Types of wicker chair designs

According to the installation method, wicker chairs are divided into hanging and floor models.

The first group includes several species.

- A traditional product with a rigid frame.

- The cocoon-shaped model is complemented by wicker walls.

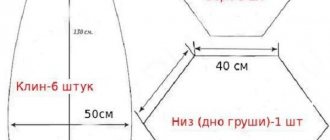

- The drop-shaped chair is more reminiscent of a fairy tale house. Ideal for children.

The structure can be mounted on a metal tripod. Its stability is achieved by a platform in the form of a circle of large radius.

If you plan to fix the chair on the ceiling, then it is worth considering that only high-quality concrete flooring will ensure reliability. In the case of voids, a high-strength polymer composition (chemical anchor) is used, into which a hook is screwed. You can use the chair no earlier than after 2-3 days. During this time, the composition will completely harden.

Coffered ceilings allow you to attach the chair directly to the beam. For these purposes, carbines or a device with rings are used, which is fixed with four bolts.

A hole is drilled in the wooden base to install a fastening bolt, which will securely hold the product.

An axial structure fixed at a certain height between the floor and ceiling will help ensure 100% safety for a hanging child seat.

In some cases, a special metal profile is used for installation, allowing the load to be evenly distributed. After finishing the work, it is masked with polyurethane beams.

In a country house or cottage, hanging the chair from a tree branch is an option.

Floor-standing models are supported by one or four legs, as well as arched runners.

Tools and materials

In order to successfully reupholster a chair, you will need a number of essential tools. We are primarily talking about a furniture stapler, which is necessary for fixing upholstery material on a wooden frame. It is inexpensive and is sold in almost any hardware store. When buying a stapler, you should not forget about staples of the appropriate size. In the case when the old filler has already failed, you will need to purchase a new one - foam rubber, batting, or both. This material is also easy to buy in the construction or hardware department.

You will probably also need a tool to remove the old staples. Although any metal stick will do the job, it is better to prepare a flathead screwdriver or even a pry bar in advance. If the chair has to be disassembled and reassembled again, then you cannot do without a hammer, pliers, a nail puller, an adjustable wrench and other required tools.

You can make the correct pattern using a small soap or a special chalk.

If it is necessary to restore the wooden elements of a chair, you cannot do without sandpaper of the required grade, a brush with metal bristles, paint or varnish. When removing fasteners, a rust-killing spray may be required. To shrink the block itself, jute twine and belts are useful.

Great idea: sew a shell pillow for your sofa and armchairs

Marine style is at the peak of fashion. Luxurious shell pillows will transform your sofas and armchairs! Spectacular little thoughts will allow kids to feel like the heroes of Andersen’s fairy tale “The Little Mermaid,” and adults will be able to relax comfortably with a book or in front of the TV. It’s not at all difficult to sew such beauty, so even novice seamstresses can try it!

You will need: stretch velvet - 3 pieces of 40 by 41 cm, thin duplerin of the same size - just one piece, any filler such as holofiber, matching threads, scissors and a sewing machine.

The most important thing is to make the pattern correctly. You can draw the future shell directly on the double sheet. Fold it in half with the adhesive part facing inward. Step back 2 cm from the bottom. Now set aside 12 cm from the fold to the edge, and 7 cm up. Connect the dots by drawing a 1/4 oval by hand.

Now divide the rounded side of the figure into equal segments and place marks - from these we will lay down “rays” to form the “crown” of the shell. So, we set aside the first beam, 26 cm long, retreating at the top point about 6 cm from the fold of the fabric. Next, using a tailor's centimeter, we will put aside 22, 17, 11.5, 5 cm in succession. By connecting the points obtained above with semicircles, we get a “crown”. Also draw slightly rounded lines connecting the top marks to the bottom ones.

