Transformable step stool + ironing board

A step stool or ladder can be made with your own hands according to the instructions given below in the article. In this article we will look at various designs of such home and useful transformers. Let's take a look at the drawings, layouts, diagrams and detailed instructions for making them from wood at home.

Such stepladders were originally intended for libraries, but later, due to their extraordinary usefulness, they began to be made for ordinary household chores : for the kitchen, garage, hallway, children's room, for the dacha and even for the office.

I wonder what else will come to the minds of the masters

THIS IS A FANTASTICALLY USEFUL THING!!!

Article menu:

- Chair + stepladder + ironing board.

- A simple DIY transformable stepladder chair.

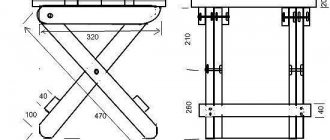

- Design of a transformable step stool + Drawing

- Do-it-yourself stool-ladder

- Folding step stool. Drawing

- DIY stepladder chair (Universal stool idea)

- Drawing: do-it-yourself stool and step-ladder chair

Transformable stepladder chair

In any home, you simply need a step stool, which is useful in all situations when your own height is not enough: when replacing a burnt-out light bulb, if you need to get something from the mezzanine, when you need to remove or hang curtains, etc. If we are talking about a summer cottage, then a transformable stepladder chair will also help out in the garden when harvesting. The ladder chair combines the convenience of a regular chair and the functionality of a mobile ladder, fitting perfectly into the interior.

A wooden step stool will be an excellent solution in an apartment with high ceilings. You can make storage systems in the kitchen or in the room under the ceiling, making maximum use of the usable space. And such a folding step-stool will help you easily reach things on the upper shelves.

It is not at all necessary to purchase a ladder in a store, because you can easily make a step stool with your own hands. Although there are models made of plastic, it is unlikely that you will be able to build them yourself. As a rule, home craftsmen choose wood as a material, because it has a number of advantages:

- wood is easy to process;

- the natural color of the wood is pleasing to the eye and harmonizes perfectly with the rest of the decor;

- wooden step stools are small in size and light in weight;

- is an environmentally friendly material;

- The ladder stool is made from available materials: wooden boards and bars.

Pros and cons of homemade design

It is necessary to highlight the pros and cons of assembling the structure with your own hands.

The advantages are as follows:

- designing a staircase chair at home will be much cheaper than buying it in a store;

- you can save time, because you can’t always find a suitable chair in the store;

- everyone will be happy to make a design for themselves that will be useful;

- common advantages of all models: compactness, ergonomics, versatility, ease of use.

Disadvantages: you need to calculate all the indicators very well, otherwise the step may break.

How to choose a step stool for the kitchen or children's room

If you look at the photo of stepladder chairs, you will probably notice how different these types of furniture can be in design. Basically they can be divided into two groups:

- transformable stepladder chair made of wood;

- wooden ladder stool without transformation mechanism.

Pieces of furniture with a transformation mechanism perform only one function at a certain point in time - this is either seating furniture or a staircase. The chair turns into a stepladder under the influence of a person - it can be a folding or retractable mechanism. Thus, the transformable ladder chair changes its functionality when the configuration changes.

Furniture of the second category is stationary, its design does not change. A wooden ladder-stool is simultaneously capable of performing both tasks - serving as a seat and a lifting device. Since furniture in this category does not have a transformation mechanism, it is larger and takes up more space. On the other hand, such products are more reliable and safer. If you are going to make a children's staircase-chair, then stop at this design. The drawing of a ladder stool for children does not have moving elements, which means that the child does not risk pinching a finger or falling if the structure is unstable.

Photo of wooden transformable ladder chairs

Photo of children's ladder-chairs without a transformation mechanism

Although the latest ladder stools are called children's stools, they are also ideal for retirees who often need help reaching something from a height.

When choosing stationary or folding ladder stools, be sure to pay attention to the design - this is the main parameter that determines how convenient and safe it will be to use the product. If a folding stool-ladder will primarily have the functional load of a chair, then choose designs with a back - large and comfortable. In this case, it should first of all be a chair and only then a ladder.

This folding ladder chair will be truly convenient and comfortable.

