Finishing MDF boards, covered on the front side with decorative film, are intended for covering walls in any room, for example, in the kitchen, hallway, with the exception of rooms with high humidity (bathroom, shower). MDF panel products are designed to carry only the function of protection, decoration and, in some cases, strengthening the wall structure.

Universal strips for MDF panels

Decorative fasteners are used as a decorative element on wall panels for interior decoration. The right fittings for MDF panels are essential to give the finishing touch to your home. This is very important not only for decorating rooms, but also for preserving the corners of the walls from damage. Therefore, components must be of high quality.

How to glue corners on MDF panels

I can’t figure out what to attach the folding corner to on the MDF panel?

It is necessary to sew up the inner corner of the room, but it is not clear what to attach them to. The corner is attached with glue called “liquid nails”, I recommend “Moment-montage”,

I don’t recommend fastening the corner with any kind of nails; firstly, there is a chance that you will miss and damage the MDF panel or your hands.

Secondly, using nails you will not achieve a good fit of the folding corner over the entire surface.

Thirdly, the structure of MDF is quite dense, problems may arise with nails.

The work is not difficult, but it also has its own nuances.

Cut the corner to the required size.

We insert the tube with “liquid nails” into the “gun” (if there is no “gun”, press with whatever is convenient, a block, a hammer handle, and so on).

Apply glue only to the corner and only in a thin layer.

Then we press the corner tightly against the MDF panel, tightly, but not tightly.

Now we tear off the corner and wait about five minutes, the glue will dry out a little during this time.

Next, the corner is returned to the panels, now you can press it more firmly and check for complete fit along the entire length.

Well, in the end, not a big piece of advice: Don’t rush to wipe off the excess “liquid nails”, wait until the glue dries, then just cut it, either with a knife or with a blade.

You won’t be able to remove the glue right away, you can’t rub MDF, it will ruin the texture.

The best way to stick to an MDF panel is with the Liquid Nails adhesive; it is universal for this type of connection. The main thing is to comply with two conditions - the glue must be fresh, it is best to look at the production date and shelf life so that it does not exceed 1/3 of the entire shelf life. The second condition is surface preparation; it is necessary to degrease the surface over the entire area of the corner and MDF. And when you glue, it is best to apply glue to the MDF and to the corner separately, let it sit for 5 minutes and then glue the corner to the MDF. If the glue is still quite liquid after 5 minutes and the corner does not hold, then you need to wait some more until the glue becomes sticky and hold objects when you touch it.

You can use both the well-known Moment and its analogues, for example these:

MDF panels are attached to the wall in two ways - using lathing and glue. And if there is a lot of information about the first method, then they talk about the second extremely rarely. One of the most important aspects of the work when fastening with glue is the choice of adhesive composition, which ensures quick and reliable fixation of the slabs to the base.[contents]

Manufacturers of construction chemicals offer customers a huge range of adhesive compositions, which differ not only in price and packaging volume, but also in basic characteristics.

It’s really difficult to make a choice with such variety.

MDF adhesive must meet the following criteria:

- Have a clearly defined purpose. The label must indicate “universal” or “designed for use with wood-based panels.”

- Provide strong and reliable fastening to a mineral (stone, brick, plaster) or organic (chipboard, OSB, DSP) type base.

- Have a high level of adhesion and set quickly. As a rule, manufacturers try to highlight this characteristic in the name with the words “strong”, “super strong”, “multi” and so on.

- Demonstrate resistance to moisture, chemicals (salt, acid, alkali), temperature and humidity changes.

We especially note that it is recommended to glue MDF panels to walls only in interior spaces, therefore frost-resistant additives are not introduced into the adhesive compositions.

Some buyers have another requirement for glue - transparency. Inexperienced craftsmen are afraid that drops of adhesive composition may appear at the joints and spoil the overall picture. However, this is an unnecessary precaution. MDF panels have a standard tongue-and-groove connection system, convenient for installation using traditional lathing or glue. And at the corners and along the perimeter, the joints are closed with decorative fittings made of MDF, PU or PVC (corners, plinths, cornices), so any defects will be hidden behind the overlays.

Let us add that transparent silicone-based compounds are produced mainly for plumbing work; they are water-resistant, economical in consumption and are intended mainly for stone, glass, ceramics, earthenware, acrylic and other similar materials. It is not recommended to glue panels made of particle boards and fibreboards with them.

