Edge functions

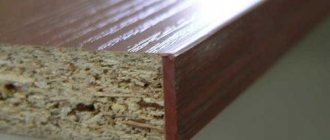

When cutting parts from laminated chipboard panels, unsightly edges inevitably remain. This is due to the peculiarity of the material, its pressed structure. To disguise the cuts, a special tape is glued to the visible ribs, which

called furniture edge.

In addition to camouflage, it performs the following functions:

- protects the ends from drying out;

- prevents moisture from entering the fabric;

- blocks the penetration of dirt into pores;

- allows you to stylize and decorate an item;

- increases shock absorption during physical impact;

- corrects, hides defects and irregularities.

All of the above is especially true for cabinets, tables, and kitchen units.

How to glue on chipboard and chipboard at home

The structure of particle boards is loose, it is sawdust and shavings mixed with glue and pressed. Due to this looseness, the material is resistant to deformation and splitting, as well as flexibility.

See also

Technical characteristics of Bustilat glue and instructions for use

The unsightly interior is visible on the chipboard cut; the material is uneven and often crumbles. Experts recommend putting putty on the cut before applying the tape to level the surface and ensure a strong connection to the edge. Use universal acrylic putties.

The cut is puttied, wait until it dries (carefully remove excess product from the facades). Then it is treated with medium-grain sandpaper. If there is no glue on the edge, choose the one recommended by the manufacturer. It is also worth stocking up on glue solvent to remove dried smudges if necessary.

Types and their features

The most striking difference between the edges is in appearance. Ribbons can be of different colors, matte and glossy, with imitation of stone, concrete, wood, leather, stucco and other textured designs.

But the main difference is the material. The final properties of the part depend on the raw materials.

Melamine

They're paper. Made from very thick paper. It is impregnated with melamine and glued to a papyrus backing and varnished, which further increases its strength.

The papyrus base can be made of one or two layers. The thickness of the tape is respectively 0.2 or 0.4 mm. The second option is more expensive, but exhibits better performance.

Melamine edges are characterized by flexibility and easy installation. Most often there is already glue on the backside, which just needs to be warmed up before applying to the end. At the same time, this is the most short-lived type. The tape quickly wears out, fades, and is fraught with excess moisture.

Suitable for back edges of shelves and table tops. Not recommended for external parts.

Polyvinyl chloride

In other words, PVC. A mass of raw materials is formed into a tape, textures are applied and painted in different shades. The imitation of wood fibers is especially successful. The low price does not in any way affect the quality during use. One of the easiest options for self-gluing.

PVC edges withstand contact with objects, household chemicals, ultraviolet radiation, and water. They fit large curves and curves without any problems. Available with or without an adhesive layer.

Thickness varies from 0.4 to 4 mm. The width can be any in the range from 19 to 54 mm. As a rule, the size is chosen slightly with a margin from the end.

Expert opinion

Korzhavin Daniil Dmitrievich

Designer of stylish home furniture

The main disadvantage of PVC tapes is their poor tolerance to sudden temperature changes. Heating during installation must be done extremely carefully; furniture should not be left in the cold or in extreme heat for a long time.

ABS plastic

Edges made of ABS polymer material. They are good because they do not contain heavy metals, which makes them as safe as possible from an environmental point of view. They are also distinguished by excellent strength and long service life, despite active physical impacts.

They tolerate temperature changes well. They successfully imitate natural materials with their texture, including different types of wood. Available in glossy, semi-gloss, matte versions.

Despite the ease of gluing with any heat-resistant composition, they have some nuances in operation. When choosing ABS plastic, it is worth remembering that it shrinks when heated. The size of the tape should be approximately 0.3-0.5 mm wider and longer than the end itself.

The main disadvantage is the high price.

Veneer

Veneer is not the most sought-after material in the edging world, but it has its place. Such edges resemble thin plates rather than ribbons. They are made by thinly cutting wood, followed by pressing and painting.

Most often, veneer edges are used when processing problematic veneered products. They are expensive and require professional skills to operate. Rarely used independently.

