Types of stone sinks

Stone sinks have a cast shape.

The market offers a wide variety of not only shapes, but also colors. Variety of shapes:

- round, oval - ideal for a small kitchen, the absence of corners makes installation and maintenance easier, but a number of materials can change color at the bend;

- corner - allows you to use every centimeter of space, practical and convenient;

- rectangular, square - are considered classics and look stylish in the interior, but are problematic when cleaning the surface.

Whatever the shape of the sink, the size of the sink should allow you to freely place the utensils and pots you use in it. In this regard, rectangular sinks win.

If the depth is insufficient, splashes of water will fall on the countertop, and a deep bowl will be inconvenient to use.

According to the installation method, products are divided into:

- Integrated - are on the same level with the tabletop and represent a single canvas with it. Installation of such models is difficult due to their large dimensions and weight.

If the countertop or sink is damaged, both components will need to be replaced.

- Mortise - installed in a hole in the countertop.

- Overlays - placed on top of the countertop. The advantages of such models are simple installation and low cost. However, during use there is a high risk of moisture getting under the sink.

Sinks with multiple bowls are popular.

They are justified for frequent cooking. The number of bowls determines the functionality. For example, one large container is more practical than three small ones. But for large families this indicator is not taken into account.

You can put dishes in one bowl, wash them in another, and clean food in a third.

In modern sinks the number of bowls can reach up to five. They differ in size, shape, depth, which determines their functionality. Additionally, the sink may have side wings for drying dishes. If space allows, then you should not ignore their presence.

The use of various coloring technologies allows you to obtain a sink in any color scheme. It is believed that dark color is more practical. Manufacturers offer sinks in natural shades.

Common colors are:

- white;

- various shades of brown;

- gray;

- black.

Russian companies produce products in colors atypical for natural stone - green, purple, pink, red.

What shapes do kitchen sinks come in?

When choosing a kitchen sink, you can count on a wide range of models with a variety of sizes and shapes. Nowadays, these products are produced both at large enterprises and in small private firms.

What are the most common shapes of kitchen sinks?

- Square ─ the most common option, suitable for a standard countertop.

- Round or oval ─ it is advisable to mount this model in a corner tabletop. The sink will save space and is perfect for washing round-shaped dishes.

- Rectangular shape is the most convenient and functional option, suitable for classic countertops. One of the main advantages is the possibility of installing additional bowls or wings.

- Corner ─ models of this shape are made specifically for installation in the corner of the kitchen, which allows for efficient and economical use of free space. It is also possible to place additional bowls or wings.

There are triangular and trapezoidal models, but they are less common.

Advantages and disadvantages

The high demand for sinks made of cast stone is due to aesthetics and performance characteristics. The list of main advantages includes convenience, practicality, and the ability to withstand mechanical stress.

Of no small importance for the buyer is the ability to choose colors, configurations, and textures.

The structure of sinks made of artificial stone resists the development of dangerous microbes and bacteria in the pores and on the surface.

The protective layer of the sink withstands the effects of aggressive components of household chemicals. To maintain its cleanliness, the use of any detergents is allowed. The wash does not lose quality from exposure to alkali, acids, alcohol, kerosene, and hydrogen peroxide.

But! The composite may be damaged by nitrogen or acetone.

- It is difficult to leave marks on the sink with a fork or knife. However, dropping large, heavy objects can break off a piece.

- Sinks made of artificial stone are resistant to maximum temperatures - they can withstand from -30 to +180 degrees. There are no texture erosions or cracks left on them even with sudden changes.

- Not all types of sinks can withstand high temperatures. For example, when acrylic products get hot water, dents remain on their surface.

- An interesting feature is that stone sinks are silent. During their use, the sounds of water jets and utensils hitting the bottom are not heard.

The sink isolates the current, which provides additional safety in environments where household electrical devices and water are located in close proximity.

Unfortunately, beautiful stone sinks also have disadvantages:

- High price.

- Large weight, which creates difficulties during transportation and installation of such products. A frying pan or a saucepan from the heat will leave dents on the stone.

- Acrylic sinks retain stains from wine, coffee, berry juices and coloring agents. And to remove such contaminants, you cannot use metal brushes.

