The kitchen is a special room that creates a homely atmosphere, coziness and comfort. Here, a huge number of people relax after a hard day at work, enjoy time spent with their families, and family and friends are invited here for aromatic coffee and a delicious lunch. Therefore, this place is considered a sanctuary of the hearth, where housewives of any age create their culinary masterpieces. Therefore, many people try to arrange this area in a special way, filling it with the most comfortable furniture and other similar interior elements. Technological progress does not stand still; new developments are appearing that help to equip our home in a better way. A tabletop made of liquid stone is a modern solution that pleases with its affordability and unique appearance.

Tabletop made of liquid stone in the interior of the kitchen.

Characteristics of liquid stone countertops

The concept of “liquid stone” drives many people into difficult thoughts. But really, how is this possible? Indeed, in our usual understanding, a stone is characterized as a solid material, and it is extremely difficult to imagine it in a different state. But in fact, everything is quite simple, liquid stone is a special composition. Once applied, it turns into a hard and durable surface. For countertops, this component is used as a decorative component due to its excellent performance parameters. For example, the finished product is resistant to high and low temperatures, has a reduced level of heat conductivity, and is safe. The best part is the optimal price, which is affordable for most people.

Due to the plasticity of liquid stone, the tabletop can be given any shape.

Due to the plasticity of the material, tabletops can be made in various shapes. At the same time, the uniqueness of the project depends only on imagination. The absence of pores in the structure ensures that the kitchen wardrobe item does not swell or crack. Therefore, scratches and stains do not appear on it, bacteria do not multiply and other negative consequences for the working surface are not terrible.

Liquid stone is resistant to moisture and high temperature.

The material is smooth, and the production process uses a seamless method, so the finished product comes out in cast form. Externally, “liquid stone” is very reminiscent of a granite surface or marble, so a kitchen with such a finish is filled with nobility and luxury.

See also: Tips for decorating a window in the kitchen

Feasibility study of the project *

The material consumption per 1 m2 of cladding of a product with a thickness of 3 mm will be approximately 6 kg of the finished mixture, which corresponds to 3.6 kg of gelcoat, 2.34 kg of filler and 0.06 kg of hardener.

Thus, to get started you will need:

| Name | Packaging volume, kg | price, rub. | Required amount of material | Total costs, rub. |

| Gelcoat | 25 | 9 250 | 2 | 18 500 |

| Pigment for painting gelcoat in 14 colors | 1 | 1 000 | 14 | 14 000 |

| Liquid granite filler in the most popular colors with minimal granule sizes | 1 | 320 | 30 | 9 600 |

| Liquid granite filler in the most popular colors with medium-sized granules | 1 | 320 | 18 | 5 760 |

| Liquid granite filler in the most popular colors with large granules | 1 | 320 | 18 | 5 760 |

| Liquid granite filler in the most popular colors with granules of different sizes and golden inclusions | 1 | 320 | 10 | 3 200 |

| Liquid granite filler in the most popular colors with granules of different sizes | 1 | 320 | 18 | 5 760 |

| Hardener | 5 | 1 850 | 2 | 3 700 |

| Gel coat solvent | 1 | 315 | 2 | 630 |

| A solution of paraffin in styrene to facilitate sanding of finished products | 15 | 5 700 | 1 | 5 700 |

| Topcoat for a glossy finish | 20 | 10 200 | 1 | 10 200 |

| Pre-accelerated glaze | 1 | 300 | 2 | 600 |

| Release wax | 0,8 | 800 | 10 | 8 000 |

| Acetone | 8,75 | 870 | 1 | 870 |

| Polishing paste for removing deep scratches | 1 | 2 200 | 1 | 2 200 |

| Polishing paste for removing small scratches | 1 | 2 200 | 1 | 2 200 |

| Lapping polishing paste | 1 | 2 200 | 1 | 2 200 |

| Total material costs: | 98 880 |

What is liquid artificial stone?

Liquid stone is an artificial substance that does not emit radiation waves. This means that the material is completely safe for residential use. It began to be used for production purposes more than half a century ago. The manufacturing technology is based on a combination of stone chips and synthetic resin. The result of this combination is a material that is very similar to polished granite.

Liquid stone is a safe material.

See also Gray kitchen in the interior. Comparing the pros and cons

Documentation

As for the legal organization of your business, it is very good that this activity is not subject to licensing. There is also no need to undergo certification. Registering an individual entrepreneur is all that is required of you. It won't take you much time. The tax system will be simplified. Which also indicates in favor of registering an individual entrepreneur. However, if you are planning expanded production where hired labor will be used, then, of course, it makes more sense to immediately establish an LLC.

You may also have to enter into an agreement to purchase a package of technical documentation for the production of artificial stone.

Tabletop in the interior

Stylists recommend choosing comfortable chairs, a soft corner, and warm lighting fixtures for the kitchen. A special place in such a room has always been given to the tabletop, because it was intended to accommodate electronic household appliances, cutlery, cutting boards, and dishes.

Design of a kitchen countertop made of liquid stone.

