The operating principle of all exhaust systems is similar to that of a vacuum vacuum cleaner, but the purposes of their operation have a number of significant differences. A kitchen hood is designed to remove combustion particles, fumes and foreign odors resulting from the cooking process from the air flow. The hood in the kitchen prevents fats from settling on the surfaces of walls and cabinets, as a result of which the air in the room remains fresh and clean.

The principle of operation of the exhaust system is based on forced ventilation, with specialized filter elements located inside it that trap soot, fumes and odors. An electronic or mechanical control panel is installed on the outer surface of the housing. The hood mount in the kitchen is usually installed on the ceiling or wall directly above the hob or oven, and for better aesthetic design it can be completely hidden in a small hanging box. The material discusses in detail the design of a kitchen hood and its basic elements.

Work specifics

This system is designed by specialists to provide air filtration, ventilation in the kitchen and removal of pollutants in the food preparation area: grease splashes, soot from the kitchen stove.

Important! The main task is to remove components of natural gas combustion that can have an adverse effect on the human body.

In addition, the functional purpose of a kitchen hood is to clean carcinogens and maintain an acceptable air concentration in the work area. It provides multiple intakes of clean air, the minimum amount of which, in accordance with current sanitary and technical requirements, must be at least 10. In other words, within one hour, the exhaust system must clean the air in the room at least 10 times.

The device for exhaust ventilation in the kitchen is directly related to the principle by which it functions. In modern hood designs, two technological methods of operation are possible: eliminating polluted air or purifying it.

Why do you need a hood in the kitchen: main functions

The design of kitchen hoods is quite complex, but its use, as it turns out, is elementary. By installing such a device in your kitchen, you become a happy owner of cleanliness and freshness not only in the place where you prepare food, but throughout the whole house.

If you run the hood after cooking, it is advisable to open the doors to the living rooms to eliminate harmful odors from there too.

Kitchen cleaners help to instantly get rid of carbon deposits, odors and smoke accumulated under the ceiling after intensive use of a gas stove. You probably know that all the grease and soot accumulates in the air and on the furniture. If the house has a hood, then it will save you from unnecessary worries regarding washing grease from the facades of the kitchen unit.

Types of kitchen hoods

The installation of a range hood directly depends on the specific type of model selected and an understanding of how a kitchen hood works.

The following options are available:

- Hanging hood – mounted under the cabinet body above the hob;

- Built-in hood – mounted inside the body of the wall cabinet, thanks to which it optimally combines with the main design of the room;

- Wall-mounted hood – installed on the wall surface directly above the stove and has the ability to connect to various cabinet designs;

- Corner hood – installed in the corner of the room;

- Island hood – designed for kitchens equipped with an island.

Before purchasing an exhaust device, make sure that the linear dimensions (length x width) of the working surface of the hob match. The dimensions of the built-in hood should be slightly larger or at least similar.

When using a hood with a smaller area, the efficiency of exhaust air suction decreases. Which will immediately affect the overall microclimate inside the kitchen and will cause some disappointment from the purchase. Another important indicator - power - is determined depending on the volume of the room, which can be simply calculated by multiplying the area of the kitchen by its height. The power (m3/h) must exceed the obtained value by 10 or more times.

For electric and induction hobs, the fume hood should be installed at a height of at least 45 cm from the work surface. For gas stoves, this value increases by 10-15 cm. Reducing the height of the hood above the stove entails discomfort when working at the stove and creates a potential fire hazard due to excessive heating of the equipment.

What types of lighting can be in hoods

Lighting under the hood improves visibility on the hob.

There are several ways to organize lighting, depending on the types of lamps used:

- Hoods with incandescent lamps are the most affordable option. Incandescent lamps are installed in budget models and create a pleasant yellow light, but consume a lot of electricity, since a significant part of it turns into heat. They also often burn out and require replacement.

- Hoods with halogen lamps are installed in mid- and premium-class models. The lamps are small in size, provide better illumination and consume electricity economically.

