The design of a furniture lock is determined by the material on which it is installed. This is explained by the fact that the lock is designed for a certain thickness of the door or drawer front and a different method of fastening (for example, you cannot screw a self-tapping screw into glass).

Castles are divided into:

- furniture locks for chipboard and wood (as a rule, designed for a thickness of 16-18 mm) When attaching furniture locks to chipboard and wood, practically no problems arise: a hole is drilled for the cylinder, and the lock body is attached on the reverse side. On the outside, the hole for the larva can be decorated with decorative overlays.

- furniture locks for glass (usually glass with a thickness of 5-6 mm is used, rarely 8 mm) Locks for glass are universal; glass of any thickness used can be secured in them. They are also suitable for metal (e.g. metal cabinets, mailboxes). Glass locks come in mortise locks (requiring glass drilling) and overhead locks. The difficulty of installing mortise locks is that not every manufacturer has the ability to drill glass well and accurately install a lock in these holes. Thus, drilling requires a special machine with drills for diamond-coated glass, drilling glass from both sides at the same time. In this case, a cooling emulsion should be supplied, which makes the process better. Such a machine costs from 5 thousand EUROS.

Therefore, rim locks are most often used for glass doors, for the installation of which it is not necessary to drill the glass. These locks have an “L-shaped bar” that fits over the glass. Screws are inserted into the holes in the bar and the lock is pressed against the glass through a plastic spacer.

Locks also vary depending on what they are for: drawers, sliding doors, or hinged doors. Locks for swing doors are divided into locks for one door and for double doors.

In addition, locks differ in the principle of operation of the mechanism: with a retractable tongue, rotary, push-button, harpoon-shaped, rack and pinion with a locking mechanism.

The designs and mechanisms of operation of locks in most manufacturing countries are very similar, so we will focus on the main models that are a priority for the Russian market.

Installing the main types of locks on furniture with your own hands

The process of installing a furniture lock yourself is not complicated. Most often, the product kit includes all the necessary components, including fastening elements for the lock, and complete instructions for installation.

The lock for wardrobes and furniture with a folding or folding opening system is installed in the same way as locks designed for swing doors. Therefore, we will consider the processes of installing locks only on swing doors.

Installation of a furniture mortise lock

Before starting installation you need to prepare:

- tools for marking (ruler or tape measure, pencil);

- drill;

- a screwdriver or screwdriver of a suitable size.

The lock is installed according to the following scheme:

- Carefully and accurately markings are made to install two lock blocks (the locking mechanism and the block for inserting the latch);

The process begins with marking

It is recommended to install the locking device at a distance of 2/3 from the floor.

- using a drill, holes are drilled for attaching the lock and inserting the locking mechanism;

We begin drilling by selecting a suitable drill bit.

- The main lock block is attached to the door leaf, and an additional one is attached to the furniture body. For this, self-tapping screws and a screwdriver are used;

- the functionality of the structure is checked. To do this, the wardrobe with a lock opens and closes several times. If necessary, the lock is adjusted.

Briefly about installation

I am sure that there is no need to tell how these types of furniture fittings are installed. In some cases, the locks are even placed on glue. But in practice this is not the most sensible solution, since further dismantling may cause problems in the future.

Installation consists of placing the lock in the designated location, making marks, drilling holes if necessary, and then securing it with the fasteners that the lock manufacturer supplied with the kit.

If this is some version of a modern lock that has a special structure or a complex mechanism, then you need to rely solely on the manufacturer’s instructions. There is no universal guide that will suit everyone in all cases.

What do you think, are furniture locks necessary and will the overlay elements be able to perform at least some protective function? Have you had experience in selecting and installing such fittings? Share your impressions.

Thanks to everyone who is with us! Subscribe, don't forget to leave comments and ask relevant questions!

Which cabinets can be equipped with locks?

Types of cabinets

Modern manufacturers produce cabinet and built-in cabinets equipped with protective devices against unauthorized entry.

When ordering cabinet furniture, you can immediately specify the installation of a lock

Built-in wardrobes can also be equipped with locking hardware

Cabinets can be made from:

- metal A metal cabinet with a lock is used in enterprises and offices in the form of safes and changing rooms for staff;

Such safes are usually installed in locker rooms

- Chipboard or fibreboard. Furniture cabinets for the home and wall cabinets are mainly made from this material. A wall cabinet with a lock is used in the kitchen for storing dangerous products, for example, vinegar essence;

Chipboard kitchen cabinets can be padlocked

- glass Glass cabinets are used at home to store dishes, books, etc., as well as in bars, restaurants, canteens, and shops.

