What types of adhesives are there for PVC?

When choosing glue for PVC products, first of all, you need to take into account the purpose of the item being repaired. Polyvinyl chloride (PVC) is used to make building structures, plumbing pipes, film for MDF furniture panels, elements of camping equipment and boats, and much more. Each type of material is connected in a certain way, and the glue is selected based on the characteristics of the elements that need to be glued, their purpose and operating conditions.

How to glue self-adhesive without air bubbles and folds

It doesn’t seem complicated - just use glue. But no. To achieve a good result, you need to know some tricks. It's better to start with small surfaces. If you are going to cover a kitchen cabinet, start with the drawers. Having mastered the techniques, you can move on to larger planes.

Which is better: heated floors or radiators?

Warm floorBatteries

The first thing to remember: it’s easier to work with horizontal surfaces. If you are gluing doors or furniture doors, it is better to remove them, place them on a table/trunk/stools and glue them in this position. You can, of course, without removing it, but this is very inconvenient, and the result will most likely be worse.

It is easier to glue on a horizontal surface

Second point. If the self-adhesive film for furniture is too thin (cheap), it can stretch and fall in waves. It is very difficult to work with it even with experience. If you are going to glue the film for the first time, it is better to pay a little more, but buy a good one. De-fix is considered the best. It has ideal density, good glue, and many colors.

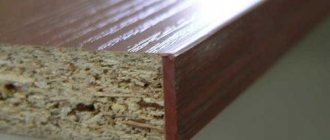

Features of PVC products

Polyvinyl chloride is a thermoplastic solid material with a low melting point. Most products require heat when gluing. This can be done using a hair dryer.

PVC adhesive may vary in composition:

- Two-component - the glue comes in the package separately from the hardener. The components must be mixed before use. The diluted composition, in most cases, does not lose its properties within 8 hours. After this, if necessary, you can add hardener again and continue working.

- One-component - adhesive, ready for use. The hardener is already present in its composition. The time of use is limited only by the expiration date - usually no more than 6 months from the date of manufacture.

Both types are effectively used for PVC. Which one will be best for a particular case is determined individually by the master. It is believed that two-component adhesives provide a higher quality connection. Among other things, the following properties are taken into account:

- adhesion;

- plastic;

- waterproof;

- heat resistance.

Important! When choosing an adhesive, you need to pay attention to the label on the packaging - it should indicate that the adhesive is suitable for PVC.

What kind of glue is needed depends on the material you are working with. Let's look at the most common options for products held together using adhesive joints.

Pasting furniture facades at home

And now we propose to consider how to glue MFD film to a facade that has a flat surface.

To complete all the work that is planned, you will need the following tools and devices:

- White spirit.

- PVC film.

- Lint-free soft cloth.

- Wide and new spatula for plastering.

- Sharp scissors.

- Stationery knife (very sharp).

- Household hair dryer.

Please note that you should really only use a new spatula, since a used tool will still have irregularities that are almost invisible, and they will scratch the films during smoothing.

The upcoming work consists of the following stages:

Gluing PVC film to the furniture facade => preparing the surface for processing => cutting PVC film => gluing the material to the furniture => trimming excess film => final leveling of the finished surface.

Instructions for gluing the PVC coating yourself are attached below. Despite the fact that the described steps for gluing film on MDF are simple in themselves, the quality of the final result will largely depend on how accurately you follow it.

- First, you should thoroughly wipe the surface to be decorated using a rag soaked in white alcohol.

- Afterwards, in order to perfectly glue the MDF film to the furniture facade, measure the perimeter of the surface to be pasted and, according to the measurement data, cut the self-adhesive film with a margin of a couple of centimeters on all sides.

- Roll the self-adhesive material into a roll with the wrong side up.

- Place the edge of the film against the edge of the facade and separate the edges of the backing.

- Next, you should gradually unroll the roll and separate the backing layer.

