Fishing is one of the popular male pastimes. Have a nice time on the shore of a pond. Experienced fishermen understand that comfortable fishing requires a comfortable place to sit. Sitting on logs is uncomfortable, and dragging a bulky chair behind you is also not an option. The ideal solution to this issue would be a folding chair with a backrest, which is compact when folded, and when used will help not put strain on your back, which quickly gets tired from sitting for a long time.

A folding chair is an ideal option for lovers of fishing and outdoor recreation.

The height of the chair can be 350 mm - 450 mm.

Store-bought options are not always suitable, since often these products are either not reliable or are very expensive. Therefore, the most rational solution is to make a folding chair for fishing with your own hands. A homemade chair will not only help you save money, but will also allow your imagination to run wild and make a good product from quality material. The advantages of such a chair are its compactness, stability, ease of transportation and simple manufacturing.

This piece of furniture is also indispensable in the kitchen and country house, since when folded it is quite compact and does not take up much space.

To make a folding chair, you can use any type of wood; birch will give it strength.

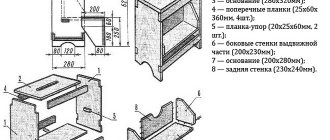

Dimensions of a folding wooden chair

There are various methods to make a chair with your own hands. When choosing a method, you need to consider both the style of the product and its purpose.

Work should begin with the preparation of a drawing of the future structure, which should indicate all the dimensions of the parts, their quantity, materials, as well as those necessary for the work. The success of the work will depend on the quality of the drawing.

Peculiarities

Features of making a folding chair with a backrest with your own hands include:

- simplicity and efficiency of assembly;

- affordable cost for consumables;

- ease of further use;

- variety of designs.

A chair assembled with your own hands will be much more comfortable and practical than a purchased model . At the same time, you will be able to think over its design, select materials, and dimensions yourself. If desired, such a piece of furniture can be decorated with artistic painting, textiles, or wood carvings. Chairs decorated using the decoupage technique also look original.

Materials and tools

When the need arises to make a wooden chair with your own hands, you need to use only solid wood. The main material for such work is wood, which is well dried and free of knots. For furniture production, pine, beech or oak are usually chosen.

It is very difficult to process oak or beech, but furniture made from such wood is durable and reliable.

Materials

- Two strips;

- Thick upholstery fabric;

- Foam rubber from which the seat is made;

- Boards of different sizes;

- Sandpaper;

- Furniture glue;

- Self-tapping screws.

Tools

Bars can be bought at the construction market. Then they need to be processed so that they become completely smooth. To do this, you need to die before acquiring roughness. First, the plate is grounded with a small piece of sandpaper (100 is suitable). Sandpaper No. 220 will give the wood the final shine.

Each job of making a wooden chair with your own hands requires special tools:

- Sandpaper;

- Stapler;

- Saws;

- Conductors,

- Hammer;

- Chisel.

Caring for metal chairs

Regular cleaning is necessary to remove dirt that tends to collect on the surface. Use a piece of sponge to clean chairs. Fabric and pillows are cleaned with special products or washed. Aluminum chairs do not rust, but they are vulnerable to oxidation.

Attention! Aluminum surfaces can be cleaned using non-greasy detergents and should not contain bleaches or industrial oil additives.

Step-by-step instructions for making a folding chair

How to make a chair? At the first stage, it will be necessary to prepare two strips. The legs of the hind limbs should measure 800x40x60. The size of the beams on the front legs should correspond to 440x40x40 mm.

In slots intended for sidewalks and the base (longitudinal and transverse), all grooves must be made at the same level. To do this, you need to connect them, the ends of the legs must match.

- Then the place where the grooves will be created is marked. Their dimensions are 20x40x15 mm. The inside of the groove should be offset from the inside of the foot. It usually lasts 10 mm.

- The legs must have grooves for fastening. There should be two of them in each leg. There are grooves at the corresponding ends of the legs. When assembly is complete, the base will look like a rectangle.

- A foot will be installed on each top. The groove is used for a chisel. The grooves are then cleared of any chips that have entered them during production.

- The rear legs need to be adjusted a little. This is done by using a contoured surface along the entire length of the foot, starting with the notch formed at the top and ending with the lower notch. The result is a smooth transition, the size of which should be reduced to 40 mm.

After creating the legs, you can start making two steps that will act as a longitudinal base. To do this, we produce four rods measuring 350x40x40 mm. There should be a spike mark on each end. The shavings are made with a chisel from pieces cut off with a saw.

The dimensions of the screws must be made in accordance with the dimensions of the groove. They should fit into the groove. In the future, it is necessary to make two blocks measuring 420x40x40 mm. They are needed to create a transverse base. The tips of such rods must also be cut off.

The next operation will be making the backrest. It is better to make them from edge boards. The average backrest dimensions are 420x80x100 mm. Grooves of the required width are milled in the hind legs. Backrests are inserted into them.

