Sinks made of artificial stone differ in shape, material structure, surface texture and design.

They are designed to replace less practical and more expensive natural stone models. A natural sink is carved from a single piece of natural stone. The process is labor-intensive and requires a large amount of high-quality material.

The artificial sink material includes quartz or granite chips, binder resins and dyes. Depending on the type of stone, the percentage of natural stone chips and binding resins, as well as the method of producing a slab of stone, differs.

According to the manufacturing method, shells are divided into two types:

- Factory production. They have standard sizes and shapes.

- Made to order from a slab of artificial stone according to individual drawings. They can be integral with the tabletop, being made from the same material.

Installation of a kitchen sink made of artificial stone, made according to individual drawings, is carried out at the factory, simultaneously with the production of the countertop itself.

Serial sinks are usually installed where the countertop is installed.

Installation of a sink in an artificial stone countertop

Product Catalog

- Artificial stone countertops

- Window sills made of artificial stone

- Artificial stone tables

- Artificial stone sinks

- Bar counters for cafes and restaurants

Fake diamond

It's hard to imagine a kitchen without a sink. This is an element of primary importance, the quality of installation of which determines the comfort of all kitchen processes.

The kitchen sink should be deep enough to make it convenient to wash dishes. Kitchen sinks are usually made from stainless steel or artificial stone.

Features of caring for a stone sink

Stone kitchen and bathroom sinks require proper maintenance to extend their lifespan. In this case, several rules are followed:

- Every day it is enough to wipe the surface with a soft sponge and regular detergent.

- Once a month, to remove deep or old dirt, the sink is rinsed and treated with anti-scale agents, which are applied for 15 minutes and then washed off.

- Traces of tea, coffee or other food colorings are removed with citric acid. Dissolve it in the liquid and leave for a few minutes.

- For cleaning, do not use hard sponges, especially those with a metal mesh. Using them for a long time can leave scratches and marks on the surface.

Options for installing a sink in a countertop

There are several ways to install kitchen sinks:

- Overhead. With this installation option, the sink is placed on top of the countertop. The installation process is simple, but there are gaps between the countertop and the sink into which water and food debris can get in.

- Mortise. This technology involves inserting the sink into a special hole in the countertop.

- Podstolny. An interesting mounting option in which the sink is installed below the countertop.

When choosing a sink installation method, you should rely not only on the complexity of the procedure. But also take into account the materials used to make the countertops and sinks.

An overhead sink is a budget option. It is more suitable for the bathroom than for the kitchen. The installation process is limited to securing the product with self-tapping screws and sealant in specially prepared places in the cabinet.

Installing a sink into a stone countertop

Carefully installing a sink into an artificial stone countertop is not so easy. If experience and knowledge are not enough, it is better to use the services of specialists.

In other cases, first you need to prepare the tools:

- grinder;

- self-tapping screws;

- metal drill and drill with a diameter of 10 mm;

- colorless silicone sealant;

- building level and tape measure;

- Phillips screwdriver;

- construction knife, ruler, pencil, corner.

The first step is to mark the location of the future drain on the countertop. After this, you should outline the contours of the sink on the table surface.

Before cutting the hole, it is advisable to make holes in the corners to make the process easier. When cutting through the tabletop, you need to make sure that the cut piece does not fall out at the end.

For countertops made of plastic or other materials, you can use an electric grinder. A grinder will only be needed for stone products.

The cut on the countertop made of artificial stone is treated with sandpaper and sealant.

A sealant is glued to the sides of the sink, and fastening devices are not completely installed on the inside. At this stage, you can carefully insert the sink into the hole until it meets completely and completely fix the fasteners.

The final stage is connecting hot and cold water.

Installing a sink under a stone countertop

Washing option. Placed below the countertop level is good. That the entire load to which the product is exposed during use falls on a special substrate made of chipboard or MDF, resting on the frame of the kitchen module.

The installation process is as follows:

- in the base of the countertop (up to the layer of artificial stone), a hole is cut about 2 cm larger than the sink (for a round sink, the hole is also made square);

- the upper side of the sink is processed with a grinding machine;

- a square is cut out of the prepared plywood base, as in a tabletop, inside of which a hole is cut according to the internal dimensions of the sink itself;

- the sink is glued to the cut hole in the countertop;

- a prepared sheet of plywood, chipboard or MDF is glued on top;

- a hole is cut out in the artificial stone from the front side, the edges are processed with sanding paper.

