Currently, there are many options for ceiling coverings. Finishing the ceiling with MDF panels is a fairly popular solution. This is due to the advantages that this simple, accessible and cost-effective material provides. Its excellent performance properties make it possible to maintain a presentable appearance for a long time.

Definition of MDF panel

It’s a common thing when, during renovations in apartments or houses, it is discovered that the ceiling is uneven or the joints of the panel slabs do not match perfectly. This situation can be corrected using a suspended ceiling. The ceiling made of MDF panels takes a well-deserved place among the huge selection of suspended ceilings.

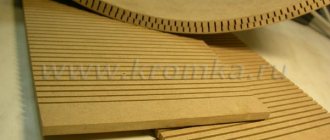

MDF panel is a fibreboard (fibreboard) produced by dry pressing of small wood chips using high pressure and temperature with urea resins modified with melamine.

Important! In the production of MDF panels, no adhesive resins that are harmful to health are used.

“Expensive walls”: options for exquisite wall decoration

In addition to the popular panels made of MDF, chipboard and plastic, there are other types of materials that can be used in the kitchen. Of course, they will not be cheap, but they will be able to create the right atmosphere in the room or emphasize the features of the interior.

- Wooden panels. The most expensive material, the main advantage of which is its respectable appearance. In the photo below you will see what kind of kitchen interior can be created using such panels. Wood is difficult to clean without damaging the structure; it is afraid of constant humidity and can become deformed. True, today such models are coated with special wax, which extends their service life.

- Tempered glass panels. Such products are popular, and their characteristics are not inferior to the ceramic tiles we are used to. But glass panels have one advantage compared to tiles, which do not have so many rich and colorful designs, and photo printing is not used on them. But on tempered glass you can create a whole picture. Glass panels can also be washed and cleaned with chemicals. If you need to wash off grease or complex stains, this is not a problem, since the glass can withstand mechanical damage. In general, this material is magnificent and beautiful, but has one drawback - high cost. The same ceramic tiles will cost less.

- Postforming products. Essentially, these are chipboard sheets that are coated with plastic. Such products combine the advantages of plastic and do not have the disadvantages of untreated chipboard. The main advantage of postforming is that such wall panels can be installed above the stove and sink. They are not afraid of high temperatures and constant moisture. The panels can be washed using modern means - they will retain both cleanliness and beauty. In addition, if you choose between laminated chipboard and postforming, the latter will have a more impressive appearance and bright colors. There is only one drawback - it is a higher price compared to plastic and MDF. Postforming panels are suitable for those who are willing to pay a considerable amount for the appearance of their kitchen. In the photo below, see what such products look like.

You should choose panels for the kitchen based on the most important parameters: they are easy to clean, they are not afraid of moisture and will be able to surprise you with their appearance for several years. The most budget options have these characteristics, but are afraid of high temperatures. More expensive products can also be installed in the apron area, but you will have to spend a considerable amount on finishing the walls.

Types of MDF panels

They can be of several types, depending on the pricing policy:

- Veneered – during production, natural veneer from valuable trees is used, so the coloring is always “wood-like”. But they always look original and rich. Outwardly they look like natural wood, but, unlike wood, they are relatively moisture resistant, will not dry out or warp, and therefore are more durable. This is the most expensive type of MDF panels.

- Laminated – using the cold lamination method, a polymer film (PVC) is applied to the outer layer of the panel, which will resist moisture. Thanks to the pattern of the film, they will look, for example, like marble or wood. The color can be different, glossy or matte. Additional advantages include antistatic properties and resistance to direct sunlight.

- Painted – colors can be different, glossy or matte. High-quality paints withstand chemical attack. Their disadvantage is that they do not have a protective film, which means they are not moisture resistant.

- Paper coated – the plate is covered with paper. Of course, they are not intended for rooms with high humidity, but in the corridor on the ceiling they can serve. Accordingly, they have the lowest price.

The front side appearance may look like this:

- flat – covered with PVC or wood veneer;

- relief – is a panel with a cut-out pattern, covered with paint and varnish material.

There is a classification according to size:

- slatted - reminiscent of building material - lining;

- tiled - in the form of square tiles;

- sheet - large sheets with a pattern.

Interestingly, MDF panels were first produced industrially in the USA in the late 60s of the 20th century. The Russian manufacturer launched production in the late 90s.

Wooden ceiling in the interior of different rooms. Photos of design solutions

The wooden ceiling decorates the interior of the room and makes it truly special.

