Felix

4257 0 0

Felix September 25, 2018Specialization: philological education. 20 years of experience as a builder. Of these, for the last 15 years he led a team as a foreman. I know everything about construction - from design and zero cycle to interior design. Hobbies: Vocals, psychology, quail breeding.

A bed with gas lift is a convenient storage system.

Greetings, my dear readers.

Nowadays, beds equipped with a lifting mechanism are becoming more common. After all, this is not only a sleeping place, but also a storage system. Most often, raising the bed is provided by a gas lift. With its help you can easily access the spacious box located under the bed.

I will tell you what a gas lift is, how to choose it correctly and install it yourself.

Application

Initially, gas lift became an extremely useful solution in the automotive industry. Its installation was carried out on trunks and hoods. The driver himself does not hold the structure, since the elevator performs this function instead. The lifts lifted and held a certain weight, preventing sudden falls, damage, etc.

But today these elements have gone much further. The main areas of application include:

- furniture industry;

- construction;

- production of doors, frames and showcases;

- medical industry;

- production of office equipment;

- weapon;

- aerospace structures;

- robotics;

- household appliances and more.

Elevators can have different sizes, they differ in their design and structure, which allows you to find the optimal mechanism for each specific case.

But we are interested in gas lift as furniture fittings. If you look around furniture stores in St. Petersburg or Moscow, or look through the pages of catalogs in Hafele Shop Ru, you will find a huge number of variations and manufacturers of gas elevators.

Main selection criteria

To choose the right gas elevator, you will need to determine:

- type of system;

- technical specifications;

- manufacturer.

Types of gas lifts. Their advantages and disadvantages

To assemble furniture we use:

- direct action lift;

- reverse action lift.

A direct-acting gas elevator operates on compression. This is the most popular version of the lifting system, as it is simple to manufacture, lower cost and easy to install.

Direct acting gas lifts

Reverse-action furniture lifts, on the contrary, work to extend the rod. Fittings are more complex to manufacture, as high precision is required during production, which primarily affects the cost of the equipment.

Reverse action furniture lifts

Gas elevators can also vary in how they open. There are models:

- with a step-by-step design, that is, manual opening. The cabinet door or other folding element in this situation is equipped with a handle that facilitates the process of controlling the lifting mechanism;

- with automatic design. In this case, the lift is equipped with an electric drive that drives the lifting mechanism.

Electric furniture lift

Automatic fittings are installed on cabinets located in a place inaccessible to standard opening (for example, high) or where manual control is difficult (for example, due to the heavy weight of the bed). It should be noted that the cost of such accessories is significantly higher.

Determination of technical parameters

In order for a pneumatic gas elevator to serve for a long time, you will need to determine:

- compression force;

- equipment dimensions.

When calculating independently, the compression force of the spring is determined taking into account:

- weight of the folding structure (facade, bed, rising part of the chair, etc.);

- the distance determined from the center of the axis of operation of the equipment to the middle of the lever (center of gravity);

- height between the center of the system axis and the equipment mounting location;

- number of installed lifting mechanisms.

Data and calculation method for gas lift for furniture

In order not to make complex calculations, you can use the recommendations of experts:

- It has been proven that when choosing cabinet lifts, a 1 kg load will require a lifting force of 10 Newtons. Manufacturers produce lifts of different strengths. The most popular devices for kitchen cabinets are 60 N - 140 N, and for sofas, beds, chairs - 1000 N;

- When choosing lifts for other pieces of furniture, the device classes are taken into account.

| Class | Maximum weight, kg |

| 1 | 80 |

| 2 | 100 |

| 3 | 150 |

| 4 | 200 |

If the lift class is selected incorrectly, this does not mean that the mechanism will not work. However, the service life of furniture fittings will be significantly reduced.

The next step is to determine the dimensions of the furniture lift. The length of the gas lift depends on the size of the cabinet door or other lifting device.

Popular manufacturers

When choosing furniture fittings, you also need to pay attention to the manufacturer, since the reliability and service life of the equipment depends on the manufacturing company. Currently, products manufactured by the following companies are popular:

Currently, products manufactured by the following companies are popular:

Performance characteristics

In order for the product to serve for many years and not make any noise, you should take a responsible approach to choosing a lifting mechanism. It should be based on the dimensions of the structure and its weight. The width is determined by the number of beds:

- 1.2 - 1.8 m - double.

- 0.9 - 1 m. - single.

- 0.6 - 0.8 m. - children's.

The weight and height of a mattress directly depends on its thickness. Some models provide for adjusting the height of the mattress by moving the slats. Also, the weight of the mattress is affected by its filling.

These parameters directly affect the choice of lifting mechanism and the power of the power elements. In addition, lifting mechanisms are classified according to the method of transformation. If we are talking about a wardrobe bed, then the transformation occurs from a horizontal to a vertical position, and vice versa. There are two design solutions:

- It takes a lot of effort to lift the base of a bed with a mattress. It is necessary to install powerful mechanisms with gas lifts.

- If the bed rises from the side, then a spring block can be used.

There are transformable beds in which only the sleeping area is raised. The lifting mechanism can be presented in two options:

- It rises at an angle to one of the sides according to the principle of a book.

- The berth rises horizontally, moving to the side. Stops at a certain height.

