Today it is difficult to imagine a modern kitchen without a modern sink to match it. Now it not only serves as a place for washing food, dishes or other kitchen utensils. An important role is played by its placement relative to other equipment and furniture, issues of design and ergonomics. Therefore, when choosing a kitchen sink, in addition to its aesthetic appearance, you should first of all pay attention to its functionality and ease of use.

In order for the sink to be comfortable to use, it is necessary to install it both taking into account the manufacturers’ recommendations and taking into account a number of tips from practicing installers and designers.

There are some general installation rules for any kitchen equipment, as well as some specific ones that will only suit certain groups of products. Therefore, we will first consider general recommendations for the placement of kitchen sinks, then their main installation types, and then the installation nuances for each of them.

Features of the sink cabinet

The kitchen is a place where the family spends a lot of time together, where neighbors, relatives, and friends drop in for a cup of tea.

Therefore, every detail of the interior is so important, creating coziness and comfort. How to install a countertop sink in the kitchen? What type of equipment to choose and install so that it lasts for a long time. You need to begin work on installing an overhead sink by preparing the structure, which is an addition to the sink. This is a module with installation features.

Both elements (cabinet and sink) are important. Place and location in the kitchen depends on:. Place and location in the kitchen depends on:

Place and location in the kitchen depends on:

- planning;

- preferences of the apartment owners;

- location of other types of furniture (in the same row with them, in a straight, corner version, or separately).

The design of the countertop is the basis for the sink. Its internal area is used to maximum benefit. It is not designed for a large number of shelves; its main purpose is to accommodate sink communications (corrugated hose, siphon) and trash cans. You can place a small shelf for detergents in it.

The surface-mounted sink is less popular today than the mortise sink.

The design depends on the countertop sink and can be in the form of:

There are certain rules during installation:

- To prevent excess moisture and deformation of the material, open areas are treated with: special mastic; silicone sealant.

- To prevent the structure from deteriorating due to leakage, it is necessary to securely tighten all the nuts using silicone sealant during installation: a corrugated pipe for water drainage; siphon; mixer

- Installed near the wall, since there are pipes in it: for drainage; cold and hot water supply; from the washing machine. water from other equipment (filter that purifies water).

The cabinet has 3 walls, so it is not rigid enough. To do this, create stiffening ribs (“kerchiefs”, wooden or metal corners, fixed in the four corners of the cabinet from the inside). This issue can be resolved by bolting the walls to other furniture or screwing them to the wall.

The cabinets are made in a variety of colors, which allows you to choose them to suit any interior style.

Fixing the sink with glue

Installation of an overhead sink is possible using glue. But this method is only suitable if the underframe almost perfectly matches the sink itself. It will be placed on top, and the ribs will “sit” on the cabinet.

Advice! Do not skimp on the sealant on the entire contacting surface. It plays the role of glue and will additionally protect the joints from moisture penetrating into them.

You will have to think about how to attach an overhead sink to wooden blocks if you do not have fastening corners at hand or if defects are found on the surface of the cabinet frame. So what do we need?

- bars of suitable size;

- furniture corners;

- small nails or screws.

The first step is to build a mounting platform in the form of a rectangular frame. It will serve as the top frame of the stand. It is he who will smooth out all the unevenness. The assembled bars are sent to the box of the overhead sink and fixed there with steel corners around the perimeter. And we place the resulting structure directly on the stand. We will secure it using the same corners, but from the inside to the walls.

Pros and cons of installing a sink into a countertop yourself

When purchasing a new sink, the question often arises of whether to install the structure yourself or invite a professional, so you should first evaluate all the pros and cons of such actions.

Advantages of self-installation:

- Opportunity to save your budget. This is the main point that encourages people to do installation without the help of specialists.

- Careful control of work performance. You can install the sink slowly, only at a fixed time. This will allow you to do the job efficiently.

The disadvantages of self-installation include the following:

- Poor installation of equipment can lead to leakage, which will lead to property damage.

- Not every beginner has all the necessary tools needed when installing a sink.

- Installation of the structure by a professional eliminates the possibility of chips and cracks.

When installing a sink yourself, you must follow the detailed instructions, then you are more likely not to make a mistake

In addition, it is important to make sure that all the necessary tools and fasteners are included with the product.

Summing up

Advantages of installing a sink yourself:

- There are tools in almost every home; attaching an overhead sink to a cabinet can be done using almost improvised means;

- You can save on the cost of a professional plumber by doing the steps yourself;

- If the plumbing product did not come with any fasteners, then purchasing them is not a problem.

If you cannot install the plumbing yourself, it would be better to turn to professionals.

Installation of a countertop sink

Installing an overhead sink is relatively easy, since you do not need to make any additional inserts or make additional fasteners. As you can see in the figure provided as an example, the overhead structures actually seem to be superimposed on the surface and located above any plane. Accordingly, the most essential requirement is the presence of some foundation on which the element is actually installed.