Living room

Such plank structures help protect the living room from monotony and boredom. Eco-friendly finishing looks very aesthetically pleasing and expressive.

The photo shows a wooden parquet board on the living room ceiling.

Bedroom

The wooden structure of the ceiling plane will make the bedroom much more comfortable, adding an atmosphere of comfort and a certain charm.

The photo shows a shabby chic bedroom with a light wood ceiling.

Children's

The ceiling plane, lined with light-colored wood, will give children freshness, elegance and decorativeness.

Cabinet

Dark wood slightly diffuses light and adds shadow to the furniture, thereby creating a more austere and restrained atmosphere.

The photo shows an office with a wooden coffered ceiling in dark colors.

Corridor and hallway

Wood will give a hallway or corridor a characteristic flavor, and a natural pattern will be an indicator of good taste.

Kitchen

Wooden structures improve the indoor microclimate and have a particularly noble and elegant appearance. Kitchens decorated with natural materials take on a comfortable and cozy look.

Attic

This is an almost traditional design for a sloped attic ceiling. Wood creates a healthy microclimate and makes the atmosphere more comfortable.

Balcony

The tree is ideal for decorating a balcony or loggia. There is always a lot of light in this room, so absolutely any, even the darkest, colors will be appropriate here.

Bathroom

This ceiling is an original solution for the bathroom. Wood treated with special impregnations will not lose its natural aroma and will always fill the room with a pleasant woody aroma.

Toilet

When designing a bathroom, natural, natural and ecological materials are always important. They always look stylish and elegant.

The photo shows a bathroom with a wooden slatted ceiling.

Pros and cons of MDF panels for ceiling finishing

Any finishing material has its positive and negative sides. Familiarization with the performance characteristics when choosing a finishing material will help everyone make the right decision. As for MDF panels, the advantages, in this case, outweigh the disadvantages, which will allow you to make the right choice by choosing MDF panels for the ceiling.

So, the advantages of the material:

- Environmentally friendly material . MDF panels are a medium-density wood fiber board. Made from natural wood chips by pressing at high temperatures. The composition does not include phenol and toxic resins, which means that no harmful fumes will be released during operation.

- Cost-effective material . The low price makes this ceiling option popular.

- Practicality. Application extends not only to residential, but also office or industrial premises.

- Noise insulation . They perfectly absorb “noise from above”, which, in itself, is especially important in multi-storey buildings. Moreover, during the installation process it is possible to enhance this effect with the help of additional soundproofing materials.

- Thermal insulation . The density of the compressed material does not allow “cold from above” to pass through and does not release “heat from below”, which is important for apartments on the upper floors.

- Resistant to temperature changes . They do not react to either cold or heat.

- Strength and durability . Thanks to their ability to resist environmental influences, they have a long service life, while still remaining attractive in appearance.

- Easy to install . It is not particularly difficult to install, repair or replace. It is possible to make MDF ceilings with your own hands, without having any special skills.

- Easy to care for . Wet cleaning will refresh the appearance of the ceiling.

- Appearance . A variety of external design options, or more precisely, offers of colors and textures, allow them to have a stylish, impressive look, for example, natural stone or a cut of natural wood.

- Minimum preparatory work . No special preparation of the ceiling surface is required before installation. You can leave the existing coating; all imperfections will be covered with beautiful panels.

Installation of MDF panels on the ceiling is considered the final part of the finishing; additional refining work will not be required.

Disadvantages of MDF panels when finishing the ceiling:

- Moisture resistance. The method of production of the panels suggests that they can be considered sufficiently moisture resistant, but not so much as to withstand room humidity above 70%. Therefore, it is undesirable to use them in obviously damp rooms, so as not to incur material and moral losses.

- Fire resistance. They are not classified as fire-resistant finishing material. When heated, not only shavings, but also adhesive resins can ignite, so in rooms with open fire you should not use MDF panels for the ceiling.

Advantages of a clamp as a fastener

When choosing fastening kits, builders recommend focusing on their functional features. The advantages of staple fasteners include:

- increasing the overall strength of the structure due to the fastening method and the material from which the clamps are made. One carbon galvanized steel plate can support up to 20 kg of weight;

- careful fastening of the casing. The tongue of the staple carefully snaps into the groove of the product without damaging the cladding. Installation on clamps allows you to avoid chips, cracks and deformations of the lamellas.