For this reason, many housewives take a very responsible approach to its choice, and prefer to make a countertop from liquid stone with their own hands.

See also: How to clean a new refrigerator before turning it on for the first time. Folk remedies and household chemicals

Advantages of using liquid stone countertops in the kitchen

The advantages of a working surface made of this material include:

- purity and antibacterial properties are achieved through special processing;

- easy to clean, no ingrained marks remain;

- resistance to mechanical damage. It is difficult to damage the stone or spoil its appearance; the working surface also has such advantages.

Liquid stone is resistant to mechanical damage.

See alsoPostforming kitchen countertops: what is it, features, pros and cons, useful tips

Flaws

The disadvantages of using liquid stone for kitchen products are:

- Hammers for beating meat or large knives should be used with extreme caution in cooking;

- high price.

Compared to other types of countertops, liquid stone is significantly more expensive.

See also Quartz countertop: manufacturing features, examples and tips

Types of liquid stone

Today, artificial liquid stone can be divided into two types - acrylic stone and quartzite. Let's take a closer look at each type.

See alsoEuropean style of kitchen design: distinctive features and interesting design ideas, photos of interior examples

Quartzite (agglomerate)

Consists of quartz chips, coloring components, polyester resins as a binding ingredient. During the process, vacuum high-temperature pressing of all components is used. The result is a durable material that can withstand significant temperature changes. This type of kitchen surface is not made at home.

There are two types of liquid stone.

See alsoStylish small kitchen design in 2022

Acrylic liquid stone

The composition includes a sufficient amount of acrylic resin and a small proportion of mineral filler. Due to the acrylic component, chips do not form on the finished product, and minor damage can be removed using sanding paste and polishing paper.

A tabletop made of liquid stone can be easily combined with any design.

See also Ceramic countertop for the kitchen: features, pros, cons, how to make it yourself.

Features of the material

Flexible stone is a thin section of sandstone in which the natural pattern is preserved after being applied to a flexible base. Not every breed is suitable for these purposes, so it is used only with a porous texture.

The prepared cladding is produced in two types:

- tiles with a thin layer of stone (up to 3-4 mm);

- polymer rolls with applied stone cut.

Premises with such finishing are distinguished by a favorable microclimate, since the flexible stone is vapor-permeable (breathes, receiving and releasing fumes). This is an excellent cladding for different types of premises.

For outdoor areas

Cladding of the facade and individual architectural elements, as well as chimneys, greenhouses, balconies and loggias, terraces and verandas.

For indoor use

Cladding of walls and various structural elements, as well as columns, fireplaces, finishing of the bathroom and pool, niches and arches, complex ceiling structures and inclined surfaces of the loggia.

The lining is applied to the prepared surface; it must be even and smooth. But if there are small cracks, stains, smudges and other defects, a flexible stone will hide these defects.

This innovative material is made from natural raw materials, but a technology has also been developed for the production of artificial “wild stone”, produced in rolls. Both options have excellent aesthetic properties; they are in harmony with other cladding on a natural and synthetic basis.

Surfaces treated with flexible stone look most organic:

- in the hall;

- in corridors and passages;

- in recreational areas;

- in large foyers and waiting rooms;

- in the greenhouse, on the loggia and balcony;

- in the living room combined with a loggia;

- in a spacious bathroom or mini-pool;

- on the staircases.

Flexible stone in the form of stone wallpaper

This is the best option for decorating walls: hallways, corridors, bathrooms. This texture will make the interior voluminous and unusual. The rolls are cut with a regular knife.

To apply stone wallpaper, it is important to properly treat the wall - clean it of excess layers

Typically preparatory steps include:

- the surface must be free from unevenness and free from dust;

- additional primer is required;

- it is important to preserve the protective film until final gluing;

- Before application, a thick layer of special glue is applied, most often based on PVA.

If you have corners or curved areas, you will need a hair dryer. It will help to increase the elasticity of the material in the right place and will allow you to more clearly convey the complexity of the relief.

Flexible stone tiles

Working with tiles is no different from working with other similar materials. The only difference is that when working with stone slabs, it is important to monitor the joints. And, again, don’t forget about the hair dryer

Thermal panels made of flexible stone

A special feature of the panels is their high moisture resistance and ability to withstand heat well. These panels are often used for finishing baths and saunas.

The upper temperature limit reaches +650°C

Thermal panels are also used for finishing fireplaces, swimming pools, stairs and floors. The manufacturing technology of thermal panels is as follows.

A special mold is used as the basis. An anti-agdesic lubricant is applied to it. Clinker tiles are placed into the cells of the mold. Next, the edges of the matrix are sprinkled with sand. Next, the form is filled with liquid polyurethane foam. Then the form is dried.

The process of making a countertop from liquid stone with your own hands

Step-by-step instructions on how to make a tabletop from this material using the spraying method with your own hands look like this:

- Prepare a mold from chipboard.

- Create an insulating layer on the inside using wax mastic.

- Apply three layers of clear acrylic. Each subsequent one is applied only after the previous one has hardened.