Acrylic 3D

Edges made of transparent hardened acrylic. They resemble an aquarium or a piece of glass - there is a drawing on the back side. The structure makes the tape voluminous and creates beautiful highlights. The ability to make any ornament opens up scope for design activity.

It is actively used for decorating cabinets, chests of drawers, tables, and doors. Requires care in cutting, cutting and gluing, as seams can be noticeable.

Expert opinion

Korzhavin Daniil Dmitrievich

Designer of stylish home furniture

The cost remains high. Many companies allow manufacturing according to an individual project.

Common Mistakes

The most common mistakes made by inexperienced craftsmen include:

- Bubble formation. Occurs due to weak heating of the adhesive base or poor pressing of the edge to the part. You will have to reheat it with the iron and press it more carefully.

- Edge offset. It is important to eliminate this defect quickly by returning the part to its place. Otherwise, you will have to tear off and glue a new piece.

- There were pieces of dried glue left on the furniture. The adhesive must be removed while it is hot, before it dries and hardens. This is done with gloves to avoid damaging your hands.

Hardened glue is removed with sandpaper or solvent. It is important to choose the appropriate remedy.

Tip: edging is necessary even for invisible areas of furniture - it will protect the chipboard from absorbing moisture and deforming the material.

Difference from profiles

Finishing profile

Confusion often arises with the concept of edge and finishing profile. You can disguise the end of the furniture with both, but the products are strikingly different from each other.

Profiles are made of PVC, wood, aluminum of different hardness. They are sold with a section in the letters T and C (aka P), and are slightly moldable. The edges are produced smooth, straight, and much more flexible.

The most important difference is the installation method. The edges are always glued with glue. Profiles are inserted into a milling groove (T form) or put on with a hook at the bottom and top of the end (C form). To shrink the profiles, they are “nailed” on top with a rubber mallet. Sometimes they are additionally glued or fixed with finishing nails.

The end for the profiles must be processed as carefully as possible - the edges are trimmed, the surface is sanded. Otherwise it will not sit correctly. There is no such problem with edges.

Profiles for processing furniture edges

Profiles are also used as finishing materials for edging, which vary in both type and material of manufacture.

Overlay and mortise edges

The edges are thicker than tape edges for furniture products, but are also made of plastic. A distinctive feature is their shape - with sides curved inward (U-shaped) or resembling a rounded letter “T” (T-shaped). The U-shaped edge is put on the outer side of the cut and is therefore called overhead, and the T-shaped edge is implanted into the slab - hence its name “mortise”.

T-shaped PVC profile U-shaped PVC profile

How to glue a U-shaped edging yourself

At home, it is usually the U-shaped edging that is mounted on the slab. The overlay profile can be bendable and rigid, and therefore it needs to be fastened in different ways.

The flexible edging is placed on the end, already generously lubricated with glue. It is pressed well and fixed for a tight connection. Gluing a hard edge requires preliminary steps of heating it with a hairdryer in order to give it the desired shape and fix it on the bend of the part coated with glue.

Which glue to choose for edges

To attach the edging, the same adhesive composition is used as is needed to glue PVC tape. This is any universal adhesive capable of joining plastic and wooden surfaces. But most often, home craftsmen use Moment or 88-Lux glue.

Fastening of T-shaped PVC edging

To install a mortise T-shaped profile, you need to use a mill to prepare a recess in the center of the slab. This type of edging has spikes, and they are implanted into the chipboard when the edging is driven in with a special rubber hammer. The edge overhangs are cut at an acute angle for better effect.

Required Tools

To work with a mortise edging you will definitely need:

- furniture mallet;

- manual router with edge cutter.

Installation technology

Before starting work, you will need to prepare the surface and collect the necessary accessories.

Toolkit includes:

Glue Moment, Liquid Nails or construction PVA (if not a self-adhesive type of edge).

The edge itself (calculate the quantity in advance around the perimeter with a margin of at least 20 cm).

Sanding block or fine sandpaper.

Painting knife, scissors (depending on the softness of the edge).

Pressure rubber roller.

Thick rags.

Hair dryer or iron.

A file and wood putty may be needed if the end has large defects.