The seat is attached with self-tapping screws and screwed in from below. To make it more convenient to turn the screws and give the chair additional rigidity, special clamps are inserted between the bases.

Due to their beautiful appearance, the chair legs should be rounded and then carefully sanded. The same operation must be done with the base. Completely finished parts must be coated with lacquered furniture and then polished.

One of the last stages is making a soft seat. The seat is cut out of a sheet of thick plywood, and foam rubber of the appropriate shape is prepared in the same way. When the chair cover is made, step back from the edge by about 15 cm. Then the plywood is covered with foam rubber with furniture fabric.

Fisherman's lounge chair

For one sun lounger you will need 2 sections of profile 1.5 meters and 2 sections of profile 1 m each. After the profiles are cut, holes are marked and drilled. The edge holes can be made at your discretion, it is important to correctly measure to the junction of the profiles it should be 40 cm, from the “top” - 36 cm. To strengthen the structure and to ensure that the bolts do not break the edges of the profile, they hammer into the places where the holes are made PCB bars. This can be done using a strong iron rod, which is hit with a hammer.

For lintels, thin-walled pipes from old cornices are used. If the chaise longue is 60 cm wide, then you will need 2 pieces of 60 cm and two pieces of 64 cm, these dimensions are calculated taking into account the thickness of the profile. If dimensions accurate to the millimeter are needed, the thickness of the nuts is also taken into account.

From these same pipes, 2 pieces of 67 cm are then cut off, washers are welded to their ends, which will serve for fastening. Sliders are made from sheet aluminum. To do this, a strip 5 cm wide is cut off. Then, it is upholstered around the profile. After this, a hole is drilled in the sliders and the edges are rounded. At this stage we have the chaise longue disassembled. Next, the structure is assembled.

Attention! When cutting metal, you must follow safety precautions.

Folding chair assembly diagram

Experience shows that when making a chair from wood with your own hands, always remember the surrounding environment. The fact is that the varnish coating causes a very strong unpleasant odor. His appearance will clearly not please your neighbors.

Therefore, it is better to do the entire painting shop outside the apartment. For example, in a garage or shed.

- Recently, special water-based varnishes have appeared. He doesn't feel it.

- The chair is assembled from prepared painted parts. The tips are coated with glue and inserted into the groove.

- All parts are destroyed by wood cyanide. If you use a metal hammer, then cover its striking part with a soft cloth.

Otherwise, the paintwork may be damaged. The seat and back are attached with self-tapping screws. The material is fastened with a stapler from the back side of the base.

What is needed to make a chair from a profile pipe

The process of making furniture with a steel frame based on a square or rectangular profile is not complicated or unusual; most of the operations are familiar to anyone who likes to do metalwork or homemade work in the garage.

Without a bending machine you won't be able to make a chair with an elegant design.

To work you will need:

- Semi-automatic welding. The equipment is quite heavy, so there is no point in taking it even for welding homemade folding chairs from a profile pipe. You can always come to a car service center or a locksmith shop, where they will do the work for a small fee;

- Angle machine - grinder with cutting wheels for metal;

- A set of clamps or stable supports, with their help individual pieces of metal are fixed before welding the seams;

- Sharpener with a “rough” stone for deburring;

- Electric drill with a series of drills;

- A bending machine or press where you bend curved parts before cutting the pipe and welding it. Typically this device weighs 10-15 kg, so you can rent a car or borrow it from friends for a couple of days.

For your information! In the case of a round pipe, the most difficult thing is to give the necessary bending and profiling.

Typically, first attempts to bend a round pipe into a curved section result in poor spirals and inclined arcs. Therefore, it is better to make small sections from a round profile that can be easily leveled and adjusted to size.

Working with a semi-automatic welding machine is quite simple, you just need to practice connecting different types of pipes; choosing the gas mode and flow rate will take no more than a few hours. An alternative to a semi-automatic machine can be an inverter welding machine. It also allows you to weld seams quite well, but working with such equipment requires very good electrodes and some experience as a welder.

Manufacturing nuances (answers from a master carpenter)

Any craftsman can make a folding chair with his own hands. It will take much less time compared to making regular chairs.

- To work, you need to have high-quality wood. The front legs and back are made of a shield. These parts will be able to move.

- Wooden poles are used to make the hind legs. Thin lamellas are glued to the back side.

- As a material for seating, you can take plywood covered with thick furniture fabric.

In order to repair the product in the desired position, you will need steel pins. They are perfect for fixing the base.

It is necessary to create spikes for horizontal fixation of the seat and installation of the shield in the slope. The seat is also secured with two steel pins.

Main types of stools

Today, furniture stores offer many types of products made from a variety of materials - plastic, acrylic, metal, wood. These materials can be combined with each other, the stool can be covered with fabric or not, and their colors also vary to suit a variety of design solutions.

Prices for products can vary greatly depending on the material and the manufacturer. According to their purpose, stools are conventionally divided into the following categories:

- classic for the kitchen;

- children's;

- folding stools for going out into nature;

- mini-stools used as stands.