- Use a spatula wrapped in fabric to smooth out the self-adhesive material so that there are no air bubbles underneath it.

- After the film is evenly glued over the entire surface, the excess film should be trimmed around the entire perimeter.

- Next, warm up the perimeter of the facade with a household hairdryer and additionally iron everything again with a spatula wrapped in fabric.

- Use a similar method if there are bubbles on the product.

If you follow all the instructions correctly, the result will be almost the same as on factory-made furniture facades.

Please note that a feature of adhesive-based PVC films is the small thickness of the material. As a result, even small specks of dust or irregularities on the surface being pasted will be visible to the naked eye. For this reason, you should wipe the facade with a damp cloth and check for dust under a bright flashlight or lamp before starting work.

Pasting tabletops with wood-look film

You are already familiar with how to cover furniture facades, and now let's look at how to finish a kitchen countertop. The main stages of the completed work will differ little from the previous method, so it’s better to just post a photo with explanations.

So, to begin with, the tabletop should be sanded using an angle grinder, and the grain size should be changed from medium to fine. The need for sanding is due to the fact that the tabletop will have a lot of chips and scratches on both the front side and the ends. Round depressions and scratches should be treated with a putty solution, and then the workpiece should be finally sanded and wiped with a lint-free cloth soaked in white alcohol.

After this, the tabletop should be laid in a horizontal position. We cut the pre-prepared film so that there is enough of it for the ends, and not just for the front surface. Apply the film, while gradually removing the backing and dispersing unevenness along the edges. When the main surface is pasted over, bend it at the ends. You should make cuts in the corners using a stationery knife and fit the bottom piece of film under the top one. Align the film along the end with a rag.

Panels

PVC panels have become widespread due to their sufficient strength, water resistance, resistance to temperature changes, and low cost. The fastening of such a facing coating is carried out not only with glue, but also mechanically on the sheathing. The adhesive method is used when the base is level and without any defects.

The main properties of the glue in this case are resistance to temperature changes, moisture resistance, and excellent viscosity. Most often, liquid nails, Moment-Montazh or Titanium are used to fasten panels.

Preparation for gluing

This is how you can use self-adhesive to change an old refrigerator

The leveled surface is cleaned of dust and dirt (with water and dishwashing detergent) and dried. Everything must be removed carefully: even drops of fat, if we are talking about changing the “image” of the kitchen set. If you use abrasive or acid-containing products, everything will need to be thoroughly removed and washed several times with water and liquid dishwashing detergent.

If the original substrate is very loose, two coats of primer may be required. After drying, check for any smudges. If everything is smooth, you can begin finishing.

How to glue self-adhesive film on furniture, expert advice

Then, having peeled off one of the sides a little, glue one part, then the second on top. The seam at the corner is, of course, visible, but not so much that it is critical. To make everything “settle down” better, the pasted area can be warmed up.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

I removed the door and began to carefully examine it; it turned out that the film had peeled off not even from the very edge, but about 2-3 centimeters from the edge. If you want to clarify something, please contact me!

Film

PVC film is intended for cladding furniture facades, swimming pools, doors and other surfaces. At home, the only possible option is self-adhesive film. To attach such a coating using glue, you need industrial equipment - a vacuum press or a welding machine.

Thus, PVC film adhesive is used on an industrial scale in furniture manufacturing plants or construction organizations. It is selected by specialists based on the purpose, temperature conditions and gluing method. Most often, two-component compositions are used, since they have a higher heat resistance class.

Self-adhesive for furniture - what is better to buy

It is important to understand that not all of the film can be glued to slab materials. If the self-adhesive you randomly chose from the market sticks to the surface of the furniture, then most likely the coating will not be perfectly smooth, but will soon begin to bristle in the corners and will come off after a short period of time. There are two solutions to this problem, namely, to purchase an industrial facade that will not peel off and will look great at the same time.

The second solution is to purchase a high-quality film that will have a high level of adhesion to all surfaces, even wood.