Glass cabinet with key

Cabinet doors can be:

- sliding (sliding wardrobes);

- swing;

- foldable.

Each type of door has its own locking system.

Cabinet selection criteria

The choice of cabinet should be based on the following criteria:

- at its location. Glass or wooden cabinets are suitable for your home. Metal cabinets are more suitable for offices and enterprises;

- on the door opening system. Sliding wardrobes and furniture with folding doors will save space in the room;

- on reliability. If you plan to store important documents or weapons in a cabinet, then it is more advisable to use cabinets made of metal. Such a filing cabinet with a lock will keep your property safe and protect it as much as possible from fires and other disasters;

- on the type of property intended for storage. If you need to place dishes, books, photographs or make a display case in a store, cafe, etc., then it is more advisable to purchase a glass cabinet. Cabinets made of wood are more suitable for storing clothes.

Additional security elements

To make a child's room and the entire apartment or house safer for a small child, you can use not only furniture mortise locks or the considered locks, but also a number of additional auxiliary components. For some, they can become the main decisions in the field of preserving the health of the baby.

- Shock absorbers. Plastic or rubber products that are attached to retractable furniture, doors, sharp corners and edges;

- Plugs. They serve to block access to screws, nails, and some decorative elements that are dangerous for children;

- Covers for edges and corners. Most often they are made on the basis of soft silicone;

- Protective tapes. They are used to cover the edges of various furniture. They are made on the basis of rubber or silicone with a sticky base for strong fixation.

I advise you to go to specialized stores and choose the best protection options.

Before you go to the store for child locks and interlocks, carefully examine your home, identify dangerous places and areas that need to be secured.

Purpose and features

Furniture locks belong to the group of detachable fastening fittings, which also includes door handles, clamps, latches, hooks and latches. According to the structure of the mechanism, they are divided into certain categories. The design of the device depends on the material it is made of. Due to the fact that furniture locks are designed for a certain thickness of material, where the installation takes place, their structure will differ.

Furniture locks are used on cabinet doors, drawers, wooden safes, bedside tables, wall cabinets and other parts of furniture items. To understand what the products are intended for, you should consider their features:

- Material of manufacture - furniture locks are mainly made of durable materials - steel, aluminum, metal alloys. If it is made from a less practical material, such as plastic, the feasibility of its use is reduced. The best are metal options that will reliably hide the necessary items;

- Fastening area – depending on the material where the lock will be installed, many of its characteristics change. For example, the option for installation on glass will have a thickness less than its counterpart, which is intended for furniture made of laminated chipboard. This indicator should be taken into account when choosing a device;

- Mechanism - according to the principle of operation, there are push-button, rack and pinion, rotary and retractable. Each of these types of furniture locks for cabinets is used for specific purposes;

- Type of lock - there is a mortise lock, which is built into the surface of the facade, as well as overhead options. The latter are much easier to install: you don’t need to call a specialist to attach them, because everything can be done yourself;

- Reliability – modern manufacturers of furniture fittings have taken care to ensure the reliability of locking mechanisms. Mechanical options are gradually losing popularity, they are being replaced by innovative analogues: magnetic, electronic and code options. They provide an increased level of reliability;

- Size – according to the dimensions of the cabinet or other furniture, locks can be selected according to the size.

The main purpose of locks is to ensure secure storage of documents and other valuables. Another functional purpose is to close doors that are constantly opening.

How to choose a furniture lock?

As a rule, stores sell bedside tables and cabinets already equipped with locking mechanisms. But sometimes the consumer still needs to replace them himself. When choosing, you need to pay attention to the shape, size and fastening of the furniture lock. Tubular locking mechanisms, which are difficult to open, are considered especially reliable. The key to such locks has a specific shape, so the owner will never confuse it in a common keychain. For those who constantly lose their keys and then puzzle over the question of how to open a furniture lock, it is advisable to opt for coded locking mechanisms that vaguely resemble case fittings. Consumers for whom it is not reliability and safety that matters, but the design of the lock, can be recommended to shop at specialized stores that offer a huge range of models.

Before purchasing a lock, you must make sure that the key turns easily and the lock moves smoothly. This is what is considered a guarantee of the reliability and durability of the locking mechanism. Remember that a high-quality model has no external or internal defects.

Varieties

There is hardly any need to talk about what rim locks, like other types of furniture locks, are used for. Everything is already very clear.

