Any table made of epoxy resin looks very unusual. The use of it and natural wood allows you to create unique interior items with your own hands, which favorably emphasize the style of modern design trends. The article will describe in detail the algorithm for manufacturing products that can turn into objects of art.

A table made of wood and epoxy resin looks unusual Source avatars.mds.yandex.net

Technical properties of the material

Epoxy resins are a chemical composition based on oligomers that can, upon contact with hardeners (polymerizing components), transform into especially strong polymers. By changing different percentages of the two components, it is possible to create materials with different technical characteristics.

More hardener - the resins are hard. Less, the resin will be liquid. Mix both components in equal quantities, the material will become rubber-like in consistency. An excess of hardener, as well as a lack of it, helps reduce the resistance of the finished product to water and sunlight. Its strength also decreases.

Epoxy resin and hardener Source d.allegroimg.com

Experienced craftsmen have long ago developed the ideal ratio of the initial components: 1x1 or 1x2. When manufactured in this way, the synthetic composition gives minimal shrinkage, which has a positive effect on the final result.

Compared to standard structures made of wood, products made of epoxy resin have special advantages. They:

- waterproof;

- are not subject to abrasive effects;

- have a non-standard, unique appearance.

Using the material, you can experiment endlessly and create completely different products each time, not similar to each other. Exclusivity is the main feature that any table with epoxy resin has. Unlimited possibilities for implementing design solutions are also supported by the fact that during the manufacturing process you can use not only natural wood, but also add paints with a phosphorescent effect, use rubber, and corks left over from wine bottles.

Each table made of resin and wood is an exclusive piece of furniture Source i.pinimg.com

Each countertop made of epoxy resin will be exclusive, but making it yourself will not be cheap. This is the only drawback of products of this kind. It takes several tens of liters of resin to make one table. And only an experienced master knows where and how you can save a little.

Advantages of epoxy tables: simple production and original design

Originality is what initially attracts an epoxy table.

Advantages of liquid glass countertops:

- have increased strength;

- resistant to household chemicals;

- do not require special care or special care;

- are not deformed;

- do not attract dust;

- do not absorb water;

- not susceptible to ultraviolet radiation;

- wear-resistant.

Tables with epoxy resin with different proportions of materials can have a different set of characteristics. Therefore, the final result is limited only by the imagination of the master himself.

In addition, the undoubted advantage of the products is their versatility. For each interior you can find your own design.

Most often, such furniture is combined with the following styles:

- bionics;

- futurism;

- rustic;

- eco;

- grunge;

- loft;

- eclecticism;

- postmodernism.

If you are thinking about making a table with epoxy resin yourself, you can always find tips, master classes and photos on the Internet. Thanks to this, even a person without special experience will be able to create a real work of art.

What kind of tables can be made?

Separately, it is worth noting that with the help of epoxy and other polyester resins they make:

- dining tables;

- countertops for kitchen sets;

- kitchen island countertops;

- coffee tables and more.

Furniture decor has a lot of options: leaves, shells, moss, stones, pieces of wood. They create a unique pattern, which determines the originality of the model.

Manufacturing technology

Making your own table from epoxy resin and wood is not difficult if you have the skills of a carpenter. The manufacturing algorithm is extremely simple. It begins with the preparation of a wooden blank.

- It is necessary to select wood with a thickness of at least 2-3 cm and sand its surface with sandpaper. The smaller the grain size, the better the surface of the wood will be closed for resin to seep through. In this way, it will be possible to reduce the consumption of the second material and preserve the natural grain of the wood. When using high-grit sandpaper (60-80), the tone of the base will be darker and the resin consumption will increase.

Polishing the countertop before applying resin Source stroy-podskazka.ru

- Then the piece of wood needs to be blown with a stream of compressed air (when you don’t have special equipment at hand, you can replace it with a soft brush). The procedure allows you to remove dust and sawdust after sanding.

- After preparation, it is important to let the wood dry thoroughly. To do this, craftsmen place it in the sun for 48 hours (in winter, it is better to place the workpiece next to a heating radiator).