- Hoods with LED lamps - lighting with LED elements is the most economical in terms of energy consumption and is designed for 30-50 thousand hours. But this type is new and still rare.

- Hoods with neon lamps are characterized by an orange-red glow and a long service life of up to 10 years. They look stylish, but are almost never found in kitchen hoods.

Classification by type of cleaning

In accordance with the features of the air purification method, all hoods are conventionally divided into two main categories. There are recirculation complexes: they conduct air coming from the kitchen through special filter elements and direct it back. In fact, they are not exhaust systems, since the air coming from the room is not removed, but is subjected to basic cleaning using the appropriate elements of the device.

Hoods of the second type are flow-through, due to which polluted air enters the home ventilation system, and from there it is discharged outside, providing effective ventilation in the kitchen. Such systems include a special pipe - it can be made in the form of a corrugated or metal channel with a round or tetrahedral cross-section. Through it, the device is connected to the ventilation system.

Important! As for the dimensions, devices of the first category are relatively more compact, and their connection is much easier.

Today, combined models of exhaust systems are also available for sale: they combine both types of devices in their operation, the user can switch between them at his own discretion.

Hood manufacturing process

It can be divided into stages:

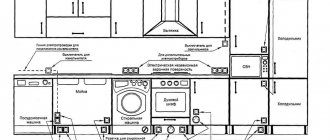

Scheme of the hood operation.

The first stage is the preparation of materials and equipment. If something from the above list is missing, you should visit a hardware store. Equipment can be rented. The second stage is applying markings. In order not to spoil the aesthetic appearance of the room, you should carefully take measurements. It will be necessary to arrange not only the hood. You should also place an air duct. It can be carefully disguised using drywall. The simplest marking option is obtained when the hole for ventilation is made from above the slab. When the hole is located elsewhere in the kitchen, you will need to place a box in which the air duct pipe will be laid. Advice! If you plan to finish the ceiling with plasterboard in your kitchen, you can partially hide the air duct under it.

The third stage is creating a frame for the air duct. This will require galvanized metal profiles. Using anchors, they are secured along the entire perimeter of the future air duct. It's good if the pipe runs in a straight line. In cases where this option is not possible, the profile should be fixed with bends in the required places. Markings for the air duct are applied on the ceiling. The first profile, which serves as a start, is laid down in several separate parts. They are attached using self-tapping screws. The fourth stage is the completion of work on arranging the plasterboard box. To complete the work, you will need to attach a second panel from the primary profile to the already completed hanging parts. You used it as a starting point for work. When the lower part is ready, transverse type strips are mounted on it. They should subsequently be covered with plasterboard. The fifth stage is the formation of the kitchen hood body. So, when all the rough work is done, you can begin arranging the hood itself. The lower part of the future appliance is fixed to the kitchen walls. It is also made from a profile. If your kitchen has a niche for the hood, this will make the task even easier. Otherwise, you will have to additionally attach the lower part to the main box from the sides. All parts of the hood are cut from a metal profile and connected to the lower part. To make the structure more rigid, you will need to strengthen the sides with jumpers. They are also made from a profile. Stage six - connecting the air duct to the ventilation system

To complete the procedure for finishing a kitchen hood, its body and the box in which the air duct is located are sheathed with plasterboard. Then putty is applied to the finished structure. With its help, fasteners and plasterboard seams are masked. After this, the hood can be painted. Some prefer other options for decorating this kitchen appliance.

Layout of sockets in the kitchen.

This type of design is perfect for both active and passive hoods. If you choose the first type, you will need to install an electric motor inside the housing. It will need to be connected to the network.

The second version of a homemade kitchen hood is made of plywood. This hood is used only for active type appliances.

Fume hood design and material

When choosing a hood for the kitchen, two indicators are of no small importance: designer aesthetics and ease of maintenance. There are quite a large number of different models on the modern market, so every cook will certainly be able to choose a hood that will fit perfectly into the interior of his kitchen. However, caring for it may cause some inconvenience.