Functional types

For each of the above types of activities, a gas lift of the appropriate type can be selected. There are several main criteria for choosing such systems.

Direction of action

In this case, direct and reverse gas lifts are distinguished. The work of the former is based on compression of the rod. By default, this element is extended to its full length. It is this type of gas lift that is used in furniture production. As for the reverse system, the rod extends from the inside.

Cylinder pressure level

Springs with a high or low degree of pressure can be installed in the design.

- For the first, a combination of a rod and a cylinder filled with inert gas is used (non-separable product). Gas displaces the rod part from the cylindrical part. As the rod deepens, the gas volume is reduced, which leads to an increase in the degree of spring pressure.

- The latter are represented by two hollow cylinders. The spring pressure in them changes in proportion to the volume of pumped gas.

It is worth noting that low pressure systems have virtually no operational restrictions. They are easy to use and maintain, starting from the stage of installation into a furniture structure (or any other).

Type of spring lock

Gas lifts with a lockable spring can be considered a separate functional type. The stop element is installed on a pressure tube or rod, which allows you to stop the progress of the structure at the right moment. In particular, this is relevant when adjusting the height of office chairs. The gas lift is fixed by means of a special button that controls the piston valve (the system is set in motion by pressing this element).

From a technical point of view, there are three methods of blocking:

- Standard (with a fairly elastic fastener). Over time, the risk of spontaneous movement of the piston increases.

- Ambivalent. When the piston is pulled out, the fixation is more rigid, which increases reliability.

- Combined. Equally rigid fixation, preventing free movement of the spring element in any direction if the lever in the structure is not pressed.

Naturally, the degree of reliability of the system affects its final cost.

Gas

The bed gas lift is based on a simple mechanism that operates smoothly, silently and reliably. If the load is correctly calculated and a shock-absorbing device is selected, such a product can be used for up to 10 years. The bed cabinet includes additional equipment with a pneumatic gas lift with two stops.

Experts recommend choosing the latter option, which is characterized by ease of use and smooth operation. The cost of such a gas lift for a bed is higher compared to analogues, but the use of the device is fully compensated not only by convenience, but also by safety.

Based on the operating principle, elevators are divided into two groups:

- Automatic, not requiring human effort and close control to raise/lower the bed.

- Frictional, with less pressure, but providing for stopping the raised part of the bed in any desired position.

Please note that the former are more popular, therefore they lead in sales on the market.

Making a lifting frame

Assembling a lifting frame with your own hands consists of two main stages, these are carpentry and carpentry work and the processing process.

Carpentry work:

assembly begins with the preparation of parts for the frame, according to the drawing, which indicates all dimensions; Next, the base of the frame is assembled, this is a box of calibrated boards. The process must be carried out on the floor to avoid distortions. To align the corners, you must use a construction square; The structure is tied using metal corners, and for strength, the joints are glued with wood glue

They are needed to attach lamellas to them. The size of the slats should be within 20 by 80 mm; The same slats act as slats, only their length will correspond to the width of the bed. They are fastened to support rails along the frame, in increments of no more than 15 cm. Plywood is also suitable for slats, but in this case the installation of a central partition is required; At this point the carpentry process is completed and the lifting frame is ready.

Frame processing:

- this process involves refining wooden parts with sandpaper or a special sanding machine and coating them with varnish;

- One of the nuances of preparing the frame is a plywood sheet, which lies on the lamellas to evenly distribute the load. Or you can lay the lamellas with a step frequency of 8–10 cm.

How to properly install a gas lift on a kitchen cabinet?

At the beginning of work, you need to select a tool and make markings, purchase gas lifts and components. Gas lifts are characterized by different parameters and the force at which the spring is compressed. The device must match the size of the furniture. Typically, the dimensions of furniture are standard and there are three main options for gas lifts in size. You need to know the maximum extension of the rod and the length of the folded mechanism.

The compression force is needed when calculating the design for doors of different weights, taking into account the entire coating and fittings. The amount of compression of the spring is standardized and indicated in the technical data sheet of the mechanism, measured in newtons and can be 60, 80, 100 and up to 140 N. Based on the weight of the door, the gas lift is calculated based on a kilogram of door mass per 10 newtons of compression force.

There are many ways to attach. Flat platforms are often used, mounted on the sides of the cabinet with screws and self-tapping screws. Screw-in holders are used for wooden furniture.

What tools will be needed during installation?

You need a set of tools - one is not enough. If you want to install it yourself, you will need:

- Meter, ruler or tape measure.

- Hammer and pliers.

- Drill (preferably electric).

- Screwdriver or screwdriver (the latter is preferable).

Step 1. Marking before installation

Before installing the device, markings are made in the cabinet niche and calculations necessary for installation are made. The centers of the mounting points are also marked on both sides of the niche and on the door.

Step 2. Installation work

Installing a gas lift on a kitchen cabinet is carried out as follows:

1. First, the bases are fixed to the sides of the cabinet in the places marked earlier.

2. Plates and brackets with springs are installed. The bracket is screwed in and the gas lift head snaps directly onto it.

3. The center of the fastening must coincide with the marked one; the base is fastened in different versions with 3 or 4 screws or self-tapping screws. The head of the structure is fixed in the holes.