Locking mechanisms or locking furniture fittings are divided into several categories depending on certain design features, materials used, mechanisms, etc.

For some, a classic old-style round lock like Pinocchio is perfect, while others will need a modern block, supplemented with electronics.

Let's look at what furniture locks can be.

- According to the material of manufacture. In most cases, steel, aluminum or an alloy of different types of metal is used. But you can even install a plastic lock, although then its reliability and practicality will be much lower. If it is important for you to get a high-quality and durable lock with a cabinet key or to prevent children from getting into places where they shouldn’t, choose metal fittings;

- Installation location. When choosing a furniture lock of the overhead type, be sure to consider where exactly the installation will be carried out. For example, the central one for a bedside table made of chipboard, MDF or wood will be thicker. But for lining glass doors, more compact and thin models are needed;

- Mechanism. According to the mechanism, all furniture locks, including overhead locks, are divided into retractable, rotary, rack and push-button;

- Locking mechanism. Previously, only mechanical fittings were offered. Now they are being replaced by electronic, coded and magnetic solutions;

- Dimensions. Here it is worth starting purely from the furniture on which the device will be mounted.

Overlay elements fit perfectly into a drawer and are suitable for hinged doors and sashes.

The main thing is to know why exactly you need a lock. And then there will be no problems with selecting a suitable model.

Features of rim locks

Such fitting options are superior to mortise fittings in that they require much simpler installation. Even a beginner can cope with installation work.

Most often, products are attached to doors, drawers and mounted on double-leaf furniture doors.

Depending on the mechanism, overhead locks for furniture are divided into several subcategories:

- Retractable. Widely used in finishing tables, drawers and chests of drawers;

- With swivel mechanism. Relevant in cases where the lock needs to be placed on a cabinet with several drawers;

- Rack and pinion. They are put on a special strike plate with teeth;

- Harpoon-shaped. Similar fittings are used when arranging sliding doors;

- Keyless. They have a built-in button that acts as a latch.

As practice shows, when installing furniture locks on glass, the most common are locks with a latch button.

It is also advantageous to install fittings equipped with a retractable mechanism on the glass. It has an elongated body and a rotary opening system. If you are thinking about installing a lock on a glass door or flap, also take a closer look at rack and pinion mechanisms. A special gear strip is included in the kit for them.

Those rim locks that come with a key are considered more reliable, and the key itself is stored in a specific and inaccessible place.

If the purpose of the lock is purely to prevent accidental opening, it is not at all necessary to take the hardware with a key.

Choosing a pen?

For the sliding system, you can choose a handle that will have the most suitable design. All existing varieties differ from each other in individual details, and therefore which option ultimately turns out to be acceptable will depend on:

- Design features of the door;

- Doorway size;

- Dimensions of the door leaf;

- Sash material;

- Personal preference.

Sprouted lentils: composition, protein, vitamins, benefits and harm to the body, recipes. How to sprout lentils at home for food?

All handles are mortise, and their handle is most often an ordinary recess used to open the sash.

Independent models

These handles got their name because they are not connected to any locking mechanism. Their design does not imply the installation of any kind of lock or elementary latch. If it is necessary to fix the sash in the closed position, to the leaf and side wall. The force generated must be sufficient to prevent the closed sash from moving.

Attention! If the door installation was carried out according to all the rules, you can safely refuse such a handle.

The popularity of independent handles is due to their:

- Fairly simple design;

- Low cost;

- Easy to install.

Most often these are mortise products placed inside the sash during installation. The handle does not extend beyond the door leaf, which makes it possible to open/close the door even with limited surrounding space. This model is suitable for cassette sliding systems, which can be completely hidden in the wall during the opening process. The installed handle in this case greatly facilitates the process of operating the door system.

Mortise with latch

This handle is initially equipped with a locking mechanism that allows you to open and close the latch when the need arises. In terms of their design, such handles are similar to models installed on swing doors, but they have some differences.

Firstly, the handle is made much smaller. Secondly, the latch comes out of the hole in the strike plate after turning a small handle or moving the slider. Both options assume that the parts used to open the door are located in a special recess on the door handle. As a result, the installation of such a handle is possible on doors that are used in limited conditions, for example, on cassette doors.

Handle with lock

This model differs from previous versions by the presence of a special hole designed to accommodate a keyhole. Manufacturers offer models that already have a cylinder of a locking design built into the handle, adapted to the operating features of the sliding door.

Article on the topic: What types of interior compartment doors are there?

Should the door slide into the wall or to the side?