For this reason, you should not opt for models of fume hoods made of inexpensive heat-resistant plastic, but give preference to an enameled or, even better, aluminum hood, which is characterized by increased wear resistance and ease of cleaning. An alternative option in the form of heat-resistant glass has great aesthetic appeal, however, it is an expensive device and not very convenient for everyday care. Ultimately, it depends on how the kitchen hood works and whether the device is cleaned in a timely manner.

- For a classic and rustic interior, it is necessary to select built-in, inconspicuous hoods in retro or country style. Carving, artificial aging of the body, elements made of natural brass or antique silver - all this will look very harmonious in traditional kitchens. At the same time, almost all companies offer retro-style models to consumers. By the way, a standard hanging hood can also be closed using a decorative trim.

- For the design of a modern interior, devices of a laconic design with a clear or rounded shape are more suitable. They can be either colored or printed. With a glossy, matte or chrome finish. At the same time, the main thing is that their size and shape do not harm the functionality of the equipment, as often happens in practice.

- Inclined built-in hoods are ineffective due to the tilt of the body, despite the fact that they look great, do not take up much space, are comfortable to operate and do not allow tall users to accidentally hit their heads on the body.

- It is best to choose the color of the kitchen hood to match the facade, wall surface or apron. The easiest to clean are hoods made of metal, as well as those in light colors, such as metallic or white. It is most difficult to care for dark hoods with a glossy surface.

Why does the hood stop working?

This happens for several reasons:

- The decorative grill covering the channel opening is dirty . This is the simplest option - you can solve the problem on the spot by removing the grille and cleaning it of soot and dust;

- Clogged ventilation duct . The air duct may become clogged with debris and accumulated dust. In winter, an ice build-up may form in it, preventing the outflow of air. Cleaning of the ventilation duct should be carried out by specialists of the management company;

- Dismantling of part of the air main by one or more residents. As a rule, the goal of apartment owners in this case is to increase living space. Such actions are illegal. In such a situation, it is necessary to draw up a collective complaint to the supervisory authorities.

Control

The fume hood can be controlled either mechanically or electronically, depending on how the hood is designed. In the first option, changing operating modes and switching lighting occurs using mechanical buttons; in the other, using an electronic control system, often equipped with an indicator displaying the specified operating mode.

The main advantage of electronic control (in addition to aesthetic qualities) is the presence of a timer function for turning the fume hood on and off. More advanced modifications are capable of automatically switching operation in accordance with the degree of pollution of the air flow, and some copies provide remote control using an appropriate remote control or a special application for a smartphone. The need for the presence or absence of such functionality remains at the discretion of the specific client and the requirements for how the electric hood works.

Optional modes include the intensive version of the device, in which the fume hood operates at maximum performance for a specified period of time, after which it switches to the standard version. And a periodic type of operation, in which the hood is activated from time to time for a duration set by the user.

Separately, it is necessary to note kitchen hoods designed to work together with stoves. Compatibility in this case is maintained at the level of the manufacturer: it must be absolutely identical. Such systems of hoods are controlled directly by the hob: depending on the use of its resources, it decides which of the possible operating modes will be optimal at one time or another, depending on how the hood works in the kitchen.

Device models offered by manufacturers

Time-tested and proven quality equipment from German, Swedish or Japanese manufacturers is considered the most reliable. But recently, domestic companies have also been producing decent models of hoods.

Bosch DFS 067K50

The manufacturer, whose quality of household appliances has remained at the highest level for many years, offers various types of hoods: wall-mounted, built-in and telescopic.

Bosch DFS 067K50

Model DFS 067K50 is suitable for installation in suspended modules; it is equipped with touch controls, a retractable screen and backlighting with variable light levels. The automatic selection of operating mode and indication of the filter status are very convenient. The only significant drawback of the product is its high price.

Shindo Avior Sensor 60 SS/BG 3E

The products of the Japanese company are characterized by ergonomics and functionality. The hoods are maximally equipped with electronic components, which increases convenience for the consumer.

