Women will confirm that the most successful interior ideas are born precisely at the moment when you can’t count on men’s help. In such a situation, it is better to wait for radical changes, but simple changes should not be postponed. Hang a new picture or shelf- a woman can completely cope with such a task herself, without a man. True, under one condition: you need to approach the matter seriously and thoroughly, having studied this article.

First of all, you need to decide what you can afford. If the wall (that is, the base for fastening) is reinforced concrete or brick, then there will be no problems. Such a design can withstand a fairly significant load, say, a hanging rack completely filled with books and magazines. Walls made of porous materials (gas and foam concrete blocks, slotted bricks) and plasterboard partitions require more gentle handling; heaviness is contraindicated for them. These walls will support paintings in baguette frames, photographs, shelves with CDs or decorative vases - nothing more. But if you really need to load the plasterboard partition, you will have to first strengthen its frame.

The next step is the selection of fasteners. To hang a shelf, you need to install at least two dowel or anchor units in the wall. They, in turn, are a system consisting of three components: a base, a plastic or metal sleeve (dowel, anchor) and a spacer element (screw or conical bolt of a steel anchor).

Hanging technology is simple

: a hole of a given depth is drilled in the wall, a sleeve is hammered into it and a screw is screwed in, which will attract the object being hung.

It is important that all components of the dowel (anchor) assembly have the same strength, which also corresponds to the applied load. The most reliable anchor will not save a weak wall. A sleeve that is not strong enough will slip out even from reinforced concrete or solid brick. A screw or anchor bolt will simply break under excessive load. Therefore, it is necessary to choose the right fasteners. In everyday life, a tandem of a plastic dowel and a screw of one type or another is usually used. In this case, the base material and the expected load are taken into account. In other words, each dowel has its place. In difficult situations or for fastening building products, steel anchors are used.

The choice of screws depends on many factors: the weight and purpose of the object being hung, the properties of the base (main wall or partition), and the element being fixed (hinge or bracket).

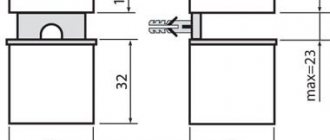

In this case, the required screw length must be equal to the sum of three values:

anchorage depths

(A),

screw diameter

(Øа),

thickness of the element to be fixed

(h).

The screws have a thread run-out at the end. To ensure the necessary expansion of the sleeve, after fully tightening, the tip of the screw should protrude beyond the end of the dowel by the amount of one of its diameter. And finally, the depth of the hole (L) should be slightly greater than the length of the anchorage (also by the size of the sleeve diameter).

Free space is necessary to compact the drill flour, which is formed during drilling and negatively affects the adhesion strength of the dowel to the base material.

Dowels

The concept of “dowel” (from the German dubel - dowel, dowel, insert tenon) in its modern meaning appeared a little more than half a century ago. In 1958, German engineer Arthur Fischer invented nylon sleeves for spacer threaded fasteners.

This is how dowels appeared - products designed for fastening screws (screws) in walls, ceilings and other structures. Now in construction practice, in addition to plastic (and not only nylon), metal dowels are used, as well as chemical fastening systems. Let us note that the products of well-known manufacturers (Artur Fischer, Kew, Germany; Hilti, Liechtenstein; Sormat, Finland; Mungo Befestigungstechnik, Switzerland, etc.) fully meet the declared indicators. If we talk about plastic fastening systems, then nylon products are still unrivaled.

From left to right: metal dowel molly crutch; universal dowel SX (Fischer), four sides of expansion; metal dowel HM (Fischer) for hollow bases; dowel type “driva” for hollow bases (plasterboard partitions and cladding); nylon dowel GB (Fischer) for aerated concrete bases; plastic butterfly dowel for hollow bases; self-aligning metal dowel with hook (KM from Fischer); nylon facade dowel SXR (Fischer); frame steel anchor.