The process of installing an undermount sink in an artificial stone countertop is clear to everyone, but doing it yourself is quite difficult. Especially. That you will need a special tool. Therefore, it is better to resort to the help of craftsmen and be confident in the quality of installation of the product.

Kitchen sink accessories

Modern fine water purification devices take up quite a lot of space under the bowl. They must be located in such a way as to ensure accessibility for servicing.

Purified water flows through a separate tap, under which an additional hole is cut out in the horizontal panel of the sink next to the mixer.

To avoid frequent blockages of the sewer drain pipe, install a garbage disposer in the sink drain hole. The grinder has an electric drive and a blade head, through which large particles are ground to a finely dispersed state.

In some cases, the drain hole in the sink is closed with a valve grid. The device is equipped with a button, when pressed, the grille becomes impenetrable to water. This drain allows you to accumulate the required volume of water at the required temperature - for soaking very dirty dishes or for defrosting food in plastic packaging.

Installation of a sink in an artificial stone countertop

Installation of a sink in an artificial stone countertop

Sinks made of artificial stone differ in shape, material structure, surface texture and design.

They are designed to replace less practical and more expensive natural stone models. A natural sink is carved from a single piece of natural stone. The process is labor-intensive and requires a large amount of high-quality material.

The artificial sink material includes quartz or granite chips, binder resins and dyes. Depending on the type of stone, the percentage of natural stone chips and binding resins, as well as the method of producing a slab of stone, differs.

According to the manufacturing method, shells are divided into two types:

- Factory production. They have standard sizes and shapes.

- Made to order from a slab of artificial stone according to individual drawings. They can be integral with the tabletop, being made from the same material.

Installation of a kitchen sink made of artificial stone, made according to individual drawings, is carried out at the factory, simultaneously with the production of the countertop itself.

Serial sinks are usually installed where the countertop is installed.

Plumbing for shower system- Electric heated floor

Installation of ventilation systems

Briefly about the main thing

Sinks made of cast stone are popular due to their reliability, practicality and aesthetic appearance. They vary in shape, size and color, and there are different ways to mount them into a countertop. Installation of the mortise model is considered the easiest to perform; it can be done independently, even with minimal experience in plumbing work.

Question

Write in the comments what you think - is it worth supplementing the sealant with a rubber (or silicone) seal during installation?

Sink material

Features of installing an artificial stone sink into a countertop directly depend on the type of material from which it is made.

Factory sinks are made of composite material. Each manufacturer uses its own recipe, which, as a rule, is not disclosed. The approximate composition looks like this: 80% quartz or granite chips, 20% binder resins, a small amount of dyes. Using a vibratory casting installation, a material with the required properties is produced, which is cast into a matrix of the desired configuration.

The best sinks are those that contain granite and quartz chips (sand). There are several main large productions with a similar recipe, but different names:

- silgranite sinks (BLANCO);

- fragranite sinks (FRANKE);

- CRISTALITE+ and CRISTADUR (SCHOCK);

- ceramic sinks (BLANCO and SCHOCK) made of porcelain stoneware;

- quartz sinks from quartz agglomerate manufacturers. They are made from the same material as quartz slabs. During installation they can form a single monolithic structure with the tabletop

Acrylic sinks and sinks made of cast marble stand out.

Acrylic sinks contain a large percentage of acrylic resins and less mineral filler, and therefore have more modest technical characteristics. They require careful operation due to their higher porosity and lower hardness than the above materials. They can irreversibly absorb dyes; over time, visible scratches and stains appear on the surface from contact with hot cookware.

Cast marble is made from marble chips and polyester resins. Loses in technical characteristics to its competitors. One of the advantages is the ability to manufacture a product of any shape. The cost of producing an individual product is not high, since it does not require complex production equipment.

Installation of an integrated sink

Installation of a sink made of acrylic stone or quartz agglomerate, made according to individual drawings, is carried out under production conditions.

There are 2 types of integrated sinks:

- bottom mounting, with a slight overhang of the countertop over the sink;

Sinks made to order from countertop material are visually very attractive. There are 2 important points to consider. The corners and edges of sinks cannot be rounded, which complicates maintenance. The design of the sink is not monolithic, like factory sinks, but is glued together from segments, which makes it less durable. This type of washing requires careful operation. Increased load should be avoided. The installation of a waste shredder that creates vibration is highly undesirable.