So, what types of adhesives provide the best fastening of panels to the wall? Conventionally, they can be divided into three groups:

- Universal compounds designed to work with heavy products made of stone, metal, glass, rubber, wood, polystyrene, etc. This category includes such well-known compounds as Titan (Titan Wild), Titebond (Multi Purpose), Moment (Moment-1), Tytan (Euro-Line No. 601) and others.

- Special assembly adhesives of the “Liquid Nails” series. In frameless construction they are in greatest demand among both professionals and amateurs.

Conclusion

To finish a door using MDF panels, you need to select the right panels in style and color. It is important to take into account the interior of the rooms that are in contact with this doorway.

It is necessary to achieve harmony between the door leaf and the opening, as well as their integrity. You need to try so that the heads of the screws do not protrude. They must be covered with special covers.

MDF panels, due to their combination of many advantages, variety of colors and stylistic solutions, and low cost, are considered the best solution for decorating door slopes.

Source: domsdelat.ru

Corners for protecting wall corners: selection options

This technique for decorating wall corners - protective corners - is not liked by everyone, but there are no special alternatives. In any case, on walls covered with wallpaper, a corner is still better than sticking out and torn canvases.

There is only one solution available for the integrity of the wallpaper without the use of decorative corners - to make a rounded corner rather than a sharp one. In this case, there will be no problem with finishing it. You can simply roll up the wallpaper without cutting it. But the corner must be drawn out perfectly, otherwise you will have to cut it again, which means that the question of protecting the wallpaper joint at the corner will again arise.

It is important to choose the right decorative corner so that it does not look alien. There are special techniques for this.

The interior looks good in the appropriate style

You need to select corners to protect the corners of the walls based on the overall design of the room. There are several standard solutions:

- To match the wall decoration. A complete color match is desirable, and even better if the texture is similar.

Either match the wall trim or match the doors

One of the options is quite logical

In general, you need to select corners to protect the corners of the walls depending on the design of the room. This can be done after the furniture has been arranged and textiles have been hung. In this case, it is easier to imagine the end result. Because the picture in our head can be very different from reality.

One of the transparent protective corners

If you just can’t find an acceptable color, and you need to protect the corners in your apartment, pay attention to the transparent plastic corners. They are of different types - rigid, flexible, with different wall thicknesses.

Conclusion

To finish a door using MDF panels, you need to select the right panels in style and color. It is important to take into account the interior of the rooms that are in contact with this doorway.

It is necessary to achieve harmony between the door leaf and the opening, as well as their integrity. You need to try so that the heads of the screws do not protrude. They must be covered with special covers.

MDF panels, due to their combination of many advantages, variety of colors and stylistic solutions, and low cost, are considered the best solution for decorating door slopes.

Source: domsdelat.ru

Types of protective corners: from what materials

According to the area of application, corners are available for external (outdoor) and internal use. For now, let's talk about how to protect corners in an apartment and a house - indoors. Let's start with the materials. Corners for protecting wall corners can be:

- Made of plastic (PVC). Different colors, textures, there are even transparent ones.

- Made of metal. Brass, aluminum (polished and not), stainless steel, with or without painting.

- Wooden. Made from different types of wood, smooth, with relief.

The corner on the arch is covered with a flexible plastic corner

Cork corners to protect corners

The most popular are plastic corners for protecting wall corners. Don’t think that such protection looks poor. In any case, no worse than frayed corners. It’s just that there are different types of plastic – polished, with a metallic effect, with a satin (matte) surface, with different reliefs. It is clear that in order to find something specific or special, you will have to run around construction stores and markets. But there are many types of design. If the corners for protecting the corners of the walls are chosen correctly, they fit organically into the design without attracting attention at all. At the same time, they protect and decorate the joints very reliably.

Shapes and sizes

Finished corners usually have an angle of 90°. The corner itself is not always sharp; there are options with a rounded one. By type, corners for protecting wall corners are divided into:

- hard external;

- internal;

Universal corner made of MDF

Questions can only be about universal ones. These are two strips of plastic or MDF connected by a thin strip of flexible material of the same color. Thanks to this connection, you can create an obtuse or acute angle, internal or external - without much difference. But in terms of reliability of protection, it is inferior to rigid ones - after all, the flexible part is quite thin.