For example, nylon dowels from the Fischer company, hammered in the middle of the last century, have still not lost their original properties, that is, neither their position nor load-bearing capacity has changed. At the same time, there are polyethylene and polypropylene fasteners on the market. The use of such fastening systems is permissible, but provided that in their production polyethylene or polypropylene with improved strength and performance characteristics was used (due to the introduction of special additives into the raw material mixture).

When purchasing dowels, you should carefully study the packaging. Products of unknown origin without family or tribe are often produced without complying with any standards and requirements. It is clear that such dowels may not have any load-bearing capacity at all.

Expert commentary

The technical director makes several recommendations. Nylon (polyamide) dowels compare favorably with products made from other plastics. Over time and under the influence of various environmental factors (temperature, humidity, etc.), their physical and mechanical properties practically do not change, that is, the load-bearing capacity of dowels does not decrease, and if it decreases, it is insignificant.

How to distinguish polyamide from other plastics? You need to lower the dowel into the water. If it does not float up, it means that the density of the material from which the product is made corresponds to the density of polyamide. Of course, this is not a 100% guarantee that this is nylon, but it is a very indicative sign by which you can distinguish quality products from fakes.

As for other parameters, much depends on the profile of the working area and the design features of the dowel. There are no strict guidelines. Only one thing can be said with confidence: the longer the spacer part of the plastic dowel, the higher its load-bearing capacity will be. In addition, you should pay attention to the number of thrust directions. If the dowel has one parting plane, this means that when the screw is tightened, the expanding forces act only in two opposite directions.

When installing fasteners, the minimum distance to the edge of the wall (edge distance) must be taken into account. In general, it should be at least two anchorage lengths. If you need to hang a shelf close to a corner, the dowel is positioned so that the spacer acts parallel to the floor. In addition, you can use special non-thrust fastening systems. In this case, it is permissible to install dowels at a smaller distance from each other and from the edge of the wall.

| a) Using a hammer drill or impact drill, drill a hole of the required depth. If the drill hits the reinforcement, the attempt will have to be repeated. b) A plastic/metal dowel is driven into the hole; in our example, a regular plastic dowel with one parting plane is used. Such a product will not work in a wall made of slotted brick. c) A screw is screwed into the hammered dowel using a screwdriver. Using a screwdriver, unscrew the screw by the amount necessary to hang the fastening element (hinge or bracket). |

At the same time, the range of products from serious manufacturers is so diverse that it is difficult for an inexperienced consumer to figure out what fasteners he really needs. To be on the safe side and act for sure, it is better to use universal products designed for concrete, brick, aerated concrete and other foundations. Such dowels behave differently in different designs. In solid walls they are held in place by friction (like ordinary dowels), and in hollow bases they show their universal character. In the voids, the “station wagons” expand, creating a stop, and in the bridges they are held due to the force of friction. In other words, as soon as the universal dowel gets into the free space, it folds into a knot that prevents the fastener from being pulled out.

Chemistry is power!

Unfortunately, the problem of weak walls is very relevant in our time. Often it is almost impossible to provide fasteners using the traditional method. The wall material does not have enough strength and density to hold the fasteners. In such situations, the only hope is chemical anchors. Such fastening systems consist of anchor rods and cartridges or cartridges with a quickly hardening, high-strength polymer composition.

The chemical “intermediary” ensures reliable adhesion of the anchor rod to the base material. The result is a strong and durable fastening unit. It is no coincidence that chemical anchors are used to connect elements of critical building structures: foundations, reinforced concrete beams, etc.

In addition, there is a wide selection of specialized products. For example, for walls made of cellular concrete and other porous materials, it is better to use special dowels. They have spiral ribs that ensure uniform pressure distribution and reliable adhesion to the base material. We produce our own dowels for insulating materials. If the walls from the inside are equipped with slabs of polystyrene, polystyrene foam, polystyrene foam or other similar heat insulator, then there is no point in hanging anything heavy on such cladding (the entire load must be transferred to the main wall). But under a light shelf or picture, you can screw in special dowels for insulating materials, which can be held in the base due to the stop-turns of the spiral thread.