PROFESSIONAL ADVICE

The best option from the point of view of the balance of beauty and functionality are factory sinks of under-table (bottom) installation with additional structural reinforcement.

Our company’s specialists will select a design that suits your individual requirements.

We are waiting for you for consultation in our showrooms, as well as on-line consultation through feedback forms on the website or by phone +7(495)212-18-29.

Installation of an artificial stone sink into a countertop

Today we will talk about how to install an artificial stone sink. Everything is extremely simple.

- Covering the drain hole with your own hands

- How to lay flexible tiles on the roof?

How to properly lay a vapor barrier on the ceiling?

Approximate marking and installation time: 20 – 30 minutes

Sink gluing time 4-6 hours

Step-by-step installation of an artificial stone sink

It is much easier to embed and install a sink made of artificial stone than one made of stainless steel. Or rather, it’s easier to attach it, but the rest is still the same. But the fact of the matter is that attaching a stainless steel sink can sometimes be very difficult.

I already wrote about the step-by-step installation of a stainless steel sink, now about the step-by-step installation of a stone sink.

The first stage of installation is marking, the second is sawing, the third is covering the cut with silicone sealant. I will simply copy all these three stages from the previous post.

STAGE 1. Looking for a location

The first task is to decide where it is best to place the sink. Let me explain - in our example, the sink is round, 51 cm in diameter, and the cabinet itself is 80 cm, therefore, it can be moved to the left or right, or embedded in the center.

When marking the sink, pay special attention to the corner version (90 gr. version) of the kitchen, since the convenience of approaching the sink depends on your choice.

STAGE 2. How much to retreat from the wall?

Having decided on the location, place the sink on the countertop with the bottom facing up. Now you need to decide how much you need to retreat from the wall.

This point is especially important if your sink is 51 cm deep. If such a sink is placed exactly in the middle of the countertop, then there is a high probability that your saw will pass along the front plank of the cabinet (this depends on the design of the cabinet itself).

The easiest way is to place a kitchen plinth against the wall and move 1-2 cm away from it. This place will be the outer edge of the sink. If the sink is shallower, then it makes sense to move the sink further away from the wall.

TIP: If the cut line still goes along the body of the cabinet, then you need to either pull off the bar of the cabinet, or remove the tabletop from the body, cut it out and put it back in place.

Take a pencil and outline the outer contour of the sink.

STEP 3. Draw a cutting line

We have outlined the outer contour of the sink. Now we need to decide on the line of the cut itself.

To do this, you need to measure the distance from the outer edge of the sink to the beginning of the installation edge (sawed groove along the edge, from the bottom of the sink). Usually this size is 1-3 cm, but it may vary for different sinks.

We already have a drawn line of the outer contour of the sink. Now we measure the just measured distance from it into the future sink and draw the internal contour. This is the cutting line. It happens that the installation edge on the sink is not level. Then you can take the smallest edging size.

It's okay if the sink doesn't fit tightly into the hole. After gluing it will stand like a glove.

Stage 4. Ewing

Using a drill, from inside the contour, next to the cut line, we make a through hole. We do it so that the jigsaw blade can pass through.

Use a jigsaw to cut along the contour of the cut. When cutting, do not rush and do not press forward with the jigsaw, but press the jigsaw against the tabletop.

It is better to cut with a “Clean Cut” blade. If the sink is rectangular, then to prevent chipping, you can use masking tape. When choosing a file, consider the cutting height.

Stage 5. Preparing the cut

After cutting, you need to process the edges of the cut.

We level the cut with coarse sandpaper and try on the sink.

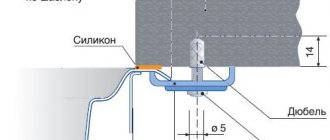

If everything is fine, then we clean the saw cut from dust and coat it with silicone sealant. Silicone will subsequently prevent the tabletop from absorbing moisture and swelling.

Stage 6. Glue the sink

This is the easiest installation step. On the very edge of the cut we squeeze out a small path of silicone sealant (for kitchens and bathrooms). Next, we install and center the sink, that is, we place it the way it should be.

Tip: Before gluing in the sink, you need to install the faucet, screw the hoses into it and install the overflow hose on the sink. These elements are very difficult to install on an already glued sink.