Now everything is ready to create the product itself. Next we proceed as follows. We are preparing a wooden frame for the tabletop. It will serve as support and protection for the top of the new table. We knock it together from available materials: there is no need to try too hard; after the process of filling the wood with resin is completed, it will be removed and disassembled.

Frame for pouring epoxy resin Source ru-smola.com

See also: Catalog of projects of houses with a porch

Place the frame on a flat base. Next, we take a plastic film, place it inside the knocked down frame, cover the sides of the support with it (the resin does not stick to the film, so its remains can be easily removed after it has completely hardened). It is important at this stage to make sure that the film is not damaged, there are no tears or creases.

The next stage is to place a wooden blank inside the frame and arrange it the way you like best. Mix a small amount of resin with hardener in the required proportions, prepare a small amount of fill (about 300 grams). This will be enough to lubricate the tree on all sides.

First, you need to put rubber gloves on your hands, and then completely saturate all parts of the wood, all its protrusions, seals, and potholes with the prepared solution. This is necessary so that later, when the workpiece is immersed in the resin, air bubbles do not form. The treated elements are left inside the frame for eight hours. This time is enough for the impregnation layer to completely harden.

Pouring a countertop with resin Source remont-book.com

At its confluence, epoxy resin is prepared to fill the base layer. For this, take a large container. It mixes the base material and hardener in the required proportions. Afterwards the mixture is left for fifteen minutes. During this time, it will “rest” and become completely ready for further use.

The finished resin is poured evenly into the frame. It is distributed by gravity inside the mold in an even layer. If after this there are air bubbles left in the filling structure, they can be removed by heating it with a hairdryer. When exposed to heat, the bubbles burst easily. After 24 hours, the frame can be removed from the table. Within another seven days, the material gains its strength. After this, the product can be used for its intended purpose.

Note! Polyethylene film is not able to provide effective tension, so after its removal, defects in the form of unevenness, sagging or folds often remain on the surface of a new tabletop. You shouldn't get upset about this. At the final stage, you can level everything using a grinder or sandpaper. After treatment, the surface loses its transparency, but it can be easily restored by applying a thin layer of resin with a brush.

The finished product looks great Source cdn.materialdistrict.com

See also: Catalog of companies that specialize in the design and construction of small architectural forms

To prevent such defects in production, special forms made of plexiglass are used. They are sold in specialized stores and are not cheap, but their use can significantly reduce the complexity of the manufacturing process, and furniture made from epoxy resin is of higher quality.

Design and construction features

Epoxy resin tables are characterized by a unique design and can fit into any interior. Most often they are used in kitchens and living rooms, and there are no strict requirements for the style solution. Epoxy is used not only to make new products, but also to restore old furniture. Many models are made by combining several materials.

The peculiarity of the resin is that it hardly shrinks after hardening, therefore it retains its original shape for a long time. In addition, it can be decorated in different ways. Resin tables come in several types of designs:

- Combined. In this case, synthetic material alternates with wood elements.

- With the presence of support. Only the top layer is filled with resin. Additionally, various decorative elements are used: leaves, coins, flowers.

- Without the presence of support. There is only epoxy here. Small coffee tables are made this way. They are not intended for significant mechanical loads.

The product can be transparent, single-color or combined. The most commonly used are light turquoise and blue shades. Often the design is equipped with additional lighting or fluorescent powder. Handmade tables have a high cost, but such furniture can be made independently. The advantage of the process is that the cost of the model is reduced. There are other advantages: the opportunity to show imagination, restoring old furniture in an original way.

Combined

With the presence of support

Without the presence of support

Material selection rules

The service life of the finished product depends on the quality of the materials used. Creating a finished masterpiece is serious, painstaking and costly work. It will be a shame if in a couple of weeks it becomes covered with scratches or quickly becomes cloudy. Experts do not advise saving money and purchasing products from trusted brands (“Bottega Maestra” or “EpoximaxX Decor”).

Their epoxy resin for countertop pouring works best. It is sold complete with a hardener, in a convenient plastic package weighing 8 kg. After preparation, such resins have a crystal clear color that does not fade when exposed to sunlight.

Epoxy resin “EpoximaxX Decor” Source dekoriko.ru

Which epoxy resin to choose

The appearance directly depends on the quality of the epoxy intended for pouring .