- Prepare the main component (three parts acrylic, 1 part mineral crumbs and the selected dye). Be sure to first wash and dry the mineral crumbs. The hardener is added at the last stage.

- Using a brush, the mixture is applied in several layers to the surface from the inside.

- Next comes the reinforcement stage. Glass material is placed on the mold, glue and hardener are applied on top. Next, a chipboard blank and a load are placed on the mold.

- The glue and hardener are applied again and left for four hours to harden.

- Then the chipboard is removed and the product is cleaned. The final stage is polishing.

Design of a black kitchen set with a countertop made of liquid stone.

See also Pyrolytic cleaning of the oven and how to choose an oven with a pyrolysis function

Gluing parts

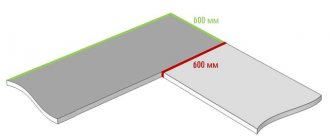

If assembled incorrectly, a corner countertop made of artificial stone will crack because a stress riser appears at the joint. To avoid this, it is important to correctly cut the slabs for corner tabletops: the joint of the panels should not be at the corner of the product. Before gluing, the parts are milled, glue is applied and tightened with clamps. Additional reinforcement is applied to the seam on the reverse side.

The edge is cut out separately and attached with special acrylic glue. Before connecting the parts, a quarter is cut out on a horizontal surface. At room temperature, it takes about 40 minutes for the polymerization reaction and complete hardening of the glue; at a lower temperature - for example, below +11 ° C - polymerization may not even begin at all. For better adhesion of the glue, the seams are tightened with clamps or the same clamps every 10 cm. After the glue has dried, the edge is sanded. The radius of the edge is 3, 6, 9 or 12 mm.

Comparative analysis of liquid stones with acrylic

In addition to composition, these varieties differ in the method of installation. Also, “liquid stone” can be cast together with the sink, and for the acrylic variation you will need an overhead sink.

Both options are not very friendly with hot utensils, but acrylic can soften from such exposure. The situation is similar with steam and moisture. Liquid stone creates a shell that prevents the negative effects of moisture on the chipboard workpiece. Therefore, such a tabletop will last for many years.

Acrylic countertop in the kitchen interior.

See also: Kitchen layout as a dining-living room

Physico-chemical properties of acrylic resin

| Water absorption in cold water, % no more | 0,5 |

| Maximum bending stress, MPa, not less | 65 |

| Hardness when indenting the ball, MPa, not less | 30 |

| Softening temperature, ºС, not less | 80 |

| Compressive stress at relative strain no more than 25%, MPa, no less | 63 |

| Density at 20C, g/cm3 | 0,98 |

| Time for complete curing of the composition at a temperature of 23±2, ºС, hour. | 2 |

| Swelling time (lifetime), at 23 ºС, min. | 10-50 |

Acrylic resins have different names:

- ASTT;

- Butacryl,

- Technacryl…

Shelf life of acrylic resin:

Acrylic resin is stored in a hermetically sealed container, protected from exposure to sunlight and precipitation, in fireproof warehouses at a temperature not exceeding 25 C. After thawing, the product fully retains its properties. The shelf life of the components is 4 months.

Packing:

The resin is sold in cans of 5, 10, 20 liters . Hardener, depending on the quantity of resin ordered, is included in the delivery package.

Acrylic resin (base), 10 kg.

8600 RUR Buy

Acrylic resin transparent (colorless), 5 kg.

4800 RUR Buy

Acrylic resin transparent (colorless), 10 kg.

8800 RUR Buy

UV acrylic resin, 5 kg.

5800 RUR Buy

UV acrylic resin, 10 kg.

9900 RUR Buy

Useful and stylish examples of countertops

The work surface made of this material has an attractive appearance, so it will become the highlight of any kitchen. The undeniable advantage of a countertop made of liquid stone is its operational parameters. Today you can find many stylish solutions for this piece of furniture.

Beige kitchen design with liquid stone countertops.

See alsoRed kitchen in the interior

Recommendations for choosing and caring for countertops

Caring for a countertop made of cast stone is not demanding. In order to remove dirt, you will need to use a microfiber cloth. This cloth should be soaked in warm tap liquid and used to clean the work surface. There is an important rule that must be followed - under no circumstances should you use abrasive preparations. These products may harm the polish.

Sharp objects on stone countertops should be used with great care.

It’s easy to give a new look to an interior item; sandpaper and polish are used for this. To remove deep damage, you need to use the services of a specialist who can spray the substance onto the defective area and then polish the uneven areas.

Manufacturers recommend using cutting boards and trivets for hot dishes. Try not to drop heavy or cutting objects, and then the tabletop made of molded material will last for many years.

Technological cutouts

The holes for the hob under the sink (if it is a kitchen) and under the sink (if it is a bathroom) are called technological cutouts and are made with a milling cutter according to a template already on site. At the corners of such cutouts, in order not to create stress concentrators, reinforcements are glued in - embeds. Such mortgages will be a kind of guarantee that cracks will not appear on the countertop during use. During work, to avoid dust, the master uses a professional vacuum cleaner.