Shindo Avior Sensor 60 SS/BG 3E

The dome model Avior Sensor 60 SS/BG 3E (made in China), with a glass visor, is made in the Art Nouveau style. A high-performance product that operates in various modes (circulation and air removal), is equipped with LED lamps and sensors that allow the device to automatically regulate the intensity of work.

Inclined hood Shindo AVIOR sensor

Siemens LC68BA572

The German concern, whose products do not require additional recommendations, offers the consumer a wide range of different types of hoods. Fans of technology with the maximum number of bells and whistles are even offered models with built-in TVs.

Siemens LC68BA572

The dome-type hood LC68BA572 is suitable for installation in spacious kitchens. It effectively purifies the air to the required level.

Extremely quiet thanks to additional sound insulation

Various types of sensors themselves determine when the device should operate. The body of the device is easy to clean, and the installed LEDs allow you to cook in the dark. But not everyone will like the price of this product.

Kitchen hood 60 cm Siemens

Kronasteel Kamilla Sensor 600

The German manufacturer, which opened a representative office in the Russian Federation, produces equipment of decent quality. The range of hoods includes models that differ in configuration and characteristics, but all of them are effective and easy to use.

Built-in hood Kamilla Sensor 60

The built-in hood Kamilla Sensor 600 can operate in exhaust and circulation mode, is equipped with two 100 W motors, a touch panel and halogen backlight. The model looks very attractive and works quietly, has 3 operating speeds, a timer and an anti-return valve.

"Elikor Integra 60"

We can safely say that recently this Russian company has begun to provide worthy competition to Western manufacturers. Household and professional hoods have an excellent price/quality ratio.

"Elikor Integra 60"

It is possible to choose a device that operates using a flow or circulation cleaning method. Budget products are equipped with various options that help Elicor products meet the needs of modern consumers. The highlight of the brand is the collection of models decorated with paintings.

Kitchen hood Elikor

The Integra 60 model is perfect for installation in small kitchens. The device is reliable; it can be connected to an air duct or operated in circulation mode.

Mesh removal handle

A fairly simple product with mechanical control and two speed modes has one obvious drawback - a high noise level during operation.

Kitchen hood Elikor in the interior

For clarity, a comparison of the cost and main characteristics of popular models is offered.

| Model | Productivity, m3/h | Width, mm | Power, W |

| "Integra 60" | 400 | 600 | 200 |

| 550 | 600 | 2 x 100 |

| 700 | 600 | 146 |

| 760 | 600 | 166 |

| 800 | 600 | 238 |

Having carefully studied the models offered by manufacturers and settled on a device that suits you best in terms of functionality, price and external characteristics, you can purchase a hood that is optimally suited for a particular kitchen.

Main components

The design principle of a kitchen hood is quite simple. In flow-type hoods, a grease filter or a coarse retention element is used as the lower section, designed to collect fat fractions and soot.

The fans are located on the inside of the air intake and are driven by electric motors designed exclusively for the fume hood. In a direct flow system, there is a duct behind the fans that is connected to the home's air handling unit.

In recirculating kitchen hood systems, carbon filters are installed behind the fans to filter out fine particles, which remove unpleasant odors as the air flow is directed back into the kitchen area. Fine carbon filters are made from durable aluminum alloy, which allows them to be cleaned like greasy dishes.

In addition, they are lightweight and resistant to corrosion, which protects the electrical circuit of the device from factors that destroy the integrity. Carbon filters are installed using a special cassette, have a very thin structure, and must be replaced in strict accordance with the recommendations specified in the operating instructions for the specific model of the fume hood.

The housing part is made of thin metal or composite raw materials with noise suppression function for the modern generation of exhaust systems. There are virtually no differences in design, and therefore, when choosing equipment, each buyer is guided by his own preferences.

The operating principle of a kitchen hood:

- Connect the plug from the power cord to an electrical outlet;

- Press the button with the required intensity of operation of the exhaust unit;

- The engine speed increases and the ventilation system operates.

Important! If the home network is equipped with grounding, then this is good; otherwise, it is better to lay the electrical wiring separately, since there is a gas pipe nearby.