If, on the contrary, you primarily need a ladder, and the ability to sit down will simply be a pleasant addition, then choose a stationary ladder-stool for children. When it is not used for its intended purpose, it can serve as a stand for flowers or decoration.

Photo of a ladder stool without a transformation mechanism. This design is the most reliable

What is

A transformable chair is a wooden product that looks like a regular chair, but can turn into a stepladder. The product has many advantages:

- takes up little space;

- does not require additional support, it is easy to move;

- able to withstand heavy weight while maintaining stability;

- you can make it yourself at home using available materials;

- Easily transforms into a staircase.

The design of such a chair consists of the following parts:

- front, rear sidewalls;

- backrest slats;

- sitting;

- steps.

Similar transforming chairs have been used in everyday life for a long time. Initially, they were used in libraries, as they made it easy to reach even the highest shelves. Soon after this, the idea spread to the people, step stools began to be found everywhere. At the same time, the appearance of the products can be completely different: the chair can be made of inexpensive wood or decorated with decorative and carved elements. Everything depends only on the carpenter’s imagination.

What to make a wooden ladder chair from: choosing the material

The easiest way to make a step-stool with your own hands is from wood - wood is affordable, it is easy to process, it has the necessary strength, and the products acquire an attractive appearance. However, there are a huge variety of types of wood, and not every species is suitable for making a folding stepladder chair. Let's find out what kind of wood to make a step stool from.

Softness of wood

To make a step stool from wood, it is important to choose the right wood for its softness. Material that is too loose and fibrous will “fluff” and peel off when trying to process the surface. The product will turn out to be sloppy and will only be suitable as a country ladder, stepladder, or stool.

If you take hardwood, you may encounter another problem - the complexity of processing. In this case, without the use of specialized equipment, it will also be difficult to properly process the surface of the folding ladder-stool. Therefore, if you do not have sufficient carpentry skills, it is better to choose medium-soft wood - it will be easiest to make a stool-ladder from such wood with your own hands at home.

So, according to hardness, wood can be divided into:

- hard – oak, beech, walnut, acacia, yew;

- soft - pine, juniper, linden, alder, aspen.

The most popular type of wood when making a DIY step stool is pine. When choosing lumber, pay attention to the region of growth: wood growing in the South has a looser and more fibrous structure, while northern trees have a denser texture.

Types of wood

What type of wood should you use to make your own staircase chair? To make the product truly durable and stable, you should not skimp on wood. To make a children's ladder stool with your own hands, choose selected or premium wood. The same types of lumber are also suitable for interior wooden stairs, transformable chairs.

Selected and first-class wood has no or only a small amount of small knots and cracks. They are completely free of rot, through cracks or traces of knots; this wood has not been damaged by bark beetles. In addition, these types of wood have a beautiful appearance with a beautiful wood grain that is uniform and uniform. This type of wood will make a transformable stepladder chair not only durable, but also attractive.

Folding ladder chairs are best made from selected or first-grade wood - they have no through defects, and the surface has a beautiful wood pattern

But what if you need to make a step-stool with your own hands from wood at minimal cost? If the aesthetic component does not play a special role for you (for example, if you plan to paint the furniture with matte paint), then you can choose second-grade wood. Its appearance is not so attractive - the presence of knots, cracks and other defects is allowed, but their number is insignificant. Second-grade wood does not have through holes, traces of bark beetles, rottenness or mold. And small loose knots and cracks can easily be filled with wood putty, which will then be covered with paint.

Matte paint will help hide any defects on the surface of the ladder, stepladder, or stool.

Is grade 3 wood suitable for a wooden folding ladder stool? If you need to put together a country stool for one or two seasons, then you can take this too. But such a tree may already have bark beetle damage and may have mold and mildew. Third-grade wood, as a rule, is loose, with large and long fibers, so the surface of a product made from it cannot be carefully processed. The strength of a hand-made ladder stool made from third-grade wood will also suffer: due to the looseness of the wood, the fastenings may become loose over time.

Wood type

What type of wood can you use to make a wooden transforming step stool with your own hands? Let's understand the characteristics of different types of wood and find a middle ground.

- Pine and spruce

If you want to make a wooden step-stool with your own hands, then you will most likely choose pine - after all, it is the most popular and widespread lumber from which furniture is made. Pine is a soft wood, so it is easy to process - you can cope with the task even without professional tools. In addition, pine has a light shade of wood, which means that a wooden step-stool with your own hands can then be painted or tinted in any color.