Next, we press down the sink with a weight, for example, a bucket of water.

We wipe off the squeezed-out excess silicone from the tabletop with a rag (it can be washed off well with polyethylene film). And wait several hours until the sealant dries completely.

If you have not completely installed the fittings (siphon, drain...) on the sink, then install it on the already glued sink. We check the joints for water leaks and rejoice at the work done.

—>

- Like

- Tweet

- Pin It

My name is Oleg, I created and am leading this project. My work is related to interior design and furniture production. I want to share my experience and cool ideas with you, I can help you with choosing an interior design or furniture.

Methods for attaching stone sinks

It is precisely because of the characteristics of the material used in production that installing a stone sink into a countertop is somewhat different from installing a regular stainless steel sink. It is necessary to properly prepare for the installation process.

There are three ways to install stone kitchen sinks:

- Apply to the surface of the corresponding cabinet. In this case, there is simply no need for a countertop.

- Embed the set into the countertop installed on top of the cabinets.

- Integrate into the work surface. The most modern way. Most relevant in the latest trends in residential kitchen design. Allows you to achieve unity of the entire composition, since the level of the countertop of the work surface and the edge of the sink are on the same level.

When choosing an integrated installation method, it is possible to achieve the effect of a single whole, where there is no transition from the countertop to the edge of the sink, or the sides of the built-in structure themselves.

Preparatory stage: tools, measurements, markings

Before installing a granite sink, you should make sure that you have all the necessary working tools, namely:

- electric drill;

- drill 10 mm;

- jigsaw;

- set of self-tapping screws;

- construction tape, ruler;

- knife;

- cross screwdriver;

- pencil;

- sealant.

If you decide to install the sink yourself, then all of the listed tools should be at hand before starting installation work.

The first thing that distinguishes artificial stone sinks from standard metal bowls is depth. Therefore, you should make sure in advance that the furniture cabinet in the kitchen in which you plan to install a sink allows you to install such a structure. It is desirable that the width of the inner side of the cabinet be at least 55 cm.

Installation steps

Having removed the product from the original cardboard packaging, do not rush to throw it away. As a rule, manufacturers provide a template for the cutout, which greatly simplifies and speeds up installation. In this case, all that remains is to cut out the finished workpiece and cut a hole along it. If the workpiece is not included in the equipment, then the work is carried out according to the following algorithm:

- To avoid damaging the surface of the countertop, protect all “dangerous” areas by covering them with masking tape.

- Sink and place the base against the countertop.

- Turn over The distance from the edge of the table to the intended cutout should be at least 5 cm, but not more than 11 cm.

- Outline the sink with a double contour: the first clearly along the edge of the product, and the second - indented to the width of the side. It is the second line that is the guideline for cutting.

- To use a jigsaw, you should prepare a small hole into which it will be convenient to insert the tool. If the sink is round, then one hole is enough. If it is square, then you need to prepare 4 (one in each corner).

- Make the cut according to the intended line: it is advisable not to retreat or bevel the direction.

- Upon completion, thoroughly clean the sections from sawdust and dust.

- Apply silicone along the cut of the tabletop. It will protect the furniture structure from moisture, and, consequently, from swelling and mold.

- The inside of the sink rim should also be treated with a special synthetic sealant (can be replaced with a thin rubber gasket).

After treating the sides with sealant, you should wait a little for it to dry. Only after this the shell is turned over and inserted into the prepared hole. When installing, you should insert the sink in one movement, without displacement, so that the sealant layer is not smeared or displaced.

The procedure for installing an artificial stone sink into a countertop

In the process of renovating a kitchen, furnishings are chosen not only by visual perception, but also by their functionality, practicality and durability. No kitchen is complete without a sink. But the choice of their models is so large that it is difficult to settle on the right model. If you take durability as a guide, then you should choose a sink made of artificial stone, and not stainless steel or ceramics.

Artificial stone is made using vibration casting, thereby obtaining a durable and homogeneous material. Its composition includes 80% chips from natural granite or marble and 20% adhesive resins, and also adds various dyes for beauty. To close all the pores, the top is covered with a special gelcoat substance.

Sinks made of artificial stone vary in texture: plain, contrasting, coarse-grained and fine-grained. According to texture - matte, glossy, shagreen, silky matte.