Similar materials can be bought in such large construction stores as Leroy Merlin, and the cost will vary from 130 to 900 rubles per roll.

The standard length of a really high-quality coating, having a thickness of 0.3 to 0.5 mm, in a roll will be 2 meters with a width of 0.45 meters. The difference in cost is determined by the thickness of the material you choose and the quality of the adhesive composition. It turns out that the higher the cost of the film, the better it is.

Fabrics

PVC fabrics are used in the production of tents, boats and other similar products. During operation, material damage may occur that must be repaired. These are the most common cases where PVC fabric glue is used.

Thermoplastic or polyurethane compounds are used for these purposes. When repairing a tent awning, patches of PVC fabric are used, which are sewn on with silicone threads, glued and heated using an industrial hair dryer to activate the glue. Instead of a hairdryer, you can use improvised means, but it is important not to damage the fabric itself.

Application technology

Before updating surfaces, prepare: scissors, soft cloth, roller, solvent, primer mixture, medium-dispersion sanding paper.

There is an action technology that will help transform a room:

Some people use another method of interior treatment if the finishing area is too large - soap and water.

Apply the solution to the adhesive surface using a sprayer and treat the furniture with the prepared material.

Instructions for using glue

When using PVC glue for various needs, you must adhere to the following recommendations:

- to glue most PVC products with a similar material, you need to perform heat treatment to secure the connection;

- when choosing a glue, it is important to take into account not only the quality of gluing, but also the presence of toxic substances in it;

- for hard structures (such as plastic), adhesives based on vinyl chloride polymers are used, for soft ones (rubber, fabrics) - based on thermoplastic polymers;

- after gluing work is completed, the joint cannot be subjected to loads for at least a day;

- when applying glue, it is necessary to maintain a uniform layer thickness and prevent excess release;

- Before carrying out all work, it is imperative to thoroughly clean, degrease and dry the surfaces.

Advice! If excess glue does appear, it must be removed immediately, otherwise the appearance will be ruined.

Glue for polyethylene: How to seal a bag at home or glue a film for a greenhouse with your own hands

- What is plastic glued to?

- How to glue plastic

- Preparation of blanks

- Cut the plastic

- Manual method of applying glue (VIDEO)

- We glue plastic using a compressor (VIDEO)

- How to throw plastic on a large workpiece

- How to peel off plastic

- Conclusion

It happens that the color of the film becomes boring or the material deteriorates and has to be removed. There is no need to try to paint the self-adhesive or paste it over with a new layer, you need to completely remove it. To remove this strong and durable material, follow these instructions:

- moisten the base with hot water;

- wait 5-10 minutes until the glue swells;

- take a sharp metal spatula or knife and start separating the film from one or more edges;

- if necessary, warm the film well with a hairdryer to melt the glue - this will work faster;

- completely clean the surface of adhesive material;

- Remove remaining glue with alcohol and acetone.

Caring for the self-adhesive is easy - you can simply wash it with a damp sponge and detergent. It is better not to use powders or granules that can leave scratches. With self-adhesive film it is easy to update the interior without extra costs, which is why this material is very popular among users.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

To connect the surfaces of different materials, it is necessary that the molecules of the substance of one element be attracted to the molecules of the substance of the second element. If you want to clarify something, please contact me!

Brands and cost of PVC glue

Common brands of glue for polyvinyl chloride products:

- "Second" . A series of inexpensive adhesives. For hard structures, and also has adhesive for soft plastics. The formulations are produced in small tubes, the cost does not exceed 200 rubles.

- Thomsit . A well-known brand that produces various adhesives. For PVC, two-component polyurethane adhesive from this manufacturer is used. The composition is of high quality, is used in industrial production, and does not contain organic solvents or toxic substances. Available in large packages. The cost for 7 kg is about 1500 rubles.