It is also worth knowing that corners can have shelves of the same or different widths. More often they are found with the same ones, but it is quite possible to find those in which one is wider, the other is narrower.

Types, shapes, sizes

The width of the shelf varies from manufacturer to manufacturer. Plastic ones, for example, can have shelves from 10 mm to 50 mm. MDF corners are made with a minimum shelf width of 20 mm, metal ones - from 10 mm, but the maximum shelf length is 90 mm (aluminum). So there is plenty to choose from.

Slopes for entrance doors made of MDF: Advantages and disadvantages - Installation of slopes + Video

When decorating an interior, it is impossible to achieve a complete look without an aesthetic doorway. When decorating doorways, one of the important conditions is the creation of smooth and neat slopes. And here, slopes for entrance doors made of MDF have proven themselves to be excellent. They do their job perfectly and, moreover, hide the fasteners perfectly. With their help you can emphasize the beauty of the door.

Recently, MDF panels have become increasingly popular. The material is of sufficient quality and can be matched to any interior. There is a huge variety of types and colors of MDF panels that can satisfy even the most demanding customer. High-quality imitation wood looks like an expensive species.

What to attach to

The choice of method for attaching corners to protect the corners of walls depends on the material of the corner and on what surface they will be attached to. The most commonly used glue is glue. Moreover, “liquid nails” are among the leaders. This is a universal compound, but before purchasing, check that the specific brand can bond the materials you need.

You can put a corner on the glue if it is even, without large flaws. If there are holes/depressions, you are unlikely to glue it. In this case, you can use silicone. If you are gluing white corners, you can use white silicone. For colored ones it is better to take transparent ones. It is not advisable to use acidic everywhere. Although it is cheaper, it can damage metals or paint.

In both cases, the wall and corner must be clean and dry. The compound is applied to the corner, it is pressed against the corner, and fixed with strips of masking tape. We grab it after 40-60 cm. If everything is smooth, you can do it after 60 cm; if you need to repeat the shape, after 40 cm or even more often.

How and with what to glue a PVC corner to the wallpaper

Leave it in this state until the glue dries or the silicone hardens. See the packaging for the exact time. Then the masking tape can be removed. It differs from ordinary tape in that it comes off even from paper wallpaper without damaging the surface. But to be sure, try sticking and peeling in an inconspicuous place.

Foam rubber corner - L-shaped and universal with self-adhesive backing

There is another option for how to glue corners to a wall with wallpaper or paint. You can use double-sided tape. First glue it to the corner, then, after removing the protective coating, press it to the corner. There are corners to which the tape is already glued. Some types of foam rubber or plastic (usually flexible or universal).

General information

Advantages and disadvantages of MDF

Installing a doorway is a rather labor-intensive process in which accuracy is important. However, this work can be done with your own hands.

The following advantages of this material are highlighted:

- Affordability;

- ease of installation;

- aesthetics;

- the material has good density, which contributes to additional heat and sound insulation;

- environmentally friendly and safe material. Can be used for finishing both external and interior doors;

- Large range of colors;

- Resistant to rotting and mold deposits;

- are durable. The panels are not able to deform and swell;

- suitable for finishing doorways of any thickness.

Unfortunately, there are disadvantages here too. Firstly, this is not resistant to strong mechanical impact, but it is quite resistant to moderate impact. Once damaged, the panel cannot be repaired. Also, the material is not able to withstand high humidity.

DIY slope installation

Any work begins with preparation. It is necessary to remove all contamination from the surface to be finished, eliminate and repair all chips and cracks in the walls. If there is such a need, install waterproofing.

Then you need to take measurements and calculate the required amount of materials.

MDF panels come in two types: L-shaped finishing and wall.

The nuances of marking and sawing MDF

In order to most accurately mark the required fragments, it is better to use a square and patterns in addition to a tape measure. You need to start with the top panels. Basically, slopes have uneven edges at a slight angle. This needs to be displayed on MDF. After installing the first panel, apply the following elements. Marking and cutting are carried out during the installation process.

MDF is cut with a hacksaw, saw or jigsaw. The last one produces the most ideal cut without any burrs or chips.

Important: When installing side elements, do not forget about the presence of a threshold, as this will affect the height of the side bar.

Arch finishing

Arch design often becomes a problem. In general, there are not many external corners in the apartment, but there are always some on the arch. And in the aisle they very often get touched. Either furniture, or other cargo, or simply a resident who did not fit into the opening. And there are no questions with the straight part, but the rounded part can be a problem.