- resistance to high humidity thanks to anti-corrosion coating. In rooms with high humidity (baths, saunas, steam rooms, bathrooms), the casing attached to nails or self-tapping screws becomes saturated with rust;

- the ability to select fasteners of the appropriate type and size;

- rigid fixation of the cladding after installation. The plates snapped into the groove reliably press the lamella to the surface of the sheathing, preventing it from “playing”;

- relatively low cost of the mounting kit.

In addition, clamps are characterized by high installation speed. Staple-type hardware products allow you to quickly cover the surface of a room, and the fastening technology is relatively simple and accessible even to novice craftsmen. About fastening the lining to this type of hardware in the video below:

Ceiling installation

Among the wide variety of ceiling coverings, installing MDF panels on the ceiling can be classified as a prefabricated method that does not require qualified training, extensive experience or any special skills.

The panels have special connecting “locks” that allow them to be fastened together, creating the impression of a smooth and beautiful canvas. The fasteners are mounted in such a way that they become invisible after installing the next panel, thus creating a continuous, integral, original ceiling covering.

The technological process of installation steps for finishing the ceiling surface with MDF panels is not particularly complicated, the main thing is to stock up on the necessary materials and tools, and carefully, keeping to the level, make a frame.

Ease of installation - an attractive element when choosing a finishing material for the ceiling lies in the ability to install MDF panels on the ceiling on your own, without outside help.

Due to the fact that, most likely, you will be installing the ceiling yourself, it will not be amiss to listen to the tips of experts in the field of repair work, which makes sense to pay attention to before starting to assemble the ceiling, namely:

- Any type of wood does not like moisture, so your task, if possible, is to provide all options for ensuring good waterproofing.

- Whole slabs are more difficult to install and replace if damaged, so it is recommended to cut them into squares or rectangles.

- Be sure to isolate the wiring from the panels in case of a short circuit, which could cause the entire ceiling to catch fire. Nothing should touch the finishing material.

- Holes for lamps must be made in advance. Don't forget to also insulate the wiring that will be connected to the lighting.

Stages of work:

A ceiling made of MDF panels is a typical suspended ceiling design. And this design requires the presence of a frame. There can be two options:

- frame made of wooden blocks;

- frame made of metal profiles.

In houses with wooden ceilings, the frame is most often made of wooden blocks.

In houses and apartments where the ceilings are concrete, preference is given to the second option, metal profiles.

Even if, initially, there is no idea how MDF panels are attached to the ceiling, it will not be difficult to learn this right during the installation process.

Tools you will need when installing a ceiling made of MDF panels:

- perforator;

- roulette;

- pencil;

- construction level;

- screwdriver;

- scissors for cutting metal.

Materials required for finishing the ceiling with MDF panels:

- MDF panels;

- ceiling plinth;

- galvanized metal profile;

- connecting elements;

- pendants.

conclusions

The installation process itself can hardly be called complex; rather, it stands out as monotonous. The price of MDF ceiling panels will fully correspond to the quality.

The last panel is always fastened with self-tapping screws or staples so that the joint is hidden by a decorative plinth. The work ends with the last stage, namely the installation of the plinth.

MDF ceiling panels have firmly established themselves in the world of modern construction. To date, no worthy replacement has been invented for these materials that would push them out of the market . Moreover, thanks to the variety of available options, everyone can find one that suits their liking and finances.

Frame manufacturing technology

1. Using a building level, it is necessary to draw a straight line around the perimeter of the room, retreating from the ceiling by at least 5 centimeters. If you plan to install backlighting, you will have to go even lower. The reference point starts from the lowest angle. After marking, you need to use a special device to determine where the hidden electrical wiring is located so as not to damage it.

2. Secure a guide profile around the perimeter of the room along the upper border of the drawn line using dowels or self-tapping screws, depending on the material on the walls. The fastening pitch is usually 40 centimeters, it is advisable to adhere to this norm.

3. The ceiling profile is inserted into the starting profile and secured with small flat-head screws; here the step can be from 40 to 60 centimeters. It is fixed to the ceiling with a metal suspension.

Important! Constantly monitor your actions at the construction level.

4. For lighting fixtures, it is necessary to mark their location and lay the wiring. In fact, the frame is ready.

Mounting methods

To fix it to the sheathing, you can use construction staples (in the case of installation on a wooden beam and using a construction stapler), nails or self-tapping screws.