4. The same steps are taken to secure it to the furniture door. The hinge angle should be 8 degrees.

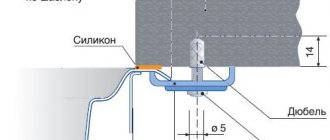

Gas lift installation diagram

5 installation tips

In connection with mounting the device yourself, we can provide some useful tips:

- The mechanism must be fixed to the sides of the niche - otherwise the fastening will be skewed.

- The door in the cabinet must be firmly secured with two additional furniture hinges.

- It is better to choose elevators with a force of up to 80 Newtons; doors of greater mass are not available in practice.

- Door fittings must be installed before gas lifts are installed.

- When installing a kitchen cabinet, it should not hang on the wall.

The upper cabinets are equipped with a gas lift.

Gas lifts are very convenient and expand the functionality of cabinets and other furniture. The low price and the ability to buy and install them yourself from the facade give them advantages over other structures. The disadvantage of the device is the inability to repair an already installed gas lift for the kitchen. There are many videos on the Internet and complete instructions on how to attach the device. You can place it on a cabinet made of any material.

Selection and installation of gas lifts for wardrobe beds

Good afternoon, dear users of the legendary 582 mechanism from OZMF. This mechanism, “leaked” by the manufacturer OZMF from the Germans around 2000, is actually from the last century. But, of course, based on it, after a lot of pain, you can put together something for reasonable money. But let me give you recommendations from an experienced (in this mechanism) person. It is clear that we are designed in such a way that we always want to get maximum pleasure for minimal money. BUT! The wardrobe-bed mechanism, no matter what manufacturer it is, is very dangerous if you (or your installers, furniture makers, assemblers) make a mistake. The danger will threaten you as the user, and your pets, children, animals... Well, at least, after half a year of operation, drag the device to the trash. Therefore: 1. Do not use laminated chipboard with a thickness of less than 20 mm for sh-k (the 582nd mechanism, and for others too). Sooner or later, under SUCH loads (gas lifts in vertical beds are 800-2200 N), it will explode! 2. Good, thoughtful assembly instructions for mech 582 here: https://stabix.ru/images/files_uploads/schkaf-krovat_stabix.pdf There, by the way, there is also a gas lift selection sign. 3. Gas lifts. The most important part of the mechanism, very high-tech and, at the same time, dangerous and finicky. Gas lift is the engine of the mechanism. — Oil leakage is NOT NORMAL, it means that the gas life is “lid”! Change it! — A noticeable weakening of the gas lift, earlier than after 10 years of operation, sometimes with the “falling out” of the bed, means that it is “kaput”! Change it! - Do not unscrew the eye under any circumstances (if it is not welded) - the thread of the gas lift rod that appears (and the thread on the side of the body, too, but a little later) will crack sooner or later, most likely along the last turn of the thread. - Under no circumstances allow the bed to sink to the floor without the legs extended, the gas lifts in this mechanism are not designed for full compression, they deteriorate from this, and will quickly fail. — Gas lifts must be installed with the rod down so that the oil inside the gas lift body regularly lubricates the rod moving through the couplings and seals. When reinstalled, the gas lift will “run out” noticeably faster. — To replace gas lifts, if they have not “leaked” yet, you need to use improvised devices to throw them off the rods. Measure the diameter of the mechanism rod - it can be 10 or 12 mm when you buy new ones - be sure to keep this in mind! No improvised alterations - you won’t be able to make homemade ones! Buy gas lifts specifically for this 582 mechanism, do not try to select them by size and effort. All gas lifts have their own operating characteristics. You can easily find a seller company on the Internet. They will be sold to you already partially compressed, tied together with a strip of plastic (tie), this will help you install them back on your bed. If this tie somehow comes off during installation, before you install the gas lifts, you should not try to compress the gas lift yourself, it is unlikely to work, and you can even get seriously injured with such efforts. Just take (send) the gas lift back to the company - the seller, they will replace you (if they are normal) with a tightened gas lift. — If you want your wardrobe-bed to work for a long time and without problems, install (change) only German Stabilus gas lifts (sold at official dealers throughout Russia). Yes, they are a little more expensive... but do you value your time and safety? Most gas lifts from other manufacturers, at best, suffer from the difference in pressure between a pair of gas lifts. This causes the bed to skew and can cause the bed base to fall apart...or at worst.... From the beginning of next year, Stabilus gas lifts will be available for sale for wagons with damping (i.e., with a smooth lowering), with a guarantee against sudden lowering, even if you try to “help” them. By the way, you will need to buy them with slightly less power than the recommended standard ones. For qualified consultations on the 582 mechanism and gas lifts, I recommend calling or writing to Rosso - good, responsive specialists work there. Good luck!

DIY mechanism: what is needed for this?

The simplicity of the basic design suggests that such a mechanism can be made by yourself. This is partly true, but only if you have experience working with metal, a drilling machine and a welding machine.

You can also make a structure with a lifting mechanism yourself.

If we talk about manufacturing in the context of general operating principles, we can highlight several key points:

- Drawing. Design features such as the width of the support plate flange, the length of the rods and the distance between the holes are calculated depending on the point of application of the load, its nature (point or distributed), as well as the position of the axis relative to the center of mass of the entire structure. If such calculations are difficult to do on your own, it is recommended to look for the most suitable ready-made solution.