In addition to sizes, coating materials and colors, sliding doors differ in their system. If you have already decided on the number of doors in your doorway, you should think about where the door leaf will slide relative to each other and relative to the wall.

Advantages of doors in walls

- You don’t have to do the standard design of the doorway with extensions and platbands;

- An open door doesn't take up space along the wall where you could put a sofa or wardrobe;

- This is an original solution that gives the room more space - there is no long “stick” above the doorway covering the guide.

Cons of sliding doors inside walls

- Difficult installation - for such a solution it is necessary to demolish walls and install plasterboard partitions;

- Difficulties in repairs - if something goes wrong, you will have to break down the walls and do everything again;

- Cleaning is difficult - dust gets into narrow cracks, and if your doors also have a bottom rail, then it is almost impossible to clean dirt and dust out of it.

Option No. 2. Install a capital mechanism

In general, this procedure is not much different from the one described above. However, take into account the following factors:

- such structures, as a rule, are larger, so you need to select the correct dimensions, preparing the cavity from the end;

- you should work slowly and carefully, because if too large a niche is formed, then backlashes will inevitably appear, which over time will loosen the shutter;

- such mechanisms often have additional guides - steel pins that are inserted into specially designated grooves, so you will need to drill additional holes for them;

- It will take more time and effort when processing the end of the blade, since such structures are often equipped with round metal plates (you will need to carefully cut the hole to the shape and size).

Taking into account these nuances, you can insert the lock into the interior door with your own hands and securely fasten it without unnecessary hassle. Below you will find photos and videos that will help you thoroughly study the installation process.

Please note that the array must be hung on hinges. In other words, all work is carried out after the finishing of the premises. It is not recommended to drill and cut holes in a horizontal position. This way you can damage the surface of the coating (especially if it is parquet or laminate), and you will also have to constantly lift and turn the canvas, as well as hold it suspended, which is very inconvenient.

Types of locking mechanisms

A vertical latching mechanism is installed on sliding sashes. When choosing a lock, you should take into account the material from which the sash is made, as well as the design features of the system itself. Sometimes you can avoid installing a locking system, since it is part of the handle.

Related article: How to turn off a doorbell

Harpoon

The constipation includes the mechanism itself and the strike plate. The lock can be purchased for a sliding door, in which the doors move towards the side walls. The locking mechanism is attached to the door leaf, and the strike plate is attached to the side. At the moment of locking, a harpoon-shaped tongue is placed in the hole of the bar, preventing the sash from moving.

Attention! This system is applicable for one-, two- and three-leaf systems. To do this, two locks are installed on the central leaf, and strike plates are installed on the side ones.

Button

An option acceptable for double-leaf models. When the push-button mechanism is closed, a special rod extends. It rests against the second door, preventing it from opening.

If the thickness of the door leaf is not enough to securely fix the rod, the push-button mechanism is inserted into a special profile. With this installation, the rod rests on the profile of the second sash. This option is often resorted to when it is necessary to fix a glass or mirror sheet. If the door has a wooden frame, you should take care of strengthening it in advance.

Button

Magnetic

If a mechanical device is not suitable for some reason, you should pay attention to magnetic models. Such locks are compact in size and therefore ideal for sliding systems with glass and mirror panels. A magnet secures the sash when the locking part comes into contact with the mating part. However, during operation, such a system can become demagnetized, which often limits its scope of use. At the same time, if the real weight of the door was taken into account when calculating the characteristics of the magnet, the lock can last quite a long time.

Glass door locks

Given the fragility of the door leaf material, the list of locking systems and handles suitable for glass doors is limited. Even the use of tempered or impact-resistant glass is not a guarantee that the integrity of the mounted sash will be ensured during the installation process.

Often a lock with a removable cylinder is installed. To do this, a special hole is drilled in the sash itself, designed to accommodate a removable cylinder. Installation work should be carried out extremely carefully so as not to damage the sash itself. A handle is inserted into the prepared hole, the position of which is fixed using a special bushing nut. When the handle is closed, the locking mechanism is activated and the door is locked in the desired position. When opening the door, you need to grab the special protrusions, which are used as a handle to remove the cylinder. After this, you can open the sash.

Option for glass door

If the doorway is wide enough and the strength characteristics of the profile used in the manufacture of the door are optimal, it is possible to install a push-button system. Installing such a lock allows you to do without drilling a hole in the glass sash.