- "Moment". The company offers a large selection of PVC adhesives for various purposes. Among them are “Moment for PVC boats”, “Moment Crystal”, contact “Moment-gel”, “Rubber” and others. The price for a 30 ml tube is about 50 rubles.

- Soudal. A large selection of adhesive products - sealants and adhesives for PVC, for almost any purpose. The cost is not too high and ranges from 150 to 250 rubles. per pack 300 g.

Which glue is suitable for working with PVC products?

Polyvinyl chloride is widely used for the production of building materials, sewage systems; boats and camping equipment are made from PVC. A good PVC adhesive does not lose its properties for several years, is not affected by moisture or liquid, does not crumble, does not change color and structure.

There are two types of PVC glue:

- one-component composition, completely ready for use;

- two-component adhesive - the kit includes a separate adhesive and a separate hardener. Before use, both components are mixed.

It is clear that two-component PVC adhesive provides a stronger and more reliable seam. But one-component types are easier to use and easy to handle even for inexperienced craftsmen.

Also, when choosing a suitable adhesive for PVC fabric, film or building materials, the main factors should be taken into account:

- purpose of application – joining parts, laying PVC finishing materials, repairing inflatable boats or sports and tourist equipment;

- degree of moisture resistance;

- temperature restrictions for application and use;

- adhesion to various surfaces;

- plasticity of the composition, ease of application on various surfaces.

How to glue PVC: overview of compositions for different types of base

There are several types of composition for gluing PVC products. PVC adhesive is selected depending on the type of material - it can be fabric, finishing materials, film, communication systems (durable and hard material).

There are different types of glue based on their properties.

- Fixing adhesive – provides only fixation of elements, but does not glue. Used for laying floor coverings; the absence of a strong seam simplifies the dismantling of fragments or the entire covering.

- Reactive adhesives are effective when laying heavy rubber elements or joining large parts.

- Contact adhesive provides the strongest possible seam and crystallizes fairly quickly.

Laying tiles and wall panels

Covering the surface with PVC panels requires the adhesive composition to be highly elastic, resistant to moisture and temperature changes. If the surface is smooth, glue is applied directly to it; otherwise, a reinforcing mesh should be applied; glue alone cannot be used.

For the installation of plastic panels, a special glue “Liquid Nails” is available for sale; the products of the long-proven “Moment Montazh” are no less popular.

PVC tiles are laid in a similar way, but here the purpose of the room plays an important role. Some craftsmen neglect the choice of glue according to the type of room, which leads to a poor-quality result - the fragments “move out” and lag behind the base.

Understanding the purpose is quite simple: if high traffic is expected, it is better to choose an epoxy or polyurethane composition; for the home, the main factor will be water resistance and toxicity. Acrylic and polychloroprene adhesives have the lowest emissions of volatile compounds. The compositions are presented in a wide range and are used for gluing to varnished bases and fastening cork products, including wall and floor finishing.

PVC materials

PVC fabric is used to make boats, camping tents or similar products. During operation, the material may become damaged, and the composition included in the repair kit is only enough for a minimal cut.

To glue the fabric together, various thermoplastic compounds and silicone threads are used. After application, the composition is carefully heated without damaging the material itself. PVC fabric adhesive is spread over an area, then subjected to high temperature using an industrial hair dryer, after which the composition “welds” the fabric parts. The most effective method is to apply patches of similar material and use a suitable adhesive.

Film

PVC film is used advantageously on a production scale - for cladding furniture, doors, swimming pools. In a particular case, there may be a need to repair or restore part of the element: attach or replace the peeling material.

For such purposes, it is best to purchase a two-component adhesive for PVC film with a suitable heat resistance rating. Not all compositions can withstand exposure to direct sunlight (this is important in the case of finishing a pool). When repairing interior doors, the temperature regime will be in second place; it is more important to pay attention to the degree of moisture resistance.