Pine wood is rich in resins, so tree parasites do not like it. But the product will have to be protected from water, since loose fibers actively absorb moisture. If you need to make your own transformable stepladder chair for use in a damp room, then pine will not be the best choice. The same is true for outdoor use - at a minimum, products should be stored under a roof. But for an interior wooden folding stepladder-chair, pine is perfect.

- Birch

Birch is harder than pine, but not as hard as beech or oak, so it is probably the second most popular type of wood among those who make their own staircase chairs. Birch has a very beautiful, unique wood pattern, so such wood is rarely covered with matte paints - it is mainly tinted and varnished. Therefore, making a transforming staircase chair from birch with your own hands will not work out very cheaply - you will have to not skimp on the type of wood. Otherwise, this is an excellent choice.

Birch wood is easy to process with both hand and power tools. The structure of the tree is denser than pine, so the folding stool-ladder can be decorated with carved ornaments - even with fine detail, the design on the birch will be clearly legible.

An important advantage of birch is its price. It is slightly higher than that of pine, but again does not reach oak and beech. You can make a transforming stepladder chair from such wood with your own hands quite inexpensively, so we can safely recommend birch to home craftsmen.

A wooden step stool made from expensive species will fit even into a rich and luxurious interior

- Nut

Walnut cannot be called a banal choice for furniture production, but such a stool-ladder will look great in the interior. Walnut wood has a deep and unobtrusive pattern, against which the carved elements of furniture are perfectly revealed. Walnut will be appropriate in a rich, classic interior.

Making a wooden folding stool-ladder from walnut is not a task for a novice carpenter, since the wood is dense and hard, its processing requires powerful specialized equipment and, of course, appropriate skills. On the other hand, due to such durability, the kitchen ladder stool will last for many years without damage, scratches or chips.

- Beech

If you are planning to make a transforming stepladder chair with your own hands that will last forever, then pay attention to beech. This wood is strong and dense, comparable in these indicators to oak. Beech perfectly reveals carved patterns and holds fastenings securely, so furniture with transformation mechanisms will last a long time. You can also make a stepladder-chair with wide steps from beech: durable wood can easily withstand heavy loads.

The main disadvantage of beech, besides the price, is the property of wood to actively absorb moisture. A beech children's step stool may not survive spilled paint and subsequent washing. You should not use furniture in rooms with high humidity. This option is also not suitable for open air.

- Oak

Those who are looking for how to make a step stool as durable as possible often choose oak. This is a fairly valuable and beautiful type of wood that has excellent performance characteristics: it does not rot, is not afraid of water, and holds fastenings securely. By making a one-time investment in making a do-it-yourself ladder stool from oak, you will receive a product that you will be happy to use for decades.

Oak wood has a beautiful and rich pattern, so stain or tinting varnish is most often chosen as a finishing method. A children's step-stool made of oak can be painted, carved patterns can be made on it - in any design it will look perfect. An oak ladder stool will fit into any interior style, and numerous photos confirm this.

Step stool – transformable made of plywood

You can make a folding step-stool not only from solid wood, but also from plywood. Moreover, the structure can be either entirely plywood or combined. The second option is preferable, since according to the drawing of the staircase chair, frame, load-bearing elements will be made of timber, and the front planes will be made of plywood.

Assembling a chair-staircase-transformer in a combined version according to the drawing is no more difficult than from solid wood, and in some cases even easier.

To make a transformable stepladder chair, you need special plywood - furniture plywood. It is made from natural raw materials, which are glued and compressed under pressure. Furniture plywood has a multi-layer structure that resembles a sandwich. In each layer, the fibers are located in different directions, due to which sufficient strength, resistance to moisture and load resistance are achieved.

Photo of a plywood ladder stool. Simple but reliable and affordable design

When choosing plywood for a staircase chair, you need to pay attention to the quality of the glue used in production. In cheap handicraft sheets, gluing can be done with toxic adhesives containing phenol and its compounds. Products made from such plywood are not suitable for indoor use, and in general it is better to choose reliable material from a trusted manufacturer.