An overhead system is also sometimes installed on glass sashes, which involves fixing the sash using a toothed strip. The second sash rests against the bar. To close the door, you need to put the locking part on the bar, which will prevent possible movement of the sash. To open the door system, the entire installed locking structure must be removed. This option is not widely used due to its large size.

How to install it yourself

Installing a furniture lock will be quite feasible for most users. The greatest difficulty is the installation of a mortise structure. Procedure:

- The necessary tools are being prepared. You will need an electric drill, a Forstner drill or a pen drill (the first is better), a ruler, an awl, and a screwdriver.

- Marking is being done. Usually a diagram is attached to the lock, which is placed on the door and the centers of all holes are marked. If there is no diagram, you need to accurately determine the dimensions and mark the drilling points on the sash. They are marked with an awl to leave indentations for centering the tool.

- The necessary holes are made. As a rule, you need a through one for the mechanism and several blind ones for fasteners, although there may be other options.

- The lock is fixed, a decorative ring is put on the cylinder.

- Next, focusing on the position of the part, the installation location of the counter structure is noted. It is attached to a fixed part of a cabinet or table.

Advantages of larch furniture board, its varieties

The last step will be to check the functionality of the product and adjust the response bracket, if necessary. As a rule, you need to slightly bend the corner to achieve the desired result. After this, the installation is considered complete, and normal operation of the lock begins.

Tools are being prepared

Marking is being done

Holes are drilled

The lock is fixed

A counter structure is being installed

Installation process

Let's consider the process of inserting a standard lock with a key, consisting of the following elements:

- Tubular core (varies in diameter).

- Overlay strip (plastic or metal).

- Response plate.

To work, you need a minimum of tools: drill, screwdriver, forstner cutter of suitable diameter (not always required), screwdriver, screws, pencil. If the lock is semi-mortise, then you need to drill a hole under the core using a cutter of the required diameter. For overhead mechanisms, all the work comes down to drilling thin holes for self-tapping screws. There may be two or four.

Initially, the location of the lock is determined. The center of the door is ideal for this. Using a pencil makes marks easy. Now the preparatory work is done: holes are drilled.

After the lock is secured, a strike plate is attached to the second door. A little trick: close the doors, apply a strip and outline it with a pencil. Now it is easily attached to the canvas in the open position.

Speaking about furniture locks, we cannot help but recall that for glass and metal doors you will need to use the appropriate drills. If they are not available, consider the cost when purchasing the lock. In some cases, it is appropriate to call a specialist.

Recommendations and selection criteria

If you are making a closet yourself, then when making wardrobe doors you should consider in advance the possibility of installing or inserting a lock.

When choosing a lock for subsequent installation in a wardrobe, you should follow a few tips and pay attention to important nuances.

- Cabinet material. Coupes are made from various materials, although most often we are talking about laminated chipboard and MDF. For glass, overhead products will be relevant. If metal, wood and its derivatives are used, then mortise products are perfect;

- Opening method. Everything is simple here. Since this is a coupe, semi-mortise designs look more advantageous and practical;

- Door sizes. A small lock on a large door is not needed. As does the large security element on the compact door. Take this into account when calculating the doors for your coupe;

- Reliability of the mechanism. It is clearly important to understand whether you need protection or just a light child lock. These are completely different things.

In fact, there are few selection criteria. But you shouldn’t approach their analysis carelessly. Otherwise, the result of selection and installation will simply disappoint you.

Why you shouldn’t save when choosing a mechanism

sliding cafe doors

interior doors

Also, the doors themselves are the most expensive parts; their quality should be given special attention.

First, let's talk about rollers. In order to ensure that they do not wear out over a long period of time, experts strongly advise purchasing only those mechanisms that are equipped with rollers that have bearings in the base. These can be either standard ball bearings or more wear-resistant roller bearings.

The next element is the frame. It must be very tough. As practice shows, one of the more reliable and durable ones are frames made of duralumin profiles. Such profiles almost always serve as a frame for the door leaf itself, and from time to time, as a fastening for fittings. In some cases, iron profiles can be used, but, as it turns out, they have a number of shortcomings.

What are the advantages of a duralumin profile? In this case, two main features can be distinguished, which are fundamental in cases where sliding doors for cabinets are selected or installed:

- The low weight of the duralumin profile, especially if you associate it with a metal structure, makes it possible to avoid possible deformation of the door leaf. This aspect is especially relevant in situations where the wardrobe has very large dimensions;

- Due to the light weight of the structure, it is possible to install a conventional door opening mechanism on a wardrobe, whereas when using steel, it is necessary to install a reinforced mechanism on an interior door or a wardrobe door.