Pros and cons are inherent in each artificial stone model. Granite and quartz have the greatest number of advantages. Products made from these materials do not get dirty, do not melt and last a long time.

Options for choosing the ideal sink

Design experts who have been creating interiors for many years recommend that every housewife study certain parameters when choosing a sink for the kitchen. At the same time, you should start tackling this issue after you have decided on the general style of kitchen design.

Then you need to understand the shape and size of the washing bowl, since each family has its own principles regarding culinary preferences and the volume of utensils used in the cooking process.

The next step is the choice of the material from which the sink is made, and its actual type and installation method.

You should also consider which mixer and additional equipment in the form of a waste grinder or water filter will be located in close proximity to the accessory.

How to choose

You should purchase a sink that combines several important criteria. The quality and strength are affected by the material used for its manufacture. The stronger the product, the higher its cost.

We must not forget about the combination with the set and the overall interior.

Dimensions

The dimensions of the sink should be selected in relation to the frequency of its use and the area of the kitchen. Thanks to the large assortment, you can find a capacious, convenient option even for a small room.

The standard width of the sink is 60 cm. You can also find a compact version in stores that will take up 45-50 cm. For spacious kitchens, manufacturers produce interesting products with original configurations. Their parameters: width – 80-120 cm, depth – 20 cm.

The number of bowls depends on the size of the free space and the personal wishes of the owners. For modest spaces, small models without space for drying dishes or corner designs are recommended. The latter type of product is difficult to install due to its complex shape.

For large kitchens, it is worth purchasing double sinks.

One compartment is convenient for washing dirty dishes, and another for defrosting or cleaning food. If desired, you can purchase a triple stone sink. And as an addition, equip it with a second wing for drying herbs, vegetables, and fruits.

Materials

Each company has its own production technology. Nobody wants to describe the “recipe”, hiding behind the beautiful names of the raw materials used.

But it is important for the buyer to know what stone the sink is made of in order to evaluate its performance.

The main types of materials used to create shells:

Marble chips.

Not very durable. More worthy analogues are offered on the market. If the composition contains polyester resins, then the product made from it will quickly lose its presentable appearance due to temperature changes, exposure to cleaning agents and impacts.

Granite chips.

Expensive material. Sinks made from it are stronger and more durable than those made from natural stone.

Composite acrylic sinks.

They are inexpensive, have an original configuration, but have a large number of shortcomings. Products are susceptible to damage and melting from hot dishes.

In many respects, sinks made of artificial stone are superior to their counterparts made of natural materials. The main thing is that the manufacturer follows technology and uses high-quality raw materials.

Problems arise less often with granite sinks.

Colors

Pigments are introduced into the composite at the stage of mixing the raw materials, that is, coloring is carried out “in bulk”. This method allows you to obtain products of any shade. Consumers prefer natural colors. A small number of companies place emphasis on brightness.

In their assortment you can find sinks made of stone in blue, green, pink, red and other palettes.

When ordering a sink individually, the client can choose any color option.

Single-color sinks are rare. Most sinks have a specific pattern on the surface that imitates stone. It gives the product a natural, respectable look. Most manufacturers offer up to 12-15 shades to choose from.

Models with specks are easier to keep clean. Small contaminants are indistinguishable on them.

If desired, you can purchase a sink with a rough or glossy texture. There are also options on sale where the bowl looks as if it was carved out of a block of stone.

When choosing the color of the sink, you need to focus on the design of the countertop and fittings on the kitchen unit. It should match these interior details in tone. When creating original, bright designs, experts choose a sink that contrasts with the furniture.

Price

- A sink made of artificial stone can be purchased for only 3 thousand rubles. This price is relevant for compact models made in Russia. For products with two bowls you will have to pay more money. The upper threshold for domestic products is within 8 thousand rubles.

- The price of sinks from European manufacturers starts from 6 thousand rubles. These are Polish companies. And the cost of famous German brands Franke, Blanco, Schock is 11-25 thousand rubles. If the model has a complex shape, with several bowls, its price can vary up to 100 thousand rubles.

- Expensive sinks are distinguished by their quality. In their catalogs, the company offers products of standard and original shapes and colors. To maintain their reputation and high demand, well-known brands regularly improve technology and develop innovative solutions.