To make a wooden step stool with your own hands, you can take plywood made from different types of wood:

- Softwood plywood

Choosing softwood plywood for a ladder stool is an excellent solution. The material is perfect for making furniture; it has a light shade, so it can be painted any color without any problems. Coniferous plywood is not the most durable, but due to its high resin content it is not susceptible to rotting and parasites. But it is better not to place plywood furniture made from coniferous wood near heat sources - uneven heating can cause the material to crack and delaminate.

- Hardwood Plywood

The production technology for this material is the same, only hardwood chips are used as filler. You can find sheets of larch, birch, aspen, poplar and other types of wood. For making a transformable staircase chair with your own hands, hardwood plywood is better suited, since, all other things being equal, the material has higher strength. But such plywood is not moisture resistant - so that the product does not warp during operation, it must be coated with protective compounds and use antiseptic impregnations.

- Combined plywood

If you are going to make a transformable stepladder chair with your own hands, then consider the option with combined plywood. In its production, both coniferous and deciduous wood was used. Typically, coniferous layers are placed in the middle, and the outer layers are made from more attractive and aesthetically pleasing hardwood.

Plywood, like other lumber, comes in different grades: the quality and appearance depend on the grade. Choose from the highest or first grade for a convertible step stool.

When choosing plywood for making a step-stool with your own hands, pay attention to the thickness and number of layers: the more layers, the thicker and therefore stronger the plywood.

When choosing plywood for a stepladder chair design, rely on the dimensions in mm, and not on the number of layers - all manufacturers have different thicknesses

The thickness of plywood sheets does not directly depend on the number of layers. Different manufacturers may change the thickness of one layer, which affects the final dimensions of the material. When choosing, base your choice on the thickness in mm, and not on the number of layers.

Step stool drawings with dimensions

The first step in how to make a step stool is to draw a drawing. The convenience, comfort and safety of using furniture largely depends on how carefully you choose the design.

The dimensions of the ladder chair must take into account, on the one hand, ergonomics, i.e. repeat the shape of the body, and on the other hand, meet the requirements for stairs. The optimal size for the steps of a ladder stool is a height of 15-20 cm. Thus, the drawings of a step stool correspond to the size and number of steps. Small stands may have two steps, but full-length and full-size chairs usually have 3-4.

Use ready-made drawings and diagrams for the staircase chair. This way you will definitely get a comfortable product that takes into account all norms and standards.

Let us give examples of drawings of a transformable stepladder chair with dimensions that you can make yourself from wood or plywood.

Drawings with dimensions for a step stool made of wood or plywood without a transformation mechanism, which you can make yourself, are given below.

How to transfer a drawing with dimensions to wood or plywood

So, you have chosen a drawing with dimensions for a transformable stepladder chair, what next? Now you need to transfer the diagrams onto sheets of plywood or wooden boards. How to do this with your own hands in order to correctly maintain all sizes and proportions? Plain checkered paper will help. First you need to print a drawing with dimensions on a regular printer and make a grid on it.

After this, you need to build a drawing of a transforming step-stool chair in real size with your own hands. To do this, glue several sheets together. Now you need to apply the same mesh markings to the canvas as on the smaller version.

Calculate the scale. To do this, use a scaled-down drawing of a wooden step-stool to measure any size using a ruler. For example, we measured the height of a stool - it is 15 cm. We know that the finished product should be 90 cm high. It turns out that the scale for our drawing is 1:6. After this, we measure the length of the square of the grid with a ruler - let’s say, for example, we did it in increments of 1 cm. Then, on the drawing of a stool-ladder in real size, we need to build a grid of squares with sides of 6 cm. This simple technique will allow us to convert even the most complex drawing of a wooden step stool.

We transfer the drawings of a wooden step stool with our own hands using the scaling method

Using squares it is easy to redraw any diagram of a staircase chair, even if it contains complex cutouts and curved shapes.

Securely secure the diagram of the chair-ladder with tape around the entire perimeter so that the drawing does not fidget during cutting.

When we have built a full-size drawing of a wooden step stool, we move on to cutting out the first part. To do this, we fix the pattern on plywood or a board - this can be done with tape, fixing it in several places so that there is no distortion when cutting. Now use a jigsaw to carefully cut out the part of the desired shape.