Closer for sliding system

This is a whole system that includes stoppers, limiters, latches and other elements so that the doors automatically close smoothly and are comfortable to use. Every third model requires several closers at the same time due to the need to close the doors in different directions. Adapters that regulate the operation of the system are installed in the upper part of the cabinet, and the closer is installed in the upper part of the guide yard.

It is worth noting another significant role that is controlled by the automatic system - security. This device minimizes the likelihood of injury when closing the cabinet abruptly.

In addition to providing safety to the owners, the structure itself has an increased level of protection against loosening. This opportunity arises due to the shock-absorbing effect that is introduced into the automatic door closer systems.

To select an automatic closer system, you should pay attention to the following factors:

- dimensions and weight of the wardrobe;

- directions for closing and opening the sliding system;

- material of manufacture of the system itself (aluminum structure or steel).

The installed systems are in demand and extremely popular due to the fact that they combine:

- Ease of use. You just need to push the door and it will smoothly close on its own. Children or pets will not be able to do this. The effort that needs to be made is not noticeable for an adult, but for children even an animal will cause difficulties.

- Aesthetic appearance. The door is always in the right position and closed for a fee.

- Safe to use. When closing the doors, neither children nor pets will be harmed. Often when playing, children can sharply push the door, and the system slows it down 5-7 centimeters from the wall itself and slowly closes it, preventing injury and damaging the cabinet body.

- Reliability. Steel and aluminum structures allow the mechanism to be used for a long time.

Business plan for furniture production

You can learn how to install a stopper with a shock absorber on a sliding wardrobe from the video.

Smart choice is the key to success

To make it easier to decide on the type of furniture protection from children, use several simple but effective life hacks.

Cabinet Contents

To restrict children's access to things like clothes, toys, and bedding, mechanical (mounted, external or internal) locks are sufficient. They are inexpensive, easy to install and relatively durable (especially those that are attached to handles).

Expert opinion Daniil Dmitrievich Korzhavin Designer of stylish home furniture

According to consumer reviews, most children by the age of one and a half years understand mechanical locks with external and internal fastening in no time. But it no longer makes sense to hide most things once the child reaches this age.

If we are talking about a first aid kit or household chemicals, it is better to use magnetic locks. Well, a smart lock will serve to store personal documents, jewelry and savings.

Features of furniture design

Be sure to consider the design of your furniture. It's not just about opening systems. For example, what about semicircular facades if you want to install a hidden mechanism? Not all locks will be able to cope with the task due to poor fit to the concave surface. The same applies to ribbed and textured facades. Perhaps the best option for such furniture would be padlocks.

Not everything is clear with retractable systems

Pay attention to the height of the walls of the box itself, and not just the facade. Drawers with high sides take up all the space in the cabinet body, so there is simply not enough space to install a hidden security device

Manufacturer and materials

Models of blockers that look identical may turn out to be of different quality, so check:

- plastic latches. Should not be flimsy or too tight;

- adhesive base. One of the common complaints about externally mounted security systems is that they are weak. This is due to poor quality double-sided tape. This is how the manufacturer saves on the product, and the buyer receives a structure that cannot even withstand its own weight;

- safety of the material and shape of the structure. Children often taste everything; during the teething period, babies get into their mouths absolutely everything that can and cannot be imagined. Therefore, the materials of the lock must be environmentally friendly, and its shape must have no sharp edges, easily separated parts, etc.

Child safety locks are a convenient invention that will make your child’s stay in the house truly safe. And with the right choice, they will last a really long time and conscientiously.

Preparing a socket for a mortise lock

At the next stage of installing a mortise lock, you will need a tool and a little physical effort. First you need to drill several holes in the end of the door, with a depth equal to the length of the lock. If possible, the drill should be selected with a diameter equal to the thickness of the lock. Otherwise, it will take more time to process the hole for the lock with a chisel. The drill should be positioned strictly vertically to the surface of the end to prevent the size of the socket from changing along its depth.

Holes are immediately drilled along the upper and lower edges of the markings. Then several holes along the height of the nest. Using a chisel, excess wood is removed and the nest is ready. When removing excess wood with a chisel, you should work carefully, avoiding splitting the wood. Holes are then drilled to match the keyhole and latch pin. In this case, it is recommended to reduce the pressure on the drill when it comes out from the back side in order to prevent splitting of the wood.

