What glue is best to use

One of the distinctive features of MDF panels is that they, like any other material containing wood, are resistant to moisture. In most cases, concrete surfaces are sheathed with such sheets. Both of these factors should, of course, be taken into account when choosing adhesive for MDF panels. The purchased fixing composition should not contain water in the first place. Also, the product must be designed to work with both wood and concrete.

Liquid nails are considered the most suitable options for fixing compounds for MDF. For finishing both wooden and concrete walls with MDF panels, a very good solution would be, for example, to use glue from the Titan wild group. “Moment Installation” and “Crystal” products are also excellent for fixing such sheets on any surface.

What is Titan wild

This product belongs to the group of universal liquid nails and is professional. In essence, Titan wild glue is a chemical alternative to screws, nails and self-tapping screws. This composition can be used to fix MDF panels on surfaces made of absolutely any material. It is not allowed to use such a product only for polyethylene and polypropylene.

If necessary, gluing MDF panels using Titan wild is allowed both indoors and outdoors.

What are liquid nails used for?

Liquid nails are most often used for wood, fiberboard, chipboard, metal, brick, polystyrene and glass. You can also use them to glue heavy natural wallpapers, such as bamboo, and ceramic tiles.

Interesting materials:

How to check the authenticity of a Xiaomi product? How to check the distributor for a spark? How to check whether a transistor is working or not? How to check the tracking number? How to check the integrity of a transformer? How to check the Moscow digital pass? How to test cottage cheese with boiling water? How to test cottage cheese with iodine? How to test cottage cheese in water? How to check an outdoor thermometer?

Glue "Moment Montazh"

Liquid nails of this brand are also ideal for gluing MDF panels. Using “Moment” of this variety when decorating walls with such sheets, as in the case of Titan wild, is allowed both inside and outside. Consumers praise this glue for its optimal combination of price and quality.

This product is packaged in a special tube, which is inserted into a construction gun during operation. Using such a tool allows you to dispense “Moment Montazh” with high accuracy. And this, in turn, eliminates the possibility of overspending.

Among the advantages of this adhesive for MDF panels, consumers include, among other things, the fact that it does not have any unpleasant odor. In addition, you can work with this product at ambient temperatures from -20 to +70 °C.

“Moment Montazh” has received simply excellent reviews from consumers, including professionals. Many masters believe, among other things, that it has better qualities than even many imported compounds of the same group.

Corners for wall slopes. Item Description

This type of fittings refers to decorative accompanying elements when finishing plastic slopes. As noted earlier, a window corner for a slope can be used to mask corner joints when working with various materials.

The corner is used to mask the junction of the slope and the wall

The decorative plastic corner is made using special technologies, when a rigid PVC sheet is bent using a “hot” method.

The product is universal and is widely used for finishing corners and joints of surfaces made of various finishing materials. Types of plastic corners differ in the material of manufacture and can be made in three versions.

Plastic elements for finishing the slopes of plastic windows have become most popular among consumers. Colored elements can be matched to any interior color scheme. The laminated surface can imitate various materials.

Where is it used?

Plastic angle corners for slopes are widely used for various types of work. It can perform a decorative and practical function at the same time.

- colored elements decorate the corners of window and door openings;

Decorative decoration of a window opening to install a plasterboard structure will require metal elements to fix the corners. Guide metal corners are used when constructing slopes made of plaster. The positive quality of this method is that the guides are not removed, but remain in the body of the structure, ensuring its strength;

Metal corners are used to secure plasterboard slopes when wallpapering walls; pasted corners for slopes will protect the corners of the walls from damage;

The corner protects the corner of the wall from damage. Installation of corner strips is carried out for finishing joints when working with various materials. The elements can be used for external slopes.

"Moment Crystal"

Liquid nails of this variety have also earned good reviews from consumers. Using Moment Crystal glue you can fix MDF panels on walls or, for example, on the ceiling as securely as possible. A distinctive feature of this product is, among other things, that it leaves absolutely no traces on the surfaces being joined.

Using “Moment Crystal” is very convenient, for example, in cases where no additional finishing is intended to be glued on top of MDF panels. In this way, in private houses, for example, attics, attics and various types of outbuildings are often finished.