Cheap formulations, which are often preferred by beginners, are disappointing with their final properties:

- do not provide transparency;

- difficult to level;

- harden poorly and unevenly;

- give yellowness;

- heterogeneous.

High-quality epoxy resin for pouring is two-component and is sold immediately with a hardener. The composition comes with instructions, following which you can easily select the desired degree of viscosity. Typically, 3 types of density are used in work:

- liquid – drains easily and is used to impregnate the workpiece and fill small irregularities;

- semi-liquid – suitable for round-shaped models and the manufacture of individual elements;

- thick – recommended for reconstruction of products.

The best epoxy resin for making all types of countertops is CHS Epoxy 520 . This composition has proven itself well and is actively used by both beginners and professionals.

How much epoxy resin is needed for a countertop?

When working with epoxy resin, it is important to initially correctly calculate the consumption of liquid glass. If you make a serious mistake, then at the most inopportune moment there will not be enough composition and you will have to waste precious time mixing a new portion. And this is fraught with a damaged product.

Therefore, it is recommended to focus on the common formula:

composition costs = (countertop length*tabletop width*thickness)* 1.1.

If we take the standard consumption, then exactly 1.1 liters of liquid glass are consumed for one square of workpiece one millimeter thick.

Options for combining resin and wood

In fact, the flight of fancy when choosing the design of a future countertop is unlimited. Today, two options for making products from resin and wood are very popular.

Some people prefer to cover the base with epoxy resin. You can add dyes to it and create very original surfaces. In this option, the resin will act as a coating that can reliably protect the tree from moisture. The method is often used to restore old products. If you introduce drops of water into the finished resin composition, they will not dissolve in it and will not disappear anywhere. After the resin hardens, drops of water will remain inside its texture and form an effect similar to a cosmic nebula or milky stains.

Table, resin, wood Source voyagechicago.com

Popular modifications

Making a table from epoxy resin is a task for a craftsman with good imagination. In addition to standard pieces of wood, luminescent paints or powders, buttons, wine corks, moss, plant leaves, sea stones, and cobblestones can be used for decoration.

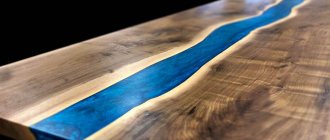

River

A special feature of the river table design with epoxy resin is that it is based on the same placement of elements: an insert made of the specified material is localized between two pieces of wood. It can be straight or follow the curves of the tree, wide or narrow, with decorative fragments, islands, and stones.

The shapes of the tabletops here are different: round, oval, rectangular. Interesting options are in which wood plays the role of a river bank, and resin plays the role of water. These products can be installed in the living room and kitchen. The model looks great in the office. With a river you can make a coffee table in Provence or country style. As for material consumption, about 13-14 kg of substance is needed for a river measuring 210 x 15 x 5 cm.

Solid surface

To create a solid table made of liquid glass, you need to use a mold of the required size. Most often, such structures are made without support and do not provide for intense loads. Tabletops of this type are used for the production of coffee tables or dressing tables. To make an epoxy resin tabletop, the dimensions of which are 100 x 60 x 5 cm, approximately 30 liters of resin are required.

From slab

Slabs are solid massive slabs of wood or stone. To make such a product at home, lighter material is taken. The tree usually represents a longitudinal cut of the trunk with remaining knots and uneven edges. This will allow you to create a unique model.

Often a slab table is made of oak. In this format you can make a kitchen surface, a structure for a living room, or an office. The thickness of the wood material ranges from 5 to 15 cm. It should not be glued or have other joints. To make a table from medium-sized epoxy resin slabs, you will need about 10 kg of the substance.

From cuts

Solid wood tables look very original and rich. Models of saw cuts of wood material coated with an epoxy solution look no less impressive. To fill such a countertop, a minimum of 7 kg of polyester substances is required. This model is perfect for kitchens, cottages in country style, eco-friendly. No matter what kind of hemp or solid trunk the cuts are made from, the design of each of them will be unique.