MDF peeled off in the kitchen after a month

Good afternoon We have a kitchen made, the facades are made of MDF, and the MDF has peeled off on the doors of the top drawers that hang to the right and left of the gas stove, what should we do? Is it the store's fault that they made it for us? hangs 55 cm from our gas stove

A shitty factory glued these facades. The store has nothing to do with it. I would advise running Moment-Montage type glue under the facades and tightening them with tape until they stick.

Well, if it is recommended to place the hood at a height of at least 75 cm

the drawers hang close to the hood, but the hood hangs higher from the stove compared to the drawers

Regarding the gluing, the kitchen was made to order, can I return it to the store that made it and let them redo it, or what should I do?

Most likely, this is not the fault of the store or the factory. MDF facades are made by vacuum pressing with pre-heating of PVC film, so that if the technology is followed, the film cannot simply peel off. But if after this the film is exposed to heat or steam, then it peels off from the base. So, I think you have the same case. When cooking on the stove, try placing your hand where the film has peeled off and thereby determine whether the facade is exposed to heat.

Did the store know that the stove was gas? Did you warn me not to go low? If not, it makes sense to try to butt heads.

2 Oleg62 IMHO, this is all bullshit. Personally, the distance from the stove to the wall cabinets is less than 55 cm. During the year of operation, nothing came off anywhere. The kitchen was made to order. There was a kitchen before it - yes, the facades peeled off periodically. Because they're glued on like crap. If the author wants to try hemorrhoids, let him butt, present it to the store. If the warranty period has not expired. Moreover, the terms of the guarantee in the contract must be carefully read.

The store didn’t give any warning and the corners of the drawers are heating up

Moreover, they themselves came and measured the kitchen

Chipboard or MDF is the base, most likely the film has peeled off, it can be PVC, laminate, plastic, etc. Try to fix it yourself, there is nothing complicated, as they wrote above, changing it is a pain in the ass.

It depends on what you use to glue it

You still haven’t said what kind of film you have? If PVC, for example, “moment” type glue can melt the film. If you find good PVA (sometimes fake), then this is the best option. If it’s plastic, then glue it with whatever you want, which will hold it stronger.

How do you find out what kind of film it is?

Here I am holding in my hands the first contract I came across. Facade: gray metallic plastic in a frame.

The question is actually this: who installed the kitchen, you or the store? If you are, then you won’t have any complaints about the store. The rules for installing a hood over a gas stove were violated. If the store representatives installed the kitchen, then you can file a claim because you did not follow the installation rules specified in the product passport. This resulted in property damage during operation. Those. in this situation, whoever followed the rules is right. And whoever does not comply is wrong. But in giving this advice, I agree with Hubert that victory will not come with little blood. Our trade does not like to admit mistakes.

All this is the machinations of not very conscientious people. salons, and not only. If the client has correctly established (that he is his own enemy), then in any case they are obliged to change it if it is their fault. But this is according to the law.

Of course, the law obliges only the seller to provide assembly services. If I remember correctly, this is Resolution 55. But the salon cannot impose assembly. Those. If the client assembles the kitchen himself, then no one can interfere with him. However, when considering disputes, the issue becomes extremely formal. Nobody cares anymore who has what experience. They look at the numbers. The hood above the gas stove should hang at a height of 75 cm from the level of the countertop. If it hangs lower, it means that the requirements are not met. And if you do not comply with these requirements, you are ready to take risks. Claims are a financial issue, which means they are extremely formalized. Well, as for changing it. If a person actively seeks to realize his rights, then they can change it. Well, if it’s passive, then they probably won’t change it. You yourself wrote in the City of Masters about a man who won a lawsuit against “Kukhnistra”. I read on the IDV forum how much it cost him. That's why I said that I agree with Hubert.

Instructions for use

In practice, the use of PVC glue does not differ significantly from the use of other compositions for joining materials. However, when carrying out work, certain rules must be followed.

- According to the technology, any surface should be degreased with White Spirit and cleaned of dust or other contaminants.

