If you want to freshen up the decor in your home and also dream of trying your hand at carpentry, these two desires can easily be combined. An excellent solution is to make wooden chairs with your own hands, photos of which are presented below. These pieces of furniture are always appreciated for their practicality. They will come in handy in a city apartment, in a private house, and in a country house. The usual design is simple and quite within the power of a novice carpenter. And for those who have experience, you can choose a more complex drawing of a chair with a backrest. In any case, the homemade product will certainly be in demand.

Required Tools

To make a chair you will need a set of the following tools:

- Hand or electric saw;

- Hammer;

- Screwdriver;

- Electric or manual jigsaw;

- Chisel;

- Electric or manual plane;

- Mallet;

- Grinder;

- Furniture stapler;

- Clamps;

- Angle ruler;

- Yardstick.

Options

Drawings of chairs that can be found in the public domain offer a choice of several of the most common and popular models. Folding and with a back, rocking chairs and on wheels differ rather in additional elements, but at the same time they are united by a common scheme.

Therefore, after practicing on easy modifications, which include a stool, it is easy to later move on to more complex and original options.

This does not mean that everything will be simple; it will require patience, skill and mastery of the main tool of any home craftsman - your own skillful hands.

Skills in handling tools will be useful in any case, since without them it is impossible to create wooden furniture. By devoting some time and attention to creativity, you can count on an excellent result that will delight your household and become an object of pride for the master.

The difference between a chair and a stool

A classic chair consists of legs, a seat and a back. The stool has no back - this is its main difference.

Stools can be used everywhere: At home, outdoors and in the garage.

A chair is, first and foremost, a home furnishing item. Moreover, as decoration, beautifully crafted chairs can decorate any room.

Action plan

Before starting work, you should carefully prepare and study a lot of samples; photographs depicting chairs made by yourself in various modifications using different types of wood will help with this. You need to take care of the availability of tools, prepare enough lumber, or better yet, with some reserve. Such forethought will save valuable time and nerves if something does not go as planned during the process.

Having the ability to draw and create drawings will provide invaluable assistance in the project, although it is quite possible to get by with ready-made instructions and photographs of ready-made models. You will also have to take care of the presence of fasteners, screws, fittings, glue and other important details for production so that the structure is durable and reliable in operation.

Wood selection

Wood for making chairs can be hard or soft. The first type of wood includes: beeches, oaks, birches, maples, walnuts, cherries. Such options have good strength characteristics and retain their shape when deformed.

The service life of such wood is measured in tens of years, but the process itself seems more labor-intensive due to the density of the material. Also, the high cost of wood requires more careful and lengthy work.

- Softwoods include alder, spruce, pine, linden and aspen. They have lower strength characteristics and are less resistant to scratches and chips.

- But there is also an advantage - they are much easier to process. You can easily do the following operations with them: cutting grooves, sawing, gluing and polishing.

- And soft wood costs an order of magnitude less than hard wood. There are types of trees that it is better not to handle with your own hands.

- These include yew, acacia and boxwood - these are all trees that have a particularly durable species.

For the manufacture of chairs, timber 60x40 or 40x40mm is usually chosen. Also suitable are boards whose thickness is 10-15 mm. You can use a small diameter log to cut boards using an angle grinder and an electric saw.

In the process of selecting a workpiece, it is necessary to check its quality. The wood must be dry, smooth, without cracks or chips, and also have the correct shape. Wood blanks are coated with a special antiseptic to increase the moisture resistance of the material.

Additional Tips

If you make furniture from solid wood, it is important to ensure that it is not only beautiful, but also safe. This is especially necessary if there are small children in the house. So, all surfaces and corners of boards and bars must be sanded. Then they should be painted or treated with stain and varnish. As for the latter, it is better to use one that is odorless - water-based. This way you can be sure that the coating is harmless.

It has already been said above what kind of wood chairs are usually made from. But there are some nuances here too. Red rocks, for example, look simply gorgeous and have a beautiful structure. Linden is lighter than oak, but with the help of stain it can be tinted to match it. Carved chairs look beautiful in elegant interiors. So if you have carving skills, do not miss the opportunity to practice on the back and even the legs of the product.