Please note that in the latter case, you need to countersink each “break” (make a recess for the head). Methods of fastening to the ceiling depend on the density of the sheet. We remember that the denser the fiberboard sheet, the heavier it is, and, accordingly, stronger materials for fastening

Protruding iron from staples or nails must be carefully puttied, because over time these iron parts will rust and show through the paint or wallpaper.

We remember that the denser the fiberboard sheet, the heavier it is, and, accordingly, the stronger the materials for fastening. Protruding iron from staples or nails must be carefully puttied, because over time these iron parts will rust and show through the paint or wallpaper.

Panel installation technology

You can begin attaching MDF ceiling panels to the assembled frame. Panels that are too long are shortened. The first MDF panel is attached, starting from the corner, either to a metal profile or to a wooden block using self-tapping screws. The next panel is inserted into the groove of the previous panel. It is secured from the groove side with a clamp. Fastening MDF panels to the ceiling is carried out using the tongue-and-groove technology, that is, the tongue of the 2nd panel fits into the groove of the 1st panel.

In the panels that will be installed under the marks made for the lamps, holes are cut out in advance in order to install the lamps later. If the choice fell on spotlights, then it is convenient to cut the holes with a drill with a special round attachment.

The assembled ceiling made of MDF panels is framed with a ceiling plinth, which will cover the first fastening and give the ceiling a finished look. Now, we can say that the work of installing MDF panels on the ceiling has been successfully completed.

Important little things

In any technology there are several important nuances that professionals forget to mention, because they believe that everyone should know such little things, and amateurs then get into trouble.

- For example, you need to join a figured or straight seam between two multi-colored MDF sheets. There is a special plastic H-shaped profile for this. You put the sheets on top of each other, cut them along a curly line, and then join them through this profile and you have everything in one plane.

The flexible H-shaped profile allows you to beautifully join both the same type and multi-colored materials

- Overhead shaped MDF strips are sold in furniture fittings stores.

- After you have mounted the pendant and covered it with MDF, you need to secure the ceiling plinth around the perimeter. Hobbyists often have problems with accurately cutting and joining plinths; how to do this simply and quickly is written and shown “HERE” .

- In two-level ceilings with a curved edge, it is easier to cover the side of the curved threshold with thin plasterboard. It needs to be rolled with a needle roller and moistened, as a result, after half an hour it will get wet and bend as needed.

- If you are making electrical wiring inside the sheathing, then the wires need to be routed into plastic or metal corrugation.

MDF is a flammable material, so electrical wiring must be hidden in corrugation

- In most houses, the wiring is walled up in the ceiling area and when a person starts attaching bars or profiles to the walls, he can damage it. If you don’t have a device for finding hidden wiring, then focus on distribution boxes; wires from them run only horizontally or vertically.

If you don’t have a device for finding hidden wiring at hand, then focus on the wiring boxes, the wires from them run either vertically or horizontally

Advantages and disadvantages of the solution

By deciding to make an MDF ceiling in your home, you will not only be able to easily hide even very significant flaws in the base surface, but also a lot of other advantages:

- It is possible to choose both the color and texture of the finished structure. The front side of more budget panels is decorated with films or painted, while more expensive options are covered with natural wood veneer.

- The frame structure of the ceiling implies the presence of some distance between the ceiling and the plane assembled from the panels. In this part of the composition you can place all the necessary wires or other technical communications.

- It will be possible to install recessed lamps in the ceiling and place them exactly where lighting is most needed.

- The heat and sound insulation of the room in which such a ceiling will be assembled will improve.

- No careful preparation of the base for work is required - just assemble the frame and attach the panels directly to it.

- The service life of the coating is many years without losing its beautiful appearance.

- Partial dismantling and repair of the coating is possible without completely dismantling the structure.

- Standard types of panels are inexpensive. Those covered with veneer will cost significantly more, but they look much better.

- The durability of the coating is quite high.

Such coatings also have several disadvantages. Most of them cannot be called too significant to give up the idea of decorating your ceiling with this material. However, you should know in advance about the possible disadvantages of the solution:

- Veneered coatings do not withstand moisture well and should not be used for finishing bathrooms or kitchens. An alternative for such rooms would be film-laminated parts.

- Laminated parts, in turn, are not recommended for children's rooms and bedrooms, since their surface is impermeable to air, and vapor permeability is important in these parts of the house.

- Due to the fact that MDF is based on wood, this material is very poorly resistant to fire and is potentially fire hazardous.