One of the distinctive features of this variety of “Moment” is that the degree of its setting depends not on the duration, but on the pressing force of the panel. Among the advantages of this product, consumers include, among other things, moisture and frost resistance.

Shapes and sizes

Finished corners usually have an angle of 90°. The corner itself is not always sharp; there are options with a rounded one. By type, corners for protecting wall corners are divided into:

- hard external;

- internal;

Universal corner made of MDF

Questions can only be about universal ones. These are two strips of plastic or MDF connected by a thin strip of flexible material of the same color. Thanks to this connection, you can create an obtuse or acute angle, internal or external - without much difference. But in terms of reliability of protection, it is inferior to rigid ones - after all, the flexible part is quite thin.

It is also worth knowing that corners can have shelves of the same or different widths. More often they are found with the same ones, but it is quite possible to find those in which one is wider, the other is narrower.

Types, shapes, sizes

The width of the shelf varies from manufacturer to manufacturer. Plastic ones, for example, can have shelves from 10 mm to 50 mm. MDF corners are made with a minimum shelf width of 20 mm, metal ones - from 10 mm, but the maximum shelf length is 90 mm (aluminum). So there is plenty to choose from.

Main stages of gluing panels

Thus, we found out which adhesive is best to use for MDF panels. But how to install such sheets correctly? The installation procedure for MDF panels is carried out using liquid nails using the following technology:

- walls are being prepared;

- marking is carried out;

- panels are glued.

At the final stage, when covering the walls with MDF panels, the rosettes and corners are finished.

Why choose the adhesive method?

Now you know how to glue MDF panels to a wall with liquid nails. But if you are still in doubt about which installation method to use - frame or adhesive - you should consider the advantages of the latter. Frame installation is more expensive and takes more time, because you will have to install a wooden or metal frame, spending additional money on materials.

The adhesive method does not take away free space from the room. If you use mechanical fasteners, then even the smallest finishing nails will be noticeable, and the adhesive method allows you to get a good result and an attractive appearance of the walls. To extend the life of the panels, MDF can be coated with an insulating primer and a layer of putty. This will prevent swelling of the material and the appearance of mold. When products have unpainted surfaces, the joints are caulked to prevent moisture from entering.

How to prepare

At this stage, work should be done as carefully as possible and in compliance with all required technologies. If the walls are not prepared correctly for gluing the sheets, the MDF panels will not last long on them.

Before installing the sheets, the old finish should first be removed from the surfaces. Also, the walls must be cleaned of dust, dirt and fungus. Next, when preparing to glue the panels:

- cracks in the walls are repaired;

- they are carefully aligned;

- the surface is primed.

Marking

Thus, it is clear what glue to use to glue MDF panels. But before you begin this procedure, you should definitely make markings on the walls. In order for MDF sheets to stand up straight and subsequently hold firmly for many years, before installing them, vertical lines should be applied to the surface to be finished. You can mark the walls when gluing such panels, for example, using a plumb line or level. But it is best to use a level for this purpose. With the use of such a device, lines on the walls can be drawn as accurately as possible.

Installation technology

After the markings have been applied, they begin the main stage of work using glue for MDF panels. Liquid nails of all the varieties discussed above are quite expensive. However, their consumption when installing MDF panels is usually not too large. This material is installed on walls or ceilings using the following technology:

- strips of glue are applied around the perimeter of the sheet without interruption;

- the same strips are applied with glue along the diagonals of the panel;

- Additionally, glue is applied to the entire panel area in thick drops in increments of no more than 20 cm.

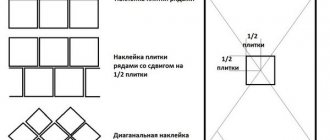

The panel coated in this way is then pressed tightly against the wall, after which it is abruptly torn away from it. This is necessary so that the stripes and points of liquid nails are slightly weathered. Next, the panel is pressed against the wall again, this time for good. After the first sheet is fixed, according to the markings they begin to install the second. Small MDF panels on the surfaces to be finished should be placed staggered in rows.

When using reliable glue for MDF panels and at the same time following all the required technologies, it will be possible to fix the sheets on the walls and ceilings as reliably as possible. When attaching such material, it is important to press it against the surface to be finished as firmly as possible. This will guarantee reliable fixation of the panels and durability of the cladding.