Installation of sinks in the bathroom and kitchen is equally common for this type. In each room, the element looks quite attractive and is functional, although, of course, some features of the models should be taken into account and, for example, for kitchens where it is necessary to minimize splashing, choose models with higher and smoother sides, and for baths it is quite possible to use more original options , where the sides may have curved shapes.

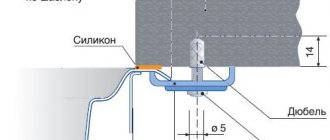

The connection method is mainly a hole with a drain, but methods such as additional gluing with the help of specialized mixtures or the use of dowels at the base, which are fixed under the sink, may also be used. On the portal you can find a video of installing a sink in a countertop, which describes in detail the features of installing overhead structures. Given the clarity of this process, here we will limit ourselves to instructions.

- First, the surface is cleared, in which a hole is prepared using a stencil.

- Drain lines are installed under the hole.

- The lower part is fixed into the sink and the part is placed on a plane, after which screw fasteners can be additionally used from the lower part of the countertop, and the structure is tightened.

In this version, the mixer is connected separately. The water supply holes are usually located under the mixer.

A few more tips for choosing

To ensure that your new washbasin brings you only positive emotions from the convenience and beauty of the product, you should remember a few simple rules when choosing:

Choose a sink that matches the style of the entire bathroom

- Check items carefully, especially those made from materials such as porcelain and glass, for cracks or chips. If found, request a replacement item. After all, even the smallest crack can grow into a big nuisance over time.

- If there are children in the family, it is better to refrain from purchasing models with sharp corners to avoid possible accidental injuries.

- Decide on the sizes in advance. When choosing a countertop sink, you should know the expected countertop size and placement location.

- The selection of the mixer must be carried out according to the height of the washbasin. The deeper your sink, the higher the faucet should be.

Installation of an overhead sink

The affordable overhead (built-in) sink is made of stainless steel. It is mounted on a separate module and covers its entire upper part. The installation is very simple here - special L-shaped elements with an oblique slot are used for fastening. About 4-5 such fasteners are provided for one sink.

Advice! The connection of the mixer is carried out before the stage of installing the sink (the sink is installed with the equipment already installed) - otherwise it will be inconvenient to do all this at subsequent stages.

How to attach an overhead sink with your own hands:

You need to attach the L-shaped fasteners to the cabinet from the inside and make notes; Screw the screws in the marked places

It is important to choose short 15 mm screws and screw them in so that at least 5 mm remains above the mark; Cover the end of the drawer with sealant - it will protect the furniture and additionally glue the sink; After this, the sink is installed on the screws screwed into the cabinet and moved until it fits completely; Then the fasteners are fixed, the excess sealant is wiped off, and you can begin connecting the sink to the water supply and sewerage system

https://youtube.com/watch?v=EQ8L_8SUqBw

Preparation for installation

Before installing an overhead sink, you need to carefully install outlets for each siphon and mixer on it. When the structure is fixed on the cabinet, this will be much more difficult to do.

Chipboards require additional protection. If the upper ends are not treated with silicone, then a water-repellent barrier will not form and over time the frame will simply swell and deform.

Step 1: Contouring the seat. We make a template from dense material in the shape of the purchased sink, leaving an allowance of 1-2 cm, and try it on the countertop.

Step 2: Select a position. Using a template, we determine the exact configuration of our element on the tabletop. When choosing a position, we take into account the general organization of the space adjacent to the sink, and think about how convenient this or that position is. We outline the stencil.

Step 3: Protect the countertop. We will treat the space around the intended hole with masking tape to prevent scratches and other damage.

Step 4: Working out the landing zone. Using a drill, we make the starting points for cutting (2mm drill), connect them with a chisel and turn them into a gap. We cut along the contour with a jigsaw, keeping the cut perpendicular.

Step 5: Installation. Apply sealant to the resulting cut and, pressing, insert the sink. Removes excess product, let the composition set for 10-12 hours, connect the water supply and sewerage.

Installation of an integrated sink

A sink purchased for installation by inserting into a countertop should be selected with the template included in the kit. Otherwise, marking and cutting out the hole for the sink can be difficult and not precise enough, which will lead to moisture penetrating under the sink and ruining the wooden countertop.

Making a hole for a sink in an artificial stone countertop will have to be entrusted to a specialist. It is quite difficult to do this with your own hands without the necessary tools for processing such material.

Tools for work:

- jigsaw and drill;

- adjustable or gas wrench - for installation of communications.

https://youtube.com/watch?v=r-k7MDckjU0

- Step 1. Carefully cut out the template for the contour. Determine a place on the countertop where elements located under the countertop will not interfere. Place the template on the tabletop and carefully align it parallel to the edge, secure it and trace along the outline with a pencil.

- Step 2. Cover the surface of the tabletop along the contour with masking tape. This is done in order to protect its surfaces from damage by the jigsaw body when cutting a hole.

- Step 3. Use a drill to drill a hole for the jigsaw blade. Cut the hole exactly along the contour. This must be done without putting pressure on the jigsaw, otherwise its blade will bend and the cut will be uneven or oblique, deviating from the contour line. In any case, this will require additional refinement of the cut using Sherhebel, a file, etc. Cut a hole for the sewer outlet and water pipes, if necessary.