- Durable plastic elements are glued with compounds based on vinyl chloride polymers, rubber or PVC fabrics are glued with thermoplastic types of specialized glue.

- The adhesive composition is applied in an even layer.

- For effective setting, the seam is always exposed to elevated temperatures.

- The connection is not subjected to any stress for 24 hours.

Useful tips

Quite often, household members forget one simple truth.

MDF film does not like elevated temperatures, and therefore you need to try to insulate the material from strong heat. Otherwise, peeling will occur constantly.

Therefore, here I can highlight several practical recommendations:

Have you ever encountered films that peel off? How did you resolve this issue? What restoration methods were used?

Subscribe, leave comments, tell us about your situations and don’t forget to come to us again!

Source

Popular brands and their prices

The “Moment” brand is very popular among users. The manufacturer offers a wide range of different types: glue for boats, “Moment Crystal”, gel, rubber. The products are of high quality, which is reflected in the price - a tube of 30 g of glue costs about 50-60 rubles.

Soudal produces an equally wide range of PVC adhesives for various purposes. For a fairly affordable price (150-200 rubles), the user can choose glue for any highly specialized purpose.

To connect solid structures, craftsmen often advise purchasing “Secunda” cold welding. Also in the line of adhesives there are excellent types for joining soft materials.

When carrying out a large volume of work, the Thomsit brand will be the best choice. The manufacturer suggests choosing a two-component polyurethane composition suitable for PVC in containers of 5-7 kg, the price is relatively low, about 1,500 rubles, which turns out to be very profitable. The glue does not contain toxins and does not emit harmful substances or solvents.

Thus, choosing a glue for PVC is not such a difficult task. It is worth focusing on the type of surfaces to be glued, operating conditions and price category of the product.

Technical characteristics of PVC products

PVC (polyvinyl chloride) is a polymer that is an environmentally friendly material, has a low melting point and is susceptible to low temperatures. These two somewhat negative properties are offset by the durability and high strength of the material.

The physical properties of the polymer give PVC pipes the following qualities:

- High ring stiffness. The pipes are resistant to water hammer and are able to maintain pressure in the system up to 120 atmospheres.

- Do not deform when exposed to high temperatures. During heating to the maximum permissible temperatures, the pipes increase by only 5%.

- Low heat resistance. The rigidity of the adhesive PVC pipe is lost when the temperature reaches 78 ºC. In this regard, the use of such pipes in pipeline systems where the water temperature may exceed 40 ºC is not permitted.

- Instability to low temperatures. Polyvinyl chloride is able to function down to -15 ºC. At lower temperatures the material begins to deteriorate. Therefore, if the main line is laid in cold regions, then it needs additional insulation.

The operational properties of the pipes will be as follows:

- Long operating time without interfering with the system for cleaning purposes. Siltation is minimized due to the very smooth inner walls.

- It is the best solution for the construction of sewer systems. Preference is given to these pipes, again, due to the smooth internal walls and their small thickness.

- Long service life. In particular, this is achieved due to the material’s resistance to ultraviolet radiation.

Why is this happening

Let's start by examining the reasons why the film on your MDF kitchen facade has peeled off.

This can happen for several main reasons. Next, you will learn what to do in this situation, how to glue it and how to protect the film from the oven and other provoking factors.

In reality there are quite a lot of reasons.

But even on high-quality surfaces, peeling is possible.

This mainly occurs due to the oven and on the facades adjacent to it.

What happens is this: The housewife is preparing some dish in the oven, which is heated to high temperatures. When you take out the dish, all the heat comes out and hits the façade. As a result, the glue melts, loses adhesion to the film, and it peels off.

There is a high probability of peeling off when exposed to sunlight. Gradual heating occurs, the film burns out, the glue dries out or melts. That's it, the grip is lost, and the result is obvious.

To summarize, the following main reasons can be identified:

Sometimes there are several causes at once, or only one factor influences.