And not only in the doorway can there be an arched vault

In general, you can use universal corners for an arch. They are flexible, which is very convenient. There are flexible, non-universal ones - plastic, made from a special polymer with increased elasticity.

But in general, corners with different shelf widths are used to decorate arches. They are even called arched. They have one shelf 10 mm (external) and the second - internal - 30 mm or more. They bend easily. You can’t twist it into a donut, but it’s not difficult to get an arc of any curvature. You just need to use a secure hold while the glue dries.

This is an arched plastic corner

If you want to bend a regular corner, you can do this by heating the plastic. For this work you need a hair dryer. The usual one - for hair - will not work, since its temperature is too low. We also need a template according to which we will bend the plastic corner. Take a piece of fiberboard, tighten screws or drive nails, forming the profile that you require.

This way you can decorate the corners of the arch with protective corners

They start bending from the middle. Warm up the area, constantly pressing on the middle, and using a hairdryer, moving from the center to the edges. So you need to bring the corner to the desired curvature and leave it in this position to cool. To prevent it from straightening out, holes are made in parallel with a row of screws for the second row. The distance between the rows is equal to the width of the corner shelf. After the plastic has bent, insert and lightly tighten the screws. After the plastic has cooled, remove them.

How to cut finishing corners

Almost always, corners have to be cut to protect the corners of walls. They are sold in strips from 2 to 3 meters long. The cutting tool is selected depending on the type of material. For wood and metal, thick plastic, you will need a hacksaw, but the blade is different - for wood, and with a fine tooth for metal or thick-walled plastic.

Thin plastic can be cut with a construction or stationery knife or sharp scissors. If you need to cut perpendicularly, it is easier to use scissors. We use them to cut to the corner on both sides, bend the corner, and cut the remaining millimeters with a stationery knife. If there are flaws, they can be easily corrected with the same knife or very fine-grain sandpaper (polishing).

How to cut protective plastic corner (PVC)

If the plastic corner needs to be cut along the fold, cut it along the inner corner using a stationery knife. There is no point in cutting through the entire thickness. You just need to leave a noticeable stripe. Then we bend the piece that needs to be removed. It comes off at the cut site. We remove irregularities with a knife or sandpaper.

Ways to design openings

Regardless of the structural profile (aluminum alloys, wood, PVC), the space between the side and top edges of the wall and the wall is sealed using:

- PVC slope panels;

- sandwich panels;

- moisture-resistant drywall;

- plasters;

- concrete solutions.

Each option has advantages and disadvantages in terms of characteristics and cost.

PVC panels

Durable plastic sheeting with internal vertical stiffeners is popular among installers and homeowners in Moscow due to:

- environmentally friendly raw materials that do not emit harmful substances and have no pungent odor;

- the aesthetic appearance of a decorated window or door niche;

- ease of processing (easily cut with hand or electric tools);

- low weight that does not affect the walls;

- large selection of dimensional parameters;

- the possibility of using decorative films with patterns, textures, and solid colors;

- low price;

- resistance to external factors (rotting, fading, short-term temperature heating).

- flammability;

- release of substances harmful to breathing during combustion;

- instability to mechanical damage (scratches, dents, ruptures of the outer layer);

- high thermal conductivity coefficient.

- length - 1.5-6 m;

- width - 200-600 mm;

- thickness - 10 mm.

A special film is glued to the front sides to protect against mechanical damage during storage, transportation and installation. External surfaces can be painted in any of the colors according to the RAL system to look organically with the selected shade of the window or door profile.

PVC panels are the “golden mean” in terms of price and quality ratio: a small number of shortcomings are compensated by low price, versatility, choice of sizes and colors. The inability of the material to retain heat can be leveled out by using polyurethane foam, stone wool, polystyrene foam, etc. to fill the space between the slab and the wall.

Sandwich panels

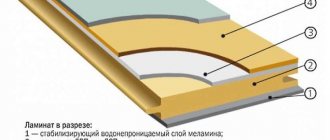

Combined multilayer fabrics are used to install “warm” slopes that can retain heat indoors. Sandwich panel consists of:

- front, back plastic covering up to 1.0 mm thick;

- intermediate filling made of foamed polystyrene or polyurethane.

