Do you want to decorate your interior with unusual furniture, but don’t yet have the skills for complex products? Then you should pay attention to tables made of epoxy resin. The result of the work in most cases exceeds all expectations.

This tabletop is quite wear-resistant. The coating is hard, not afraid of mechanical damage, and protects moisture-sensitive materials well from corrosion and rotting. The hardened resin can easily be washed with water, even with household chemicals.

Good in any interior

Epoxy resins are oligomers that, when mixed with hardeners, form cross-linked polymers. The material is resistant to halogens, some acids, and alkalis. It is used to prepare glue, plastics, varnishes, plastic cements and other materials. Recently, epoxy has been increasingly used in craft furniture production.

There are few disadvantages to using an epoxy countertop. For example, there is no need to subject the hardened resin to prolonged heating to avoid melting. Another drawback is the presence of toxic substances in the composition. Therefore, some craftsmen advise opening homemade furniture with varnish in order to bind toxic substances and prevent them from getting into the air.

Their epoxy resin tables come in several types:

- with a board (plywood) base - resin is used as a decorative layer and to protect the wood;

- entirely made of epoxy resin - such countertops can withstand minimal loads (for example, coffee tables);

- combined - resin inserts are combined with wood, metal, and other materials.

Furniture pieces with a partially or completely resin tabletop look especially impressive. Translucent material transmits light well. Therefore, LED lamps or strips are often built inside to create an additional light source. It will not replace a chandelier, but as a night light or decorative lighting it justifies itself and looks very impressive, especially in the evening.

The resin is used both in its pure form and with various fillers - shimmer, color, phosphor. Thanks to additional components, you can create the most unusual effects - a starry sky, a flowing stream, a stone or mineral surface.

In addition, a wide variety of decor is used. These could be coins, photographs, or just beautiful images. Dry plants and insects are placed inside: the resin acts as a good preservative: the organic matter underneath does not deteriorate and retains its color for a long time.

Epoxy table goes with most popular styles. Furniture combined with wood will easily fit into country, loft, modern, fusion, boho, bauhas, grunge, kitsch, minimalism. Models with metal look organically in industrial, rustic, steampunk, futurism, techno, etc. spaces.

Making the right table

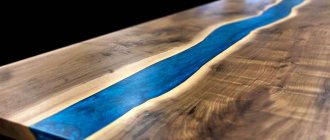

To create the effect of a river flowing right in the middle of the table, an insert is made into its surface that imitates a mountain river.

The table can be any shape - you can beautifully decorate a square, oval, or even a triangular table. The insert is made of water-colored blue or green-blue resin. Decorating the “river bed” with stones, shells, will help add bright accents.

Resin for countertops: how to choose?

There are certain requirements for resin for furniture:

- good fluidity and low viscosity for an even coating and good adhesion to other materials (thicker compositions are recommended for jewelry);

- high transparency.

For countertops you can purchase the following products:

"Art-Eco"

Resin is also used for layering. The composition already includes a coloring pigment, the color palette is quite wide. The disadvantage of the product is possible yellowing during use.

EpoxyMaster

Epoxy is suitable for forming a layer up to 5 cm. The product has good fluidity and forms a smooth, even surface.

QTP-1130

The composition is designed for layer-by-layer pouring, which is ideal for a beginner. The maximum thickness of the product should not exceed 3 cm.

CHS Epoxy 520

It is used for making decor on wooden or metal tabletops, as well as for restoring wooden furniture.

Often craftsmen try to save on materials by buying budget brands of epoxy. But the savings are not justified. As a rule, cheap compounds turn yellow after drying, and the surface is not always perfectly smooth.

Advantages

In furniture made of epoxy and wood, not only the appearance attracts attention; the positive qualities of the resin are also transmitted to objects made from it, these are:

- Wear resistance. Epoxy resin perfectly tolerates various unfavorable factors: humidity, high temperatures, mechanical stress, etc. Such coatings do not wear out during long-term use.

- Durability. Thanks to this quality, the material significantly increases the service life of furniture.

