The interior of the bathroom, like all other rooms in the apartment, should be thought out to the smallest detail. Bathroom furniture will not only remove all household details from view, but will also make the room more stylish and harmonious. When things are scattered, it makes the room unkempt and cramped. Properly selected furniture will help visually increase the space of the bathroom and make it cozy.

Currently, manufacturers offer many options for bathroom furnishings, and in order to make the right choice, you need to be guided by certain criteria. Today we will find out what material is best to choose bathroom furniture from.

Advantages which one is better

Before you decide on the best material and start doing something, it’s worth considering the pros and cons of each.

In the photo - chipboard and MDF:

Pros and cons of chipboard

Let's start with chipboard and its positive characteristics:

- moisture resistance;

- strength;

- ease of processing;

- securely hold screws and nails that are used to fasten the structure;

- slabs can be painted and glued;

- they are superior to natural wood in certain physical and mechanical qualities;

- low cost.

Such material is not without its disadvantages:

- the presence of components harmful to health;

- high hardness of the material does not allow for fine processing;

- although the product is characterized by high hardness. For this reason, for decorative finishing of kitchen furniture from, however, after sanding the structure becomes loose.

You can find out which is better MDF or chipboard for furniture from this article.

Pros and cons of MDF

Now let's look at the advantages of MDF:

- high environmental friendliness;

- the material can resist moisture and temperature changes;

- long service life;

- MDF can be subjected to even the finest mechanical processing;

- optimal ratio between hardness and thickness;

- the presented product has a flat, smooth, uniform and dense surface, making external processing of the slabs much easier;

- MDF boasts all the benefits of wood, but the price is much lower and its service life is longer.

You can find out which is better for a cabinet using chipboard or MDF by reading the article.

The video explains which is better than MDF or chipboard for furniture:

About the difference between fiberboard and chipboard, photos and other technical data are indicated in the article.

As for the minuses, there is only one here - it is not well-established production of the material in Russia. It follows that purchasing a kitchen made from MDF will cost much more.

Now we can summarize and identify the furniture that is best suited for installation in the kitchen. If you choose between chipboard and MDF, then in terms of environmental friendliness, reliability and design, MDF wins. But not everyone can afford it, because the cost of a slab is much higher than that of chipboard.

How moisture-resistant tongue-and-groove chipboard is used for flooring is indicated in the article.

Installation of chipboard on joists

The sequence of laying tongue-and-groove chipboard along the joists:

- Prepare your work surface. Clean it of all dirt and level it.

- Install waterproofing. The concrete base should be covered with plastic film, and the wooden base with glassine or waxed paper.

Advice. The waterproofing material must be laid with a slight overlap in order to subsequently wrap the ends of the chipboard slabs with it.

- Install the joists. Boards made of hardwood or softwood are installed on clay brick posts no more than 20-25 cm high. The logs are laid in increments of 40-50 cm and fixed with self-tapping screws. A gap of 1-2 cm should be left between their ends and the walls.

- Lay heat and sound insulating materials. Fill all the gaps between the joists with them.

- Install chipboards. Lay the sheets away from the wall towards you, tightly joining them together using a tongue-and-groove pattern. Before joining, glue or mastic must be applied to the lock joint to securely fasten the slabs. Chipboard can be fixed directly onto the logs with self-tapping screws, mastics or glue.

Choice for the bedroom

For such a room it remains a very important accessory. For this reason, choosing the material from which it will be made is a very important process.

Today, very often people order bedroom furniture from chipboard or MDF, but still do not understand which is better. First, let's look at chipboard. The presented product is obtained from shavings, which are then treated with a binding component, namely formaldehyde resins.

DPS today are very relevant in the manufacture of cabinet furniture, or rather bedroom sets. The main advantages of chipboard material can be considered: easy processing, strength, excellent water resistance, the material perfectly and firmly holds all fasteners and is not expensive.

You can see what a kitchen countertop made of chipboard looks like in this article.

Chipboard is very often used in the production of economy class furniture. In this case, furniture sets are often installed in offices. However, for those who do not have a lot of money, they can also try installing a chipboard product in their bedroom.

However, the presented material has one significant drawback: when formaldehyde resins evaporate, a negative effect on human health occurs. In addition, there is a specific type of chipboard that is prohibited for use in the manufacture of bedroom furniture.

You can find out what the thickness of laminated chipboard is from this article.