A special topic is plasterboard partitions. Several types of dowels are used here. Driva products, which are a cone-shaped screw, are very popular. At the same time, butterfly dowels have proven themselves well. When the screw is tightened, their wings straighten, creating a reliable stop.

It is known that before the advent of plastic dowels, wood plugs were used as bushings for screws. It would seem that hanging a shelf on a wooden wall is a piece of cake. But this is only partly true. Before tightening the screw, you need to drill a small hole in the wood. Otherwise, there is a high probability of local damage to the wood, which may adversely affect the strength of the fastener. Moreover, we do not recommend driving nails into a wooden wall. Over time, they can become loose and, in low humidity, even fall out. In addition, screws are produced (Fischer, etc.) that can be screwed in without pre-drilling.

Hanging a shelf on a tile

To attach the shelf to the tile, it is better to use a drill or hammer drill, dowels and self-tapping screws. The reason for choosing this type of tool is the fragility of the tiles.

A good guide to horizontality will be the seams between the tiles

The first stage - selecting a surface, marking holes and checking with a level - is the same for all types of surfaces. The second stage is the actual moment of drilling. But it is he who conceals his own nuances. For the effectiveness of this process, it is worth drilling the tile itself at low power, and then changing the drill to a smaller one and working fully.

You should not forget about the fastidiousness of tiles. Any wrong action can result in a crack in it. You should be very careful and follow the recommendations.

If you still need to drill the tile, mark the location of the hole on the masking tape

Drilling and tightening

It is not enough to purchase a high-quality dowel; you also need to install it correctly. To drill a hole and tighten a screw, you will need special power tools: a hammer drill, a drill and a screwdriver (Bosch, Kress, Metabo, Germany; DeWALT, Skil, Black & Decker, USA; Hitachi, Makita, Japan, etc.). We will talk about their functionality using the example of household products from Bosch. It's good if you have an impact drill in the house (such as the PSB1200-2 RPE). It has three operating modes: drilling, hammer drilling and screw driving (screwdriver function). An impact drill can be used to drill holes in medium-density stone, concrete and brick, as well as wood and metal.

The drilling depth limiter allows you to obtain a hole of a given size. The rotation speed is adjusted during operation using the on/off button. At the same time, our drill also has a speed switch. The slower the drill operates, the more powerful its impact on the material and the larger the hole can be made. And vice versa, the higher the speed, the smaller the hole, but the work goes faster. In addition, thanks to the speed switch, you can adjust the tightening force when tightening screws in screwdriver mode.

To make a hole in a reinforced concrete wall, you will need a hammer drill. Such tools operate in two or three modes: drilling, hammer drilling and impact. In our example, we used a three-mode rotary hammer RVN 2000 RE. He can also drive screws if necessary. In heavy materials (concrete, brick), working with a hammer drill is faster and more convenient: there is no vibration typical of a drill, and you need to put in much less effort (and you have to rest against the drill).

Tips for women, life hack for men.

For any power tool, operation at low rotation speeds (that is, at low speeds) under high load is contraindicated. If you stop the tool with great force while pressing the on/off button, the electric motor may burn out. True, with screwdrivers, the “ratchet” is triggered at a critical moment. The Bosch 1200-2 RPE impact drill has a safety shutdown function. But for rotary hammers and conventional drills, low speeds are like death. That is why it is not recommended to use these tools to tighten screws without sufficient skill.

And one more nuance. Reverse can only be switched when the drill has stopped completely (after turning off the button, it continues to rotate for some time). It is necessary to protect tools from falls from great heights and from becoming clogged with dust and other construction debris. To prevent drill flour from getting into the chuck when drilling in the ceiling, you can close it with a regular lid for home canning (drill a hole in the lid and put it on the chuck).

To drive screws and self-tapping screws, bits are inserted into screwdrivers. They differ in diameter (marking 0, 1, 2, 3, 4, etc.), length (25 - 150 mm) and profile. The simplest option is slotted bits for self-tapping screws with a longitudinal line in the middle of the head. Phillips screws are tightened with bits marked PH

(Philips).