The scaling method is suitable for complex and curved drawings of a wooden step stool

Drawings of wooden transformable stepladder chairs often have symmetrical but mirrored details. To cut out absolutely identical fragments with your own hands, first transfer the paper pattern onto a sheet, cut it out, then place the part in a mirrored position on another sheet or board, trace it and cut it out. In order for the dimensions of the parts of the staircase chair to match, you will need to sand both elements, periodically placing them on top of each other.

We cut out with our own hands all the elements of the drawing of a transforming chair-staircase

Using this method of constructing drawings, you can make all the details of a wooden transformable step-ladder chair with your own hands. They will be smooth and the right size. All that remains is to connect the structural elements.

The dimensions of the stool-ladder parts coincided with the drawing, and the product is ready for assembly

Back assembly

If you decide to make a transformable garden bench, then at the next stage you can work on the back. It will also serve as a tabletop at the same time. This part of the product must be made from 5 boards that will form a common plane. The dimensions of the backrest are 57x126 cm. The blanks are connected to each other using a pair of planks. Self-tapping screws that hold the boards together will help with this.

On one side of the tabletop, stops should be fixed, which will have a thickness of 20 mm. The workpieces must be cut at an angle of 115°. It will determine the backrest angle. Using self-tapping screws, all stops are fixed in the next step. Subsequently, you will use screws and metal connections that will allow you to connect everything into a single structure.

DIY step stool

In this example, we will show how a small number of boards can make an excellent stepladder-chair. We decided to make a folding step-stool with our own hands because of the increased functionality and simplicity of the device.

The step-chair diagram consists of the following parts:

- seat;

- support post;

- ladder;

- connecting strips.

The most convenient and reliable design is a step stool with the following dimensions:

- the distance between the strings of the stairs is 48 cm;

- the maximum distance between the bowstring and the support post is 60 cm;

- seat height – 60 cm;

- seat dimensions – 30x50 cm.

For comfortable use of a wooden staircase chair, two or three steps are enough, located at a distance of 15-20 cm from each other. From the floor to the bottom step and from the top to the seat, the distance is also 15-20 cm.

How to make a wooden ladder stool seat

In order to make a comfortable seat for a ladder chair with your own hands, we will need 5 transverse slats and 2 base slats. First you need to treat the surface so that the wood becomes perfectly smooth. Then the slats are fastened together. At a distance of 5 cm from the edge, lines are drawn on both sides, and a groove is made using a cutter, the width of which is slightly less than the thickness of the base slats. Next, the transverse bars are fixed to the base slats. To ensure the strength of the structure of the chair-stool-ladder, the joint is glued. The finished seat of the kitchen ladder stool is shown in the photo below.

You can also make the seat of a transforming ladder stool from two boards measuring 150x500 mm each, which are attached close to each other.

How to make the support part of a wooden ladder chair

To make the supporting part of a folding stepladder chair, we need 5 slats, two of which are guides, two provide a horizontal connection, and the fifth rail serves to increase the strength of the structure by connecting the guides at an angle.

In the photo, the elements of the supporting part of the ladder-stepladder-chair are laid out as they will later be attached

All connections are made using dowels. To do this, holes are drilled at the ends of the slats, the diameter of which is slightly smaller than the diameter of the dowel. The counter holes are also made in the slats-racks of the future chair-stool-stepladder. To ensure the strength of the stool-ladder, the joints are glued. The end result was the back of the stepladder.

When installing the support post, you should remember that the distance between the guide rails must be such that the seat support rails can be secured between them.

How to assemble a ladder for a stool chair

Please note that the flight of stairs of the chair-stool-stepladder will be fixed at an angle, and the steps should be positioned strictly horizontally, so the grooves for the steps should be made at an angle. To determine the angle, it is recommended to assemble the structure without steps and without connecting rails on a flat surface. Set the distance between the string and the support post to 60 cm and, by adjusting the angle of inclination of the structure, ensure that the seat of the wooden step stool is positioned strictly horizontally.

If necessary, the length of the bowstrings and support posts should be reduced so that the height of the seat of the wooden step stool is 60 cm. Now the structure must be secured using connecting slats and the lower ends of the bowstrings and support posts must be cut at the desired angle. Next, mark the position of the steps and make recesses using a router. If you attach both strings to each other, as shown in the photo, you will clearly see the symmetry of the grooves for the steps of a wooden transforming step-ladder chair.