Paneling walls is popular for several reasons - there is no need to level the walls, remove wallpaper, paint or other covering. Finishing is convenient and simple. The method is cost-effective and clean thanks to the consumables, the main one of which is glue for MDF panels. There are quite a few varieties of it, so it’s worth getting to know the main ones before starting repairs.

Silicone corners for wallpaper. Decorating corners in an apartment: how to decorate a room with corners

Options for using decorative corners in the interior design of a room depend on many factors:

- Surface materials. A white plastic corner glued to the corner of clapboard walls will look ridiculous.

- Finish colors. Under no circumstances should a red element be placed in a room designed in pastel colors.

- General stylistic solution of the interior. A polished stainless steel profile will not fit into a classic interior; a polyurethane “stucco” profile will not fit into a high-tech style.

- Purpose of the room. Silicone corners are great for children. They will keep the corners intact and help protect the child from injury.

Wallpaper design options

To complete the finishing after wallpapering, a profile made of any of the above materials can be used. The main criterion when choosing a corner will be its color. The choice of color can be approached in different ways. If the joining walls are approximately the same shade, you can choose the product to match the color of the walls; if they are different, you can match the color of the wall to which the eye is most often drawn. For example, when finishing the corner between a room and a hallway, it is more logical to choose a profile that matches the color of the room’s decoration.

One of the finishing options is decorating with a wooden corner, tinted to match the color of the doors or floor using impregnated stain and coated with varnish. Products made of MDF and PVC, decorated to look like wood, are suitable for the same purposes. When decorating a strict, laconic interior, metal corners will look good.

Solution for corners on slopes: the better way to seal corners in an apartment

To complete the finishing of the slopes, corners are used in the color of the slope, almost always white. Often the material for slopes is a sandwich panel, therefore, to ensure that the material does not differ much, PVC corner profiles are used. The width of the shelf is selected so that it covers the end of the panel or gypsum board. If there are any finishing defects near the window opening, for example, unevenly cut wallpaper, the corner is chosen to be of such a width that these errors are covered.

The angle between the wall and the slope is usually more than 90°; in order for the corner to lie flat, it should be slightly “bent” - placed on a flat surface or a large-diameter pipe and lightly pressed with your hands, moving along the corner.

In the cold season, the profile must warm up to room temperature before use.

Requirements for the adhesive composition

Despite the wide variety of MDF adhesives on the market, they all meet a number of requirements:

- the purpose of the composition has specific purposes - for working with chipboards or for universal use;

- the coupling with any base is strong and reliable;

- resistance to humidity, chemicals, temperature changes - increased;

- strong or super strong adhesion.

There are no frost resistance requirements for MDF glue, since the panels are most often intended for indoor use.

#I love Leroy Merlin

Your current store:

Join Leroy Merlin!

Receive information about new products and great offers!

Your city

or, select another city:

- Moscow and region

- Noginsk

- Saint Petersburg

- Arkhangelsk

- Barnaul

- Belgorod

- Vladivostok

- Vladikavkaz

- Volgograd

- Volzhsky

- Voronezh

- Ekaterinburg

- Ivanovo

- Izhevsk

- Irkutsk

- Yoshkar-Ola

- Kazan

- Kaliningrad

- Kaluga

- Kemerovo

- Kirov

- Wedge

- Kostroma

- Krasnodar

- Krasnoyarsk

- Kursk

- Lipetsk

- Magnitogorsk

- Naberezhnye Chelny

- Nizhnekamsk

- Nizhny Novgorod

- Novokuznetsk

- Novorossiysk

- Novosibirsk

- Omsk

- Eagle

- Orenburg

- Penza

- Permian

- Petrozavodsk

- Pskov

- Pyatigorsk

- Rostov-on-Don

- Ryazan

- Samara

- Saransk

- Saratov

- Smolensk

- Sochi

- Stavropol

- Sterlitamak

- Syktyvkar

- Tver

- Tolyatti

- Tomsk

- Tula

- Tyumen

- Ulyanovsk

- Ufa

- Khabarovsk

- Chelyabinsk

- Cherepovets

- Elista

- Yaroslavl

What glue is suitable

Despite the wide variety of adhesives for MDF, their main purpose is to tightly and reliably glue and adhere the panels to the wall. All its types are divided into groups:

- universal compounds;

- special;

- polyurethane foam;

- liquid Nails.