Turn the folded dublerin over to the other side. If the fabric is thin, the design will be visible on the reverse side. Circle it to make a whole shell. Now, using a hot iron, glue the dublerin onto the wrong side of one of the pieces of fabric. Machine stitch along the crown and ray lines from and to the indicated points. (Only one piece of fabric at a time!)

Now fold two pieces of fabric back to back and stitch again along the lines already laid.

Types of chairs

Today we’ll talk about armchairs that are not found in every home. Their uniqueness lies in the material used. If you wish, you can make your own products from a curved surface or from lamellas (strips). Design products are much more complex; parametric furniture made from plywood has recently become popular. It contains extraordinary lines - smooth, curved, streamlined, but does not lose functionality.

Plywood chairs are varied in shape, size, purpose and methods of execution. Conventionally, they can be divided into stationary and rocking chairs. Let's try to understand their diversity using some examples.

Designer rotating model created by cross-folding lamellas.

An exclusive set of plywood furniture in the form of an armchair and a stool.

The product is made from glued plywood sheets connected into a thick mass.

An example of a parametric chair made of plywood. It is produced in a wave shape, which allows it to swing without resorting to runners.

A two-color fixed model made from small shaped elements.

Standard product "shell". It is installed on 3 or 4 legs.

Computer chair made from plywood fragments.

Model with a “house” for pets.

An example of how a product can be decorated with a soft seat and back.

Carved model of a rocking chair.

Double parametric product design.

An original model of a designer chair on three supports.

An extravagant product made of bent plywood, designed for modern interiors.

Rocking chair on runners, in a contrasting design.

Throne chair made of birch plywood.

A beautiful, unusual model, but not designed for heavy weight.

Specifications

An ordinary shell garage is designed to store one passenger car. It is made of steel or iron sashes. One is installed on the ground, and the second opens like a gate.

Materials used

In order to make such a garage, you need durable metal sheets. If they are thick, the final weight of the structure will be about a ton. The sheets themselves are heavy, so moving them may require equipment or the help of other people.

Note! The assembled shell can only be moved using a crane.

Safety

The design itself is not considered safe. Water can get into the cracks between the doors, and then there is a risk of damage to the car. Therefore, seals will be needed for additional protection. But you can replace them with canvas capes. The latter option is less reliable, since the metal under the tarpaulin is highly susceptible to corrosion.

Weather conditions are not the only problem. The car can also become a target for car thieves. Therefore, a lock is installed at the junction of the two sides of the garage. But you need to choose the most reliable protection, since shells often become the target of potential robbers.

Manufacturing materials

One of the main structural parts of an office chair is the frame, which can be monolithic or collapsible. The first forms a single whole, making the product more durable. In this case, the armrests can be removable. In collapsible models, the armrests act as an element connecting the back and seat. The connecting part can also be a metal plate.

The frame is made of high quality steel or durable plastic. The presence of a high-strength frame increases the service life of the product. The seat and back are made of multi-layer plywood. High-quality foam rubber or polyurethane is used as a base coating, which creates the elasticity of the products.

To create a hard version, no filler is used; the base is immediately covered with upholstery material. For soft and semi-soft types, polyurethane foam or foam rubber is used - the thicker the layer, the softer the product. Unique products have an anatomical shape, where there are two bases with pillows. The split back creates a massage effect and stimulates blood circulation.

Durable, wear-resistant materials are used for upholstery. These include:

- Genuine Leather. The material is strong, elastic, breathable. Disadvantages: expensive, requires special care.

- Faux leather. It is practical, durable, and UV resistant, but can change color in direct sunlight and gets very hot, creating discomfort.

- Synthetic fabric. It is distinguished by its durability, ease of maintenance, hygroscopicity, breathability, and antistatic properties. The material is beautiful, has many textures and colors. Cons: wears out faster than the first two options, can fade in the sun, absorbs odors.