The dimensions of the step stool steps are as follows: width is 44 cm and depth is 15 cm. The grooves for attaching the steps should have a width slightly smaller than the thickness of the step. Attaching the steps of a step stool with your own hands is done using glue and self-tapping screws.

In the photo, the steps of the transformable staircase chair are glued with your own hands and tightened with clamps - in this position you need to wait until the glue has completely dried

DIY staircase chair assembly

To assemble a step stool, you need to connect all the parts together. Final installation is carried out in the following sequence:

- the ladder strings and support post guides are attached to the seat. The upper ends of all slats must be rounded, otherwise they will cling to the seat when folding the wooden transforming stepladder chair;

- the slats for connecting the ladder and the support post are fixed at one end on the bowstrings, between the seat and the upper step, the other ends are fixed in the middle of the support posts.

The finished stool-ladder is coated with three layers of varnish. It is recommended to cover the steps and seat with a large number of layers. It is important to know what varnish to coat the stairs with; the durability of the product will depend on this. Then you can use a step stool for the kitchen without fear that the wood will be damaged by water.

In order for the staircase chair to serve you faithfully for many years, it is recommended to periodically update the protective coating during operation. If there is no need for a ladder at the moment, it can be folded and hidden in a dry, warm place - but do not store the folding step-stool near the radiator, as the heat may cause the structural elements to warp. Try not to leave the product outside, especially in damp and cold weather, which has a detrimental effect on the structure of the wood and will lead to premature damage to the stairs.

Watch the video on assembling a step stool with your own hands to clearly see all the aspects of making the structure.

Manufacturing instructions

As noted, the procedure for making a stepladder directly depends on the type of material chosen.

Made of metal

To create a metal folding ladder, you need:

Cut a metal profile with a cross-section of 20x40 millimeters into 4 equal sections, from which the support posts will be made in the future. Drill holes at equal distances on the sides of the guides for fastening the steps. Cut metal steps of appropriate length. Attach the guides like a wigwam using metal hinges. Using bolts, secure the steps to the guides. To increase the strength of the structure, it is recommended to weld each part to the support posts

At this stage it is very important to maintain the level of the steps.

At the end of the process, you also need to secure the limiters, as indicated earlier.

Made of wood

To make a simple folding ladder, you need to prepare bars of the following sizes:

- 2 meters - 4 (for support);

- 59 centimeters - 2;

- 50 and 50.4 centimeters - one each;

- 45.5 centimeters - 1;

- 41 centimeters - 3.

You also need to prepare 2 fastenings with loops. After this you need to do the following:

- Apply markings to 2 support posts at a distance of 40 centimeters. The lower step must be mounted at a distance of 10 centimeters from the floor.

- According to the applied markings, cut grooves on the support posts.

- Cut tenons on the edges of the bars that will be used as steps.

- Insert the tenons of the steps into the cut grooves and secure the parts with self-tapping screws or nails.

- The two remaining supports are connected to each other by planks, which are fastened in the form of the letter Z (two planks are installed horizontally, and the third is installed at an angle to the first).

- Connect both support structures together using metal hinges or other mechanism that allows you to fold and unfold the stepladder.

At the end of the work, it is recommended to attach rubber pads to the legs, and treat the entire structure with an antiseptic and varnish (paint).

How to make a folding step-stool with your own hands: an alternative design option

A folding wooden step-stool is made somewhat more complicated than the previous version of the stool, but at the same time it has a more sophisticated look and, if necessary, can be transformed into a regular chair.

The shaped elements of a folding stepladder chair are cut out according to patterns. The edges are processed using sandpaper. The moving part is connected to the fixed part using piano hinges. With certain skills and patience, you can make a similar design with your own hands.

Watch the video on how to make a chair that turns into a stepladder in a couple of seconds.

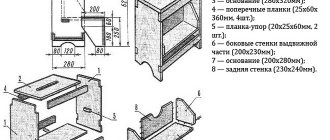

Another alternative could be a design consisting of a stool and a movable module, which is hidden under the seat when folded. The module consists of two stages and is pulled out using guides according to the same principle as drawers. The photo shows an example of a retractable design of a transforming step-stool chair made of wood, which you can make with your own hands.