- Construction type. The manual version is the simplest from a production point of view. However, if you want to install a compensator, the choice here is obvious - a gas shock absorber. Installing a spring requires an accurate calculation of its stiffness: a weak one will not hold the base, but a too stiff one will require significant effort when opening. In addition, it may simply not be in the store.

- Nature of use (intensity). This will determine how powerful (reliable) the mechanism is needed.

How to install a door closer yourself

Installation of complex, expensive shock absorption systems such as electric lifts should be done by professionals. Any home craftsman can handle the installation of simpler and more common structures.

The easiest way is to attach special loop closers to furniture hinges.

The arm or bowl of the hinge must have special grooves, the closer is placed on top and snaps into place.

If the hinges are not suitable for fastening shock-absorbing devices, use cabinet or mortise closers.

Installation of a cabinet closer

The cabinet closer is installed in close proximity to the furniture hinge. Placement in the middle, between the loops, is allowed.

How to install:

- For convenience, remove wall cabinets from the wall. Place the piece of furniture on the floor or table.

- Mark where the device will be fixed, put dots in the places of the proposed holes.

- Drill holes for the mounting bolts. For self-tapping screws, puncture the surface with an awl.

- Screw the base of the closer with self-tapping screws or bolts.

- Check if there is any interference when opening and closing the doors.

- Hang the cabinet in place.

Surface-mounted body closers can be equipped with a limiter. It is applied to the edge of the part and the device is immediately secured with self-tapping screws without preliminary marking.

Mortise devices

Mortise closers are mounted at the end of the side part of the cabinet opposite the door. For wall cabinets, choose the top or middle part of the part, for floor cabinets - the bottom.

- Mark the installation point of the closer at the end of the part. Make a small hole with an awl.

- Using a drill corresponding to the length and thickness of the closer rod, drill a hole to the appropriate depth.

- Insert the mechanism into the hole.

It is better not to use glue or sealant for fixation. They will create difficulties during dismantling in case of breakdown. The closer will not move or fall out without additional means of fastening.

Gas lift installation

Operating procedure:

- Mark with a pencil the installation locations for equipment fastenings.

- Pre-drill holes for mounting bolts. If you use self-tapping screws, you don't need to do this.

- Having attached the fasteners to the intended places, secure them with screws or bolts.

- Insert the closer mechanism into the fastening holes and click into place.

Structure and design features of office chairs

All existing office chairs can be divided into the following groups.

For managers. They are distinguished by their large dimensions and solid appearance, most often upholstered in natural or artificial leather. They have the greatest number of functional capabilities, for example, a synchronizing mechanism that ensures repetition of the movements of the seated back and seat, mechanisms that regulate the depth of the seat, back resistance, negative tilt, etc. Executive chairs are comfortable and sized.

For staff

They must be comfortable and reliable, so when choosing them, the main attention is paid to the shape of the seat and backrest and the gas lift mechanism, and not to appearance. They are lightweight, which allows for a high level of mobility, and have modest functionality, which includes mechanisms that regulate the height of the armrests and seat, as well as the angle of the backrest.

This group includes computer chairs and operator structures with armrests.

For visitors. Such chairs must first of all be comfortable, beautiful and stable, and therefore they are devoid of any functionality. They often have four stationary legs, without a cross on wheels or a rotation mechanism. A modern chair is a functional and comfortable piece of furniture.

Almost all models are equipped with armrests. Cheap designs are made almost entirely of plastic, while more expensive ones are made of stainless or anodized steel.

Despite the existing differences, all chairs consist of the following basic elements:

- a five-beam cross, which is the basis of the entire structure and is made of plastic or metal;

- rollers, plastic or metal, having an internal hinge and metal fastening;

- pneumatic cartridge, or gas lift, which is the leg of the chair and provides elasticity;

- a swing mechanism that helps fix the chair in one position and tilt;

- piastra, which looks like a metal platform equipped with a lever, and is necessary for adjusting the height of the seat;

- permanent contact connecting the seat and backrest and responsible for changes in the position of the latter.

Multifunctionality is the main criterion when choosing a chair.

Office chairs have the following features designed to make working at your desk more comfortable:

- height adjustment, allowing you to choose the optimal seat height for each person;

- changing the tilt of the backrest, ensuring constant contact of the back with it, even when the sitting position changes;

- rotation around an axis and mobility created by rollers.

An office chair is a rather complex device and any of its structural elements can fail.

Basic Concepts

A gas elevator is a special mechanism that is used to lift surfaces attached to it. Many people compare this design with car shock absorbers. Externally, the design has the shape of a small cylinder with several clamps and a moving arm.

This mechanism consists of several main elements:

- A cylinder containing gas. Often the container is filled with nitrogen. It should be noted that the mixture inside is under very high pressure, so it is not recommended to disassemble gas lifts yourself.

- Oil damper.

- Piston with rod. These elements are used to transmit force to the external environment.

Specifications

The gas lift allows you to calmly, without visible effort, raise and lower the bed. Everything happens smoothly and silently. Main technical characteristics of the device:

- The main working substance of the structure is inert gas. Nitrogen is most often used here;

- steel is used for the manufacture of the working chamber, rod and support tips;

- the wall thickness of the cylinder filled with gas is at least 1 mm;

- any gas lift can be compressed with your own physical effort;

- For normal operation of the device, the temperature indicator must be in the range from +80ºС to -30ºС.