Compounds for MDF stickers

Compounds, or polymer resin, contain “Moment”, “Titanium” and other additives, thanks to which the adhesive is used on wooden, stone, and metal surfaces.

A distinctive feature of this glue is its versatility.

Special Edition

Chemists have developed this series for gluing not only to ordinary surfaces, but also to concrete. It can be used by both professional builders and amateurs who decide to do the repairs themselves. As a supplement to the glue, a gun is used, which makes gluing MDF much easier.

The special series includes “Montage”, “Macroflex” and others. Their fixation is strong and reliable. It is possible to economically apply a thin layer of glue and use it to eliminate surface defects.

Construction foam

Despite the fact that construction foam is most often used for sealing, its use when installing panels is quite possible. Construction foam is produced in two types - for external and internal use. When fixing MDF panels, it is permissible to use both types of fasteners. After drying, the polyurethane foam remains soft. Flexibility avoids deformation of MDF. This is especially true if their composition is based on wood chip materials.

Liquid Nails

The glue is universal, has high adhesion, resistance to corrosion, and can be used for installation of various building materials, especially those containing wood. Due to its ease of use, the option of using liquid nails is very popular. Using a gun, applying glue is convenient.

Adhesive for MDF panels on the wall. Composition and types

As a rule, the panel contains wood dust. It is obtained by processing sawdust. The material is heated in special ovens until lignin, a kind of viscous substance, appears. Thanks to this component, the raw material mass is bonded. MDF is given good strength by pressing.

MDF has similarities to plywood and cardboard, so it is possible to produce products of any size. A hacksaw is used for this.

This material practically does not conduct heat, but it has a disadvantage - there is a high probability that the melamine film may be damaged.

Such wall panels are reproduced using the same method, however, the coating can be made from various materials, because of this there are three types of MDF:

- veneered: real veneer is used as decoration. Due to this coating, it looks like the product is made of natural wood, but it is quite expensive;

Veneered

- laminated wall panels are the most popular. Their essence is the presence of a melamine film on the surface, which is why it may also seem that MDF is made of real wood. You can also stick a glossy film on the panel to improve its appearance;

Laminated

- The corridor is also finished using painted panels. In this case, the manufacturer is not faced with the task of creating a panel that looks like wood, because here a layer of paint of a certain color plays its role.

Painted

When choosing decoration elements, you need to know that very thin parts have little strength, as a result of which they are used for finishing walls and ceilings. Here's about finishing the ceiling.

Materials thicker than 1.2 cm are often used as heat-insulating layers. Due to its properties, such insulation replaces a brick wall fifteen centimeters thick.

Review of effective brands

Among the above groups of glue, several brands with high performance have gained the most popularity. According to reviews from professionals, when choosing, you should give preference to such brands.

Titan wild

Glue belongs to the group of liquid nails and is a universal professional product. The Titan wild composition successfully replaces fastening with screws, self-tapping screws or nails. The glue is capable of fixing MDF panels on any surface. It is used both indoors and outdoors. The advantages of the brand include:

- reliable fixation without damaging the structure of the material;

- moisture resistance - 100%;

- cost-effectiveness;

- setting speed;

- Possibility of use at different temperatures.

Titebond

The adhesive is based on an aliphatic resin. It is used in carpentry for gluing wooden parts, applying laminate, MDF, chipboard, and assembling furniture. The advantages of Titebond glue include:

- fast setting;

- readiness to work;

- resistant to moisture, heat, solvents;

- ensuring the strength of the bonding boundary is much higher than that of wood.

The glue has the appearance of a viscous yellow emulsion, after drying it is translucent. Resistant to freezing, ignites when temperatures exceed 100 ⁰С.

"Moment-1"

Universal adhesive “Moment-1” is perfect for gluing surfaces made of different materials, is moisture-resistant and can withstand temperatures from -40 ⁰С to +110 ⁰С. The glue dries very quickly thanks to the components included in it:

- rubber resins;

- rosin;

- ethyl acetate;

- acetone;

- hydrocarbons.

Glue "Moment-1" is a light yellow thick liquid. The optimal temperature for work is from +18 ⁰С to +25 ⁰С. When attaching the panels, air flow should be ensured to avoid poisoning by toxins.