Base color is white. Depending on the production technology of the outer shells and the presence of decorative film, sandwich panels can be:

- matte;

- glossy;

- laminated.

The main positive difference from PVC plates is the use of a heat insulator, which reduces the thermal conductivity coefficient.

Positive qualities are the same as those of PVC panels:

- environmental friendliness;

- moisture and UV resistance;

- long - more than 10 years - service life;

- ease of installation and maintenance.

Some disadvantages are also inherited:

- the decorative layer is easy to wrinkle, scratch, or puncture;

- Plastic is flammable and emits acrid smoke when burned.

Universal slopes

Based on PVC plastic, alternative materials for finishing slopes are produced, which are sets of basic and additional elements:

- canvases up to 6 m long and 20 to 50 cm wide;

- bendable part 60 mm wide;

- detachable decorative end strip.

The plate is hollow, with internal stiffeners. The bending part is needed to optimally shape the angle between the slope and the wall. A detachable plug is placed on the end of the flexible strip for decoration.

Advantages of purchasing a universal slope:

- The kit includes the minimum required set of materials for finishing the niche;

- you can choose any size of the kit depending on the parameters of the opening;

- in total, a universal kit costs less than buying elements separately.

- of the available colors - only white;

- In any case, you need to buy a starter profile.

- not suitable for non-standard finishing solutions (slope width - more than 50 cm), for large-format stained glass openings.

Qunell slope system

Qunell is a company from Germany, a manufacturer of building materials that produces standard kits for simple and quick decoration of slope spaces. The system consists of:

- decorative canvases 10 mm thick, up to 600 mm wide, up to 6 m long, with locks on one side;

- a set of plastic holders;

- PVC platbands 75 mm wide.

Lamination of the surfaces of platbands and slopes makes it possible to paint openings in dozens of colors and structures, including the popular mahogany, walnut, dark, natural, and golden oak.

Use the system as follows:

- The initial profile strips are screwed to the upper and side edges of the profile of the installed door with self-tapping screws;

- measure and insert into the grooves of the canvas (cutting is done from that part of the slab on which there is no lock);

- plastic holders are mounted to the edges of the walls, to which the panels are then fixed at the desired angle;

- cut trims are attached to the slope locks to size.

Tools for work

To perform the job of gluing PVC wall corners onto wallpaper efficiently, you will need the following tools:

- glue gun;

- metal scissors (convenient for cutting plastic profiles; simple scissors will not cope with the load);

- a hacksaw or grinder with a metal disc (for cutting wide corners used to frame arches);

- miter box (used for cutting and adjusting the joints of slats at an angle of 90° and 45°);

- painting knife;

- masking tape;

- square;

- roulette;

- pencil;

- sponge, cloth or rag.

Glue selection

There are several types of glue for gluing decorative corners to wallpaper corners, which differ in chemical composition, purpose, method of application, and setting time. The most common adhesives for such work are:

- liquid Nails;

- polyurethane glue;

- silicone sealant.

Liquid Nails

The main advantages of this type of glue are: a high degree of strength, quick adhesion and good adhesion properties to the surface, which allows you to reliably attach plastic profiles to any material: wallpaper with a convex pattern, concrete, wood. It is possible to choose either colorless glue, which can be used to glue white corners to the wallpaper, or different colors. The disadvantages of the white adhesive mass include the fact that over time it begins to turn yellow and becomes visible at the seams and joints of the plastic.

Liquid nails vary in purpose and composition. They are universal, suitable for working with any materials, and special, which are used for gluing the materials specified in the instructions on the packaging.

Liquid nails may contain synthetic rubber and solvent-based mineral components or water-based acrylic. The first type is characterized by fast setting, moisture resistance, frost resistance, and good adhesion. Allows you to glue not only light plastic slats and profiles in wet rooms to moisture-resistant wallpaper, but also heavier materials. The downside is the strong unpleasant odor, which takes up to 48 hours to dissipate.

The second type is environmentally friendly and does not emit a strong odor, but its use is permissible only at temperatures above 0°C in dry rooms.

Liquid nails are easily applied to the surface using a special syringe.

Polyurethane glue

Advantages: strength, elasticity, excellent adhesion to the surface, rapid hardening, no contamination. Disadvantages: pungent odor and higher cost compared to other adhesive mixtures.

Polyurethane adhesive for plastic corners can be one-component, ready-to-use, or two-component, which requires mixing the components in the required proportion immediately before use.