- Step 4. Carefully treat the cut surfaces with silicone sealant. Allow the necessary time for hardening. Try on the sink.

- Step 5. Install a siphon of the selected design on the sink. Install a drinking water tap on the countertop (if necessary). Using a template, mark the holes on the sink panel for installing the faucet. Drill holes. Attach the mixer with the connected flexible hose to the sink. Install the sink fasteners included with the product. If their reliability is insufficient. You can make your own mount from metal mounting tape by threading it through the holes of the mounts.

- Step 6. Seal the edge of the tabletop with a rubber seal or apply a layer of sealant. Install the sink panel. On the bottom side, inside the cabinet, secure the mounting tape with tension using self-tapping screws to the cabinet parts. Apply a layer of transparent sealant around the perimeter of the installed panel (excess can be trimmed off after hardening).

- Step 7. Connect communications inside the cabinet.

https://youtube.com/watch?v=aRz6hW5N-R8

A more difficult option for installing a built-in sink in the kitchen yourself is to install a panel under the countertop. To do this, after cutting the hole according to the template, an additional groove is made along the perimeter of the cutout on the back side of the tabletop.

- Step 1. Make a template that will follow the dimensions and contour of the surfaces of the sink and the “wing” of the panel that must be open. Apply the outline according to the template on the top side of the tabletop.

- Step 2. Cut a hole along the contour, file the rough edge of the tabletop, and sand it. Turn the tabletop over.

- Step 3. Select a groove on the reverse side so that the tabletop panel fits freely into it.

- Step 4. Apply a layer of modified silane glue into the resulting groove and place the sink panel there (install the sink in the “upside down” position). Press the panel along the perimeter with your hands, then tighten it through the backing with clamps in several places and leave the glue to harden for 12-24 hours.

- Step 5. After the glue has hardened, the sink is additionally fixed with two-component epoxy resin. The composition is prepared according to the instructions and poured into the gap between the panel and the body of the countertop. After hardening, the junction of the countertop and sink is taped with aluminum tape.

- Step 6. Turn the countertop with the installed kitchen sink over and place it on the cabinet. Carefully cut off excess glue around the sink. Connect water and sewerage.

Installing sinks in the kitchen is not as difficult as it may seem at first. The main requirements are the careful implementation of work to seal all possible places of water penetration and the exact matching of the hole for installing a built-in sink.

How to install an undermount sink

Mortise sinks are designed for installation in a countertop, which emphasizes the integrity of the furniture ensemble, covering all its constituent elements with a continuous sheet. To correctly mark the location for cutting the installation opening without disturbing the aesthetics of the kitchen unit, you need to use a marking template. Its functions can be successfully performed by cardboard packaging, in which a built-in kitchen sink is often sold. Followed by:

- Lay out the template on the countertop, temporarily securing it with adhesive tape or tape. Trace the outline of the planned opening with a pencil.

If there is no template, then the body of the sink itself is used for marking. It is turned over, applied to the tabletop and traced. From the resulting line, they retreat inside the contour so much that after cutting it out, the bowl has a slight backlash in the opening. - Drill a hole on the insertion line so that the jigsaw file fits freely into it.

- Smoothly moving the jigsaw along the contour, make a circular cut. To prevent premature loss of the sawn part and jamming of the file, periodically screw the screws into the cut slot. They will perform the function of temporary fastening, wedging the removed fragment of the tabletop.

- Insert the sink into the manufactured opening and check that all elements match each other. Additional pruning may be required.

- Treat the end of the opening around the entire perimeter with a moisture-resistant sealant. This will protect the hydrophilic material of the solid tabletop from swelling if water accidentally gets on it.

- Glue an elastic seal along the bottom edge of the kitchen sink.

It must be included with the product or purchased separately. It is a good idea to additionally cover the seal with sanitary silicone on top. - Now finally insert the sink into the cut opening. Correct its position relative to the outer contour outlined during preliminary marking. Lightly tighten (not completely) the included brackets. Add sealant to possible voids between the edging of the sanitary bowl and the countertop.

- While screwing in the screws of the fasteners from below, carefully press the sink. For better adhesion of the bracket tenons to the tabletop material, you can lightly tap them with a hammer. The operation of putting the sink in place should be performed in stages:

- angles attract, but not completely;

- the middle fasteners are tightened;

- again, starting from the corners, the sink is pressed completely. In this case, the excess squeezed out sealant is carefully removed with a damp cloth.

After completing the compression of the plumbing bowl, connect the mixer to the cold and hot water supply lines, and the siphon to the sewer outlet. As in the case of an overhead sink, it is advisable to install them on it in advance, even before the installation operations begin.

