay out several covers along the edge of the tabletop. This is necessary to accurately determine the thickness of the furniture tape. Decorative elements should be buried in epoxy resin by at least half their size. Having chosen the appropriate filling height, glue the tape and lay out the lids with the pattern facing up. This is a final layout, so you need to think carefully about the drawing.

We coat the back side of each part with glue and lean it against the surface. You must work very carefully, since even the slightest leak of the adhesive mixture will be visible through the transparent layer of fill.

Rules for pouring resin

The final and most important stage of making a coffee table is pouring epoxy resin. We begin to pour in the prepared composition from the middle. It will spread over the surface on its own, leveling out under its own weight. If the countertop area is large, you can retreat slightly from the center to the edges.

When the epoxy resin reaches the edges of the furniture tape, it must be carefully leveled with a spatula. Add a little mixture to the places where there are voids and irregularities. Puncture the resulting bubbles with a toothpick or remove them with a hairdryer. Having refined the solution to the desired consistency, you can create various decorative elements. More viscous epoxy is used to make drops, lenses, and sculpt complementary elements. Then the surface is covered with polyethylene and left to dry completely for several hours. This will prevent the formation of defects and dust.

Plain or transparent tabletop

Making a table with a single-color tabletop begins with cleaning and degreasing the workpiece. If a material that absorbs liquids (for example, wood) is used as a base, then it must first be primed with resin. This will prevent bubbles from appearing during operation. The next step is to make an epoxy mixture and pour it into the mold.

If the table is to be made in color, then the appropriate coloring pigment must be added to the resin, and it is desirable that the dye be from the same manufacturer as the epoxy. If you want the color of the tabletop to be combined, then during the pouring process you need to use resin with dyes of several shades.

After pouring, you need to leave the countertop for 10-15 minutes, and then remove any bubbles if they appear. After two days, you can grind and polish the product. After a week, the table is completely ready for use.

Product care rules

Correctly poured resin onto the countertop will create a perfectly flat surface. To extend the quality characteristics, it is necessary to treat the product with care and provide timely care. Contact with high-temperature objects must be completely avoided. You cannot place hot pots or a boiling kettle on such a table. It is guaranteed to melt.

For cleaning, you can use soapy detergents, sponges, and soft rags. Aggressive mixtures with abrasive particles should be excluded. Upon contact with them, the surface will become cloudy and lose its shine.