Tables of this type have different shapes: round, oval, rectangular and even square. The number of fragments used depends on its choice. The material must be of high quality and the required diameter. Cracked elements are not recommended to be used.

Features of care

The finished product will last much longer if it is periodically wiped with a soft cloth to remove dust and dirt. It is forbidden to rub the surface of hardened epoxy resin with alcohol solutions and acetone. Do not allow hairspray to splash on it.

Final polishing of the product Source alexia.by

Materials

To create a designer resin table, you need the following materials:

- Epoxy resin for countertops and large pours*.

- -20% Out of stock

Multifunctional epoxy resin “Trasparente” 8 kg

11460 rub. 9195 rub. More details

- -15% Out of stock

Multifunctional epoxy resin “Trasparente” 16 kgRating 5.00 out of 5

19990 rub. 17025 rub. More details

- Resin dyes (optional).

- Grade 5.00 out of 5

Dye “Colorfun Deluxe” 15 ml 39 colors

170 rub. Choose …

- Alcohol ink “Jacquard Pinata” 15 ml 22 colors

350 rub. Choose …

- Grade 5.00 out of 5

Metallic pigment “Sahara” 10 g 10 colors

170 rub. Choose …

- Transparent dye “Vitrail” from Pebeo 45 ml 20 colors

260 rub. Choose …

- A hand-held gas burner or a technical (construction) hair dryer to remove air bubbles from the surface of the pouring.

- Wood or other filler that will be inside the resin filling (stones, lids, corks, coins, etc.).

- Plywood/boards for creating formwork (shapes).

- Glossy self-adhesive film (to allow the cured resin to come away from the mold after curing) or other dense film/material to which the resin does not stick after curing.

- Glossy self-adhesive film “Shiny Shield” for creating a base 32 cm

From 210 rub. Choose …

- Glossy self-adhesive film “Shiny Shield” for creating a base 16 cm

From 120 rub. Choose …

- Not available

Glossy self-adhesive film “Shiny Shield” for creating a base 96cm x 3m2150 rub. More details

- Silicone sealant or silicone paste (to eliminate cracks in the formwork).

- -15%

Rating 5.00 out of 5

Pasty silicone “iGum” 500 gr

1300 rub. 1105 rub. Add to cart

- -15%

Pasty silicone “iGum” 1000 gr2400 rub. 2040 rub. Add to cart

- -15%

Pasty silicone “iGum” 250 gr880 rub. 748 rub. Add to cart

* – the type of resin depends on the thickness of the filling layer: up to 2, 3 and 5 cm at a time (relevant only for our resins). If your future table is expected to be thicker, then you can do several fills with an interval of 24-36 hours (depending on the size).

Features of the material

Epoxy resin is a multi-component chemical substance. These oligomers, which contain epoxy groups, form cross-linked polymers when mixed with a hardener. In its pure form it looks like a clear liquid. It has many shades - from white to wine red. It was first developed in France by chemist Pierre Castan in 1936, and in 1938 he filed the first patent application.

In a short time the material became in demand. It began to be used in industry: aircraft manufacturing, automobile manufacturing, construction, in the production of radio electronics, electrical engineering, and in other industries, including space. In everyday life, raw materials are used for various purposes; they are used to make crafts, decorations, and are used for the production and repair of furniture.

One of the main features of the substance is that it is not used in its pure form. Its properties appear after combining with a hardener, the type of which determines characteristics such as strength, density, rigidity, and elasticity. The components are mixed at room temperature, the proportions depend on the manufacturer, usually indicated in the instructions for use.

Cured resin is considered harmless, but in a liquid state it can cause serious harm to health, cause damage to the respiratory system, and skin burns. When working with raw materials, you should use personal protective equipment: gloves, respirator, goggles, painting overalls.

Recommendations for working with epoxy resin

Working with the material is quite simple. This does not require special skills or professional tools. The main requirement is adherence to technology. However, to prevent frequent mistakes, you should listen to the advice and recommendations of experts:

- Strict adherence to safety regulations.

- Mandatory use of personal protective equipment.

- If a liquid substance gets on the skin, immediately wipe the affected area of the body with alcohol and wash your hands.

