Soft closing systems have become commonplace in modern furniture - regardless of its purpose. Thus, in the market of sliding wardrobes, door closers have already moved from the category of fashionable options for premium products to the category of standard offerings for cabinets of any level. However, unlike drawers and hinges, where the closer is most often pre-installed, soft closing systems for sliding wardrobes are independent devices that require installation and configuration.

At the same time, the sliding door system based on aluminum profiles “Versailles” and its analogues remains the most popular among furniture manufacturers. This means that this is where the highest demands are made on door closers and their properties.

Selecting a soft closing system

First of all, the closer must match the characteristics of the door, but the range of possible options for facades in terms of weight and size in sliding wardrobes is almost limitless. At the same time, choosing a separate closer for each type of facade is extremely inconvenient, since this forces the manufacturer to inflate the range and complicate the work. Therefore, versatility is one of the most important properties of a smooth finishing system.

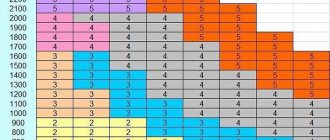

The closers developed by European engineers, which are presented in the MDM assortment, are divided only into right and left - according to the direction of movement of the facade. All other characteristics are configured at the installation stage. The permissible weight of the facade for using this finishing system is from 10 kg to 80 kg.

Such a wide range of loads is available thanks to an additional spring, which is installed on the closer when using a door over 50 kg.

Important: the closer is suitable for many analogues of the Versailles system presented in Russia.

Manufacturers of fittings for kitchen cabinets and bedroom furniture

Expensive oil closers use higher quality and more expensive oil. Let's look at the most popular manufacturers of kitchen furniture fittings:

- BLUM fittings . Austrian company producing various kitchen accessories. The most popular manufacturer of lifting mechanisms in Russia is bloom. The price of products is very varied (from 140 rubles to 800 rubles).

- Vauth Sagel . The second most popular manufacturer, popular in Russia. The German company is recognized as the best in the world. The price for closers is from 300 rubles to 1000 rubles.

- Hettih . German company - manufacturer. The cost of mechanisms and handles for furniture ranges from 150 to 400 rubles.

- Siro . Austrian company. The price of door closers ranges from 130 rubles to 500 rubles.

- agoform. The German company is a manufacturer of fittings for kitchen furniture. The cost of the company's products varies from 200 rubles to 900 rubles.

Video presentation of Bloom fittings:

Kitchen cabinets are used daily, which wears out the fittings. It is necessary to timely care for and clean the door closers from dirt.

- When a squeak appears, you need to tighten all the screws on the hinges.

- All fittings and roof rails in the interior are cleaned with a soapy solution and clean napkins.

- The hinges must be lubricated periodically.

- Do not clean the door closer mechanism with soda or other granular cleaning agents.

- You cannot “help” door closers close the doors all the way.

The mechanism of the closers is very simple, so breakdowns with proper operation are practically excluded. If a breakdown does occur, it is better to call a specialist or replace the broken door closer with a new one.

There are many manufacturing companies with different prices for accessories, so it is quite easy to select and install door closers according to your capabilities and needs. Installing the mechanism is also not difficult. The main thing is to follow the instructions exactly. You need to take care of kitchen fittings in the same way as all other household items. Proper installation and maintenance will allow you to enjoy silent closing of kitchen cabinet doors for a long time.

Facade size

When calculating the height of the facade (the length of the handle profile), you should use the standard formula h = H – 40 mm , where H is the height of the opening. The presence of a soft closing system does not affect the size of the facade, which eliminates the possibility of errors at the furniture design stages. The recommended width of the facade is from 450 mm, which is due to the overall dimensions of the device (the length of the closer is 382 mm). This size is necessary to ensure a working stroke of 120 mm, which, in fact, guarantees the high-quality functioning of the system. Like the braking distance of a car, the working stroke of the closer directly affects the smoothness of the façade stopping.

How to install

To install door closers yourself, strictly follow the instructions, and also purchase special screws and a screwdriver.

After studying the instructions and preparing the necessary materials and tools, you can begin installation.

- To simplify the process, furniture can be removed from the wall and placed in a convenient place.

- The first step is to secure the holding part of the mechanism in the cabinet. When using large closers, the piston is installed on the immovable part of the shelf, the rest of it is attached to the doors. The compact-sized door closer is installed on the stationary part of the shelf.

- Having marked on the opposite side the place where the entire body is attached, small holes are made using a hammer and screwdriver.

- Using a screwdriver, screw the fastening elements.

- At the end of the process, you should check the quality of the installation. If the furniture door opens and closes freely, then everything is done correctly.

Installation of closer

The closers are installed on the top bar of the door and fixed with self-tapping screws. Depending on the choice of handle profile type (symmetrical/asymmetrical), it is necessary to correctly determine the position of the closer on the top door strip. For this purpose, mounting platforms are used, which are included with the closers and ideally position the device (Fig. 1-2).

Rice. 1 Installing a door closer on a door with an asymmetrical handle.

Rice. 2 Installing a closer on a door with a symmetrical handle.