Now you can move on to MDF. The presented product is characterized by a slab, the production process of which takes place from sawdust. Their fastening is carried out using paraffin and lignin. Compared to chipboard, this material is environmentally friendly, therefore it is very widely used in the manufacture of bedroom furniture.

The main advantages of MDF can be considered:

- environmental friendliness;

- minimal thickness, making it easy to process;

- has all the benefits of wood.

Laminated chipboard - what is it?

Chipboard (chipboard) is compressed wood sawdust and shavings; formaldehyde resins are used as an impregnation and binding composition. The slab has a heterogeneous structure; the density, depending on the grade, is 300–600 kg/m3. For the production of furniture, types with high performance are used. More loose varieties are used for technical purposes or as packaging material.

Next, the chipboard is laminated - covered with a layer of melamine film under high pressure. The result is a laminated chipboard (laminated chipboard) material that is ready for use in furniture production.

The coating performs several functions:

- prevents the release of formaldehyde, which is quite harmful to the human body;

- protects the stove from external influences and moisture;

- gives the slab an attractive appearance - laminating films of various colors, decors and textures are used to make furniture laminated chipboards.

There is an international classification of the environmental safety of laminated chipboard. High-quality material used in the manufacture of household furniture must comply with class E1. When purchasing, check with the seller and ask to see certificates. Products of class E2 are completely prohibited in Europe and have significant restrictions on use in Russia.

For children's room

The process of making children's furniture can also take place using chipboard or MDF boards. Of course, the most optimal material in this case would be natural wood. But the reason for the high cost is that not everyone can afford it. And then chipboard and MDF boards can act as an alternative. Also, later doubts may still arise as to what the difference is between MDF and laminated chipboard and which is better.

Let's take a closer look at MDF. They have a medium density and wood-fiber structure. For its production, small sawdust is used. The bonding process is carried out using paraffin. In terms of environmental friendliness, this material is the most suitable for children's furniture. A similar material is used to produce backs for chairs, cribs, and tables. Also, MDF boards are indispensable when obtaining cabinets, shelves and various parts.

How to choose the material for MDF furniture is indicated in the article.

The cost of such children's furniture will be much more expensive than that made from chipboard. But the indicators of strength, environmental friendliness and reliability of MDF material are much higher.

Chipboard is used to make the back walls of cabinets and act as the bottom for drawers. In a child's room, a closet is a very important element of furniture, so it is necessary to use reliable materials for its manufacture. The reason is that the bottom made from chipboard is very flexible, so it very often has to be repaired. But such material is characterized by low cost and long service life.

How much a 16 mm chipboard sheet weighs is indicated in the article.

Although chipboard boards have one important drawback, due to which many parents refuse to install furniture based on it in the nursery. This disadvantage lies in formaldehyde resins, which release elements harmful to health during evaporation. At the same time, it is these resins that give the slab fire resistance.

In conclusion, it should be noted that a product made from MDF boards inspires more confidence among people, but parents are not always ready to see chipboard material in their baby’s room. The reason is that this material is not environmentally friendly.

What sizes of MDF panels there are are indicated in the article.

For the living room and hallway

- wipe the dust with a dry cloth or a special compound for plastic;

- promptly remove moisture from the surface with an absorbent sponge;

- do not overload hooks and shelves so that fasteners do not break off;

- Do not use waxes and mastics intended for polished wood.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

Bathroom material

To be honest, none of the materials under consideration are suitable for making bathroom furniture. If, of course, there is no particular choice, then it is best to use an MDF board that has a laminated surface. But to the general misconception, you can choose a good laminate for the bathroom.

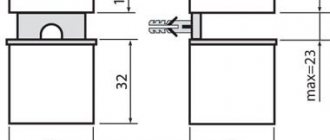

As a rule, such processing is present only on one side. If we consider chipboard boards, then they are generally not suitable for installation in the bathroom. You can, of course, also purchase a laminated product, but over time the furniture will begin to delaminate and deteriorate, and the furniture set will begin to lose its attractive appearance. Both options can be mounted on dowel nails that comply with GOST.

You can find out how to install a kitchen apron from MDF with your own hands here.

There is only one conclusion here: neither MDF nor chipboard are suitable for the bathroom, but for those who choose from these materials, laminated MDF has a great advantage.

How effective are slabs made from finely dispersed fractions?