Types of sinks by installation method

Nowadays there are many models of sinks for kitchens and bathrooms on the market. They differ not only in appearance and dimensions, but also in installation methods. To make it easier for you to understand, we have presented the main characteristics of the most popular varieties in the form of a table:

| Kitchen sink type | Highlights of design and installation |

| Tabletop | Tabletop-type products are now virtually not used. In most cases, such a product is a bowl that is installed on top of the countertop and is in contact with it only at the location of the drain hole. A small number of tabletop sinks are represented by premium models, so their price will be appropriate. |

| Invoice | Overhead units are mounted on a cabinet without a top: flat areas near the bowl replace the missing tabletop. In most cases, such models are made of stainless steel, and therefore they are characterized by a relatively low price. |

| Mortise | Unlike the overhead, the mortise design is “recessed” into the countertop, which significantly complicates installation. The mount for the mortise sink is installed from the reverse side and reliably presses the sides of the bowl to the kitchen furniture. |

| Podstolnaya | The bowl, as the name suggests, is placed below the level of the tabletop. In most cases, models for tables made of non-natural stone have this design. To fix the product, special brackets are used; in addition, the joint of the bowl with the lower plane of the table top is sealed with a special glue. |

| Integrated | The most expensive variety. The bowl is installed in the countertop so that the gap between them is minimal. In most cases, products made of synthetic stone have this design, but it is also possible to find experienced varieties made of stainless steel. |

It must be emphasized that attaching a sink to a countertop made of artificial stone or installing an integrated structure is a rather labor-intensive task that should be entrusted to specialists. But attaching an overhead sink to a cabinet or installing a mortise product can be done by any craftsman with sufficient dexterity.

Surface-mounted sink

This type of washing was once the most common on the domestic market. A special feature of the overhead sink is that it is installed on a free-standing cabinet without a countertop. It can be square in shape (for a one-door cabinet, the bowl is located exactly in the center) or rectangular in shape (for a two-door cabinet, in addition to the bowl, there is a small ribbed surface for washed dishes). Moreover, the shape of the bowl can be any: square, round or oval.

The overhead sink is provided with a profile rim as a support - in the form of a channel. It simultaneously serves as a stiffener and a mounting point to the cabinet.

To securely fix the sink to the frame of the cabinet, special plastic fasteners are used. They are made in the form of a corner with an oblique slot on one side.

These mounts can be included with the sink, or they can be purchased separately. The fastening method is simple: 1. First, attach a fastener to the inside of the walls of the cabinet with emphasis on the end and draw a line in the slot. 2. Having stepped back about 5 mm upward from the lower point of the mark, drill a small recess in the wall for the self-tapping screw. 3. Screw in the self-tapping screw. The length of the screw depends on the wall thickness. In most cases, the furniture board for walls has a thickness of 16 mm, so the self-tapping screw should not be larger than this size (for example, a 4x16 mm wood screw). And in order for it to press the mount well against the wall, it must have a semicircular or semi-secret head - the main thing is that it fits into the lower (largest) hole of the mount and does not slip through the rest of the slot. The self-tapping screw is not screwed in completely, leaving a gap between the head and the wall slightly larger than the thickness of the sink mount. 4. If the end of the walls is not treated with a protective edge, then a layer of sealant is applied to it. 5. The sink is installed in place and “put” on the head of the fastening screws. In this case, the mounting angle should be directed upwards and inward relative to the cabinet, and the second “beam” of the corner should extend beyond the side of the sink. 6. To pull the sink to the cabinet, the fastener is tapped from the short side of the slot to the screw. 7. After the screw fits tightly into one of the recesses of the slot, it is screwed in completely. After this, you can install the siphon and connect the sink to the sewer. Installation of the mixer depends on the type of water supply. If the mixer is mounted on a sink, it can be secured to it before installing it on the cabinet.

How to install an overhead sink

Surface-mounted sinks are usually made by stamping from sheet steel - formerly enameled, but now stainless steel.

This standard plumbing fixture has a rectangular shape and can be attached directly to the wall plane using special brackets.

However, this is the most outdated installation method, suitable only for use somewhere in the country. Therefore, it is worth considering the more common method of installing an overhead rectangular sink on a kitchen cabinet designed for this purpose. The following three installation methods are practiced:

For adhesive sealant

The width of the sink is selected so that it matches or slightly protrudes beyond the dimensions of the top of the cabinet. Before putting the sink in place, the ends of the furniture are covered with a thick layer of silicone adhesive sealant. When the perimeters of the cabinet and bowl are aligned and leveled, the latter should be loaded until the adhesive composition is completely polymerized (it is indicated by the manufacturer on the packaging). After the sealant has dried, the sink will be securely fixed.

With brackets

Overhead kitchen sinks produced by official manufacturers are often equipped with a set of fastening brackets, which can also be purchased separately. The fasteners are L-shaped metal or plastic plates with oval holes for self-tapping screws.

1. Screw in, without tightening, 4 self-tapping screws along the edges of the cabinet from the inside, at a distance of 1 cm from the top. 2. Place the sink on the cabinet. 3. Secure the sink by putting the corners on the screws and sliding them in the direction indicated by the arrow.

The plates are attached from the inside of the bedside table to two walls opposite to each other, two pieces on each side. The ends of the cabinet walls are coated with a layer of sanitary silicone. As in the previous method, the washing bowl is leveled on the seat. L-shaped brackets are inserted into engagement with the edges of the flange and fixed with self-tapping screws, securely pressing the sink to the walls of the cabinet.