You can distinguish an original sink from a popular brand from a fake by the packaging. Large manufacturers place the product in thick cardboard with stiffening ribs to reliably protect the artificial stone from damage and chips, onto which a hologram or company name is glued.

Cheap analogues are placed in thin cardboard without identification marks.

In order not to stumble upon a fake, it is recommended to purchase sinks made of composite stone from official dealers and be sure to check the quality certificates.

Bowls and their varieties

Sometimes the size of the sink is very important - in small kitchens, narrow countertops. In this case, a sink with sides is usually used. It is simply a bowl, along the perimeter or circumference of which there is a thickening or protrusion - a rim. The width of the side is several centimeters.

The second type is a kitchen sink with a work surface - a wing to the right or left of the bowl. Some models are “reversible”, meaning they can be installed either way. Also called a “wash with a wing”. They are interesting because you can lay out washed dishes on the surface, leave food, etc. The draining liquid ends up in the sink.

Kitchen sink with two bowls. Moreover, there are two options:

- both bowls are the same size (can be called a double sink);

- one bowl is larger, the other is noticeably smaller (in size and/or depth).

One and a half sinks - two bowls of different sizes

Two identical bowls can be used to wash dishes faster: one bowl contains soapy water, the other contains clean water for rinsing. The second option is also called a one-and-a-half sink. The second - a smaller vessel is used for defrosting food, for squeezing out excess liquid, etc. You can put a mesh (called a colander) in a shallow bowl, which increases functionality.

There are also kitchen sinks with two bowls and a wing. They are good for large kitchens. In principle, they can be used both under a window and on a long working wall.

5 most common problems with artificial stone sinks

Reading reviews on the Internet, it is easy to find quite a lot of complaints about artificial sinks. We have collected five of the most popular complaints and concerns, which is why many people prefer the good old, proven stainless steel kitchen sinks.

- “A stone sink will develop stains over time. On a light sink there are dark stains (from coffee, tea, red wine, beets, juice, etc.), on a dark one there are light stains (something hot was accidentally put on).”

- “Due to boiling water, the sink may crack, and hot dishes should not be placed on the surface of the stone.”

- “If you accidentally drop heavy dishes, the sink may break, chip or crack.”

- “A sink like this requires daily care, all you have to do is clean it.”

- “Artificial stone is not at all like natural stone, it looks like plastic”

Our review will help you figure out which of this is true and which problems can easily be avoided by simply choosing the right sink.

Myths or truth?

If you read about how the bottom of a sink made of artificial stone fell off after boiling water was poured into it, how it cracked when a pan or a heavy knife fell into it, how there were traces of hot dishes on it, you were almost certainly talking about an acrylic sink integrated into the countertop , and not about a mortise composite sink made of artificial granite or marble.

Granite sinks are not afraid of stains (if they appear, they can be easily cleaned with ordinary detergents and a sponge) or hot objects. If a granite or quartz sink is cracked, chipped, or stained, the reason may be a manufacturing defect, or you have come across a fake (read below for how to avoid being scammed).

But sinks made of acrylic stone are much more capricious and require more maintenance.

The most common cause of problems with acrylic sinks is the choice of cheap, low-quality material (for example, from Chinese manufacturers) and/or a violation of the countertop production technology.

Acrylic stone, which is used for countertops and integrated sinks, is much inferior in strength to artificial granite. But it is much easier to process and sands well.

You can easily make a sink of any shape from it, and the border between it and the countertop will be completely invisible.

But despite the fact that the seam is not visible, it is there. And with a strong impact, vibration or sudden temperature change, this seam can “open up”. Especially if the craftsmen who made the countertop cheated, violated technology or used low-quality glue.

If you want a sink without seams that will completely “merge” with the countertop, choose the manufacturer carefully, handle it carefully, and it will faithfully serve you for many years.

The big plus is that surface defects in an acrylic stone sink can be easily removed. Thermal marks from a hot frying pan, small chips, cracks and scratches can be removed by sanding; the seams can be sealed. But for this work it is worth inviting a specialist.

- Built-in sinks made of artificial granite cannot be repaired, but problems with them are many times less than with acrylic ones.

- When purchasing a sink, be sure to find out the composition of the material and read the manufacturer’s recommendations on how you can and cannot handle it.