Genuine leatherArtificial leather

Synthetic fabric

There are also modern models with upholstery made of rigid acrylic mesh. The material is used for covering the backs and seats of ergonomic products. The mesh allows air to pass through well, making a person feel comfortable even in the heat. The disadvantage is the insufficiently high level of strength, leading to a decrease in service life

Upholstery indicates the status of the employee, so it is also necessary to pay close attention to it

There are office chairs used in various professional fields, for example:

- medical (made of polyurethane, should be easy to process, have an antistatic effect);

- hairdressing salons (resistant to disinfection, with footrest, height adjustment in the form of a pedal);

- industrial workers (for workers in warehouses, workshops, conveyor enterprises) - monoblock rigid structures with a special vinyl coating with no texture, so as not to accumulate dirt, suitable for processing by any means.

For medical workers

Hair salonFor production workers

Properly selected mechanisms contribute to the longevity of furniture:

- Permanent contact. Serves to adjust the chair according to seat depth, backrest tilt, and height.

- Rocking mechanism. A reliable, durable spring-screw device provides swinging.

- Synchro mechanism. Adjusts the angle of the backrest, its height, and seat depth. The device is complex and expensive.

- Asynchronous. Same as synchronous, but adjusts the seat separately from the backrest.

Examples in the interior

Many people believe that English armchairs can only be placed in an “antique” interior. However, this is not true. Today, such products will look great even in modern interiors.

The English fireplace chair is made in a neutral color. Has curved wooden legs.

Fireplace "eared" chair. Has bright playful colors. Perfect for installation in the bedroom.

A spectacular chair with “ears”. The upholstery is “carriage tie”, made of leather.

English armchair with a high back. The upholstery materials are fabric and eco-leather.

Armchair in the English style, egg shape

Made in rich red color, very bright and eye-catching

Gaming chair made in English style. It has “ears” and high armrests.

English armchair in Provence style. It has delicate colors and fabric upholstery.

Classic English armchair. Made in blue color.

Review of the classic English chair in the next video.

How to do it yourself?

The easiest way is to make a frameless chair. To do this, you need to sew a cover from upholstery fabric and stuff it with foam rubber, giving it any shape. For the nursery you can make it in the form of a fairy-tale animal or a cartoon character, you can use multi-colored appliqués.

Frame chairs are made from particle boards, wooden blocks, plywood, fiberboard sheets, foam rubber and upholstery fabric. Before starting work, you need to decide on the dimensions of the future product, draw up a sketch, make a drawing, cut the fabric and cut the foam rubber.

Assembly steps:

- to make the body, you need to nail the cut out sides to the frame, you get a box;

- assembly of the folding part. We knock together three frames from blocks and cover them with plywood. The width of the resulting modules is equal to the distance between the armrests with a small margin for the thickness of the upholstery. If armrests are not provided, then the width of the seat and bed. We fasten these 3 blocks together using loops. We check that when folded they resemble a book, without protrusions or distortions;

- we process wooden surfaces with sandpaper;

- We put foam rubber inside and cover it with upholstery fabric;

- we check how the modules are laid out and screw the legs to the last part;

- Reinstall the backrest and armrests.

Decor options

The final finishing, which gives the product a complete look, is carried out before the furniture is assembled into a single structure. However, this should be done only after adjusting all the elements, because having remade them, the master will be faced with the need to re-decorate. Particular attention must be paid to sanding the edge parts remaining from the jigsaw. The main fabric is brought to P600 grit.

An additional decoration for a plywood chair can be a designer pattern that matches the interior of the room. If you have stencils (or talent), you can draw a cartoon character, an ornament, or landscapes on a stool. An optional, but stylish and functional element will be the piping along the edge of the soft seat, giving the product a finished look.

Making home furniture yourself requires at least basic skills and abilities. But making a chair from plywood with your own hands is not difficult, you just need to familiarize yourself with the production technology and the requirements for materials. Such a responsible approach will give the highest quality results.

This is interesting: Choosing a rocking chair for a summer house

What is furniture restoration and what types does it come in?