The result is the same. The film has peeled off and needs to be fixed.

Adhesive installation of polyvinyl chloride pipes

Glue for PVC pipes and fittings is also called cold welding, and not by chance, because it distributes the load, which increases strength and extends the service life of the pipeline to the same extent as it ensures the connection of elements by real welding. PVC pipe adhesive creates a polymer splitting reaction in solvents. After the pipe walls have softened, a fitting with softened walls is attached to them. This process is also called chemical welding.

In this case, it is worth considering one feature. Due to the fact that the chemical properties of additives and solvents vary, the choice of adhesive for PVC pipes must be made taking into account the thermoplastic compounds being welded. As a rule, companies producing plastic pipes offer instructions on the optimal solution to this issue. Be that as it may, it is worth remembering that when joining parts made of chlorinated polyvinyl chloride (CPVC) and regular PVC, you need to use different brands of glue.

The use of glue for PVC sewer pipes is considered a fairly popular method, which ensures excellent tightness of the finished structure.

Remember that uneven coating of pipes with glue or the presence of a large number of irregularities can cause partial glue failure. Complete non-gluing may also occur - this happens when both layers of glue dry out. Please note that you only have a few minutes to complete the connection operation.

The appearance of a soft adhesive layer is caused by a low ambient temperature or by allowing a small amount of time for hardening.

The layer may become porous - this happens when the adhesive layer is enriched with air due to poor mixing of the components.

Types of adhesives and installation methods

All chemical compositions for plastic pipes with glue belong to two groups.

The first group includes hot fusion adhesives for sewer pipes. In addition, they are suitable for connecting both air and water pipes made of PVC. When used correctly, the adhesive composition results in a high-quality and durable connection. For this, instructions from the manufacturer are included - they will allow you to use the substance correctly, so that the joints will be completely sealed.

Review of effective brands

Among the above groups of glue, several brands with high performance have gained the most popularity. According to reviews from professionals, when choosing, you should give preference to such brands.

Titan wild

Glue belongs to the group of liquid nails and is a universal professional product. The Titan wild composition successfully replaces fastening with screws, self-tapping screws or nails. The glue is capable of fixing MDF panels on any surface. It is used both indoors and outdoors. The advantages of the brand include:

- reliable fixation without damaging the structure of the material;

- moisture resistance - 100%;

- cost-effectiveness;

- setting speed;

- Possibility of use at different temperatures.

Titebond

The adhesive is based on an aliphatic resin. It is used in carpentry for gluing wooden parts, applying laminate, MDF, chipboard, and assembling furniture. The advantages of Titebond glue include:

- fast setting;

- readiness to work;

- resistant to moisture, heat, solvents;

- ensuring the strength of the bonding boundary is much higher than that of wood.

The glue has the appearance of a viscous yellow emulsion, after drying it is translucent. Resistant to freezing, ignites when temperatures exceed 100 ⁰С.

"Moment-1"

Universal adhesive “Moment-1” is perfect for gluing surfaces made of different materials, is moisture-resistant and can withstand temperatures from -40 ⁰С to +110 ⁰С. The glue dries very quickly thanks to the components included in it:

- rubber resins;

- rosin;

- ethyl acetate;

- acetone;

- hydrocarbons.

Glue "Moment-1" is a light yellow thick liquid. The optimal temperature for work is from +18 ⁰С to +25 ⁰С. When attaching the panels, air flow should be ensured to avoid poisoning by toxins.

Tytan Euro-Line 601

Adhesive is a type of universal construction adhesive. It is used indoors and outdoors. The base on which MDF is mounted can be made of wood, concrete, brick, or plaster.