Steel sheet thickness

Sinks are made of steel with a thickness of 0.4 to 1.2 millimeters. The thinner the steel sheet, the worse the washing performance will be. It can bend from gravity, vibrate from the flow of water, lift one edge, breaking the tightness of the structure.

The minimum steel thickness for high-quality washing is considered to be 0.6 millimeters. When purchasing, you should apply the principle: “The thicker, the better.”

Operating characteristics of stone sinks

A sink made of stone for the kitchen is distinguished by its positive characteristics during the period of its use.

The surface of the product is quite unpretentious, so it does not require special and labor-intensive care.

It is resistant to mechanical damage, with the exception of glossy surfaces, where small scratches appear when using abrasive substances for cleaning. The surface can withstand temperature changes and can be easily cleaned of contaminants.

A stone sink has a low coefficient of expansion, so rapid temperature changes cannot damage or crack the surface. A ceramic product may become unusable due to sudden heating or cooling.

But the stainless steel model remains safe and sound when boiling water hits it, but at the same time it begins to emit a deafening and very unpleasant sound.

Another positive performance characteristic is resistance to chemically aggressive compounds. The polished surface remains in good condition even after exposure to various acids.

However, acetone or a concentrated nitric acid solution can damage the surface and leave unpleasant marks.

Sink selection

Before you go shopping for a kitchen sink, it’s worth considering the requirements that apply to it. First of all, pay attention to the volume of the product so that it is convenient to wash dishes in it.

Pump for a summer residence: types, description of modern models, selection criteria and main parameters of the pump (125 photos)- World Print Company

- Check valve for water: purpose, tips for choosing and installing it yourself. 130 photos of selection and installation of a check valve

The sink must be durable and wear-resistant and can withstand temperature changes. When choosing, the dimensions of the room where the sink will be installed are also taken into account.

Consumers are also interested in the question of where to buy a kitchen sink. The best option would be to purchase goods from trusted retail outlets. When purchasing, pay attention to the manufacturer, material and cost of the product.

How to install

Mostly, professionals install stone sinks. This is due to the fact that sinks are often mounted on a countertop made of the same material, and the process itself is complex. Specialists not only install the product correctly, but also make sure that the seams between the sink and the work area are completely invisible.

It is not recommended to carry out installation yourself in such cases.

If you decide to install a stone sink in a regular countertop, you can do it yourself. All that is required from the master in this case is to follow the step-by-step instructions.

The first step is to cut a hole to fit the size of the sink. Standard options include overhead sinks 60x60 cm. At this stage, you need to draw an outline to create a hole. To make all the markings correctly, it is best to use a template made of cardboard or paper.

A jigsaw is used to create the hole.

After this, you need to process the edge using a sealant for this purpose. Often a special sealing tape is mounted on this part, which is also convenient. At the same stage, you need to process the perimeter from the top side.

After this, the sink is slowly and carefully mounted into the countertop, using special screws to secure the product. They are fixed on the bottom.

After installing the sink, you need to work on the faucet. It is fixed on the sink, and then connected to the water pipes. A siphon is connected to the drain hole.

At the final stage, the remaining sealant is removed. After this, the sink will be ready for use.

What types of kitchen sinks are there according to installation method?

When choosing a kitchen sink, you should pay attention not only to the dimensions, appearance and material from which it is made, but also to the method of its installation. Depending on the method by which the products are installed, they are divided into four types: overhead, mortise, integrated and under-table.

When installing your sink, there are a few important things you should keep in mind. It is not advisable to install the sink near a gas stove. The most convenient option would be a placement in which the product is located between the refrigerator and the cooking area, not far from the cutting table. The sink should be at least 60 cm away from other kitchen appliances. If you are the owner of a small kitchen and are forced to save space, then it is better to place the sink close to the refrigerator rather than to the stove.

Sinks are connected to sewer pipes and water supply, as a result of which they are traditionally installed in the corner of the kitchen or next to the wall adjacent to the bathroom. However, keep in mind that nowadays technology allows you to place the product anywhere in the kitchen that you find convenient.

How to choose the right sink type? Focus on your own preferences, take into account the design of the kitchen, and decide on the finances you are willing to spend. Don't forget to take into account the features of your kitchen unit. If it has a composite design, you can choose a cheaper overhead model. But if you are going to install sectional furniture with a single work surface in the kitchen, then you should give preference to mortise or integrated products: this will protect the cabinets from mold.