The ladder chair consists of the following elements:

- 4 legs 10x72.5 cm;

- 2 upper legs 3.8x18 cm;

- 2 lower legs 10x42 cm;

- 2 upper drawers 12.5x34.5 cm;

- 1 lower drawer 10.5x34.5 cm;

- top step 27x25 cm.

All parts have a thickness of 19 mm. To make the side pads of a stepladder chair you will need plywood - 2 sheets 3 mm thick with dimensions 17x25 cm.

The retractable module of a stepladder-chair with wide steps with a retractable mechanism consists of the following elements:

- 2 medium legs 10 cm wide and 47 cm long and two small legs 10 cm wide and 21.5 cm long;

- 2 step rails 10 cm wide and 40 cm long;

- 2 front drawers of step stool steps made of plywood 9 cm wide and 22 cm long;

- 1 rear step frame 10.5 cm wide and 30 cm long;

- 2 steps 18 cm wide and 29.8 cm long.

A drawing of a plywood step stool is shown in the photo below. All parts have a thickness of 19 mm.

To make a ladder chair you will also need:

- guides – 2 sets, each 31 cm long;

- fasteners: dowels, dowels, screws;

- sandpaper;

- glue, putty, paint or furniture varnish.

To make a step-stool with your own hands, you need to stock up on tools: a hacksaw, a jigsaw, a plane, a drill, a grinder and clamps.

First, the legs are cut out from pre-polished blanks 10 cm wide, as shown in the drawing of a plywood step stool with dimensions below.

Then the legs and plywood overlays are cut out. You can build drawings of a step stool made from plywood with your own hands according to the diagram with the cells below.

Next, depending on the chosen type of fastening of the retractable ladder-stepladder-chair, you need to select grooves for the dowels or drill holes for the dowels and connect the middle legs. The junction is cut at a slight angle. The corners of the plywood step stool legs are rounded with your own hands, which will help prevent them from chipping.

The drawers are cut out, and their upper ends must be beveled at an angle of 80°. All the steps of the transformable staircase chair are also cut out, after which their edges are slightly rounded. On the bottom step, it is necessary to make corner cuts of 3.8 by 3.8 cm, as shown in the drawing of the transformable plywood stepladder chair above.

When all the parts are ready, the step stool is assembled with your own hands using dowels and screws without the use of glue. This is necessary to identify and correct possible flaws. Assembling a step stool from plywood with your own hands is done in the following order:

- large legs are connected to the upper legs using screws;

- the upper drawers and lower drawers are attached, and the upper step is mounted;

- The middle legs are assembled in pairs, the legs are attached to the outer side of each pair. The resulting nodes are connected by drawers;

- small legs are attached with screws to the legs and connected by a drawer. We strengthen the remaining 2 steps.

If all steps are performed correctly, you should have two parts of a transforming ladder-stool. Now you need to install them the way they will be connected, and attach a guide to the outside of the movable legs, and its rear ends should be located at the same level as the rear edges of the legs. The entire process of attaching the retractable mechanism of a chair-stool-ladder is shown in the diagram.

To avoid distortion of the wooden ladder stool, we install the front edges of the movable steps in one line, after which they are completely pulled out into the groove of the legs and the free parts of the guides are secured.

We check how well all the moving parts of the chair-stool-ladder work, and make adjustments if necessary. When everything is finally adjusted, the wooden ladder chair is disassembled and reassembled using wood glue.

A step stool made of plywood, assembled with your own hands according to a drawing, is covered with transparent putty. After it dries, apply 3 layers of varnish. The plywood overlays are painted, after which the functional and aesthetic ladder stool is completely ready for use.

Watch the video of making a step stool with your own hands.

Types of children's high chairs

What chairs are available for children? Modern manufacturers offer a wide range of chairs for children of all ages.

They may differ in purpose, design, material and other criteria.

Many models can be produced independently of each other.

The most common and practical types of high chairs are the following:

- A simple high chair is a regular high chair with a backrest, as described in this article.

- The reclining chair is a versatile chair with rich functionality. It should be possible to change the angle of the backrest, adjust the steps, attach the tabletop, etc.

- Rocking chair - the name of the chair speaks for itself. All children, without exception, love to swing on such a chair. Modern models offer the possibility of using the rocking chair as a rocking chair.