Tytan Euro-Line 601 adhesive is based on rubber. It is used for repairs and finishing with MDF panels. The main characteristics include:

- strong and fast grip;

- strength;

- hardening within 24 hours;

- heat resistance ranging from -30 to +60

"Moment Crystal"

The glue is colorless, transparent, dries quickly and leaves no marks as a result of working with it. Liquid nails reliably fix MDF panels installed on the ceiling or walls indoors. "Moment Crystal" is well suited for gluing panels without top finishing.

The peculiarity of this variety is that the speed and reliability of setting depends on the force with which the surfaces were pressed. “Moment Crystal” is characterized by high frost and moisture resistance.

Makroflex MF220 Heavy duty

This brand of glue is intended for joining different materials:

The form of the glue is a white paste based on polyacrylates. The optimal temperature for fixation is +10 ⁰С and above. Among the characteristics of Makroflex:

- maximum holding time - 15 minutes;

- no odor;

- Possibility of use outdoors and indoors;

- great gripping force.

Liquid Nails LN-910 Panels

This brand of liquid nails is indispensable for quickly covering a room with panels, gluing decorative elements, baseboards, and moldings. The adhesion is reliable if brick, concrete, wood, plywood, chipboard and other materials are used as the base.

The adhesive is intended for interior use. It is distinguished by a number of characteristics:

- elasticity;

- the ability to adjust the gluing within 15 minutes after connection;

- obstacle to deformation;

- long (up to 20 years) service life;

- ability to freeze and defrost.

Liquid Nails LN-901 Heavy Duty

The composition is based on synthetic rubber. Capable of creating the strongest connections in difficult conditions. Can be used both indoors and outdoors. Sets quickly. Can be used at temperatures from -40 ⁰С to +70 ⁰С. The following materials are used as glued materials:

Temperatures from -40 °C to +70 °C are optimal for operation, from +5 °C to +38 °C - for work.

Tips for choosing adhesive for PVC pipes

When choosing what to glue PVC pipes with, be sure to read the instructions and also take into account the properties of the material.

The following parameters are considered the most important:

- Connection type – cold or hot. These concepts have been described above.

- Freezing time. For cold welding, this period is 4 minutes at room temperature, and about 1 minute at temperatures above 40 ºC. For hot welding, the indicators will be as follows: hardening time - about half an hour; hardening – 150 minutes; final polymerization – 24 hours.

- Method of application and correct storage. If you neglect this point, the adhesive properties of the material will significantly deteriorate.

On the glue package you can see data on a list of characteristics, such as viscosity, color and density. Given the fact that PVC pipes can be soft, hard or corrugated, some manufacturers divide adhesives into certain types.

There are two types:

- For products made of soft materials. These include corrugated pipes and water supply pipes.

- For hard products. This includes siphons, plastic fittings for PVC pipes and so on.

Regardless of how hard the material is, the newest adhesives easily cope with exposure to both cold and hot water. When choosing such products, try to buy products from well-known manufacturers. Actually, we’ll talk about them below.

Well-known manufacturers of adhesives for PVC pipes

Any adhesive for this type of pipe consists of a certain amount of polyvinyl chloride dissolved in tetrahydrofuran and other similar substances.

The most common and high-quality brands include:

- TANGIT . Country of manufacture: Germany. Can be used to connect polyvinyl chloride pipes in water supply systems. This glue provides high-quality gluing, the resulting joints are durable. The glue is easy and simple to use. The jar comes with brushes. The products are accompanied by certificates indicating that the glue can be used in systems with drinking water supply.

- MARS . Manufactured in Russia. The adhesive composition is based on compounds of synthetic resins together with organic solvents. This adhesive is suitable for joining pipes and other elements made of polyvinyl chloride. The advantages include the high adhesiveness of the substance, as well as the quality of the connection, the strength of which is excellent.

In addition to these brands, experts also recommend adhesives of such brands as “Phoenix” and “Vinilit”. They also provide a reliable connection as good as the brands described above.

Above we described how to seal a PVC pipe and how to seal a plastic sewer pipe correctly. We hope everyone was able to obtain the necessary information for themselves.