Homemade plasterboard hood

Tools and materials

The easiest way to make a hood is to build a corrugated pipe with an electric fan into a kitchen cabinet located directly above the stove or hob. But such a hood cannot be called beautiful - which means we will take a different, more complex, but more productive path!

Frame elements

To make a passive dome hood we will need:

- Moisture-resistant drywall - from this we will make a box to house the air duct and the dome of our hood itself.

- Galvanized metal profiles for the frame of the box and dome.

- Perforated metal corner for decorating the corners of our hood.

- Corrugated pipe - air duct.

- Fastening elements.

- Insulating material for wrapping corrugated pipes.

- Putty and paint for finishing the dome.

Corner overlay

The set of tools with which we will make our hood will be familiar to anyone who has ever worked with drywall:

- Hammer.

- Screwdriver.

- Metal scissors for cutting profiles.

- Tape measure and level (preferably laser).

- Spatulas and brushes.

When everything is ready, you can start working.

Manufacturing

We begin work on the manufacture of the hood by marking the room. We will need to place on the wall not only the hood itself, but also the air duct, which we will hide in a plasterboard box to ensure the aesthetic appearance of our kitchen.

The easiest way to mark is if the ventilation hole in the kitchen is located above the stove itself. If the hole is to the side, you need to mark on the wall the position of the box for laying the air duct.

Hood placement diagram

When we have decided on the placement of the air duct, we proceed to making a frame for it:

- We attach a starting profile made of galvanized metal to the wall at the level marking the lower surface of the air duct box. To fasten the profile we use anchors with a 6 mm plastic sleeve.

- We also attach the starting profile to the ceiling according to the markings we applied. If we plan to make the air duct box curved, we cut and bend the profile before fastening it.

- From the starting profile, we lower several vertical fragments of the main profile down, attaching them to the starting profile using self-tapping screws.

Drywall box

We complete the formation of the frame for the box by installing another panel of the starting profile on the resulting hangers. We install transverse strips on the lower part of the resulting profile, which will then be covered with plasterboard.

You can study in more detail the technique of working with drywall and the profile for it by watching video instructions on the Internet.

Making the hood body

The box is ready - it’s time to move on to making the hood itself:

- From the starting profile we make the lower frame of our hood, securing it to the kitchen walls. The easiest way to attach the frame is if we install the kitchen hood in a niche - otherwise the side parts of the frame will need to be additionally attached to the box.

- We cut out the frame elements of our future structure from the main profile, and use them to connect the box with the lower frame, as shown in the photo.

Hood frame

To add rigidity to the structure, we reinforce the side surfaces of the hood with transverse bridges from the profile.

The frame is ready. Now all that remains is to attach the air duct from the corrugated pipe to the ventilation hole - and you can cover the dome with plasterboard.

To prevent the air duct from making noise during operation, we wrap it with batting or other soundproofing material.

Hood finishing

We finish the hood as follows:

- We cover the air duct box and the hood body with plasterboard.

- We protect the corners with a metal perforated corner.

- We putty the resulting plasterboard structure, masking the joints of the plasterboard sheets and the locations of the fasteners.

- We paint the hood in the color of our choice or finish it in another way. Our homemade kitchen hood is ready.

Exhaust after putty

The advantage of this technology is that this instruction is suitable not only for the manufacture of a passive hood, but also for the manufacture of an active type hood. In this case, it is enough to install an electric motor inside the housing at the entrance to the air duct and connect it to the network.

Electrical components

Almost every kitchen hood includes at least two lines:

- Lighting for which the use of LEDs is not recommended, since a rather complex circuit is formed, leading to flickering, which has a detrimental effect on human health. Basically, either an ordinary incandescent lamp or energy-saving components located on the inside of the hood are used.

- The second basic element is the hood motor, which has a number of safety mechanisms. It consists of fuses and capacitors to eliminate sparking in electric motors with a commutator operating principle. In order to protect against the occurrence of a spark discharge, the engine circuit provides for the installation of varistors, the resistance of which varies during voltage surges. This element must be installed in pairs. When a spark occurs, voltage is supplied to the body compartment of the hood and distributed along the entire perimeter of the system, protecting the household electrical network from excessive load, and the electric motor winding from burnout.