Texture affects not only the visual appearance, but also the difficulty of cleaning, the appearance of scratches and other things.

It is sinks made of artificial stone that have a wide variety of shapes to suit every client’s taste. They come in classic shapes, “shell”, “butterfly”, with one or two bowls.

According to the method of installation, sinks made of artificial stone are divided into the following: overhead (they are the simplest, they are placed on a floor cabinet without a countertop), mortise (to match or in contrast with the countertop) and integrated (the most modern, they are mounted flush with the countertop, made from the same material, this composition looks like a single whole).

There are many advantages of artificial stone when choosing a sink material. First of all, it is resistance to temperature changes from -30 to +150 degrees and to the effects of chemical elements - acids, solutions and other reagents. And there’s no need to talk about durability; the stone will withstand a blow from any kitchen item.

The main advantage of such a product is that it is easy and simple to care for, so the appearance will always be perfect.

Caring for such a sink is easy and simple; there will be no bacteria, plaque, odor, or radiation. Even if a scratch or pothole appears somewhere, these defects will be very easy to eliminate. The service life of an artificial stone sink in your kitchen will be more than a dozen years.

In order to install a countertop made of artificial stone and a sink made of the same material with high quality, you need to very carefully monitor the tightness of all joints of these components.

Preparation

Before starting installation you need to go through the following steps:

The first is to prepare the entire necessary set of tools: electric drill, 10 mm drill, jigsaw, self-tapping screws, tape measure, pencil, ruler, knife, Phillips screwdriver, construction angle, silicone sealant.

The second is to measure the sink as accurately as possible to cut an opening in the countertop.

And that’s it, now you can start installation!

Regardless of the shape, installing an artificial stone sink into a countertop begins with markings:

- Most often, the manufacturer completes the stone sink with a template for cutting out a hole for it. If there is no such template, the sink is placed on the countertop and traced along the contour with a pencil or marker.

- For a mortise sink, which is installed on top of the countertop, it is necessary to apply a second contour along which the cut will be made. The difference between the lines is the width of the sink rim, usually 12 - 15 mm. With the correct shapes of the sink, there are no difficulties in applying the 2nd line, but for curved ones it is better to make a template. A fragment of a thin lath can be used as a material. By methodically applying it to the contour, you will be able to draw its exact repetition.

- First, glue the area where you drank it with molar tape; this simple step minimizes the likelihood of chips appearing on the surface of the tabletop.

- Holes are drilled in the corners of the internal contour for inserting a jigsaw file.

- Use a jigsaw to cut out a hole for the sink. The piece being cut should be supported from below to prevent it from splitting when it is almost sawn off.

- To protect the countertop from swelling in the event of accidental moisture getting under the side of the sink, the edges of the cut are treated with silicone sealant, distributing it over the entire cut area. Aquarium sealants are best suited for this purpose; a thin layer of which will reliably protect the MDF board.

- Attach the brackets to the sink. Each of them has 2 legs in its design, which must be carefully driven with a hammer and a punch into specially designed holes.

- Depending on the manufacturer, the sink may be equipped with holes for the mixer. In this case, it is necessary to apply a chipper or a screwdriver to the place of the drink, and knock out the cork with a light blow of a hammer.

- But not all samples provide such a service, so if it is not there, you need to arm yourself with a Forstner drill or a bimetallic cutter. Using a conventional ceramic drill, a small recess is drilled to support a Forstner drill or crown. In non-impact mode, drills drill a hole of the required diameter, the edges of which are then polished.

- Apply a layer of adhesive sealant around the perimeter of the cutout and install the artificial stone sink, pressing it tightly to the surface.

- I snap the brackets into place at the bottom of the sink and securely fix them with the installed hardware.

- After this, the mixer and sewer siphon are installed.

- Remove excess sealant from the front side of the countertop.

The installation of a sink made of artificial stone into a countertop made of marble and quartz agglomerate is carried out in a similar way.

Preparatory stage

If there is no drawing included with the product, you will have to make it yourself. The mortise sink is placed on the countertop; it can be replaced with a sheet of paper, especially if the coating is dark and the lines will not be visible on it. Trace the outline of the product, leaving 12-15 mm on each side for fastening the side. Then the paper blank is cut out and placed in the chosen place. For accuracy, it is fixed with double-sided tape. After this, further work begins.