However, when choosing a polyurethane adhesive, you should pay attention that not all adhesives of this type are suitable for gluing decorative plastic products to wallpaper. This information is indicated on the packaging.

Silicone sealant

This glue can be used not only for attaching plastic products to wallpaper, but also to facing panels made of PVC, MDF, and ceramic tiles.

However, silicone sealant is not the best choice for attaching plastic slats, since in some places they may not adhere tightly to the wallpaper, which will shorten its service life. Silicone with the highest adhesion rates can be used in places with low traffic intensity, where the likelihood of damage and chips is low. For plastic corners in high traffic areas, it is recommended to choose acrylic sealant.

The main advantage of silicone sealant is a durable and elastic seam, which is suitable for places subject to vibration (doorways, light partitions). Thanks to this, this adhesive mixture does not chip.

Slopes for entrance doors made of MDF: Advantages and disadvantages - Installation of slopes + Video

When decorating an interior, it is impossible to achieve a complete look without an aesthetic doorway. When decorating doorways, one of the important conditions is the creation of smooth and neat slopes. And here, slopes for entrance doors made of MDF have proven themselves to be excellent. They do their job perfectly and, moreover, hide the fasteners perfectly. With their help you can emphasize the beauty of the door.

Recently, MDF panels have become increasingly popular. The material is of sufficient quality and can be matched to any interior. There is a huge variety of types and colors of MDF panels that can satisfy even the most demanding customer. High-quality imitation wood looks like an expensive species.

How to glue a plastic corner onto wallpaper

There are two ways to fix plastic corners on walls covered with wallpaper:

- on wallpaper without trimming;

- onto the wall surface with trimming a strip of wallpaper.

If the wallpaper is smooth or has a shallow relief pattern, then you can glue the plastic corners to the wallpaper without trimming. If the relief of the pattern is large, then unaesthetic gaps form between the strip and the surface of the wallpaper, in which dust accumulates. In this case, it is better to glue the corners while trimming the wallpaper. To do this, the profile is applied to the installation site and a strip of wallpaper is cut along its edges on both sides with a paint knife.

How to cut correctly

For simple cutting of PVC corners, use scissors, a hacksaw or a grinder with a metal disc. If it is necessary to precisely align the corner joints at the required angle (usually 90° or 45°). For accurate cutting in this case, use a miter box or a self-made template, which allows you to get an even edge of the profile.

How to glue

After choosing the method of gluing the corners (on wallpaper or with trimming them), the step-by-step instructions look like this:

- Glue is applied to the inner sides of the corner.

- The plastic profile is applied to the corner of the walls and pressed using a dry sponge or napkin.

- The profile is fixed to the surface with masking tape.

- When the glue has firmly set, the tape is removed.

The glue must be applied closer to the center of the corner in waves, strokes or dots. This will reduce the likelihood of excess glue squeezing out beyond the edge of the corner and will prevent the wallpaper near it from getting dirty. If excess glue does get on the wallpaper, you need to wait until it dries completely, then use a sharp knife or blade to remove the excess, being careful not to damage the finish.

Since the PVC profile is flexible, it is difficult to level it by hand. To do this, use a metal ruler or rule paired with a building level.

As for fixing the corners with tape, you can glue plastic corners onto the slopes without it. But gluing plastic corners for arches onto wallpaper is more difficult and you can’t do without securing the decorative corners with tape. The type of tape is selected based on the type of finish, so both masking and packaging tape can be used.

When joining the corners, their ends are also coated with glue, the excess of which is removed from the plastic after the glue has completely dried.

When forming arches whose length exceeds the length of the PVC corner, extensions are made from pieces of corners. In this case, it is better to make the center of the arch from a solid profile, and add extensions to the sides. The joints of the profiles can be sealed with silicone sealant to match the color of the plastic.

General information

Advantages and disadvantages of MDF

Installing a doorway is a rather labor-intensive process in which accuracy is important. However, this work can be done with your own hands.

The following advantages of this material are highlighted:

- Affordability;

- ease of installation;

- aesthetics;

- the material has good density, which contributes to additional heat and sound insulation;

- environmentally friendly and safe material. Can be used for finishing both external and interior doors;

- Large range of colors;

- Resistant to rotting and mold deposits;

- are durable. The panels are not able to deform and swell;

- suitable for finishing doorways of any thickness.