A built-in hood can be equipped with a commutator motor that is not afraid of excessive heating, but manufacturing companies equip them with thermal fuses in addition to the standard equipment. As a result, the level of noise exposure will exceed the permissible standard: for a fume hood, this parameter is directly determined by the type of built-in electric motor. Accordingly, it will be cheaper and more efficient to operate an asynchronous motor with a squirrel-cage rotor if its connection is provided for in the electrical circuit of the kitchen hood.

In conclusion, a few more lines about lighting elements - many users do not attach proper importance to them, and in vain. It is more correct to use halogen lamps, because they are economical, are not afraid of repeated switching, and emit diffused light, which does not strain the eyes.

Purpose of kitchen ventilation

During the cooking process, a whole bunch of dangerous chemicals are released into the air.

Among them are:

Carbon monoxide (CO), better known as carbon monoxide. An extremely toxic substance, even in small concentrations leading to severe poisoning of the entire body. And when the concentration of CO in a person’s blood reaches 5 ml per liter, almost instantaneous death occurs. The main danger of carbon monoxide is that it has neither color nor odor. Therefore, its dangerous concentration can be detected only by a sharply deteriorated state of health - a severe headache accompanied by vomiting. CO is released during any combustion, including when frying food on a stove fire.

- Natural gas (propane, butane, methane) is another dangerous chemical component present in the kitchen. It is commonly used as an energy carrier for gas cooktops. But in high concentrations it can not only cause human poisoning, but also cause fire and explosion. Every year, hundreds of people around the world become victims of gas leaks that could easily have been avoided with an effective ventilation system.

- Carcinogens are volatile substances released into the air when foods are fried or fats are burned in a frying pan. This is the same child that stands in the kitchen while preparing food, and then settles on the walls and ceilings of the room with a greasy coating. Carcinogenic substances, although they cannot lead to immediate death of a person, like CO or propane, are capable of accumulating in the human body. When these substances enter the liver, kidneys, and lungs, they ultimately cause severe pathologies, including cancer.

- Water vapor is released when cooking soups or boiling a kettle. By itself, it is absolutely harmless to humans. But in high concentrations it condenses on the walls and ceilings of interior spaces, causing the appearance of fungus and mold. The fungus significantly reduces the service life of finishing materials, and can also affect the load-bearing elements of the building structure. Microscopic spores released by mold into the air cause severe allergic diseases - dermatitis, asthma, chronic bronchitis.

Exhaust fan

For a kitchen hood, an important element is a fan that draws polluted air out of the room. Diametrical or tangential fans have performed well in the operation of kitchen hoods - they regularly hold the maximum load.

The exhaust fan impeller resembles a hollow cylinder with blades slightly curved forward, resulting in uniform air exchange. Such devices are characterized by high efficiency = 0.7, high air flow, which is easily directed in the direction required for work, and low noise impact. In addition, the system maintains a fairly low pressure, depending on how the kitchen hood operates.

Types of filters for kitchen hoods

The process of air purification largely depends on the filter elements used. Manufacturers offer hoods equipped with only one grease-absorbing filter or two at once - a carbon and a grease filter. In flow-through products, only the first type of filter elements is used. This is explained by the fact that there is no point in purifying the air from odors, since it will still go outside and be purified using a natural method.

- Grease filters. Every exhaust system is equipped with a grease filter element. It is designed to trap fatty particles in the air, which are blown into the device by a fan. Such an absorption filter can be used once, or maybe several times, depending on the material.

Disposable products are made from padding polyester, non-woven fabric or acrylic and are changed when dirty. Unlike these models, reusable filters last almost the same period as the hood itself, since they are made of metal and can be washed. The classic anti-grease filter is a rectangular cassette with a mesh segment made of mesh or perforated foil.

Perforation in this case is made asymmetrical. The holes on the mesh and the asymmetry of the perforation serve to change the air flow and trap fat particles. Metal filter filters are made of stainless steel, galvanized steel or aluminum.