- If epoxy accidentally gets into the eyes or mucous membranes, you must seek help from a medical facility.

- It is recommended to cover the surface on which work is carried out with plastic film. Plain paper will not protect the base from negative consequences.

- You should not work in a room with high humidity and air temperature less than +22 ° C, in this case hardening will occur slowly.

- Moisture must not enter either the individual components or the mixture.

- To prevent the hardened resin from turning yellow over time under the influence of sunlight, you can buy a substance that contains a UV filter.

- It should be remembered that under the influence of low temperatures, the hardened material delaminates.

- If mixed unevenly, spots and uncured areas may appear on the finished product after drying.

- If, after leveling, there are still bubbles in the layer of the mixture, then the surface must be slightly warmed up with a construction hairdryer, without stopping for a long time in one place.

How to choose a resin

Different types of epoxy are used for the job. The choice of a particular brand depends on many factors. First of all, the budget allocated for these purposes is taken into account. Parameters such as transparency and hardening period are also important. Depending on the type of table, its thickness, and the presence of decorative elements, a specific composition is chosen. Let's look at a few common options:

- ED-20. The only advantage is low cost. Experienced craftsmen do not recommend using it for furniture production. It has increased viscosity; after hardening, air bubbles are visible on the surface; over time, the transparent appearance is lost, and the substance turns yellow.

- EpoxyMaster. The composition is characterized by low viscosity. Allows you to work with large objects, pour one layer up to 5 cm thick. This variety has good fluidity, self-leveling, and penetrates hard-to-reach places.

- QTP-1130. A transparent material that is suitable for making a desk or coffee table if the thickness of the fill does not exceed 3 mm.

- PEO – 610KE. Under the influence of sunlight and heat it does not lose its transparency.

- Art-Eco. Manufacturers produce a wide range of different colors. Filling is done only in thin layers. However, when exposed to light, a yellowish tint may appear.

- CHS Epoxy 520. One of the most popular types used in the production of tables. Allows you to fill decorative elements, for example, coins, corks, herbariums.

How to cook

From epoxy resin you can make not only a coffee table or desk, but also a kitchen countertop, bar counter, chair, stool, and other pieces of furniture. Having decided on the type of future product and choosing the appropriate brand of chemical, the novice master always has the question of how to make the solution with his own hands.

Typically, epoxy is sold complete with a hardener, which starts the chemical reaction. These two components must be mixed in the correct proportion. Each manufacturer has different parameters, so before starting work you should read the instructions and carry out all actions strictly according to them.

To mix the ingredients you will need two measuring containers. First you need to measure out the resin. If a color is used, it should be added and thoroughly mixed before adding the hardener, preheated to a temperature of +30-35 ° C, but no more, so as not to spoil the mixture.

A hardener is added to the prepared composition in the ratio specified by the manufacturer. The resulting material is slowly and thoroughly mixed until a homogeneous mass is formed. If there are bubbles, carefully blow them out with a hairdryer. It is worth remembering that the finished mixture has a limited shelf life for pouring.

Features of density

One of the important characteristics of a material is its viscosity. Consistency affects the final result. The choice of thickness depends on many parameters, such as the decor used, the type of work performed. For some purposes, liquid compositions are chosen, for others, viscous ones. There are several states of matter, each of which is used for different purposes:

- Liquid. The finished mass flows easily from the stick. The resin spreads well, penetrates into all hard-to-reach places, fills all the depressions, recesses, corners, and impregnates the wood.

- Semi-liquid. The consistency is thicker and more viscous. Used for filling round tabletops, allowing you to create decor if necessary.

- Thick. This mixture is not suitable for pouring. Used for restoration work, for repairing vertical surfaces, as an adhesive.

Some craftsmen, trying to save money, use chemical additives to increase fluidity. For example, when a regular varnish solvent is added to the mixture in a volume of 5% of the total mass, the fluidity increases by 60%, but the strength of the composition decreases by 35%.

A safer way to reduce viscosity is to heat the components. In this case, the components are heated separately at a temperature not exceeding 50 °C. In some cases, on the contrary, it is necessary to make the substance more viscous. For this purpose, special powder fillers are used, for example, wood flour.