Using wooden blocks

It may also happen that standard fasteners are missing or for some reason are not suitable for fixing the plumbing product. In this situation, flat steel angles are suitable (they are used for assembling furniture or adding rigidity to joinery), as well as wooden beams of the appropriate section.

The bars are placed in a flange box, after which 4 furniture corners are attached to them in pairs.

The assembled structure is installed on the ends of the cabinet treated with silicone. In this case, you should definitely press it firmly, and then screw the corners to the walls of the furniture.

Important! Before starting the installation of a sanitary bowl, it is advisable to attach a mixer and siphon to it in advance. Otherwise, after its installation is completed, performing these operations often turns out to be difficult or even impossible.

Main types of washbasins

The technology for installing a plumbing fixture depends on the type of sink, which can be wall-hung or overhead, and the rest of the products belong to their varieties.

Domestic and foreign manufacturers produce different models of washbasins, but the most in demand are the following:

- Built-in

. They are placed on the top of a table, cabinet or other flat surface. They are convenient because furniture doors make utility lines completely invisible. - Console

. The suspended design of the washbasin allows you to fix it on the wall using a ready-made installation system. - With a pedestal

. The “tulip” type product has a decorative element in the form of a pedestal, on which a massive bowl is placed. The drain fittings are located inside the support. - With half pedestal

. Such models also have a pedestal, but it rests not on the floor, but on the wall. This makes wall-mounted washbasins look more elegant. Installing a sink makes it difficult to raise the drain to a certain height.

Built-in products can also be installed on top of the table top, fixed with edges around the perimeter of the base, or built into the structure from below. In bathrooms where it is not possible to place a countertop of a standard width, it is more convenient to use semi-built-in models.

When installing this plumbing equipment, you will need to use an improvised cabinet to hide pipes and other communications behind its walls.

Typically, console and built-in structures are preferred by owners of properties with small bathrooms, in which every centimeter is important.

In addition, all commercially available sinks for installation in bathrooms have a variety of shapes and configurations, so there are models:

- round;

- oval;

- cubic.

Selecting a location

First you need to find a suitable place to install new equipment.

Where not to place

Experts recommend that before installation you familiarize yourself with the places where you definitely cannot install an electric refrigerator.

Under the window

If you study the manufacturers' requirements for the use of equipment, you will notice that many of them do not recommend placing it under windows. The body of the device should not be exposed to direct sunlight, as this will cause it to deteriorate.

Near a heat source

There are several heat sources that refrigerators cannot be installed near.

Battery

In an apartment or private house where there is heating, special batteries are installed. Some people decide to place household appliances near them, but this should not be done. Under the influence of high temperatures, the housing will begin to quickly collapse.

Radiator

In many apartments you can see heating radiators on the walls, which are responsible for heating the room. In winter they are hot, and therefore it is better not to place anything near them.

Oven

In some kitchens, in addition to gas stoves, there are special ovens used for preparing baked goods. During operation, such ovens generate a lot of heat, and therefore it is contraindicated to place refrigerators near them.

Plate

The stove is an indispensable device in the kitchen, as most dishes are prepared with its help. Refrigeration equipment should be located at a distance of 100-120 centimeters from the gas stove.

Other

There are other appliances that can generate heat during operation. These include convectors, infrared heaters, heating stoves, and electric stoves.

Next to the sink

Some people decide to place the refrigerator close to the sink. Experts do not recommend installing it in this location due to the following factors:

- high humidity, due to which the case will quickly deteriorate;

- high probability of water getting on equipment.

When choosing a suitable location, you need to consider the location of the outlet. Equipment must be connected to grounded sockets that are connected to special stabilizers. They help equalize the voltage and prevent the connected refrigerators from burning out.

When choosing a place to install a refrigeration chamber, pay attention to the features of the floor covering. It must be smooth and highly durable

If the floor is uneven, you will have to install special pads under the legs of the device so that the body does not wobble.

What determines the quality of our work?

Any installation of an overhead sink begins with studying the template configuration. The more complex the shape of the sink, the more effort will have to be made to cut the appropriate hole. The slightest mistake can lead to damage to the tabletop.

For a good craftsman, high-quality installation of a mortise sink does not depend on its model, shape and material from which it is made. Today in fashion:

- round sinks made of stainless steel and stone;

- double sinks with two drains in a variety of materials;

- built-in and surface-mounted granite sinks.

One of the popular models of sinks is a bowl made of granite chips. It looks solid, washes well, and lasts a long time. Its installation is more difficult than installing sinks made from other materials.

If there are no holes for installing such a sink, then installing a granite sink turns into a filigree work. Sometimes there are holes, but they are too small and you have to cut them out additionally.

Our craftsmen do an excellent job with this work, using special drills with a “diamond” crown and other tools. To determine how much it costs to install a kitchen sink, you need to know what material the master will have to work with.