Tytan Euro-Line 601

Adhesive is a type of universal construction adhesive. It is used indoors and outdoors. The base on which MDF is mounted can be made of wood, concrete, brick, or plaster.

Tytan Euro-Line 601 adhesive is based on rubber. It is used for repairs and finishing with MDF panels. The main characteristics include:

- strong and fast grip;

- strength;

- hardening within 24 hours;

- heat resistance ranging from -30 to +60

"Moment Crystal"

The glue is colorless, transparent, dries quickly and leaves no marks as a result of working with it. Liquid nails reliably fix MDF panels installed on the ceiling or walls indoors. "Moment Crystal" is well suited for gluing panels without top finishing.

The peculiarity of this variety is that the speed and reliability of setting depends on the force with which the surfaces were pressed. “Moment Crystal” is characterized by high frost and moisture resistance.

Makroflex MF220 Heavy duty

This brand of glue is intended for joining different materials:

The form of the glue is a white paste based on polyacrylates. The optimal temperature for fixation is +10 ⁰С and above. Among the characteristics of Makroflex:

- maximum holding time - 15 minutes;

- no odor;

- Possibility of use outdoors and indoors;

- great gripping force.

Liquid Nails LN-910 Panels

This brand of liquid nails is indispensable for quickly covering a room with panels, gluing decorative elements, baseboards, and moldings. The adhesion is reliable if brick, concrete, wood, plywood, chipboard and other materials are used as the base.

The adhesive is intended for interior use. It is distinguished by a number of characteristics:

- elasticity;

- the ability to adjust the gluing within 15 minutes after connection;

- obstacle to deformation;

- long (up to 20 years) service life;

- ability to freeze and defrost.

Liquid Nails LN-901 Heavy Duty

The composition is based on synthetic rubber. Capable of creating the strongest connections in difficult conditions. Can be used both indoors and outdoors. Sets quickly. Can be used at temperatures from -40 ⁰С to +70 ⁰С. The following materials are used as glued materials:

Temperatures from -40 °C to +70 °C are optimal for operation, from +5 °C to +38 °C - for work.

Operating Instructions

Knowing some secrets of technology, it is not difficult to fasten MDF parts. There are two main ways:

- using lathing;

- gluing the panels to the prepared base.

Each method has its positive sides:

- when using the first method, the condition of the walls does not matter;

- a metal frame in rooms with high humidity will keep the panels undamaged longer;

- insulation fits well under the sheathing;

- the second method is less expensive and easier.

Pasting on the wall

Before gluing the panels, the wall is prepared and proceed according to plan:

- Old wallpaper, dirt is removed, the surface is degreased.

- The wall is primed.

- Mark the panels and cut out the required size.

- Apply the adhesive in waves or dots to panels or walls.

- Gently, but with force, press down on the MDF to glue them together.

- If necessary, align the joints.

- The seams are filled with sealant.

- Leave the panels to dry.

Do I need to glue the corners to the wallpaper? What is the best way to glue a plastic corner to the wallpaper?

You have hung the wallpaper and purchased the necessary fittings. There is only one question left: how to glue the plastic corner. Various methods of fastening this element are known. We will tell you about the most effective ones, and analyze the pros and cons. Read more in the article.

Basic methods of installing a corner

First, let's talk about what you should not use to glue a corner to the wallpaper. On the forums you can find advice on using adhesive for ceiling tiles. At first glance, this is a good recommendation. If the ceiling glue can withstand the weight of the tile, then the corner will definitely grab tightly. But the consistency of the composition is liquid. You will have to work extremely carefully. On paper wallpaper, along the plastic border, yellow stripes will appear over time. PVA glue is not suitable for these purposes either. If only at the corners of window openings, where no special mechanical impact is expected.

Common Mistakes

Inexperienced craftsmen often try to choose colorless MDF glue for panels, fearing that it may stand out in the area of joints and give an untidy appearance to the finish. This is not entirely true, since joining the panels “in a groove” eliminates this possibility. All the glue remains on the back side.

If the composition accidentally gets on the front side, you should not wipe it with a cloth that is too damp, as the decorative coating may peel off.

When using polyurethane foam, you need to pay attention to its shrinkage coefficient and choose a brand with a low rate. The foam can collapse and not stick if you do not wait for a while after its application.