The cylinder is filled with gas under high pressure, so if it is deformed or otherwise malfunctions, independent disassembly is prohibited. Gas lift force options are shown in the table.

| For vertical models | ||

| Bed weight, kg | Gas lift force, N | Bed size, cm |

| 50 | 800 | 80/90x200 |

| 60 | 1000 | 100x200 |

| 70 | 1400 | 120x200 |

| 80 | 1800 | 140x200 |

| 90 | 2000 | 160x200 |

| 100 | 2200 | 180x200 |

| For horizontal models | ||

| 40 | 400 | 600-800 |

| 50 | 500 | 600-800 |

| 60 | 600 | 800-900 |

| 70 | 700 | 800-900 |

| 80 | 800 | 900-1400 |

Advantages of lift-up beds

Gas lifts are installed in various types of beds. Some models are complex transformable systems. In others, the piston is used only to lift the frame on which the mattress rests.

Several advantages of such products should be highlighted:

- Practicality. The space under the bed is perfect for storing things, bed linen, and blankets.

Strength. Gas lifts not only reduce the load on a person, but also protect the bed frame from rapid destruction.

Simplicity. To activate the mechanism, significant effort and special skills are not required. Even a child can do this.

Variety of designs. This type of furniture is very common on the market, which allows you to select products to suit every taste and color. You can find both rectangular-shaped beds and options with a round bed.

Economical. This is achieved due to the fact that the space under the bed can be used as a locker.

Purpose

Thanks to the lifting mechanism, you can free up a significant part of the room area. This can be done in several ways - either the entire bed goes into a vertical position and is retracted into a niche in the wall, or only the sleeping area is raised to provide access to the storage area.

The first option is the best solution to the problem of lack of free space in one-room apartments and studio apartments. Thus, the sofa is transformed into another element of furniture/interior while in a vertical position.

The second option is often used in two-room rooms, saving bedroom space. Perhaps, with the installation of a transformable bed, the problem of storing bed linen or personal belongings will be eliminated. A transforming sofa, which provides storage space, will cope with this task perfectly.

The space inside the bed can be divided into several compartments so that the bed functions as a full-fledged wardrobe.

The transformer bed lifting mechanism provides additional features:

- Storing things. The base of the bed fits tightly to the lid of the box and does not allow dust to enter.

- Since the bed fits tightly to the floor, dirt does not penetrate under it, which means the process of cleaning the room is easier.

- The transformation process is quite simple and the better the lifting mechanism, the easier it is to lift the top cover, regardless of the weight of the structure and the mattress.

Lifting mechanisms for opening doors

When talking about lifting mechanisms for kitchen furniture, gas lift immediately comes to mind. This is a kind of furniture bracket. It is used, but more often for installing kitchen furniture doors that open upward.

The advantages of the mechanism include the following:

- You can open the doors silently;

- closes slowly and without popping;

- the stroke is independently regulated;

- the door is securely locked in the open position;

- The gas lift device allows you not to use handles; opening occurs with one click.

With such advantages of the mechanism, the kitchen set will serve for many years with reliability and convenience.

Gas lift design and operating principle

The gas lift is assembled from the following parts:

- button;

- outer cone;

- gas valve;

- plastic sleeve;

- external cavity;

- gas lift cone;

- gas bypass channel;

- internal cavity;

- inner cone;

- seal;

- lifting rod;

- thrust bearing;

- landing cone.

Do not open the gas lift housing. The slightest intervention will damage the seal of the housing and lead to injuries and injuries. And since this mechanism is non-separable, it is no longer possible to repair the gas lift.

The operating principle of gas lift is simple and is based on a gas spring and a hydraulic shock absorber. If you open the door leaf by 8–10ᵒ, then it will open on its own. Closing happens the same way.

The internal cavity of the housing is blown with nitrogen gas. For this process, the furniture lift received the name gas elevator. It is worth noting that filling with nitrogen occurs during the creation of the mechanism, and then it is hermetically sealed, so it is impossible to repair the gas lift.

After all, thanks to the reliability of the mechanisms for kitchen cabinets, the furniture will last a long time, and storing kitchen utensils in cabinets will become orderly and ergonomic. The kitchen area will become neat and convenient for cooking.

Furniture hinges are important components for any kitchen furniture that has opening doors. Their range for different needs is quite diverse. Particularly popular in the manufacture of most modern kitchens are systems with comfortable and durable door closers.

A door closer is a compact device specially installed on cabinet doors to allow them to close slowly and smoothly. Gradual and soft closing prevents the formation of paint chips and cracks, which increases the life of the door and the kitchen cabinet as a whole.

Closers must hold kitchen cabinet doors closed. However, they do not guarantee the possibility of a sharp slam of the door if it is closed carelessly. If there is a glass shelf in the cabinet or there are fragile dishes, damage cannot be avoided.

Closers used on door hinges are not suitable for roll-out shelves, drawers and other elements. In such designs, special types of closers are used that have visually invisible special guides. Retractable closers are more expensive than hinged closers, but their price is justified by their reliability and ease of use.

To organize optimal storage in hard-to-reach corner kitchen cabinets, rotating mechanisms are installed, which, when the door is opened, pull out the shelves and bottoms of the storage systems, and when closed, return the entire structure back.