1.

Kitchen sinks

Mortise models are the best choice if you care about maintaining cleanliness and hygiene in the kitchen. This sink is mounted into the countertop in such a way that its sides do not protrude above the work surface and moisture does not collect under them. To install such a product, you need to cut holes in the countertop that correspond to the dimensions of the sink. The owner of kitchen furniture made from chipboard will be able to cope with this task independently. If the furniture is made of hardwood or artificial stone, you should use the services of professionals.

To install a mortise-type sink, you need to stock up on the following tools: an electric drill and wood drills, a jigsaw, several screwdrivers, pliers, a ruler, a square, a pencil, silicone sealant and a rubber seal.

Having purchased an undermount kitchen sink, you will most likely find in the components not only the necessary fastening elements, but also cardboard templates. If they are not included in the kit, apply markings on the product itself.

Before you begin installation, you should consider how exactly the product will be placed on the headset. The sink should be built in such a way that you do not have to bend over while washing dishes, and drops of water do not fly onto the floor. The sink should be at least 5 cm from the edge of the countertop and not come into contact with the internal parts of the set - spacers and sidewalls.

On the countertop you need to place a ready-made cardboard template or the sink itself upside down, and trace the outlines with a pencil. Then you should step back from this line inward by 1-2 cm and draw the second contour ─ the working one.

You need to drill holes for the jigsaw along the inner contour. Then start cutting out this outline exactly along the marked line. Don't forget: the cut is made only according to the internal markings! If you do it on the outside, the sink will collapse inward during installation.

The fragment of the tabletop that you are cutting out must be supported from the inside, otherwise the intact part may break off under its weight. Having finished the work, the contours of the fresh cut must be thoroughly cleaned of sawdust. Then go over it with sandpaper and cover it with silicone sealant.

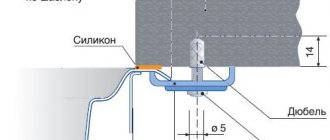

Attach the fasteners to the sink following the instructions provided. Place the sink in the resulting slot, pay attention to how accurately it matches the dimensions of the product. You also need to check the installation of the mixer and hoses.

If you do not find a silicone seal in the components, which should be applied to the sides of the sink and protect the countertop from moisture, apply sealant to the cut edge again. Then place the product in the slot and press the edges tightly: all air cavities should be filled with sealing compound. Using the fasteners, tighten the sink from the bottom, starting from the corners and ending with the fasteners in the middle.

The final stage of work is connecting the sink to the sewerage system and water supply. You can't do without a siphon. Give preference to the double-breasted type: such models are much less prone to blockages than bottle-shaped products. After installing the siphon, connect the faucet to the water taps and make sure that all connections are securely sealed.

2.

Overhead kitchen sinks

Such models are perfect for kitchen sets consisting of several modules. Products with an overhead installation method are made from different materials, the most common models are stainless steel. Overhead sinks are in great demand because they are inexpensive and easy to install. The main disadvantages: the bowls are quite thin, which creates noise when washing dishes; a gap is formed between the cabinet and the tabletop, in which moisture accumulates.

Before you move on to installing the sink, you need to assemble the cabinet underneath it. The finished product is a structure with an open top and a connector in the rear wall, necessary for connection to sewerage and water supply. The side and bottom parts of the cabinet are fastened using the connecting elements included in the package.

Place the cabinet in the designated place and begin installing the sink. Start by preparing the necessary tools: you will need plastic corners, flathead and Phillips screwdrivers, 3x14 screws, silicone-based sealant, masking tape.

An overhead kitchen sink can be installed in three ways: using sealant, brackets or wooden blocks. The first method is the easiest. The ends of the cabinet must be coated with silicone sealant, and then the sink must be placed on it. The sealing compound will dry and securely secure the product, and moisture will not accumulate under the sides of the sink.

In most cases, when installing an overhead model, mounting brackets designed specifically for this purpose are used. If these parts are not included, you can purchase them separately. Start by screwing in self-tapping screws from the inside of the cabinet walls and attach brackets to them. Then lightly tighten the screws, place the sink and slide the fastener along the screw, fixing it in the recess of the fastener. Once the sink is tightly connected to the base, tighten the screws completely.