So, in order for water not to be absorbed into the material, it must have a very high density, and thanks to the dry pressing of very small particles of wood, this quality is most pronounced in MDF panels. In this case, production is carried out under the influence of high temperatures and using binders, which, when heated, impregnate the wood fractions. In particular, urea resins are used; they are the safest in terms of the release of formaldehyde, a volatile substance that is quite harmful to the body. In such resins combined with melamine, the formaldehyde content is negligible.

MDF boards for bathroom

As for density, it is possible to achieve values such as 600–800 kg/m2, due to which moisture simply does not find cavities between the fractions, which, moreover, are already saturated with a binder. Don’t forget about the natural connector lignin, which is released from wood fibers when heated. Thus, with a sufficient thickness of the slab, you can count on high strength and reliability of the material. Therefore, instead of expensive clinker tiles for the bathroom, you can get by with decorative MDF panels, although they can hardly be called cheap either. But taking into account the durability and almost complete waterproofness, the benefits of using such cladding are obvious.

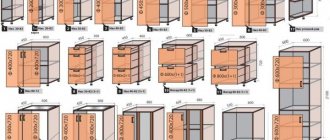

How furniture is made from two materials

MDF can be amenable to various types of mechanical processing, due to which it is actively used in the manufacture of facades for cabinet furniture. In this case, CNC machines are used during production. Thanks to this equipment, it is possible to make various patterns and figured designs.

The production process from MDF involves the use of a thermal vacuum press, as a result of which various PVC films can be applied to the surface of the board. For this reason, the cost of MDF boards is much more expensive than chipboards. In order for the final product to have excellent quality and price, the furniture production process can be based on a combination of these materials. As a rule, it is possible to produce not only furniture facades, but also table tops.

It was the low content of harmful components that allowed MDF boards to be used in the manufacture of a crib. Today there is a large number of PVC films, on the surface of which many children's drawings are applied. The result is durable and practical furniture that is very easy to care for. In addition, milling the edges allows you to avoid sharp ends, which is important when making furniture for a children's room.

Chipboard and MDF are very popular products today, which are actively used in the manufacture of furniture. It’s impossible to say unequivocally which material is better. Indeed, in terms of environmental friendliness and beauty, MDF material wins. But the cost is lower and the service life of chipboards is longer. When choosing furniture, pay attention to the purpose for which you are buying it and under what conditions it will be used.

MDF - what is it?

Decoding the abbreviation MDF (fine fraction) says a lot about the raw materials for the manufacture of this tile material. First, wood waste is crushed to a homogeneous fine fraction, dried and compressed. The main binder is lignite, a natural substance found in wood. Formaldehyde is used in the production of MDF in small quantities, and additional processing of parts completely prevents their release.

The result is a material with a uniform and high density (600 - 800 kg/m3), a smooth and even surface, without the content of harmful chemicals. As a protective and finishing layer on MDF, in contrast to chipboard, a variety of materials are applied: PVC film, wood veneer, enamel, plastic, etc.

Fiberboard as a budget option for covering walls

If this material is inferior in density to MDF, it is only slightly, and only because the fractions used in the manufacture of fiberboards are quite large. However, the use of synthetic resins, paraffin and rosin in combination with hot pressing under high pressure makes it possible to obtain moisture-resistant and, most importantly, durable panels. In a mixture of wood fibers, coniferous species sometimes predominate, which significantly increases the material’s resistance to water after pressing at high temperatures, when the resins are partially released from the fractions. To obtain a particularly durable class of panels, additional impregnation with pectol - tall oil - is used, which also increases moisture resistance.

For a bathroom, you can use fiberboard panels of different classes, but bitumen ones are best suited; they are practically not subject to deformation during prolonged contact with water. It is recommended to choose material of such brands as T-B, that is, untreated hard slabs with a high level of water resistance. They are perhaps the most inexpensive of the acceptable options. The price for wall cladding of the T-SV brand will be higher, which stands for solid panels that have a layer of decorative coating made from fine wood fractions, and also have high water resistance. The second option is more preferable, since it does not require additional finishing in the form of painting, varnishing or tiling.

conclusions

MDF and chipboard are one group of materials, but different in properties and different in manufacturing methods. Professionals claim that MDF will very soon displace other materials that seek to replace natural wood. Since MDF is a natural, environmentally friendly and reliable material.

This means that it can be used to make cabinet furniture for both children and adults. Chipboard is an inexpensive, weaker material that some people consider toxic.