Lifting mechanisms are also useful devices in the production of kitchen furniture. Conventional kitchen drawers are opened by swinging the doors open or tilting them down parallel to the floor, which is not always convenient in limited kitchen space.

Modern kitchen sets today use convenient doors that open upward. Such cabinets require lifting mechanisms with closers that smoothly open to the desired height. Opening the doors and removing objects from the shelves of such cabinets becomes a more convenient process; it is not at all necessary to attach the handles; lifting is carried out by lightly pressing the surface of the door with your hand.

Options for lifting mechanisms for beds, nuances of operation. For apartments, especially small ones, the real problem is the lack of free space. Therefore, their owners are looking for any ways to save usable space. A lifting mechanism for the bed can be of great help in this, the use of which will free up part of the living space. Let's consider the characteristics of different designs of lifting mechanisms and beds. The purpose of the mechanisms.

Lifting mechanisms allow you to expand the functions of beds and thereby free up part of the living space of the house. Two methods are used for this. The first makes it possible to move the bed into a vertical position and put it in the closet. Or you can transform it into another piece of furniture for the time when the bed is not in use, thereby freeing up scarce living space. The second method adds the ability to the bed to store household items, linen and clothes.

bed gas lift repair

The box for it is placed under the rising bed. This solution can eliminate the need to purchase a linen closet, saving money and the bedroom space that would be required to install this piece of furniture. Beds with lifting devices have some other useful qualities: They carefully store things - the sleeping place closes the box very tightly and does not allow dust to pass through, They have an aesthetic appearance - bedding can be put away in the box without any problems and the sleeping place looks very aesthetically pleasing, They make cleaning easier - under such the bed does not accumulate dust and it will always be clean. To lift and hold the berth, special mechanisms are installed.

Varieties. There are three types of bed lifting devices: Manual. This is the simplest lifting mechanism for a hinged bed.

The principle of its operation is based on the use of human physical strength, because it does not contain power units that compensate for the weight of the raised bed. The advantages of manual mechanisms: low price, strength and reliability. It is not recommended to install manual lifting mechanisms on beds for children.

The child may not be able to cope with unfolding the bed on his own and may be injured. Spring-loaded. As a lift, such mechanisms use twisted springs, which take on part of the load and significantly facilitate the transformation of the bed. If it is necessary to reduce the force of the mechanism, it is enough to remove the springs, but it is impossible to increase it. Over time, the springs gradually stretch, the connections wear out, and eventually the mechanism has to be replaced. On gas shock absorbers.

This lifting mechanism is the most comfortable because it takes on the entire load when lifting the bed. This quality allows women, teenagers, and people with disabilities to use beds with this mechanism. This bed lifting mechanism uses a gas shock absorber as a power unit. It consists of a cylinder filled with nitrogen under high pressure, an oil damper and a piston with a rod. The gas shock absorber mechanism consists of: Metal plates and angles, Steel axle, Gas lift. Plates and corners are attached to the berth and to the sides of the box. When lowering, the plates rotate on the axis and the gas elevator is compressed under the pressure created by the weight of the berth.

When lifting, the force of gas pressure pushes out a piston with a rod, which smoothly moves the stock to a vertical position. The power of gas elevators is indicated in Newtons (N). Beds require mechanisms with a power from 600 N to 2200 N. The only disadvantage of a gas lift is its high cost, which, however, is justified by its ease of use and durability. Dimensions and characteristics. Beds differ from each other in several characteristics, each of which is important when choosing the optimal option for a bed lift. Dimensions. Length – the standard length of beds for adults ranges from 200 to 220 cm, for children – from 120 to 190 cm.

Width – depends on the number of beds. Children's beds have a width of 60-70 cm, single beds 90-100 cm, the standard width of double beds is from 120 to 160 cm. The height is chosen so that it is easier for its users to lie down and get up (for children - lower, for older people - higher ). Combinations of length and width within the specified limits can be very different and are chosen depending on the desires of those who will sleep on it. Beds measuring 160x200 cm and having a lifting mechanism with a gas lift can be considered the standard for double models. All these parameters influence the choice of lifting device only in combination with other characteristics.

The weight of the sleeping place is mainly influenced by the mattress. There are a lot of varieties of its fillers and their weight can vary significantly. The weight of the part of the bed being lifted is a major factor in determining the type and power of the lifting mechanism required. For example, for lifting a double bed with an orthopedic mattress, a spring mechanism is not very suitable, not to mention the manual version.

And for a single bed with a foam mattress, the use of an expensive gas mechanism would be unjustified. Design. Beds with a lifting mechanism have two types of design - with a horizontal lift of the berth and with a vertical lift of the entire bed (wardrobe bed). You can raise the bed in two ways - by fixing the box parallel to the horizontal level at a certain distance from it, or by opening it like a book, from the foot of the bed. In addition to the foot, any side of the bed can also be raised if you install the lifting mechanism a little differently. A side lift is needed in cases where, for reasons of optimal placement, it is decided to place the bed sideways close to the wall.

All options require symmetrical installation of two lifting devices of the same type on the box. For a single version of this design, any lifting device is suitable. In double beds, as a rule, gas lifts are used, regardless of the weight of the bed.