Another type of bit - PZ

(Pozidrive) is used to tighten fasteners, which, in addition to the cross, also have additional slots.life hacking comes from the English word life hacking and is a slang term borrowed from the IT lexicon. Life hack means

a little trick or useful advice that helps solve one or another everyday problem.

Close Russian equivalent words: “ savvy

”, “

recipe

”, “

nahodka

”. A set of methods and techniques allows you to save time by “hacking” the surrounding life and established incorrect stereotypes. Skills simplify the process of achieving your goals by mastering various useful tips and clever little tricks.Life hacking includes questions: how to hang a shelf, a picture, or unscrew a broken light bulb from its socket; how to stand in line less or remember your phone number or PIN code; how to complete more complex tasks faster and how to spend less time commuting to work.

Drills and rotary hammers are powered from the mains, which is not always convenient. In addition, they have a fairly decent weight. And if you need to drill a hole at a height for a new cornice, then with such a tool it will take seven sweats until the job is done. Heavy lifting exercises can be avoided by using the Uneo hammer drill. Of course, it is inferior in power to its full-size “colleagues”, but it is not tied to an outlet (it is powered by lithium batteries) and is quite lightweight. And if you consider that in everyday life you usually need holes with a diameter of no more than 10 mm, then this “baby” is a real find not only for active housewives, but also for experienced home craftsmen.

Another good thing is a screwdriver. Its main purpose is to drive screws. But with a screwdriver you can drill holes in “light” walls. The tool has a special “ring” (torque switch), on which numbers from 0 to 10 are printed. The higher the number, the higher the torque and, therefore, the power of the screwdriver.

Required Tools

Tools for attaching shelves to the wall

To securely hang a shelf on the wall, you should use the following tools:

- drill or hammer drill;

- screwdriver;

- level;

- dowels;

- self-tapping screws;

- pen or pencil.

drill of the required diameter;

Drills are different drills

If we're talking about tools, we can't help but mention the equipment; drills (drills) and bits. To drill various bases, you need appropriate drills. Moreover, different drills are inserted into hammer drills and drills. The differences relate primarily to the fastenings. For household hammer drills, the cartridges are marked SDS+. This means that installation of the equipment is done by hand, without the use of special keys (which are needed when using professional equipment). A burse is inserted into such a cartridge using an SDS+ mount (shank). For drills, drills with cylindrical shanks are used.

Reinforced concrete and brick walls are drilled with drills made of hard alloys. In addition, there are drills for wood, aerated concrete, metal, etc. For the sake of convenience, they are painted in different colors (at least that’s what the Bosch company does). For example, “gold” drills are coated with titanium nitrite, which increases the service life of the equipment.

To the beginning of the INFORMATION SECTION

How to hang a garland without ruining the wallpaper?

On corrugated wallpaper with an uneven surface (vinyl, non-woven), it is better to use ordinary safety pins. Push them in at an angle and carefully place the garland wire over the pins. After you remove the garland and carefully remove the needles, the punctures on such wallpaper are not visible.

Interesting materials:

How to extend a partition using the command line? How does celery grow? How to stretch a cashmere product? How to stretch an image in Photoshop? How to stretch a cotton T-shirt to length? How to stretch cotton jeans? How to stretch a wool sweater? How to stretch a viscose shirt? How to stretch a shrunken wool sweater? How to stretch a shrunken sweater?

Non-standard methods

In addition to the standard, well-known methods for installing shelves, original options using various available materials are used. These details not only allow you to conveniently and easily fix the structure, but also act as decoration.

Rings with hooks

You can hang the shelf using rings with attached hooks. The rings are attached to the wall, and the hooks are attached to the loops that are screwed into the structure in advance.

Water pipes

The method is useful in any room. Holes are made in the furniture fabric slightly larger than the diameter of the water pipe. The shelf is “put on” and fixed with a flange in the desired position. The design may consist of a single panel, or it may be an open shelving unit.