Restoring antique furniture is a labor-intensive and painstaking process, the main task of which is to restore the item while preserving its original appearance. It requires not only special skills, but also enormous patience. Sometimes, in order to bring an antique product back to life, you have to completely disassemble it, put each individual element in order, and then put it back together again.

Depending on the purpose of restoration, restoration can be either museum or commercial.

- During museum restoration, the master is faced with the task of preserving the current condition of the object: since the furniture of the museum collections will not be used, interventions in the structure are undesirable and are kept to a minimum.

- Commercial restoration assumes that after restoration the furniture will be used for its intended purpose, so it is important to restore not only its appearance, but its functionality.

Restoration does not always require disassembling the product. Sometimes it is enough to restore only the damaged part, update the decorative coating or change the upholstery.

Decor

When creating an unusual room interior, decorative furniture elements are important. Voltaire's chairs don't have so many of them:

Carriage tie. This design looks luxurious and expensive. Initially, the method was used to uniformly distribute the filler. To apply this decorative effect, you will need a thick fabric without patterns. Suitable leather, satin, high quality leatherette. Only dense material will not tear when tightened. On a canvas with drawings, the carriage tie will be almost invisible. Carved frame. It is fixed at the bottom of the product or frames the back. The carving looks harmonious in tandem with the elegant shape of the English chair

When decorating, it is important to adhere to the measure; the width of the decor should not exceed 8 cm. Bent, turned and carved legs. Great idea for decorating furniture

Curves may be present on all 4 legs or only on the two front legs, while the back legs remain straight. Decorative rollers. The upholstery of the products can have folds and be complemented with interesting overlays with silk tassels.

Preparation of the drawing

Surely, the diagram of the chair you like is freely available on the Internet. It specifies the exact dimensions, necessary materials, and tools for manufacturing. If you are not satisfied with the presented models, you can study several of the most attractive ones and model your own circuit.

By making a chair from plywood, you can not only create a high-quality piece of furniture, save money, but also get great pleasure from the work.

In order to make a drawing correctly, design your chair on paper, ideally from several angles. Visually divide it into main parts and draw them. You may need patterns, a pencil or marker, a ruler, a tape measure, a corner, and scissors. Select sizes based on your own needs.

A rocking chair made of plywood with your own hands is an excellent option for relaxing in the country, in a country house, or just in nature.

Step-by-step manufacturing instructions:

- Transfer your drawing from paper to a sheet of plywood;

- Saw the parts of your chair;

- Sand the cut areas;

- Pre-assemble your chair without using fastening parts. Use helpers. This is necessary to deliberately eliminate shortcomings.

- Glue the necessary parts;

- Drill holes for self-tapping screws.

- Connect all the parts together.

Don’t be afraid to experiment; as a result, you will get a comfortable, beautiful and original piece of furniture.

Alternative solutions

Structures made from metal profiles have a lot of advantages, but some are not satisfied with their weight, problems with transportation when they need to move often, and some other nuances, so alternative solutions are selected. If you have to move often or go on vacation, then you can use a shell awning.

Essentially, this is the same garage, but instead of sheets of metal, it uses high-strength fabric. It does not allow precipitation, wind or sunlight to pass through. In some cases, a tarpaulin is used for this, but it is better to use polyester fabric, which must be impregnated with special compounds. In addition, such an awning can be a good option for temporary housing on vacation, at the cottage, and so on.

Nuances of choice

Weaving furniture from artificial rattan or purchasing ready-made products requires you to understand the differences between brands of poly rattan. The fiber is made from primary granules of HDPE (low-density polyethylene), polyurethane and polyvinyl chloride (hereinafter referred to as PVC). Each material gives the final product its own characteristics, which must be taken into account if you decide to purchase fiber and weave interior or decorative items.

| Polyrattan type | Material characteristics |

| Polyethylene |

|

| Polyurethane | Elastic material, resistant to cracking. Best suited for furniture that will be used intensively. Resistant to mold and UV rays. Polyurethane loses its properties during processing and is therefore unsuitable as a recyclable material. |

| PVC rattan | For manufacturing, polyvinyl chloride is used in combination with additives that provide elasticity to the material. Of all the types, this artificial rattan is least suitable for wintering at low temperatures. In addition, it can also be damaged by strong UV exposure. Such furniture must be removed or protected with covers. |

Carefully study the characteristics of the material before placing an order. Otherwise, you risk getting something that is not what you need. We remind you: high-quality polyrattan has a rating of 5 on the material aging scale!