The sink itself is quite heavy, so installing the sink into a kitchen countertop is done with great care so as not to drop or break expensive plumbing fixtures. More and more people are installing a convenient and practical double sink in their kitchen. It is usually made of stainless steel, so it is easy to clean and is not “afraid” of chips if you accidentally drop the plate into the sink

But there are other models - marble, granite or quartz. Installing these “stone” double sinks is similar to working with a granite sink

It is usually made of stainless steel, so it is easy to clean and is not “afraid” of chipping if you accidentally drop the plate into the sink. But there are other models - marble, granite or quartz. Installing these “stone” double sinks is similar to working with a granite sink

More and more people are installing a convenient and practical double sink in their kitchen. It is usually made of stainless steel, so it is easy to clean and is not “afraid” of chipping if you accidentally drop the plate into the sink. But there are other models - marble, granite or quartz. Installing these “stone” double sinks is similar to working with a granite sink.

Unlike a conventional sink, installation of a countertop sink with a double sink includes two drains. This turnkey sink is installed by our specialists and delivered to the owners in working condition.

Installing a round sink in the kitchen or bathroom is no less popular. Like other models, it can be made from a variety of materials

The laconic geometric shape attracts attention and looks great in any interior.

The installation of any models of built-in or counter-mounted sinks is a little complicated by under-counter installation of the sink, because you have to work in an inconvenient narrow space.

Before you ask how much it costs to install a kitchen sink, tell our operator which model you want to install. By inviting a specialist to install a sink, you can be sure that a qualified technician will come to you.

By calling us and ordering any plumbing service, you will be convinced that we work not only efficiently, but also quickly. The best specialists of our company will go to fulfill your order.

Installation rules: all the nuances of installation

Are you undertaking a major bathroom makeover? Have you decided to renovate and create a new style that includes an overmount sink with a trendy countertop? We will tell you how to install a sink into a countertop yourself. For those who want to join individual furniture into a single composition with their own hands, we offer a detailed description of the process of installing a sink into a countertop.

So, we purchased convenient plumbing fixtures that fully meet the owners’ needs in practicality and appearance. By the way, stainless steel sinks are popular for kitchens today. Firstly, they are affordable, light weight, and durable to use.

The universal color “metallic” can be combined with a variety of color schemes in the room.

Installation is quite simple, there are only two stages:

- Assembling the sink cabinet;

- Installation of an overhead stainless steel sink on a cabinet.

The sink is an indispensable attribute of the kitchen. You can easily install it yourself - you do not need to have special knowledge and skills.

What material are sinks made from?

Quite often, choosing a kitchen sink becomes a difficult task. Errors in operation lead to the fact that products have to be constantly changed, so it is necessary to familiarize yourself in advance with some of the features of each material.

Table No. 3. Materials for making modern sinks

| View, illustration | Description |

| Stainless steel | Often used in the production of sinks. Products come with a rough, matte and glossy texture. The main advantage of the material is its low price. In addition, even a beginner can handle installing such a sink without fear of damaging the surface. Metal products have an aesthetic appearance, thanks to which they fit perfectly into the interior of various kitchens. In addition, stainless steel does not suffer from exposure to various chemicals. The only disadvantages that can be highlighted are the possibility of scratches and dents. |

| Ceramics | Washbasins of various types are often made from this material. At the same time, the main advantage of ceramic products is their attractive appearance. Such designs are especially suitable for kitchens of classic design. In addition, such a surface is not damaged when exposed to hot water or aggressive alkali, and there are very rarely scratches on it. Another clear advantage is the ability to install the sink yourself without the help of a specialist. One of the disadvantages is the fragility of ceramics - this means that the sink can break with a strong impact. |

| Fake diamond | This is the most modern material that is actively used for the manufacture of sinks. It is based on natural and synthetic components. The first option has a higher cost, it is resistant to various damages and chemicals. The main advantages include a variety of colors. |

Composite sinks

The material used for the production of this version of sinks is filler. It is held together using a polymer binder. Granite chips, fiberglass, and quartz sand can be used as filler. Thanks to the filler and the dye used, it is possible to achieve the required shade of the overhead sink.

The advantages of this type of sink include the lack of absorption of food dyes, unlike enameled surfaces. Granite sinks are not afraid of the harmful effects of aggressive substances. There are no scratches on their surface, therefore, the appearance will be observed for a long time. If we talk about the disadvantages, composite products are not cheap, but they also have a longer service life.

Read more: Installing a siphon in the kitchen, assembly diagram and installation for a sink

Installation of an undermount sink

Kitchen furniture consists of different products, each of which performs a specific function. The countertop is one of the main elements of the kitchen. It provides a work surface and can also serve as a frame for a sink. The material from which it is made is important; its ability to withstand loads depends on it. Thin composite panels will only support stainless models. Stone sinks require a massive surface; it must be made of a similar material and have a special design that includes holders.

Installing a sink in a wooden countertop can be done with your own hands; as for granite, it is better to entrust the work to professionals. Of course, you can try to make the cut yourself, following the recommendations for working with a specific material, but this will require a special milling cutter or hydraulic cutting machine, the price of which will be many times higher than the cost of the hole. Let's take a closer look at the method of installing mortise sinks.

