Design Features

In the modern understanding, a sewing table is a kind of transformer. When folded, it is a compact bedside table, which, if necessary, expands into a full-fledged workplace. The cutting table for a sewing machine is ergonomic and highly functional. You can completely hide your equipment in it. Inside, the product is equipped with many drawers of different sizes, spool pins, and shelves. The main task of a sewing table is to make the master’s many hours of work more comfortable.

Having a specialized workplace, a seamstress can easily make cuttings and apply patterns. All tools will be at hand, and the machine will not move during operation. In addition, if there are small children at home, a folding transformer will protect children from sharp and dangerous objects, which is almost impossible when working at a regular desk.

Patchwork table: differences and important details

Not long ago I became interested in patchwork sewing. You can see my endeavors here. And this is the difference I discovered with the table for sewing clothes.

- Length may be shorter. It is a fact. A sewing table length of up to 110 cm is sufficient.

- The width may also be slightly smaller. About 60 cm is enough.

- Place for an iron. This is the most important difference. If when sewing clothes you simply place an ironing board nearby, then in patchwork sewing a hot iron should be at hand. Therefore, they make a place for ironing right on the table. I will tell you how to make a special ironing mat for a table later in a separate master class. To avoid missing out, subscribe to the news (right).

In patchwork, there are a lot of additional tools that need to be stored somehow. To save space in the apartment and give a corner to your husband, children, cats and dogs, you need to improve the sewing table.

Ikea sells excellent hooks with double-sided tape.

They can be used to cover a table and hang rulers. You can also sew bags for storing small items, and also place them on these hooks.

Varieties

The modern furniture market offers a wide selection of ways to organize a workplace for needlewomen. Sewing tables are available in several types:

- Classical. Designed for household or industrial sewing machines and accessories. All studios, as well as large factories, are equipped with it. The sewing machine is securely fastened to the work surface. This table does not fold, but is adjustable in height, which is very convenient for those who are tall.

- Multifunctional. Often made angular, it includes several main and additional modules. Some models can be compactly folded into one large cabinet. Such a sewing table often has many sections, compartments, and drawers. It looks like a full-fledged workplace. Most models have an organized cutting surface.

- With built-in lighting. Such products are presented in a wide variety of models. The main advantage is the presence of built-in lamps that provide proper illumination of the work surface.

- Table transformer. When unfolded, it is a spacious workplace with many compartments for storing necessary small items; when folded, it is a regular folding table that can be used as a desk.

- Book. A budget and simplest table for needlework, consisting of three or more sections, one of which is stationary, and the rest are folded out as needed. Often, such models are equipped with compartments for storing a sewing machine and accessories. The main advantage is the ability to adjust the height of the table.

- Angular. Larger model with a spacious work surface. Allows you to cut, sew and do all the necessary work without changing position.

- Professional table for cutting and drawing patterns. It is often more convenient for seamstresses to work at large tables, which simultaneously house a sewing machine and a cutting surface. The model is suitable for those who constantly sew.

- Cabinet with sections for storage. The most budget option. Actually, this is an ordinary bedside table, which has drawers and shelves for the dimensions of sewing equipment. They are often accompanied by a folding tabletop, screwed to the cabinet on hinges. The main advantage of this model is its compact size.

Of course, for a hobby in the form of tailoring, any table with or without a drawer is suitable, but if sewing becomes the main profession, it is advisable to give preference to special products that are height adjustable and have a large working surface area. Because only correct and comfortable body position during long-term work will preserve the health of the spine.

Classical

Book

Multifunctional

Professional

Table transformer

Angular

Cabinet

The principle of folding “buffet” facades with compartments for small items

The cabinet table for handicrafts and sewing is equipped with special hinged doors. Strictly speaking, in terms of their functionality and design, they already become part of the body.

On the reverse side of the facades, an additional box is designed in which shelves and hangers are placed to accommodate various containers, reels, hangers and small tools. It can be folded in half or just like a book.

In its design, the book-shaped craft cabinet is very reminiscent of a kitchen buffet, which also often had shelves for storing various jars and bottles on the back of the facades. As, however, you can see it in the refrigerator.