- Carbon filters. Recirculating products typically have activated carbon filter elements installed. Indeed, in such hoods it is important not only to retain fumes, soot and fumes, but also unpleasant odors that are typical when preparing certain dishes. A carbon filter is installed after the grease filter, and it also needs to be changed when it gets dirty, which will be indicated by a light on the panel.

The choice between recirculation and direct-flow hood

For most cases in which it is possible to organize a direct-flow hood, it is more advisable to opt for this exhaust device: removing polluted air will clear the room of foreign odors more effectively than filtration.

A straight-through fume hood can be installed in any location. The only requirement will be the presence of a ventilation system nearby, with which it can be connected. You should not extend the ventilation pipe over a long distance that is not provided for in the exhaust diagram, as this may not only seem unsightly, but also lead to a decrease in the performance of the exhaust system. According to experts, if you arrange a duct with a 90-degree turn, the efficiency of the ventilation system decreases by approximately 5%.

The direct type exhaust device is equipped with a coarse metal grease filter designed to prevent grease deposits from entering the internal elements of the device - engine components and housing parts. Ultimately, this can lead to engine failure and, over time, become a source of unpleasant odors. As a rule, such a filter element is removable. It can be cleaned and functions at all stages of operation of the fume hood. However, practice proves that it is often difficult to clean, so from time to time the user finds himself in a situation that requires replacing the filter.

A simple kitchen hood with air recirculation is in most cases equipped with two filters: the first is designed to eliminate oil contaminants. A second carbon filter is used to eliminate unfavorable fumes. The carbon filter is also disposable, and therefore needs to be changed periodically. It is easy to imagine that the costs of such cleaning elements can reach a significant cost. This is especially true if you do a lot of cooking at home.

Many models of kitchen exhaust systems are equipped with an audible warning about the need to replace the carbon filter or carry out preventive maintenance on the metal grease filter. This can be provided, in particular, by means of a light indication on the control panel. In a simpler version, these may be special symbols on the filter element that disappear when it is cleaned.

In this regard, a recirculating hood in an apartment kitchen is used for installation in cases where it is impossible to install direct-flow exhaust systems: if there is no access to the ventilation shaft or, due to aesthetic requirements, it is impossible to lay an air duct (for example, over a kitchen “island”). You should also take into account how the kitchen hood is designed, and the fact that the operation of recirculating hoods does not entail a decrease in the temperature in the room, which may be relevant, for example, in a country house.

Direct-flow kitchen hoods quite often provide the ability to operate in recirculation mode: in this case, you will have to additionally purchase a filter element, which, as a rule, is not included in the standard package.

But it is still better not to pay attention to budget direct-flow hoods that do not have any filters: they, of course, will cope quite well with removing contaminated air, but they will soon become contaminated to such an extent that cleaning them will be very difficult, and the work has stopped. This problem is also relevant when installing a homemade hood, since its full functioning requires high-quality factory-made filter components.

Ventilation features

When installing a hood, you need to choose the right air duct. In practice, the following types of ventilation systems are used:

- Corrugated sleeve made of aluminum. The main advantage of such a model is the ability to change the shape for acceptable parameters. The material bends well, which makes it possible to make a ventilation duct with turns in the right places. The disadvantage of the product is the creation of noise during the passage of air flows. In addition, grease, dust and dirt constantly settle on the surface of the corrugated sleeve. It needs periodic cleaning to remove dirt.

- A round plastic air duct is assembled from several parts (adapters, angles and couplings). The connection of all parts is carried out using shaped parts. To prevent tears, the joints are coated with special glue, then additionally secured with self-tapping screws. The main advantage of such a system is considered to be silent operation.

- Square plastic ventilation ducts are made of polyvinyl chloride. The product in question has the same characteristics as the previous type.

The plastic models of air ducts are supplied with additional parts that can be used to install the most complex engineering systems. Such products are characterized by high cost and complex design; their installation must be carried out by a professional.