Belts

Shelves suspended on belts look original. To do this, take two leather products of the same length, fold them in half and drill them towards the wall. A shelf is inserted into the resulting loops. To prevent the canvas from moving, the straps must be screwed to the shelf with small self-tapping screws.

Ropes

Shelves hung on ropes will look great. A thin rope is used for this. 4 holes are made in the tree through which the rope is threaded. Knots are tied on both sides, thus fixing the shelf. The ends of the ropes are tied together and attached to the wall.

Hidden fasteners in books

The shelf is an old book with a metal corner screwed into it. The second part of the fastening is fixed to the wall. This shelf will hold several more books.

What types of fasteners are there according to method of use?

Among the diversity of the construction market, fittings are divided into categories depending on size, material, load capacity, and strength of the base. Craftsmen advise using wooden choppers instead of dowels; this measure will help the bookcase to fall soon. Over time, the tree dries out, in conditions of high humidity, and with temperature changes, it often and greatly changes in size.

Hidden fasteners for shelves to the wall

Often this method of fastening is chosen due to the design features of the room. Installation involves complexity and is rarely used. Hidden fittings are suitable for shelving made of wood, laminated chipboard, and plywood sheets.

These can be rods, bars, plates, hinged loops. The latter imply that first the hinges are attached, screws are screwed into the wall, and then the part is hung. The fixation is not visible, everything is securely hidden.

Rod products distribute the load perfectly. They are placed inside the shelf so that at least 2-5 cm remains to the edge. Often, sections of reinforcing rods, construction studs with threads, and drive-in anchors are used as rods. Depending on the expected weight of things, rods with a thickness of 1 to 1.8 cm are taken.

Concealed mensolo holders are rods that are attached to the back side of the shelf and a bracket for fastening to the wall. This way out of the situation is possible if there are holes inside the shelf without loss of functional qualities.

Multi-level products are successfully mounted on plates that are firmly fixed to the main surface.

When using wooden beams, a sheathing is assembled, on which a shelf is placed on top.

It creates the impression of a floating or floating shelf, weightlessness.

Open fittings, brackets

The easiest installation method is to use open fittings.

Corner brackets are suitable for inserts, withstanding loads of up to 20-40 kg, which depends on the type of fastener.

When an increased load is planned, reinforced parts are taken, with additional jumpers, capable of holding up to 100 kg.

Shelf bracket

If you don’t plan to put a lot on the shelf, decorative corners with a maximum load capacity of 10-30 kg, called mensolo holders, will suffice. This fastener has decorative qualities that complement the interior.

Wooden or metal slats are divided into single-level with a horizontal direction and two-level with a vertical direction.

Reinforced fittings are often used when decorating storage areas inside utility rooms, where increased load is expected. In other cases (in residential premises, offices), decorative holders are suitable.

Concrete wall in a residential building: advantages and disadvantages, repairs

In the construction of modern houses, one of the most popular materials is concrete mortar. If previously it was used only for pouring foundations, now it is used to make almost all load-bearing structures of a building.

Ease of use, wide availability and low cost of this material have led to the fact that most modern multi-storey buildings are built using monolithic frame construction technology, so a concrete wall, as well as the floor and ceiling, is present in almost every residential apartment.

Original concrete wall decoration in a modern interior.

However, when moving into a new house, not all residents understand where to start renovating an apartment or, for example, how to hang a carpet on a concrete wall.

Invisible fasteners and drywall

Often, partitions in a house are made from sheets of plasterboard. It is more difficult to attach stands to them with invisible fittings.

GCR is a rather fragile, thin material; it is not designed for high loads. However, if the walls are leveled using drywall, this option can be considered.

In the place where the shelf will be located, a wooden block is fixed between the gypsum board and the wall. Afterwards, the metal pins for fastening are inserted through the plasterboard, the block and inserted into the wall itself, and then the shelf is hung. Heavy objects should not be placed on such a structure, otherwise the fittings may not hold up.