By analogy, designers often design kitchen cabinets, pencil cases, inside of which there is a shelf that serves as a working surface for placing household appliances. Very convenient: small appliances are hidden from view and do not create visual noise in the kitchen interior. And at the same time it is always available for use.

A retractable tabletop can be made under the main work surface to provide greater ease of use.

However, DIY cabinets for handicrafts are rarely made to the same depth as kitchen cabinets. Therefore, it is not very rational to make retractable tabletops - after all, they can only be the same depth as the body of the craft cabinet. Therefore, a drawing of a cabinet for handicrafts and sewing can most often be seen with a folding tabletop and retractable legs, in the manner of a book-table.

Some needlewomen find it more convenient to use screw-in metal legs instead of folding supports - after all, they do not take away the depth of the lower shelves, and they can be stored in a separate section. And then the drawing for the cabinet, table for needlework and sewing can be drawn differently.

Book doors with shelves are attached to the base of the transformer cabinet with a folding table for needlework.

They can also be folded in half, then you can draw a transforming cabinet table with your own hands like this.

As can be seen in the drawing, it will be necessary to reduce the internal filling of the cabinet body to the depth of the “buffet” facades that fold inward. While the first level of folding doors with shelves increases the size of the external dimensions of the cabinet in depth.

Manufacturing materials

When choosing a folding table for needlework, it is important to consider the weight and strength of the material from which it is made. Sewing tables often fold and unfold, which directly affects their durability and ease of use. In addition, in sewing you cannot do without an iron, the temperature from which can also affect the condition of the working surface.

The following types of materials are used to produce this furniture:

- Solid wood. By purchasing a sewing table made of this material, the master receives the most durable and wear-resistant working tool. This attribute will fit perfectly into the interior of any room. The array is not afraid of high temperatures, so you can place a hot iron on it. One of the disadvantages of such models is that wooden furniture is quite heavy and expensive.

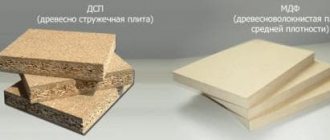

- MDF. The main advantage of this material is ease of processing, light weight and low cost. Even an unskilled worker with a minimal set of tools can independently assemble a workplace from such material. MDF tables are often made on wheels, which provides good mobility, and the light weight of the furniture prevents scratching the floor covering. The disadvantages of MDF boards include fragility, fear of moisture and high temperatures. The coating of particularly cheap slabs can swell if you put a mug of boiling water on it, so you won’t be able to work with steam unless you add an additional protective coating.

- Chipboard. Perhaps the cheapest and most impractical material. Furniture made from chipboard has an attractive appearance, light weight, but is afraid of moisture and high temperatures, releases toxic substances and cannot withstand heavy loads.

- Chipboard. The optimal material for a sewing table is laminated chipboard. Pressed sawdust with the addition of special resins makes this material durable, environmentally friendly (subject to production standards), resistant to high temperatures, easy to process and, accordingly, quite cheap. A variety of materials will help you optimally fit the sewing machine table into any interior.

Although today laminated chipboard is the most popular material in the furniture industry, it has several significant disadvantages - it is afraid of water, formaldehyde may be released if it is not produced correctly, it is practically impossible to repair, it is relatively fragile and cannot withstand strong physical stress.

Chipboard

laminated chipboard

Solid wood

MDF

Original ideas for organizing workspace in the home

To date, based on the requests of people involved in creativity, a large number of cabinets for needlewomen have been created. Depending on the purpose, transformable cabinets and tables are designed. Such furniture can embody all the whims of needlewomen. Pull-out cabinets, shelves, folding doors, etc. can help systematize the placement of certain creative items.

The assembled craft cabinet occupies a small living space and does not spoil the aesthetic appearance of the room. This furniture can be transformed into a work area in a short time.

How to choose

When choosing a table for cutting and sewing, you need to consider several nuances:

- The area of the future workshop. Often, seamstresses choose small rooms for work that can only accommodate compact models of furniture. The best option in such cases are cabinet tables and books. Transformers are perfect for larger workshops.

- Sewing machine size. Most modern household machines have rather modest sizes, but if the master has one of the advanced or industrial models, then it cannot be hidden in a small-sized sewing table; in such cases, it is better to choose universal products.