- The Transformer is a set of chairs and tables that can be set up and used in a variety of ways. When assembled, the transformer serves as a comfortable high chair; when disassembled, it serves as a simple high chair and table, standing separately.

Some models have adjustable leg height and backrest position, and the high chair “grows” with the child.

If you have little experience in carpentry, it is better to limit yourself to making a regular high chair without additional functions. The main thing is to understand the basics and operating principle, and in the future you will be able to create more complex models of chairs.

When making a chair, it is recommended to use environmentally friendly materials with high strength. In most cases, the following materials are used:

- Natural wood;

- Plywood;

- Chipboard.

The production of children's furniture (chairs, beds, tables, etc.) from plastic pipes is very common. After assembly and decoration, you get very attractive and unusual designs, but their reliability and durability are very questionable.

It is recommended to choose wood, plywood or wood. Chipboard Since these materials are absolutely safe for children, they have a long service life and other positive characteristics. With the help of this article you can make a high chair out of wood.

The following structural elements must be prepared for the construction of the chair in accordance with this drawing:

- 1 - top rod (1.9 x 4.1 x 16.5 cm);

- 2 — two rear legs (3 x 3 x 55 cm);

- 3 - carved beam (1.4 x 4.1 x 16.5 cm);

- 4, 6 — stripes in the middle and bottom (1.4 x 2.9 x 16.5 cm);

- 5 - Double-sided seat (1.4 x 10.5 x 26.3 cm);

- 7 - two kings and two slats on the sides (1.4 x 2.9 x 17.7 cm);

- 8 - two front legs (3 x 3 x 30.5 cm);

- 9 - two handles and two front stripes (1.4 x 2.9 x 19.5 cm).

For the feet, it is recommended to use pine stones with a cross-section of 3 x 3 cm.

The legs of the chair should gradually be as follows: The back legs should be up to 1.9 cm from the center of the chair, and the front legs should be up to 2.4 cm from the center of the chair.

Tip: To make assembling the bands and kings as easy as possible, only reduce the outer edges of the pieces. This ensures that the inner edges are parallel to each other.

How to fit a step-stool into the interior: design and decor of the staircase

Regardless of the chosen size of the ladder stool and its configuration, the furniture can turn out beautiful and elegant. A wooden transformable stepladder chair can be:

- paint with semi-gloss or matte paint;

- open with matte or semi-gloss varnish;

- tint with stain;

- cover with fabric;

- paint or decorate with decoupage napkins.

When choosing a method for decorating a staircase chair with your own hands, do not forget about safety requirements. In particular, it is not recommended to cover the steps with glossy paint or varnish or use any other finishing techniques that will make the steps smooth and slippery.

Look at the photos of stepladder chairs of different configurations to choose the finishing method you like.

Metal step ladder

Today, metal ladders with 2 or 3 steps are very popular, and there are models with one-way or two-way ascent. These stepladders are lightweight, durable, compact and easy to fold. Anti-slip coating on the steps and rubber pads on the legs of the ladder ensure its safe and comfortable use.

The advantages of such a ladder are obvious: it has a durable metal frame and a fairly wide platform, making it very stable. The height is enough to reach the ceiling from her seat in an ordinary apartment. The stool ladder is easy to use and does not require too much maintenance. All fastenings are made using standard bolts, which can be easily replaced if necessary.

In addition, a metal stepladder looks good and fits perfectly into a modern interior. Unlike wood, it can be stored in damp and cold areas.

- Author: admin

Rate this article:

- 5

- 4

- 3

- 2

- 1

(7 votes, average: 4 out of 5)

Share with your friends!

Tools and consumables

We will need the following tools:

- hacksaw for metal (optional - circular);

- jigsaw (preferably electric);

- screwdriver;

- grinding wheel and rim for cleaning wood;

- hammer;

- Bulgarian;

- self-tapping screws;

- brushes and paint (optionally, paint, stain) for final finishing.

Experts recommend using multilayer plywood (at least twelve millimeters thick) as the main material. If the base is thicker, then, undoubtedly, the product will become stronger, but its “weight category” will increase. And we are for a compact and not too bulky design. A small clarification: when you plan to work not only indoors, but also outdoors, you need to choose a moisture-resistant version of the plywood sheet.

You can sit down and relax