It is necessary to choose poly rattan based on the quality characteristics of the furniture you are interested in. Will it be used frequently or occasionally

The cost of faux wicker furniture can vary greatly, so it's important to understand how much you're willing to spend and whether it's necessary. There is no point in giving large amounts of money if you come to the dacha only on weekends exclusively in the summer

But if you take furniture to a house where you live permanently with your whole family, you simply need to think about the quality of the materials.

Who might be interested in a polyrattan furniture set? First of all, these are the owners of country houses and summer cottages. Such furniture will allow you to decorate terraces or living rooms with high quality, creating a characteristic light color. Artificial rattan goes well not only with textiles, but also with leather, glass, and metal. It can even be seen in offices, where stylish sets decorate reception areas and meeting rooms.

Second on the list, of course, are the owners of cafes, restaurants and other entertainment venues who need a high-quality interior that can withstand intensive use. In this sense, artificial rattan is the best way to invest in the interior. Visitors like this kind of ambiance, which means it will attract customers. Openwork hanging chairs, furniture such as papasan and mamasan look especially impressive - they are large in size, allowing an adult and a child to sit in it. A set of wicker sun loungers by the pool will turn your summer cottage into a tropical beach. Artificial rattan is also used to decorate counters in stores - this is very impressive furniture that at the same time meets sanitary requirements.

Technorattan furniture is even becoming a business item. Not only sales, but customization or production of rattan itself. Nowadays it is done not only abroad, there are domestic companies that work with high-quality raw materials.

Plywood selection

Chair made from a sheet of plywood: top view with dimensions.

The thickness of this building material has a wide range, and processing methods are chosen taking these parameters into account. If the thickness does not exceed one and a half millimeters, such a sheet can be cut with a hand jigsaw. Up to 6 millimeters, cutting is done with an electric jigsaw, or a circular saw can be used. Plywood, like other types of wood, is a fibrous material, so chips and cracks cannot be ruled out during the process of cutting sheets or sawing. It happens that it is necessary to work across the fibers. In this case, weakening cuts are first applied; they are made parallel to the sawing line using a sharp knife.

For a good rest in a city apartment or in a country house, you first need comfortable furniture, and a hand-made chair will be a very popular interior element. Rocking chairs are especially popular, or you can choose a regular option. You can choose the model you like based on a ready-made sample or create a completely exclusive version, your own.

Chair elements

To make such a chair you will need only one sheet of plywood 1250x2500 mm.

Drill holes for screws in the places where the fasteners will be, and sand each cut out part. While the single structure has not yet been assembled, prime each element and paint it with weather-resistant paint. Do not begin assembly until the parts are thoroughly dry. You should start assembling with the seat and backrest. They can be assembled from thin strips. The shape of the seat of the chair should be curved, taking this into account, the strips are glued.

Next, the assembly process consists of twisting all existing parts with self-tapping screws

Please note that the screws must have the optimal length; it is unacceptable for the ends to stick out from the opposite side after tightening. In addition, the tenon connection of elements can be considered the best, and only in cases where this is not possible, we use glue and self-tapping screws. At the same time, mask the screw caps with plugs

You can choose the appropriate color at any hardware store.

At the same time, mask the screw caps with plugs. You can choose the appropriate color at any hardware store.

https://youtube.com/watch?v=7H5W12IiGHA

To make an excellent chair out of plywood with your own hands, you will need skill and perseverance, as well as a desire to try yourself as a designer. Furniture made from plywood is always a good idea, and it’s easy to make it a reality!