If you are making furniture for a baby, do not use metal corners, because he can get hurt on them. The parts can be connected with screws or dowels. To make the structure more stable, simply choose thicker parts.

Types of chairs

There are many types of chairs. We will look at two of them: a kitchen chair for dining and a living room option. They both have a similar shape, but the dining chair has a narrower seat.

The following materials are used to produce chairs:

- Metal blanks;

- Wood;

- Polyamides;

- Composite materials.

There are special versions of chairs made of glass or rare stone. Such designs have, first of all, decorative value.

Of the above materials, the most practical is wood - it is easy to process, has high strength characteristics and looks aesthetically pleasing.

Wood selection

Before you make a chair, you will have to learn the basics of carpentry and understand the features of using the most popular types of wood. Some types of wood are easier to work with than others and also have a greater margin of strength.

Glued is cheaper than solid, although in this case it is necessary to take into account the final goal and purpose. These subtleties will have to be taken into account so that the resulting product is durable and beautiful. It is important that the lumber is of high quality and has undergone the necessary pre-treatment.

No cracks are allowed on the boards; the edges must have even cuts and be thoroughly cleaned. Remaining knots can affect the production result, so you should not use such specimens to make your own work easier.

Pine and beech are the right choices, as they are strong enough and have the necessary characteristics to create a high-quality product. In addition, these breeds are quite common and availability problems usually do not arise. This is exactly the case when excessive savings are not the best choice, since we are talking about the production of an item of everyday use.

Design differences

Models with complex shapes are unlikely to be suitable for making chairs yourself. At home, it is quite possible to make a wooden chair of a simple design.

For its production you will need the following elements:

- The presence of two front and hind legs;

- Four drawers for secure fastening of the seat;

- Four connecting strips for securing the legs;

- Seat;

- The back of the chair.

Slats and drawers can be used in large quantities if you think that the chair will not have enough stability. The main disadvantage of the model is its simplicity. Against the backdrop of a beautifully decorated room, an ordinary-shaped chair will fall out of its interior.

Popular and beautiful models

The most common models of chairs among home furniture makers are:

Massive products. Such designs are the easiest to manufacture .

There are no curly lines here. Therefore, the item is suitable for beginners to craft. The massive chair is practical and easy to use. It is stable and fits well into different designs.Its only drawback is its large size, which does not allow furniture to be installed in cramped and small spaces.

When choosing such a model for a dining room or kitchen, you should choose original designs that differ from the standard options. It is better to make the frame of the chair from solid wood.

In this case, carved legs and an elegant back made of slats will look good. The seat can be made of plywood and covered with textiles.

- Folding beds. This option is more appropriate for street use.. A chair made of natural wood, which is lightweight and quickly folds and unfolds, is useful for an outdoor picnic.

It is compact in size and light in weight. Also, such a piece of furniture can be installed in the garden, on the terrace, or on the balcony.As for the dimensions of a folding chair, you should choose models with a height of 75 cm, a width of 39 cm, and a height from the floor to the seat of 30-35 cm.

- Armchair chair. It is a little more complicated to make and requires the experience of a carpenter. But such a piece of furniture will fit harmoniously into the recreation area. Its dimensions can be similar to those of massive models, or larger or smaller.

Advice : novice craftsmen should opt for classic massive products.

Making your own chair

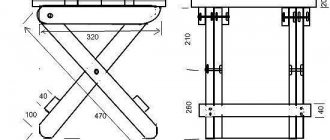

Any production begins with a drawing. Even the simplest sample requires a scheme according to which the necessary parts will be produced. When the sketch of the model has been created and thought out, wooden blanks of the required sizes are cut.

- The dimensions of all prefabricated units must be maintained with an error of no more than 1 mm.

- Otherwise you will have to do extra work with a file.

- Let's take the standard dimensions of the chair (LxWxH) - 500x410x900mm.

Preparation of assembly units

After making the bars of the required dimensions, you need to make grooves in them into which the connecting elements will fit. These grooves can be made with a hand router, having previously marked in which places the recesses will be cut.