Required tools and materials

Before starting work, you should inspect the existing tools and purchase additional ones if necessary. Standard set includes:

- measuring instruments, pencil, marker, cardboard, tape;

- construction knife, glue, sealant, screws;

- adjustable, open-end wrenches, screwdriver, pliers;

- electric drill, drills, jigsaw;

- sink, mixer, siphon, hoses for water supply.

Marking and cutting out a niche

Having determined the location of the product, all that remains is to perform a number of simple steps with the help of which the installation of a sink in the kitchen will be successful. The step-by-step process is as follows:

- Drop-in sinks are sold complete with ready-made cardboard templates and fasteners. If there are none, you will have to cut out the patterns yourself. In this case, the sink itself will become a template. A sheet of cardboard is applied to it, a silhouette is drawn along the contours, and a blank is cut out.

- To determine the internal contour according to which the cut is made, the width of the side is measured. After which this data is transferred to the workpiece to indicate the final type of pattern.

- The drainage area is marked on the countertop. A template is attached to it, secured with tape, and an outline is outlined. In this case, the distance from the front end of the working surface to the side of the sink should be more than 5 cm, and from the rear - 2.5 cm.

- Holes are drilled along the contour of the finished marking using an electric drill. A drill diameter of 10-12 mm is sufficient to pass the jigsaw blade. The number of holes depends on the shape of the bowl being installed. For a round one, the step between them will be 7 cm; for a square, rectangular one, four passes of the drill in the corners are enough. Drilling and cutting work is performed from the front side of the surface. Next, use a jigsaw to cut out a hole for the sink. After which the cut is cleaned of dust and sanded with sandpaper.

- The edges of the cut are treated with silicone-based sealant. It protects uncoated wood from swelling. Insufficient sealing can lead to rotting of the tabletop at the cut site, so it is better to apply a double layer.

The process of installing and connecting the sink

- Using a brush or spatula, apply a layer of transparent silicone to the work surface in the area of the sink rim trim.

- The inside of the sink is treated with sealant. It provides reliable fastening of the objects in question and does not allow liquid to pass through at the junctions of the elements.

- The next step is to install the sink in the cut hole. It is applied from the faucet mounting side. It is gradually pressed until the objects are in complete contact. Excess sealant that appears is removed using a rag.

- Using fasteners, the sink is fixed to the countertop. They can be plastic or metal. Iron clamps are more reliable.

- After the installation is completed, the necessary communications are connected. Usually the sink is mounted with a mixer fixed on it, and the only thing left to do is to screw the water supply hoses (hot, cold) to the water pipes.

- At the final stage, a drain is installed. The siphon outlet is inserted into the sink, and the corrugated pipe is inserted into the sewer.

Features of working with artificial stone

As a rule, stone countertops are made to order in accordance with the preferences of the buyer, and the hole for installing a sink is provided in advance. But there are also exceptional cases when, for example, it was initially planned to install an overhead sink in the kitchen, and the countertop had to be solid.

An artificial stone countertop is quite difficult to process. It must be handled with care as the material is fragile

For such work, it is better to invite a qualified specialist with a professional tool, who will make a hole of the required diameter with a correctly processed cut and install the sink in accordance with all requirements.

If you decide to make a hole for installing a sink on your own, saving on labor costs, instead of a jigsaw, it is better to take a grinder and when cutting, protect your eyes and respiratory tract from stone dust. The work algorithm is not much different from installing a sink in an MDF countertop.

Two popular installation types of kitchen sinks

A wide range of kitchen equipment users are most familiar with two types of washing bowls - overhead and mortise.

Many overhead sinks can be classified as a universal and inexpensive segment, however, today they are becoming less and less common. They are distinguished by simple designs, mainly made of thin stainless steel. Their installation usually does not cause difficulties even for home craftsmen. Often installation is carried out on top of a separate cabinet, thus replacing the tabletop with it. The popularity of overhead bowls is also supported by the fact that they:

- have a limited number of models;

- when installed, they rise above the level of the working surface to the height of the flange, which does not look entirely aesthetically pleasing;

- have a design for which it is difficult to achieve a tight seal of the gap under the edging flange, where moisture then penetrates and dirt collects.

In the segment of overhead sinks, special models have begun to be found, for example, made of stone. However, they cost a lot, so they are not widespread.

Built-in sink - its name speaks for itself. Under it, an opening is cut out in the common tabletop (working surface), where the sanitary bowl is mounted. The edges of the opening are waterproofed, and the mating gap is carefully sealed. Due to the tight fit, as well as the slight elevation of the sink above the countertop, moisture and dirt do not accumulate. Such modern products have a significant selection of models that are precisely matched to the overall style of the kitchen set. For example, a mortise sink, in addition to the standard rectangular one, may have a round, oval, angular or special complex shape, manufactured to special order.