In cases where it is not possible to install a sink using sealant or brackets, you can build a mounting platform with your own hands using wooden beams and furniture corners of the required size. Place the bars in the sink slot, screw four corners to them and place the product on the resulting surface.

If you need to fix the sink directly to the kitchen wall without using a special cabinet, you need to purchase special brackets, which are sold in plumbing stores. Select the height at which you intend to mount the product. Draw a marking along it consisting of two lines, the gap between which is equal to the thickness of the back wall of the sink.

Measure the distance between the points where the brackets will be installed. Label these points. Drill holes in the wall, screw the brackets and secure the sink.

Installing an overhead model is a fairly simple process that you can handle yourself, without resorting to the services of professional installers.

3.

Integrated kitchen sinks

This type of kitchen sink got its name due to the design features, installation method and connection to the countertop in the form of a single work surface. To install this model, it is necessary to prepare the cabinet in a special way, since the sides of the product must be located flush with its surface. The edges of integrated sinks must be perfectly smooth, and this is not just about aesthetic appearance: for such sinks this is the key to successful installation.

It is not surprising that high quality standards are provided for integrated models: even small defects on the sides of the product will prevent proper installation. Integrated kitchen sinks are made only from thick steel sheets ─ from 1 cm or more.

By choosing an integrated model, you will take the comfort of your kitchen to a new level. It will become much easier for you to clean work surfaces; water will not accumulate near the sink and under its sides, which means mold will not grow.

An integrated kitchen sink can be installed in three different ways: flush, above or below the countertop. The most common are the first and third options, with the latter best suited for stone or plastic cabinets.

When installing an integrated sink, one of the most important tasks is to correctly prepare the connector for the product and carefully seal it. You need to stock up on the necessary tools - the same ones that are used to install other sink models. You will also need a milling machine.

Begin installation work by marking. For this, use a cardboard template, which in most cases is included in the package. Using the marked lines, cut a hole whose dimensions are equal to the dimensions of the sink without taking into account the side. Then, along the perimeter of the resulting hole, it is necessary to mill a quarter equal to the width of the side of the sink. The depth must be set using stops on the milling device.

The next step is to place the sink and seal the joints using silicone-based sealant. Then the product needs to be secured. To do this, use the connecting parts included in the kit. Otherwise, you can purchase them separately.

4.

Undermount kitchen sinks

Such models of kitchen sinks have the highest cost. They are installed slightly below the level of the countertop surface, due to which they provide complete sealing. In addition, these sinks look very impressive and stylish. Most often they are mounted in cabinets made of natural wood, artificial stone or plastic. The installation process is quite complex, so if you are not confident in your skills, it is worth using the services of professional installers.

If you decide to fix such a sink yourself, you need to stock up on special tools, which include diamond-coated saws and jigsaws.

The algorithm of actions is approximately the same as when installing other sink models. However, the product must be glued under the tabletop using a plywood or chipboard backing. The substrate itself should rest on the frame of the kitchen unit. The sink must be fixed using special brackets. When installing a sink into a countertop made of natural stone, the brackets are additionally secured with screws and dowels.

The hole for the undermount kitchen sink is cut very carefully and precisely, and then carefully sanded. If the cabinet is made of wood, the perimeter of the finished hole must be covered with a seamless waterproof film to prevent moisture from accumulating under the sink.

How to choose

Even when choosing such a universal option as a stone sink, you need to take into account several important features. Due attention must be paid to the stability, strength and moisture resistance of the surface.

When purchasing, check whether the product has antibacterial properties.

An important point is the ability to recover in case of damage. Stone is one of the most resistant materials, but sometimes situations occur from which no one is immune. Basically, the artificial look is easy to restore, which is what makes it superior to other options.

- During the purchasing process, pay special attention to the depth of the sink. Check the distance from the front to the back of the sink.

- Decide in advance on the type of installation. There are overhead and mortise options. The most interesting and original types include integrated sinks.

- Focusing on the style features of the interior, select the shape of the product. Round and square models look quite interesting. A rectangular sink would also be a good choice.

Characteristics of steel

A sink containing chromium and nickel has remarkable anti-corrosion properties, resistance to food acid and high temperatures.