Save

Classes of exhaust systems and their cost

The cost of kitchen hoods is determined depending on:

- Device design;

- Power and performance characteristics;

- Type of control (electronic or mechanical type);

- Number of speed and operating modes;

- Additional functional options.

Classifications of exhaust systems in the context are as follows:

- Economical. Inexpensive equipment with a capacity of up to 450 m3/h. The equipment provides support for up to three speed modes. Mechanical control.

- Standard. Equipment of the middle price segment. Power up to 650 m3/h. The control system is either mechanical, electronic or touch.

- Luxury. Equipment capacity up to 1250 m3/h. The control uses sensors and a remote control. Fume hoods are equipped with sensors for humidity, temperature, and degree of contamination of the filter element. The equipment has automatic operating modes and a timer.

Some practical tips

If you have no financial restrictions, opt for a kitchen hood that can function in two ways - to divert the air flow outside the room and in automatic recirculation mode.

About the engine. To avoid negative effects on the hearing organs, it is recommended to use two low-power motors instead of one high-performance motor. We also offer the most silent models of exhaust systems with a noise level not exceeding 40 dB.

There are a huge number of models in special retail outlets, and sometimes it can be quite difficult to decide and understand how to properly make a kitchen hood. Taking into account the recommendations set out in the material, you can make the right choice in favor of a reliable home assistant that can make daily culinary work easier and make it safer for the health of all family members.

Where to start installing a hood

A very important question, you need to pay close attention to it, otherwise instead of a positive effect you will get a negative one.

| Action | Short description |

| Remove the decorative grille and carefully inspect the channel surfaces. To make inspection easier, use a flashlight. The channel must be clean, the smoke from the burning paper must be completely drawn into it. If there are cobwebs, black soot and other foreign deposits, then this indicates poor natural ventilation; representatives of the management company must be called to correct the problems. Further re-equipment is done independently, we will tell you exactly how below. |

| It can be flow-through or circulating. The first is connected to the channel and exhausts the exhaust air outside. As we mentioned above, it has several important installation restrictions; the requirements must be met. The second type of hoods is not connected to ducts; the unit purifies the air and returns it back to the room. This is a completely autonomous and safe system, but it has one significant drawback - it requires frequent filter changes. |

| Technical parameters of the hood | The main thing is to select devices taking into account the volume of the room and the minimum air exchange rate. The fan performance should be at least 20% higher than the required volume of air exchange; operating the electric motor at its maximum capabilities significantly reduces its operating time. If the main factor is determined, then you can select ventilation according to size, noise level, availability of additional functions, design, type of control, etc. These indicators do not affect the cleanliness of the air in the kitchen, they only increase the comfort of using the device. |

How to choose a hood for the kitchen

TOP 7 best hoods.

| Model | Advantages | Capacity (m³/h) | Installation width, cm |

| Hansa OSC 6111 WH | Budget hanging model Hansa OSC 6111 WH with comfortable slider control. Housing - stainless steel steel. Noise level is low. | 335 | 60 |

| The hanging hood Indesit H 151.2 WH has a flat design that is installed on the wall above the stove. The Indesit H 151.2 WH hood operates quietly, producing a maximum noise of 60 dB. Cleaning is done with a grease filter. An additional carbon purifier can also be installed. The kitchen work surface will be illuminated by two light bulbs built into the hood. | 230 | 50 |

| Akpo WK-4 Vario eco | An elegant fireplace hood with a powerful motor will not take up much space in your kitchen. Three operating speeds will allow you to adjust the device to any level of air pollution, and thanks to its high performance, the device will perfectly cope with a combined kitchen-dining room or kitchen-living room. | 650 | 50, 60 and 90 |

| The hood is made in white and has an inclined position. The intensive mode allows you to instantly purify the air, and control is carried out thanks to the touch display. | 620 | 60 |

| Two operating modes can draw polluted air into the ventilation or purify it and release it back into the room. The aluminum filter is easy to clean from grease in the dishwasher. | 650 | 90 |

Once all the above points have been agreed upon, you can proceed with the actual installation of the hood.