By the way, this can also be avoided if you press a wooden block tightly to the exit point of the drill. After inserting the lock, the front lock bar is marked. Then the wood is selected to the thickness of the strip so that it becomes flush with the surface of the end of the door leaf. Depending on the shape of the plank, a flat or semicircular chisel is used.

Next we do the following:

- insert the lock,

- secure it with screws,

- install keyhole linings and handles.

And we move on to marking and installing the locking strip.

Installing the striker plate

Several methods are used to mark the installation location of the locking plate and the location of the socket for the latch and bolt of the lock. To do this, you can use carbon paper. It is applied to the surface of the door frame opposite the lock. Then you should turn the key (close the lock) and turn the handle a couple of times. In this case, an imprint of the bolt and latch of the lock will appear on the surface of the door frame. You can also get an imprint of the latch and bolt using shoe polish by applying it to the corresponding parts and turning the key.

Instead of carbon paper, you can use plasticine applied in a thin layer to the door frame. The imprint of the bolt and latch is also quite clear. Another method allows you to do without these additional materials. After turning the key one turn, we put the locking bar on the lock bolt and close the door. The top and bottom edges of the striker plate are then marked on the jamb.

Using a carpenter's level and a ruler, mark the location of the locking plate and the holes for the bolt and lock latch. After this, holes are drilled and excess wood is cut out. The depth of the hole for the bolt must be no less than its length in the fully closed position of the lock. All that remains is to install the locking plate in the same way as installing the front lock plate. That's it, the installation of the mortise lock has been successfully completed!

Making a key for a lock

Making a key for an old-style lock for old antique furniture is included in the cost of restoring the item itself - a wardrobe, chest of drawers, table, secretary, chest, sideboard, casket, icon case.

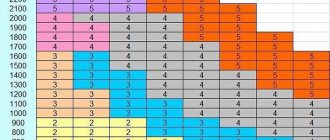

Price for repairing locks and making keys and locks, rub.

For repairs, more than 3 similar products receive a discount10%

.

*Key making includes routine repairs to the lock.

**medium and major repairs of a lock include making a key

Current repairs include cleaning, lubrication, and fault diagnosis.

Medium repairs are carried out when disassembly is necessary; sliding surfaces are subjected to grinding, adjustment, and straightening.

Major repairs are carried out in the event of missing or broken individual parts.

High-tech models

In addition to traditional options operating on a mechanical principle, there are more modern high-tech models. Among them there are the following varieties:

- Coded. There are electronic and mechanical versions. They work on the principle of typing a specific sequence of characters using a keyboard or rotary rollers. In addition, this product may have a magnetic key. The peculiarity of this model is the large number of options for digital combinations. One of them is the key. The advantage of this design is the ability to find the desired combination by selecting options. If you go through the combinations for a long time, sooner or later the desired sequence of numbers will be found. This feature comes in handy when a combination is forgotten or lost. The disadvantage is that they are quite large in size, which complicates installation and can ruin the appearance of the furniture.

- Electromagnetic lock. Driven by power supply. A strong magnetic field is generated, retracting the latch and allowing the door to open. It locks in the usual way, like any spring type. Installation consists of attaching the mechanism itself and connecting the power wire to the electromagnet. The advantage of such locks is that it is impossible to pick up a master key, as well as their resistance to corrosion. Users note durability and ease of installation. The disadvantage is that it stops working when there is a power outage. The situation can be corrected by using a backup power source.

- Electromechanical. It is a set of a lock mechanism, a power source and a control unit. If there is a sudden power outage, programming failures are often observed, which requires reconfiguring the system. This procedure is not particularly difficult. Disadvantages are sensitivity to moisture and tendency to form condensation. Not suitable for installation in areas with high humidity, such as a bathroom.

- Electronic. One of the most modern, advanced models. The key to such locks is digital cards or chips. Installation first requires the installation of a mechanical drive, then the connection of an electronic recognition system. The advantage is the absence of a regular key and the impossibility of counterfeiting a chip or card. In this case, the code combination is quickly changed if necessary. The electronic lock is sensitive to temperature changes, power surges, and short-lived.

Purpose of furniture corners, advice on selection, installation rules

Each furniture lock has one degree or another of reliability. The most burglar-resistant types of locking mechanisms are: electronic, coded, and mortise lever.

Modern models are usually used for office furniture. At home, they are inappropriate and spoil the appearance of the headset.