Self-tapping screws for fixing the closer, also supplied in the kit, are selected for the facade filling material - for glass or slab material (Fig. 3)

Rice. 3 Self-tapping screws for fixing the closer

Key Benefits

When a compartment door begins to make a lot of noise and slam loudly, many rightly think about how to repair and correct this situation.

An excellent solution would be to install a door closer.

It provides a number of objective advantages:

- the doors close smoothly and neatly;

- extraneous noise goes away;

- facades are protected;

- damage to the cabinet body is prevented;

- safety increases;

- additional protection measure for children;

- animals will not be able to open the compartment themselves and get inside;

- dust and dirt will not get inside the cabinet.

Strong arguments, in my opinion.

If you know how to assemble the coupe itself, then installing the door closer should not be a problem. But if in doubt, it is better to turn to specialists.

Installation of the activator

The soft closing system activator is installed in the top guide. To correctly position the activator, it is necessary to move the door to the closed position and mark the position of the closer slider on the guide. Then you need to install the activator in accordance with the mark (Fig. 4). To adjust the soft closing system, the longitudinal adjustment of the stopper position provided by the oval hole is used.

Rice. 4 Installation and fixation of the activator in the upper guide

Each door closer includes:

- 2 springs for facades weighing from 10 to 50 kg and from 50 to 80 kg

- 6 self-tapping screws for fixing the door closer to the top strip of the facade

- 3 mounting platforms for doors with asymmetric profile

- 3 mounting platforms for doors with symmetrical profile

- activator with 3 screws.

Operating principle

To understand how a kitchen door closer works, let’s look at its operating principle:

- The basis of the mechanism is a spring, which is located inside an oil-filled capsule.

- The door closing speed is controlled by special valves.

- Pressure is applied to the furniture door, and under the influence of its weight it begins to close.

- The door begins to put more pressure on the special stop of the closer.

- The liquid covering the spring flows into its rear part (sleeve), where it is retained by a double system of seals.

- The speed of closing the doors is determined by a special adjustment element, which narrows and expands the outflow channel.

How to remove and repair a door closer

If the mechanism does not work, it can be dismantled and repaired. To do this, unscrew the screws from the housing, then from the connection point of the lever. Often the problem occurs due to the following factors:

If the rod is deformed, proceed as follows:

The damaged part must be repaired immediately, otherwise the structure will break completely. The condition of the fittings must be carefully monitored, as they require more careful care. Periodically wipe the mechanisms from dust and lubricate with oil.

Operating principle of a sliding door closer

Closers for compartment doors are mechanical devices that prevent sudden collisions of door leaves. Structurally, the product is a metal body that houses a damper, a lever and a piston system. On its outer surface there is a special adapter that has an auxiliary effect on the operation of the closer.

When the sash is closed, the adapter presses on the lever, which causes the damper to operate. As a result, the door slows down, and when the damper reaches its final position, the leaf stops completely. Damping the sliding door closer helps to absorb the applied force, so the door closes without a characteristic knock or force blow.

Installation of a sliding door closer can be carried out with a closer in one direction or in both directions. As a rule, the devices are designed for door structures weighing 60–100 kg, made of laminated panels, PVC, veneer, glass, aluminum profiles, solid wood. Most often, they are installed in high-traffic areas, where constant opening and closing of the door leaf leads to a rapid loss of functionality of the entire door system.

Criterias of choice

When planning to purchase a sliding door closer, it is advisable to pay attention to its technical characteristics, which can be found in the attached instructions. Products with incorrectly selected parameters can lead to premature wear of door hardware and significantly reduce the functionality of the door leaf, therefore, when choosing a device, it is recommended to consider the following criteria:

- The type of traction mechanism installed in the housing - as mentioned above, modern manufacturers present to the market door closers with several types of mechanisms, which largely determines the location of their installation. In particular, devices with a standard rod are mounted directly on the door leaf, and devices called “elbow” are mounted on the door frame.

- Door dimensions - the wider and more massive the door leaf, the more powerful you should choose a door closer for compartment doors.

- Temperature conditions - many products operate smoothly in the range of -40...+70 °C, but some models lose their technical properties at low temperatures. For this reason, when purchasing a mechanism for unheated rooms, you need to take into account its operating conditions.

- Installation method - for glass doors it is advisable to buy devices with a floor mounting method; for all others, both floor and top mounting are suitable.

- Design – to ensure that sliding door closers fit perfectly into the overall interior design, it is best to give preference to kits that match the color palette of the door structure.

- Maintainability - if the structure fails, it should be easily replaced with a new one. In the catalog you can find universal sets of rollers with closers, suitable for all types of coupes. Our qualified employees will help with the purchase and organize its delivery in Moscow and the region.

Why is “silent” furniture so valued?

Constant background noise has a negative impact on the psyche. We may not notice it and not pay attention, getting carried away by some activity or simply “switching off” when resting after a hard day at work. However, the body cannot be deceived: noise contributes to depression of the nervous system and the emergence of a constant state of stress. And this leads to exacerbation of chronic diseases and the emergence of new ones.

Thanks to modern technologies of soundproofing systems, the entry of noise from outside into the house can be reduced to a minimum. The main task remains to maintain healing silence in the room. But how?