The main task of preparing an object is to remove all burrs, seal large holes, and level the surface as much as possible. When using sandpaper, the surface must be completely dry. If putty is used, it must be given time to completely cure. Then start gluing the tape.

How to glue

The algorithm for using tape without an adhesive layer and with it is slightly different.

Self-adhesive

- Measure and cut a piece of tape 2-3 cm larger than the end.

- Apply an area of about 20 cm, level it and heat it with a heated iron or hairdryer for several seconds.

- Roll the heated area with a roller.

- Proceed to the next segment. Continue this way the entire length.

- Trim off excess tape with a paint knife. Glue the edge.

Without adhesive layer

- Measure and cut off the tape to spare.

- Apply glue to the end and level the layer.

- Wait for the initial drying time (indicated on the packaging for each type of glue).

- Apply the tape in small sections, rolling it with a pressure roller.

- Wait until the adhesive has completely cured. Cut off excess.

When working with a self-adhesive edge, it is possible to level the entire length to the end, secure it with masking tape in several places, then warm it up. Before treating the area with tape, it must be removed before heating.

Expert opinion

Korzhavin Daniil Dmitrievich

Designer of stylish home furniture

Adhesive may come out during the process. It is collected with rags immediately, without waiting for it to dry.

We glue furniture edges with our own hands

There are two technologies for gluing furniture edge tape. The first is for those that have glue applied to the back. In this case, an iron or a hair dryer is needed. The second is for gluing tapes without glue. In this case, you need a good universal glue that can glue plastics and wood products and a furniture roller, a piece of felt or a soft rag so that you can press the edge well against the cut.

It’s possible to get such an edge at home

A little about what thickness of edge to glue on which parts. Those edges that are not visible, according to GOST, do not need to be glued at all, but basically they try to treat them so that less moisture is absorbed into the chipboard, and also to reduce the evaporation of formaldehyde. Melamine tape or 0.4 mm PVC is glued to these edges. The edges of the drawers (not the fronts) are also processed.

It is better to use 2 mm PVC on the front ends of the facade and drawers, and 1 mm PVC on the visible sections of the shelves. The color is chosen either to match the main surface or “in contrast”.

How to glue edging yourself with glue

The adhesive composition is applied to the melamine edge; it can be applied to PVC. If you choose PVC, it’s easier to start with thin ones - they are easier to process, any melamine is easy to glue.

We take an iron and a fluoroplastic nozzle on it. If there is no nozzle, thick cotton fabric will do - so as not to overheat the tape, but to melt the glue. A hair dryer is also suitable for this purpose. We set the iron to about “two”, while it is heating up we cut off a piece of tape. The length is a couple of centimeters longer than the workpiece.

Place the edge tape on the part

We apply the edge to the part, level it, smooth it out. There should be small pieces hanging off both sides. We take an iron and, using a nozzle or a rag, iron the edge, heating it until the glue melts. It is necessary to heat evenly over the entire surface. After the entire edge is glued, let it cool. Then we start processing the edges.

Warm up with an iron

The edge can be cut with a knife, both with the sharp and blunt sides. Some people use a regular metal ruler, while others find it more convenient to use a stainless steel spatula.

So, take the tool you have chosen and cut off the hanging edges of the edge. They are cut close to the material. Then cut off the excess along the part. Melamine and thin plastic are easily cut with a knife. If the PVC edge is thicker - 0.5-0.6 mm or more, difficulties may arise. Such edges can be processed with a hand router, if you have one. This guarantees good results in a short time. The processing will take longer if you use sandpaper, but the result may not be worse.

You can even use a spatula with a hard blade

One important point: when gluing thin edges, the cut of the part must be smooth, without protrusions and depressions. The material is plastic, which is why all defects are visible. Therefore, first go over the cuts with sandpaper, then thoroughly remove dust and degrease. Only after this can you glue.

Edging with PVC tape (no glue on the back side)

With this method of gluing PVC edges yourself, you need universal glue and a piece of felt or rag. We read the instructions for the glue and carry out all the steps as recommended. For example, for Moment glue, you need to apply the composition to the surface and distribute it, wait 15 minutes, and firmly press the surfaces to be glued.