The surface in the area of the resulting grooves must be cleaned with a file and then sanded. Also, on all wooden surfaces, right corners are rounded.

Making a soft seat

After you have cut out a piece of plywood of the required thickness, you need to put it on a piece of foam rubber and trim the latter, leaving 1-1.5 cm around the edges.

- Then cover the seat with fabric around the perimeter with an extension of another 5-6 cm.

- Glue the plywood to the foam rubber with a special glue, and then cover the seat blank with fabric and fasten it with a furniture stapler.

- Drive the staples at a distance of no more than 1 cm to avoid swelling.

To begin with, four staples are attached in the center of the surface, and then staples are placed in other directions. After the fabric is tightly secured, its excess sections are cut off with scissors.

Chair assembly

It is done in the following order:

- Lubricate the place where the front drawer is attached with glue and attach it to the front legs of the chair, using a clamp for reliable fixation;

- Glue the back drawer and back in a similar way and attach it to the rear legs of the model;

- Wait a while for the glue to dry;

- After drying, attach the soft seat and connecting strips to complement the fastening of the legs;

- The finished model should be turned upside down to dry completely.

Final work

After the chair is ready, you need to look again at all the surfaces and joints. Excess burrs are carefully cleaned off, and all sharp corners are rounded. The holes for the screws are filled with putty, and the entire structure is covered with bioprotection for wood.

The final operation is to coat the chair with varnish in 2 layers; if desired, you can coat the product with enamel.

Decoration

Furniture assembly work ends with decoration. Before decoration, the surfaces are treated with sheets of sandpaper and coated with clear varnish. Decoration is carried out using the techniques of decoupage, patination, engraving, simple or artistic coloring, etc.

Wood carving allows you to create original patterns and engravings. The design can be contour, geometric, relief, etc. Fine carving will give the room lightness and airiness. After engraving, the product is coated with transparent varnish or thick paint. The design method is suitable for rooms in the Art Nouveau, Baroque, and Shabby Chic styles.

Antique chairs are decorated with your own hands using decoupage techniques. Furniture is complemented with floral prints or reproductions of art paintings, artificially aging the surface. The work is completed by varnishing the surfaces. The decor will suit rooms in retro, vintage, Provencal styles.

Coloring allows you to harmoniously fit furniture into the interior, making models contrasting or neutral. When applying enamel, it is possible to use patination techniques, stylization like marble and glass. Paints can be translucent or dense depending on the interior design.

Photo of a homemade high chair

Drawing up a drawing

The easiest option for the master is to choose a ready-made drawing with a detailed description of each element of the chair. The optimal sizes of furniture are designed for the average height of men (170–175 cm) and women (160–165 cm). In accordance with these parameters, the ideal indicators of each element are calculated:

- height of the structure to the seat - 40–45 cm;

- seat depth - 50 cm, width - 40–45 cm;

- back width - 30–40 cm;

- the distance from the floor surface to the upper edge of the chair back is 85–90 cm.

The back of the chair is made straight or with a slight slope of 8–12º. Typically, the maximum loads that furniture can withstand do not exceed 100 kg. Drawings with standard dimensions can be used by people with average height and weight. In all other cases, it is necessary to select models that correspond to individual parameters. To do this, you need to sit on the seat and keep your knees at right angles. Then measure the distance from the knee to the hip, from the hip to the neck, which will allow you to clarify the optimal depth and height of the product.

Making your own baby high chair and stool

Making chairs is possible only if you have precise parameters. There are other recommendations that allow you to choose the right sizes. A certain person's height corresponds to the specified furniture height:

- 146–177 cm - 43 cm;

- 159–188 cm - 46 cm;

- 174–207 cm - 51 cm.

The most comfortable chair is considered to be one with a back, in which the depth is equal to 2/3 of the length of the thigh. It is in this position that correct posture is maintained. Based on individual parameters, the finished scheme is adjusted. To do this, it is enough to change the dimensions that do not fit: the length of the legs, the height of the chair, the seat parameters. When changing dimensions, be sure to respect the scale. An excellent option would be to use special programs that independently create drawings based on the entered data.

Chairs with armrests are considered the most comfortable. The models reduce the load on the spine and can be used in any room.