There are also two options for lifting the wardrobe bed. The bed is raised either by the foot or by the side. In both cases, the transformation can be done with very little effort if the lifting mechanism of this bed uses a gas lift. But its power for each single-bed version will be different. When lifting from the side, it is possible to use a spring lift. A manual device is usually not used for this design. Installing a very powerful gas lift on a bed is not recommended, since in this case it will be very difficult to lower or raise the frame.

You can roughly determine the required power at the rate of 10 N per 1 kilogram of the weight of the structure being lifted. When choosing the type of lifting device, you need to take into account three more factors: Mode of operation - regular lifting of the bed or occasional, Physical capabilities of the person who will sleep on it, Cost of the lift - the cost of different types of lifting devices differs by an order of magnitude, so not every user will be willing to pay money for an expensive lift unnecessarily. Rules for safe use. When using lifting beds, you should follow simple safety rules: The wardrobe-bed in a vertical position must be securely fastened to the wall, When raising and, especially when lowering beds, it is recommended to stand to the side of the structure, When using a device with a spring shock absorber or a manual one, the berth in the raised position it must be additionally secured with a special support. Gas lifts are considered the safest. They hold the bed securely in the raised position because the piston of the gas elevator is fully extended and in this state it cannot contract spontaneously. Some companies offer a gas lift lock on the gas spring rod in the kit, but this is for overly cautious buyers.

In principle, the bed cannot fall down sharply. Even if one gas lift suddenly fails, the bed will slowly lower due to the second one. Reliability. All bed lifting mechanisms have a fairly high level of reliability. But here we need to make a reservation - this applies to products from manufacturers who occupy leading positions in the market for these devices and have earned the trust of customers. For example, the best gas elevators are considered to be German, and spring devices are Italian. In spring lifting mechanisms, the main load falls on the spring itself, which leads to its wear.

In addition, devices of this type do not withstand increased loads on the sleeping area. During use, the springs sometimes pop out and gradually stretch. For these reasons, their warranty does not exceed 5 years.

Gas elevators have a 10-year guarantee and are designed for 20 thousand raising and lowering of the bed, which indicates the high reliability of the gas lifting device. The most reliable and durable mechanism is recognized as a manual device on hinges. The reason is simple - there is nothing to break there.

Finally, advice on how to choose the right bed lift mechanism. Spring devices are perfect for light single beds. But, if your budget allows, it is better to choose gas. Its high price will justify itself - the device will last for many years without repair or replacement.

Well, the manual version is suitable for small beds that do not have to be opened often.

see also

- BED REPAIR

Bed assembly and repair. Furniture manufacturers recommend assembling the structure with a partner. Together, such work is carried out more quickly and efficiently...

- REPAIRING A BED WITH A LIFTING MECHANISM AT HOME

Bed repair at home. repairs beds at home at low prices in Moscow. Our specialists, having extensive experience,…

- REPAIR OF A BED WITH A LIFTING MECHANISM

Bed repair at home. repairs beds at home at low prices in Moscow. Our specialists, having extensive experience,…

- BED FRAME REPAIR

Bed assembly and repair. Furniture manufacturers recommend assembling the structure with a partner. Together, such work is carried out more quickly and efficiently...

- REPAIR OF BEDS WITH A LIFTING MECHANISM IN MOSCOW

Assembling the bed. Assembling a bed can take a long time if you are not a professional. Therefore, we recommend entrusting this work to the specialists of the company Repair...

Tags: gas lift, beds, lifting mechanism, repair, sleeping place

Installation Rules

Before installing a gas elevator, the following features should be considered:

- It is worth installing two gas lifts on one front so that when opening there is no great tension, which can cause distortion;

- due to the high level of liquid, using gas elevators with a force of 100 Newton is in most cases impractical;

- adjustment of the front with the lifting mechanism is carried out by hinges securing it to the box;

- the assembly of the box in which the fittings will be mounted must be preceded by the installation of fasteners;

- by moving the installation location of the fasteners to the front part of the side, you can increase the angle at which the door will open;

- Installation of automatic elements requires strict adherence to instructions.

Trust a professional to install gas lifts.

Preparing the necessary tools

For installation you will need the following tools:

- ruler, meter or tape measure;

- hammer;

- drill (preferably electric);

- pliers;

- screwdriver or screwdriver.

When installing furniture connecting elements, it is convenient to use a drill using a special drill.

Marking before installation

Before installing a gas lift on a kitchen cabinet, it is necessary to make markings in the niche, as well as calculations for accurate installation. It is worth marking the centers for the mounting points on the door and on the sides of the niche.

Before installation, try on the gas lift several times.

First of all, you should check the suitability of the equipment. For example, for a cabinet with a height of 365 mm, a gas lift measuring 355 mm will be required. The marking order is as follows:

- Mark the middle of the fastening on the sides. To do this, measure 37 mm from the front side of the sidewall, and 366 mm from the inside of the top cover.

- Mark the center of the fastening on the sash. To do this, measure a segment from the side end equal to the height of the fastening on the side of the cabinet, usually 19 mm, and from the top cut - 128 mm.

Use detailed instructions for installing a gas lift.

Step-by-step installation instructions

Instructions for installing a furniture gas lift on a kitchen cabinet are as follows:

- Attach the bases to the sides in the marked places.