Code

Electromagnetic

Electromechanical

Electronic

Features of locking devices

Locks for metal cabinets have a high degree of security. With their help, you can close the cabinet and restrict other people's access to its contents. Today, similar products are used on safes, mailboxes, gun cabinets and even wardrobes for clothes and accessories. All of them are divided into four classes according to the degree of resistance to hacking.

| Reliability class | Reliability level | Relevance of installation |

| First | Short | To limit children's access to the contents of the cabinet, to protect things from dust, insects, and pets. |

| Second | Average | Suitable for cabinets with documents that should be kept away from prying eyes. |

| Third | High | The most common type, as it combines affordable cost and a high degree of reliability. Relevant for furniture that contains valuables. |

| Fourth | Maximum high | Locks for cabinets with valuable papers or things, jewelry, money, weapons are relevant. |

The first and second classes are considered lowly reliable, since an experienced burglar can easily find a way to get into a cabinet with such a lock. The third and fourth classes of products indicate that it will be much more difficult to break into a cabinet with a similar locking device. Such locks are reliable, so you can be 99 percent sure that no stranger will take possession of the contents of the cabinet in the absence of its owner. For greater confidence in the safety of personal belongings, you can install two locks with different security classes on the cabinet at once.

Reliability rating

Each lock has a certain degree of resistance to burglary. According to this indicator, the reliability of the device is determined. Based on this information, a rating has been compiled showing the gradation from the most reliable locks to the options that are prone to burglary:

- Electronic furniture lock - this type has a high cost, so the reliability of such a product is considered the highest. It’s not for nothing that electronic options are installed on lockers in the locker room, where a person’s personal items are in potential danger. A code is pre-recorded in the reading device, the key to which exists in a single copy;

- Coded analogue - such a lock is also considered reliable, but no more than the electronic version. Its disadvantage is that you can forget the code number combination. It will take a lot of time to hack such a device;

- Level mortise lock - due to the cleverly designed mechanism of operation, this option will ensure the safety of storing things inside the furniture;

- Rotary and retractable type options - due to the use of a key to unlock the lock, these products are considered reliable, but they cannot be called devices that ensure complete safety and security;

- Magnetic locks are less reliable devices, the operating principle of which is to use a magnetic base;

- Latch locks - such options are considered outdated, as they are not particularly reliable. They are less often used on furniture products, giving preference to innovation.

From the information provided, we can conclude that furniture locks based on power supply are considered the most reliable. It is impossible to find a code for such devices, so they provide increased safety and security of things in furniture.

Suvaldny

Turning

Magnetic

Espagnolette

Drawer solutions

Some will say that you can hang regular magnetic locks on the drawers. But powerful magnets are expensive, but simpler options will not withstand even the efforts of a child.

For curious children, drawers are of great interest. They are easy to hit and pinch fingers when actively opening and closing.

The essence of the protective mechanisms is to block the extension of the structure. The blocker is secured from the inside using screws.

For parents, using the box will be simple and convenient, but the child will be protected from accidental pinching of fingers or the box falling on his feet when fully extended.

There are 2 main types of locks for drawers.

- Internal. The mechanism structure is located inside. Locks with holes are glued to the shelf of the drawer, and the hook to the front;

- External. Two elements are attached to the box. One is pressed to the side, and the other to the edge. When closing, the locking elements are connected to each other and latching occurs.

Most often, plastic clips are used for drawers. They are inexpensive, easy to use, but difficult for a child to understand.

After use, when the child grows up, the lock can be removed. The big plus is that they don’t leave any marks on the furniture.

Finishing touch

The service life of a lock depends, first of all, on its quality: the better it is assembled, the stronger the material, the longer the lock will last. Good locks, in addition, should not change their color or fade, that is, they should have a high-quality coating.

Also, when purchasing a lock, you should pay attention to how smoothly the mechanism works, and most importantly, the key from one lock should not fit another. Manufacturers of quality locks have thousands of different combinations to avoid this situation.

You can familiarize yourself with all of the above lock models in more detail in the electronic catalog or at the MDM office, where professional managers will show you each model in action and choose the best option for you.

Come and choose “Locks worthy of your furniture”!

Making keys for furniture and watches

In a restoration workshop, select or make keys for furniture based on an old-style lock, make rowlocks, latches, hooks, handles, hinges, and other fittings based on antique models. Keys to 19th century locks. They are distinguished by their special shape, beauty, and are classified according to the number of secrets. The secret is the parameters of the key: its thickness, the diameter and length of the guide pin, the length of the bit, the location of the levers, the shape of the oarlock cutout, additional barriers that do not allow the use of other devices for opening.