What you need to know when making a chair from plywood

Plywood is sheets of wood glued together that have high strength, a smooth surface, an attractive appearance and are easy to process. There is a wide selection of material thicknesses. Each type of sheet requires basic knowledge of cutting techniques.

Necessary tools and materials

To make a chair from plywood with your own hands, you should prepare the following tool:

- sheets of plywood with a thickness of 15 mm;

- tape measure, pencil, scissors;

- hand saw or electric jigsaw;

- screws and thin nails;

- paint, varnish and stain;

- wood glue;

- foam rubber and upholstery material (if you plan to manufacture soft components).

Tips for choosing plywood sheets

Due to the existence of a large number of types and grades, you need to know exactly which plywood to choose in a given case:

- Visible furniture parts should be made from elite sheets that will not develop chips or cracks during the cutting process.

- If you plan to paint or laminate the chair, 1st grade plywood is suitable. For invisible parts, choose grade 2.

- It is forbidden to use raw materials of the 3rd and 4th grades in the manufacture of furniture.

- A chair that will be used in dry rooms can be made from FK brand plywood.

- The FSF brand is perfect for garden furniture.

Drawings of designer chairs

There is a high probability that the diagram of the model you like is freely available, indicating the exact dimensions, type of raw materials used and the sequence of work. You can carefully review several options and determine how a particular chair is made. This will help you draw a diagram and drawing yourself if you don’t have them.

Features of cutting, processing and fastening of canvases

The cutting method directly depends on the thickness of the raw material. Sheets of plywood with a thickness of 1.5 mm can be easily cut with a kitchen knife, 1.5-6 mm with an electric jigsaw, and more than 6 mm with a saw with a disk.

After cutting, be sure to sand the ends with sandpaper and remove dust. In addition, to protect against the destructive effects of moisture, it is advisable to treat the surface with antiseptic impregnations.

Regardless of the fasteners used, holes of the appropriate diameter should be drilled before screwing them in. If the plywood is made of soft wood, special protective gaskets are used before joining.

To prevent the material from breaking off at the fastening point, the distance from the edge to the screw must be at least 12 mm.

AppleMark

AppleMark

Step-by-step instructions for performing a model on three legs

To make a chair with your own hands from plywood, you can use the available diagram of a hemispherical model with three legs. The project includes 1 piece with two legs, 1 with a back support, 2 pieces of armrests and 9 semicircular blanks for assembling the seat and backrest.

First you need to scale the drawing to the required size and draw patterns. Then transfer them to sheets of plywood so as to save material as much as possible.

The cutting is carried out with an electric jigsaw. In this case, all movements must be smooth, without stopping or increasing speed, because they will be clearly visible and will require lengthy grinding. After all the workpieces are ready, their edges are treated with sandpaper, antiseptic and wood glue to prevent damage to the material.

Assembly is carried out in the following sequence:

- A workpiece with front legs is inserted into the second groove in front of the middle part with a rear support, obtaining a stable structure that will be convenient to work with in the future.

- Then semicircular identical parts are mounted in the remaining 9 grooves.

- At the final stage, the edges of the seat elements are connected to the armrests.

Before installing all components, the counter grooves are generously lubricated with wood glue or PVA and secured with clamps. This model does not require the use of screws as fasteners, since after drying the connections are strong.

The finished chair is coated with a layer of varnish. You can complement the furniture with soft pillows and covers.

Other variations on the theme of homemade chairs

Numerous ideas and drawings give the novice master a lot of room for choice. Some models may seem quite difficult to implement, others are simple but original.

Rocking chair

The manufacture of such furniture is assembled according to the same principle as other chairs, but there is one stumbling block - the runners. This can be avoided by using thick boards or timber, but such material is not always available. Replacing it with 3-layer plywood solves this problem, but there are some nuances:

- the middle layer must be twice as thick as the outer ones;

- if the glue is PVA, then small nails are used as reinforcement;

- all glued connections require double-sided diagonal fixation with self-tapping screws;

- the supporting surfaces need protection, this is provided by: rubber sheets (5 mm) or thin slats made of wood and hardwood.