- Workplace mobility. The noise from the sewing machine can disturb the rest of other family members. If the table is small, light and mounted on wheels, it will not be difficult for the seamstress to quickly move the workplace to another part of the apartment.

Also, when choosing a place to work, you need to take into account the distance from sockets, the presence of natural or artificial lighting, the ability to hang finished products and roll out the fabric to measure the desired size.

Consider the area of the future workshop and the dimensions of the machine

Other nuances of designing handmade cabinets

To equip book-folding facades, not ordinary furniture hinges are used, because they are convex, with their shoulder and bowl they will interfere with either filling the shelves or partitions. Mortise hinges are most often used.

Or piano, card loops. They can also be different, with installation on the end or the girth of the sidewall. When choosing, you need to correctly evaluate the optimal mounting location and the visibility of the mounting area when closed. Ideally, the loop is not visible at all: it is attached somewhere on the wrong, invisible side. If it is technically possible, of course.

You can read more about the types of furniture hinges and the differences here.

Also, when designing the internal filling of the doors of a handmade sewing closet, you need to have a clear idea of the sizes of all the accessories for the internal filling. Sometimes it’s a shame that in order to squeeze in another container or organizer, literally a centimeter is not enough. You can use ready-made office, kitchen, and cosmetic organizers.

Therefore, it is worth first deciding what storage containers, boxes and hangers, the very format of the stored materials will be built into the transformable table cabinet for needlework and sewing. And then, based on their size and the space occupied inside the shelves of your future workplace, start drawing drawings for the cabinets for handicrafts with your own hands.

How to make your own universal sewing table

For those who know how to read blueprints, handle a jigsaw, a screwdriver and a tape measure, making a universal sewing table will not be difficult. The model in question will not take up much space and will not require expensive materials. Another advantage of this table is that it is mobile and contains everything you need. To make it you will need:

- 5 furniture wheels;

- 1 latch;

- MDF or chipboard;

- lock (can be taken from an old cabinet);

- shelves (purchase at a hardware store or make from food containers);

- hinges for the top cover and door, which should open more than 180 degrees;

- system for lifting the machine (ask at sewing shops).

laminated chipboard

Furniture wheels

Machine lifting system

Hinges

Espagnolette

Step-by-step instructions:

- Cut the lumber to the dimensions indicated in the drawing.

- Tie the structure with self-tapping screws.

- Place the hinged lid and door on the hinges, screw in the latch, and install the lock.

- Cut a hole in the lid to fit the size of your sewing machine.

- Install the lift and screw the cut piece to the lifting system.

- If the machine has holes, you can attach the equipment to the lifting system.

- Attach compartments for storing tools and accessories to the inside of the door using self-tapping screws.

- The last step is to bolt the wheels.

The maximum time for such work is no more than 3-4 hours. The cut sides of wood boards must be glued with furniture tape. Otherwise, there is a risk of damaging your hands or damaging the fabric on a rough surface.

A homemade sewing table saves the craftsman’s budget, and in terms of its performance characteristics it is not inferior to factory versions. In addition, the needlewoman still has the opportunity to make changes to the drawing or independently design the table according to her needs.

Drawing

Cut lumber to size

Fasten the structure with self-tapping screws

Cut a hole in the lid to fit the size of the sewing machine

Collect all the parts

Install and secure the machine

What sizes can handicraft cabinets have and what do they depend on?

Firstly, a folding table imposes certain restrictions on the size of a craft cabinet.

If you want to use metal twist-out legs, they are 730mm long. To store them inside the cabinet, the cabinet itself must be about 800mm wide.

The dimensions should be approximately the same with folding supports, as in the first drawing with a tabletop depth of 500-600mm.

Otherwise, you can make the size of the handicraft cabinet the way you need it. Usually the height is set to about 1600-2000mm; higher shelves will no longer be available for storage without the use of a chair. In this case, the height of the tabletop is set at the level of the desktop - 750mm from the floor.

The depth of a craft cabinet with a folding transformer principle is usually calculated as follows: 300-350 is set for a fixed body and about 100-180mm for facades with shelves.

But it all depends on the storage systems that you plan to use for storage! You calculate the external dimensions based on what will be built inside the cabinet shelves and its facades.