- Reliability. Resin is very similar to glass, which is often used to create interior items, but it does not break, does not form dangerous chips, and also weighs half as much.

In addition, when epoxy hardens, it is a very plastic material that can be given any shape. It is quite easy to process. The resin adheres well to different surfaces, forming very strong connections. These features of the material attract not only craftsmen, but also amateurs.

How to calculate the amount of material

Before starting work, you need to calculate the amount of material. To do this, use the volume calculation formula. Prepare a drawing of the tabletop, determine the length and width. If you plan to make a tabletop in which the resin will form a sector over the entire height of the product, multiply the resulting area by the thickness of the boards, but if only the top layer will be formed, then multiply by its thickness.

Expert opinion

Korzhavin Daniil Dmitrievich

Designer of stylish home furniture

Resins harden when mixed with a hardener, which tends to expand. Therefore, the solution ready for pouring increases in volume by 10–50%. This must be taken into account when calculating the material. The expansion coefficient is indicated in the instructions for the drug.

- Calculation example. There are two boards 10 mm thick and 1000 mm long. According to the master’s idea, between them there will be a transparent sector made of epoxy resin 300 mm wide. To find out how much resin is needed for pouring, multiply 10x1000x300 mm, resulting in 300,000 mm3, or 300 cm3. This volume corresponds to 3 liters of epoxy resin diluted with hardener.

Preparing for work

The final result depends on the quality of the preparatory work. The surface with which the resin will come into contact is cleaned, washed, degreased, and dried.

Further actions:

- The resin is heated to 50 °C (unless otherwise specified in the instructions).

- Epoxy is poured into a clean, dry container that can then be thrown away.

- Decorative fillers are added - pigment, aerosil, microsphere, wood dust, plasticizer or other materials (as necessary).

- Pour in the hardener in a thin stream, constantly stirring the resin. If you add a component quickly, the base may boil and immediately harden.

- Stir the mixture thoroughly for 2–4 minutes.

It is necessary to strictly observe the proportions of the components. If there is an excess of hardener, the resin thickens too quickly, and if there is not enough, it does not set. Then sticky areas form, causing the quality of the finished product to deteriorate.

When exposed to ultraviolet light, the resin may turn yellow when dry. To prevent this from happening, a UV filter is additionally added to the mixture.

1-Surface preparation; 2-Pouring resin into a container; 3-Adding fillers; 4-Creating frames

A frame for filling is pre-made from scraps of boards and slats. The joints of the box are sealed with sealant to prevent liquid from spilling out. The interior space is carefully lined with film.

Expert opinion

Korzhavin Daniil Dmitrievich

Designer of stylish home furniture

Countertops made of epoxy resin are quite heavy - 35 kg/m2 or more. Therefore, the base and legs should be quite strong.

Preparing the formwork and internal filling of the product

The formwork is created based on the selected tabletop model.

It can be either whole or consist of separate fragments. The edges of the formwork should not contain jagged or uneven surfaces; it is advisable that they be completely smooth. The joints between the sides of the formwork are treated with silicone sealant to avoid resin leakage.

The finished formwork is installed on the base.

Next, the decor is carefully glued to pre-selected places, avoiding the appearance of glue behind the contours of the base of the decorative elements - subsequently it will be visible through the layer of transparent resin.

The mold must be degreased and treated with a primer or wax-based product to avoid resin sticking. It is allowed to use transparent polyethylene film to line the inner surface.

Instructions for making a table top

Inside the frame, the elements that will form the tabletop are laid out on the film - wood, chipboard, plywood, metal. If you plan to coat them with epoxy resin, then they should be lower than the sides of the formwork.

Next, the resin is poured, starting from the center. The composition spreads over the form under its own weight. If necessary, carefully level the surface with a clean, dry spatula.

1-Pouring the epoxy resin 2-Drying the resin 3-Sanding the product 4-Final finishing

Leave the first layer until completely dry. This may take up to several days. The top of the mold is covered with film to prevent dust or other debris from entering. When the layer has completely hardened, repeat pouring and drying until the desired thickness is formed.