The choice of material depends on the characteristics of use. If the furniture is intended for a summer house or country house, then treatment with an antiseptic is mandatory. A combination of wood and metal is possible. The first is used for seats, the second for the frame.

Shell chair

This type of furniture looks unusual, but to make it yourself you need almost mastery of a jigsaw. All geometric details are complex, deformation of the plywood is necessary, so without an accurate diagram or a computer printout, it will not be possible to do the job adequately.

To fasten the parts together, use wood glue, and to fix them, use a clamp. If you choose fastening with self-tapping screws, then they must be deeply embedded in the wood. The finished shell furniture is sanded and coated with several layers of varnish.

Furniture made from stumps, driftwood and their “colleagues”

It is very difficult to carve such a chair with your own hands, however, with a lot of time, imagination and perseverance, you can get a real work of art. Furniture made from branches, roots and intricately curved branches can decorate not only the site, but also the interior of the home.

It is not difficult to create a unique but simple chair with your own hands. You can use wood, metal, rattan or plastic bottles. The main thing is desire and perseverance in achieving the goal.

You can learn about the intricacies of making a shell chair by watching this video:

DIY garden chair

Before starting work on the manufacture of the chair, it is necessary to prepare the following materials and devices:

- cedar veneer;

- screws;

- wood glue;

- sandpaper;

- finishing varnish;

- drying oil;

- scotch;

- thick paper for patterns;

- plane;

- saw;

- milling equipment;

- hacksaw;

- drill;

- clamps;

- a simple pencil;

- measuring tape.

Prices for the range of drills

Drill

Approximate diagram of creating a chair

Preparing parts

Step one: first you need to make patterns for the design, marking the dimensions of the parts on thick cardboard. In our case, we should get the following elements:

- legs (4 pieces) – 2x25x78 centimeters and 2x7.6x53 centimeters;

- back - 2x28x91 centimeters;

- armrests - 2x12x40 centimeters (2 pieces) and 2x7.5x61 centimeters;

- connecting strip - 2x5x58 centimeters;

- additional strip (2 pieces) – 1.2x2x2.5 centimeters.

Garden chair elements

Step two: you need to cut out the parts from cardboard, and then transfer them to the wood (circle), after which you can saw the parts of the future chair. This should be done very carefully - the peculiarity of cedar boards is that they are susceptible to chipping, so cutting should only be done along the grain.

Sawing the parts

Connecting parts

Step one: before starting assembly, all parts must be thoroughly treated with an antiseptic against fungus and dried. Only then can you proceed to the next steps.

Preparing the product for processing

Step two: we adjust the finished parts to the required size and at the same stage leave markings for the holes for fasteners.

We trim the parts of the structure exactly along the intended contour

Step three: use a drill to make holes for the fasteners, and then fix the parts together.

The location of the boards affects the strength of the entire chair frame

Step four: fix the chair leg (back) at an angle of 90 degrees, and fix it on the other side in the same way. It is necessary to connect the sides of the structure.

The end parts of the planks and the opposite ends of the legs must match, which will allow you to obtain the correct location of the structure

Step five: place the supports and then secure them with clamps.

The joint should be very tight

Step six: install the backrest guide from above using screws, adjusting it to the crossbar from below. We mark the markings with a simple pencil on all the crossbars, as well as on part of the back, after which we make a hole, holding the bar.

We fix the planks one by one

Step seven: make curves by cutting the boards along the marked lines.

Installing the rail on the seat

Step Eight: The last step is to sand the entire surface of the chair using sandpaper.

It is important to achieve perfectly smooth wood without burrs. Then you need to treat the product with heated drying oil and cover it with several layers of varnish

After applying the varnish, the chair should dry for some time.