This is very easy to check; just run a regular magnet across the sink. If it sticks, then the iron is much higher than the permissible level and over time the sink may be exposed to rust.

For a more detailed check, it is advisable to check the entire volume of the sink, since sometimes manufacturers make different elements from different alloys (this applies to welded products).

Care

Based on reviews from customers who have already installed a stone sink in their kitchen, you can understand that the material is completely unpretentious in maintenance. But it is worth familiarizing yourself with several important recommendations that will help maintain the original appearance of the surface.

Do not drop heavy objects onto the sink, as this may cause cracks to appear.

It is not recommended to place hot dishes on the surface. Basically, indicators from +80 degrees are detrimental to the material.

The surface should be cleaned with soft sponges that do not scratch the stone.

Too hard types affect the appearance of the material. To clean the surface, use only detergents that do not contain chlorine. Exposure to concentrated acids is also detrimental to artificial stone.

During use, do not damage the integrity of the sealant. Basically, damage often affects the joints between the sink and the countertop.

Production method

Based on the production method, sinks are divided into pressed (stamped, exhaust) and welded.

Exhaust sinks are made using the pressing method; they do not have welded seams and are cheaper. But the steel sheet used in this technology is quite thin.

A welded sink is made from several steel sheets by welding; thicker steel is used in their production and the structure of the sink is more uniform. But poor-quality welding can lead to leaks.

- All about orthopedic mattresses with spring support

- DIY air freshener: step-by-step description of how to make a natural, effective air freshener (105 photos)

Ceramic air humidifier with battery - types, features of selection and application (90 photos)

Currently, manufacturers have learned to seal the seams so well that the average buyer will not even notice them. The prices for such sinks are slightly higher than for stamped ones.

Popular colors

Artificial stone kitchen sinks are available in a wide range of colors. As a rule, the manufacturer offers up to 12 classic shades in catalogs. In addition, when made to order, the number of available shades increases significantly.

This can be done due to the fact that the material is not natural and can be painted depending on the required shade.

The most common color when ordering these sinks is white. In addition to pure white (with splashes imitating natural stone), all shades of beige from milky to mustard are common, as well as gray in varying degrees of saturation.

Black sinks are a less popular but still commonly used option. A variety of shades from graphite to chocolate are also available here.

Obviously, the most popular models are those that imitate the natural colors of natural stone.

But clients have the opportunity to order sinks in blue, orange, red and other non-natural colors, which will complement the designed room design, making it unique.

Quality Manufacturers

Well-known brands of plumbing fixtures produce beautiful, functional and high-quality products. Their products have a 1-3 year warranty and a service life of up to 20 years. Such sinks are usually sold in stores. The markets often offer products made in China, the quality of which meets minimum standards.

Popular international brands:

- Longran;

- Villeroy&Boch;

- TEKA;

- Blanco;

- Reginox;

- Ukinox;

- Smeg;

- Foster;

- shock;

- Florentina;

- Alveus;

- Franke;

- Polygran and others.

The best design examples with an artificial stone sink

As already noted, ordering stone sinks according to an individual design is very popular. Thanks to this possibility, this piece of furniture not only fits into the required dimensions, but can also become a real art object, standing out from the surrounding space due to the presence of:

- sinks of non-standard shape with several separate compartments, each of which has its own drain;

- sinks with several steps of different heights;

- sink embedded in the work surface (the most expensive option);

- an overhead sink, when not only the top edge, but the entire depth of the sink is visible;

- non-standard colors.

It is absolutely clear that a stone sink is the best option for any kitchen.

It combines aesthetic superiority over analogues made from other materials, ease of use and durability.

What sizes are kitchen sinks available?

The most functional option is a kitchen sink with a bowl depth of 15 to 20 cm. A model with a smaller volume will cause water to splash, and an excessively large one will force you to bend over while washing dishes.

The gap between the side of the bowl and the wall, as well as the edge of the cabinet, should be at least 5 cm.

The dimensions of the product must correspond to the dimensions of not only the countertop, but also the entire kitchen.

If you are choosing a sink for a spacious room, you can choose a complex-shaped model equipped with additional wings. For a kitchen with small dimensions, it is worth purchasing a simple model of a corner or round shape, but with a voluminous bowl.