- Install brackets with springs and plates. The brackets should be screwed in and the elevator heads will snap right onto them.

- Attach the center of the fastening so that it coincides with the markings. The base is secured with three or four screws or self-tapping screws. In this case, the head of the structure must be fixed in the holes.

- Carry out similar actions, securing the gas lift to the door. In this case, you should achieve a hinge angle of 8°.

The bed can also be equipped with gas lift.

The procedure for installing the mechanism on the bed is as follows:

- Drill three holes at the markings (14-15 cm from the edge, at the height of the legs).

- Secure the lower part of the mechanism with bolts.

- Attach the corner of the device to the frame of the structure.

- Lower the base of the mechanism deep into the frame and mark four holes on each side. In this case, future attachment points must correspond to the bottom bar of the device.

- Open the frame and drill holes.

- Secure the top bar so that there is a gap between the box and the frame for the full functioning of the mechanism.

Gas lift allows you to make the bed multifunctional.

Adjustment

When adjusting, it should be taken into account that the distance from the ceiling to the top of the cabinet must exceed the dimensions of the door, since it will open upward and it should not touch the ceiling.

The door can close silently.

The adjustment allows for slow and silent operation of the doors. To do this, you need to tighten the basic fastening elements of the product.

Installation of lifts

Another auxiliary source will be further instructions. It is general in nature, but describes the most common and universal principle of installing lifts.

The installation involves performing the following actions:

- First, the bed frame itself is assembled. After all, it is to the lower body that the mechanism will be attached;

- The lift itself is assembled, if it is not one-piece, or it comes with parts;

- The device is fixed on the side panel. In general, it is optimal to take a ready-made lifting mechanism already assembled. It is difficult to assemble such devices with your own hands; this requires experience and knowledge;

- Now the berth itself is connected to the lift. You may need help here, since the fixation is carried out with the base raised.

At this point, the installation is considered complete. Be sure to check the functionality of the lifting device, perform several lifting and lowering procedures, and make sure that the gas lift is securely fixed in the raised state.

The main aspect that ensures the correct installation and further operation of any type of bed lifting mechanism is the correct calculation of the load capacity and the selection of the required mounting location.

Since each bed has individual characteristics, there are no general recommendations. But there is a large assortment of lifts that take into account not only the financial capabilities of the buyer, but also specific requirements, operational parameters and expected load.

Lifting and transformation mechanisms are used everywhere. Take, for example, folding armchair beds or mainly a children's loft bed, where full-fledged sleeping places are also formed with simple movements, and additional furniture possibilities are revealed.

Beds with lifts are frankly comfortable and functional. These are the same standard beds, but with expanded capabilities. An alternative to them can be models with drawers.

Thank you all for your attention!

Subscribe, leave comments and ask relevant questions!

A bed is not just a place to sleep. This piece of furniture can be made more functional with an interesting headboard made in the form of cabinets or shelves for books. But this is not the limit of functionality. You can store rarely used items under the bed itself, hiding them from prying eyes. But in this case, free access to boxes and drawers is of particular importance, which can be achieved by equipping the bed with special lifting mechanisms - a pair of pistons operating on the principle of gas lift for the bed.

Variety of elevators

Today there are more than enough types of lifting mechanisms, and almost all of them are suitable for installation in a bed structure. They differ only in cost, design features, and service life. The peculiarity of each type of lift lies in the possible force used for a particular design.

Based on the principle of operation, lifts are divided into three types.

How to properly install a gas lift on a kitchen cabinet?

At the beginning of work, you need to select a tool and make markings, purchase gas lifts and components. Gas lifts are characterized by different parameters and the force at which the spring is compressed. The device must match the size of the furniture. Typically, the dimensions of furniture are standard and there are three main options for gas lifts in size. You need to know the maximum extension of the rod and the length of the folded mechanism.

The compression force is needed when calculating the design for doors of different weights, taking into account the entire coating and fittings. The amount of compression of the spring is standardized and indicated in the technical data sheet of the mechanism, measured in newtons and can be 60, 80, 100 and up to 140 N. Based on the weight of the door, the gas lift is calculated based on a kilogram of door mass per 10 newtons of compression force.

There are many ways to attach. Flat platforms are often used, mounted on the sides of the cabinet with screws and self-tapping screws. Screw-in holders are used for wooden furniture.

What tools will be needed during installation?

You need a set of tools - one is not enough. If you want to install it yourself, you will need:

- Meter, ruler or tape measure.

- Hammer and pliers.

- Drill (preferably electric).

- Screwdriver or screwdriver (the latter is preferable).

Step 1. Marking before installation

Before installing the device, markings are made in the cabinet niche and calculations necessary for installation are made. The centers of the mounting points are also marked on both sides of the niche and on the door.

Step 2. Installation work

Installing a gas lift on a kitchen cabinet is carried out as follows:

1. First, the bases are fixed to the sides of the cabinet in the places marked earlier.

2. Plates and brackets with springs are installed. The bracket is screwed in and the gas lift head snaps directly onto it.

3. The center of the fastening must coincide with the marked one; the base is fastened in different versions with 3 or 4 screws or self-tapping screws. The head of the structure is fixed in the holes.

4. The same steps are taken to secure it to the furniture door. The hinge angle should be 8 degrees.

Gas lift installation diagram