Complete polymerization of epoxy resin occurs in approximately 24 hours. This depends on the thickness of the layer and the properties of the hardener. Therefore, gradual filling takes a lot of time.

Next, they move on to sanding to get rid of irregularities. Although some manufacturers produce products that do not need to be processed after hardening (this should be indicated in the manufacturer's instructions).

Coarse sandpaper

Fine sandpaper

Grind the hardened resin with waterproof sandpaper with a coarse grain, and finally with the finest dusting. Recommended skin numbers are from 80 to 2000. The stove is watered all the time. Then finishing is carried out with abrasive pastes.

The next stage is finishing. Standard coatings are applied to wood - protective impregnations, waxes, varnishes. The part of the tabletop formed with epoxy resin must be covered with film or mounting tape.

Features of working with resin

- When working with epoxy resin, you must strictly adhere to the proportions of components specified by the manufacturer.

- The room should be dry. Do not allow moisture to get into the resin so as not to spoil the product. The optimal temperature for work is +22 °C. When the temperature drops sharply, white flakes appear in the pour. Therefore, temperature changes must be avoided until the resin is completely dry. Do not work with the material at low temperatures, as the resin may delaminate.

- The colder the room, the thicker and more difficult the material to work with. The higher the room temperature, the faster the resin hardens.

Expert opinion

Korzhavin Daniil Dmitrievich

Designer of stylish home furniture

Do not speed up the drying process. If you heat the surface from above, the tabletop may become deformed.

- Mix the hardener with the resin slowly and carefully. Active stirring can lead to the formation of air bubbles in the mixture, which are difficult to get rid of.

- The components must be connected carefully. If the mass is not uniform, then poorly hardened areas and sticky spots will form on the countertop. To prevent this from happening, craftsmen recommend pouring the resin from one container to another several times. In this case, you need to mix the mass in the thickness, trying not to lift the tool to the surface.

- If bubbles do appear, you can get rid of them. While the resin has not hardened, the problem area is heated with a construction hairdryer.

- Cloudiness can also be eliminated. Thus, masters claim that the mass becomes transparent again, as soon as it is heated to a temperature of 60 °C.

- Experts recommend mixing no more than 1–5 kg of resin at a time (depending on the size of the table). A large volume of working solution can harden directly in the bucket in a matter of minutes. It is recommended to use only modern hardeners such as Etal-45M.

Another danger of unused epoxy resin is the possibility of it catching fire when stored in a thick layer. For this reason, it is recommended to pour the resin in thin layers. This technology has its advantage: you can create a stereo effect if you additionally decorate each layer.

Epoxy coating on wood table

The manufacturing technology for such epoxy tables is as follows: first, you have to make the table itself of the chosen shape.

You can take a suitable stump as a basis; even a moss-covered, bleached log, or an original strong branch will do. After this, the base is decorated to taste: you can use plants, leaves, shells, small souvenirs, pebbles and much more. After this, the surface is filled with a thick layer of epoxy, forming sides.

Safety rules when working with resin

When working with epoxy resin, adhere to the following safety rules:

- Use personal protective equipment - gloves, respirator, goggles. If the mixture gets on the skin, eyes or mucous membranes, chemical burns are possible. Prolonged inhalation of vapors can cause poisoning.

- Small children or animals should not be allowed into the workroom.

Do you like the look of epoxy resin tables?

Very! Not really

- Tools and dishes are cleaned with acetone - the liquid dissolves the product well, or thrown away.

- It is prohibited to carry out work near an open source of fire.

Even a beginner can handle making a table from epoxy resin. But there is a condition: you need to follow all the instructions of the material manufacturer and listen to the recommendations of the craftsmen. Otherwise the material will be damaged. And if safety rules are not followed, you can also harm your health.

What types of tables can be made using epoxy resin

Epoxy material gives a wide choice of shapes and models. You can make a table based on various parts of a tree - stumps, cuts, branches. A completely transparent table made from epoxy alone will also be spectacular.

Various combinations of epoxy materials and fillers can be used.

Epoxy is best suited for making tabletops; other materials are usually chosen for legs, although if desired, the entire table can be made of resin.