Apply glue and wait - no problem. To press the edge tightly to the cut, you can use a wooden block wrapped in felt. Instead of a block, you can take a construction float and also attach felt to its sole. As a last resort, you can roll up thick fabric in several layers and press the tape to the surface.

Press firmly, leaning with all your weight

The selected tool is pressed against the laid edge, pressed with all its weight, pressing it to the surface of the chipboard. The movements are stroking. This is how they iron the entire edge, achieving a very tight fit. The part is left in this form for some time - so that the glue “seizes.” Then you can start processing the edges.

Lifehacks

Professionals advise paying attention to the following tricks:

- Ends hidden from view are often not processed. This is acceptable according to GOST, but in practice it is not very reasonable. It is optimal to go through parts that are invisible during operation with at least the thinnest melamine edge. This will reduce the absorption of vapors and moisture, and extend the life of the furniture. Relevant for shelves, drawer bodies, countertops.

- When working with an iron, it is highly advisable to wear a fluoroplastic attachment or add thick cotton. This reduces the risk of overheating the glue and melting the tape itself.

- The edges are selected either tone-on-tone or in strong contrast. A difference of 1-2 tones will make the furniture visually uneven.

How would you disguise the end of the furniture?

EdgeProfile

- To improve the fit, the ends must first be vacuumed and wiped with alcohol to degrease.

- The optimal heating for an iron and hair dryer is medium mode (usually 2).

- For facades and external ends it is better to use PVC edges 2 mm thick. There the friction is highest.

If it is necessary to replace the old tape, it is removed in the same way, but in reverse order. Heat the surface, use a knife or spatula to separate a piece from the end. Clean the surface, then begin installing fresh material.

Installation procedure

You can only glue melamine tape and U-shaped PVC edging yourself. Let's consider the technology of how to glue the edge. This method will help restore old furniture or decorate new ones.

- Unwind the roll of melamine border. Apply to the end of the surface to be treated. Mark the length with any additional trimming allowance. The standard self-adhesive edge has a width of 2.1 cm, and the width of the chipboard is 1.6-1.8 cm.

- Apply tape, align edge along one edge, iron.

- Iron in small sections of 10-20 cm.

- Roll over heated areas with a roller or felt.

- Depending on the chosen material, you need to glue the edge using an iron at a certain temperature. With a properly heated iron, the adhesive base will evenly adhere to the end without swelling.

- After the tape has cooled, begin trimming and rubbing the protruding edge with sandpaper or a file.

You can see all the stages of work more clearly in the video below:

The stage of pasting the end surface is completed. The tape allows you to decorate edges of various configurations. If you follow all the recommendations, the end will be of high quality, without scratches, minor defects and glue.

Edge tape for furniture is used not only by craftsmen who make furniture, but also for the restoration of wooden structures by home craftsmen. Any type of edge that is applied to the end of the chipboard independently or by furniture manufacturers gives the product an aesthetic appearance. It also protects the structure from moisture, microorganisms, and insects that can destroy the internal or wood structure of the product, so gluing the edges to the chipboard is simply necessary.

FAQ

Can there be a cheap edge on expensive factory furniture?

Hardly. Manufacturers do not skimp on such details, realizing that the durability of the product depends on this. If the edge is cheap, the price is likely unreasonably high.

How to properly make joints on furniture edges?

It is advisable not to do them at all. The following approach will allow you to avoid joints: round the corners with a file, measure the entire perimeter of the tape, start gluing from the center of the front end, first going around the left side, then along the right. You need to connect the ends in the center of the rear end, in a place that is most invisible to the eye.

If this option is unacceptable or the edge is hard, you can leave sections at the corners and cover the seams with decorative overlays.

On veneer, the joints are sealed with putty, sanded and the entire perimeter is coated with varnish, wax or paint.

The edge breaks when cutting off excess. What to do?

The problem may be a dull blade or the direction of movement of the knife. The cutting is carried out inside the part, from top to bottom. To be on the safe side, you can use a metal spatula.

The hard edge does not adhere well.

For complete pressing, you can use a wooden beam the length of the entire end. After rolling with a roller, you need to press the block on top, secure it with tape or clamps and leave it until the glue dries completely.