Specifics and models of wall-mounted sinks

The latest modern trend in sink installation is to mount the unit to the wall surface. This type of arrangement is one of the most familiar and favorite among Russians, since this type of installation has worthy and significant advantages. By installing the sink on the wall, you will save the desired meters of space, and the space under the sink is very convenient to use and keep clean.

Hanging washbasins save space in the bathroomBefore you begin installation work, choose the model of wall-mounted sink that has the most ergonomic design. A separate model has specific design aspects, which, of course, affects the method of its installation. Therefore, it is so necessary to have at least some knowledge about the installation and specifics of connecting the device to the general water supply system.

A wall-hung sink above the washing machine is an excellent solution for a small space

An interesting solution is to install a sink above the washing machine; this saves precious space in the bathroom.

Connecting the siphon to utilities

When installing a sink, special attention is paid to installing the siphon. First you need to secure the outlet, for which a mesh, a silicone or rubber gasket, and a clamping screw are placed in the drain hole

The use of a gasket is an indispensable condition, since its presence creates a tight connection.

During its installation, you need to make sure that it fits as tightly as possible and fits the drain of the plumbing fixture without the slightest displacement or gaps. First, you should make sure that the gasket is installed correctly, and only then tighten the clamping screw, thereby connecting the siphon and the outlet.

Next, the end of the outlet pipe, made of corrugated tube or hard plastic, is connected to the sewer socket. When connecting to a sewer pipeline, seals must be used, the function of which is performed by rubber gaskets or cuffs for corrugated pipes.

Step-by-step equipment installation technology

The problem of how to install a sink with a pedestal is solved quite simply.

The work is carried out in stages:

The bowl is then inserted into the pedestal and leaned against the wall, with the marked line and the top edge of the hardware aligned. A pencil is inserted into the holes on the back of the device and places for fastenings are marked.

A level is necessary for proper installation of the sink

- Preparing holes. Using a puncher or drill, holes are made whose diameter is slightly smaller than the diameter of the dowels. A little glue is poured into the prepared holes for a stronger connection, and the spacer dowels are driven in.

- Preparing the base for the pedestal. The floor must be perfectly level, otherwise the equipment will wobble. If necessary, you will have to level the surface with a solution.

Sink installation. Plumbing self-tapping screws are screwed into the prepared holes. The shell bowl is placed on them. We install it on a pedestal, making sure that the drain hole is located exactly in the center of the structure

We put spacer washers on the screws and carefully screw the structure to the wall

Do not overtighten the nuts: the shell may burst. It will be enough to tighten the washers so that the bowl does not wobble. Tightened nuts are covered with decorative plugs

- Siphon installation. The outlet element is connected to the sink. A mesh with a gasket and a screw is inserted into the drain hole. Installation of the outlet must be carried out with the installation of gaskets, which must fit tightly around the sink drain without the slightest gaps or displacements. We tighten the screw and connect the siphon to the outlet, after which we fix the outlet pipe in the sewer socket.

- Mixer installation. Any pedestal bathroom sink should be equipped with a faucet. It is mounted using a flexible line connected to the water supply. The design consists of hoses with fittings or other components for mounting on a pipeline. In any case, a special winding is used to install it, most often fum tape, designed to prevent leaks and seal the connection.

These stages are present during the installation of any equipment. A corner sink with a pedestal is installed in the same way.

Designer models

This type has little functionality, pursuing design goals. They are installed for decoration or cooling drinks. They are made of different materials: copper; bronze; glass; wood; stone.

The advantages of overhead sinks include a successful combination with any kitchen interior design.

This is one of the popular models for the kitchen. The advantages include:

- simple installation;

- democratic price.

The disadvantages are the gaps between the walls of the cabinet. Installing overhead sinks is considered a simple job, especially with standard module sizes.

This type of sink is more suitable for kitchen sets consisting of separate modules; they are easily installed in corner kitchens with standard dimensions.

Kitchen sink made of artificial stone

Features of installation of structures of unusual shapes

If the sink has an unusual shape, but is a mortise type, its installation will not take much time and effort. It will be enough to use the template included in the kit. The material can be any: steel, stainless steel, plastic, MDF, chipboard. Another thing is integrated sinks, which are mounted below the countertop level. This type of installation is typical for products made of granite, natural stone, plastic or wood. Their shape can be round, oval, square, triangular or abstract

In any case, it is important to ensure perfect sealing and precision when cutting the hole. As a rule, jig milling machines are used to cut them out.

It is thanks to the possibility of programming such equipment that the accuracy of the cut and the entire trajectory as a whole is ensured.

This type of sink will definitely appeal to musicians.

Types and materials of manufacture

They are subject to the general rules of kitchen interior and design, its dimensions, layout, ease of use, and practicality. There are the following types of cabinets:

- Floor-standing, characterized by: ease of installation; solid sizes.

- Suspended, winning visual weightlessness. Communications of this design are easily hidden under it. The disadvantages include difficulties in fastening and insignificant internal volume.

- Corner cabinet, characterized by compactness. It can be suspended or floor-mounted.

Cabinets are made mainly from wood and chipboard.

1280×960 Images may be subject to copyright. Read more... Corner kitchen sink