To patina large-area wooden surfaces - door leaves, furniture facades, wall panels, you can use a slightly different aging technology. The preparatory operations are similar to those discussed above, and the surface should be primed with a special primer based on polyurethane or acrylic.

After the primer has dried, apply one thin coat of paint for patination. The completely dry painted surface is sanded with a metallized sponge - scotch tape - with Bright.

Next, the surface is wiped and opened with colorless polyurethane, acrylic or nitro varnish. The shade of the varnish depends on the natural color of the wood being rolled. For surfaces made of walnut, birch and linden, light, yellowish varnishes are used; for oak, alder and wenge wood, darker varnishes are used.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

The structure of this building material helps give the wood a special look, blackening out the carvings, recesses and relief protrusions and edges. If you want to clarify something, please contact me!

We create a patina with our own hands on metal and wood

- first remove all defects from the wooden surface by sanding it with sandpaper, after which the wood is thoroughly cleaned of dust residues;

- the surface is primed with a special primer (included in the antique restoration kit) and dried for 24 hours;

- apply the first, main layer of patina paint, avoiding smudges, and dry it for a day;

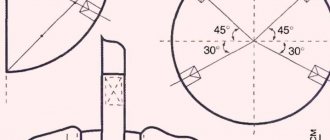

- the second layer is applied with small brush strokes in different directions - when excess patina or coloring composition is formed, they are rubbed with a foam swab;

- without allowing the second layer to fully set, rub it with a dry cloth;

- after drying, if there are “rubbed marks,” they are removed by local tinting, which I also rub with a dry cloth;

- After complete drying, a finishing layer of varnish is applied to the surface.

Mechanical resistance

The indicator is quite low for facades covered with film: traces are easily left, for example, from a cut with a knife. Also, do not expose the surface to aggressive cleaning agents, such as powder.

Patinated facades withstand mechanical stress well. With strong pressure, a mark may remain that will not be noticeable on a surface of a certain texture. Patinated furniture is also resistant to abrasion.

Veneered facades are resistant to mechanical stress. Even cuts leave virtually no traces behind.

Applying patina to wood with your own hands

The patination process is simple and can be done at home. For work, it is better to choose high-density wood species that are resistant to changes in humidity, or use MDF or chipboard.

Chipboard and MDF boards have a homogeneous structure, unlike wood, so their preparation has its own peculiarities. To give it abrasion, the surface can be carefully treated with fine sandpaper, but the most effective is a more complex technology:

- applying a barrier primer to enhance the adhesion of the top layer of the slab to the patina,

- after drying, apply a polyurethane primer, which will become the basis for the patina,

- sanding the created coating with sandpaper to reproduce the wood structure,

- actual patination.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

For work, it is better to select wood species with a high degree of density, which are also resistant to changes in humidity, or use chipboard and MDF. If you want to clarify something, please contact me!

Possibility of repair

Defects that appear on the film cannot be restored or painted over - the entire coating will have to be replaced.

The facade in the style of antique furniture very rarely requires repair. Not only is it resistant to many factors, but the consequences of impacts such as a cut are almost invisible. If the defect is noticeable, it will be quite easy for the technician to correct it, provided that the damage has not gone deep into the film.

Veneer facades are easy to repair. For minor damage, sanding can be used. For more extensive ones, a patch is used. As a last resort, you can dismantle the panel and replace it with a new one.

DIY patina video

- apply a dark patina,

- let the product dry a little, apply another layer of material of a lighter tone to highlight the dark pores,

- instead of a light tone, you can take gold or silver if we are talking about furniture in a classic style,

- as it dries, sand the base with fine sandpaper to create a scuffed effect,

- fix the result with shellac or acrylic varnish, choosing a matte composition.

However, unlike others, the technology for patination of MDF facades is not so complex that it should be abandoned. You just need to know the general principles of the patination technique, and mastery will come with experience. The money spent will pay off in the sale of truly truly exclusive furniture.

Patination of MDF facades is the treatment of the facade coating in order to give it the effect of an aged natural or artificial material and highlight the surface texture with special paints (patina).

The process of patination of an MDF facade in PVC film consists of the following stages:

Which is better: heated floors or radiators?

Warm floorBatteries

adhesive barrier primer is applied in a thin layer to the surface of the previously thoroughly cleaned MDF facade . To achieve the best quality, the primer is applied using a spray gun.

2. The second layer is applied with colorless polyurethane primer for patina.

4. A patination compound is applied. Patina or patination compositions are special paints and varnishes with special properties, used to visualize the aging of a facade or create decorative color effects on it.

5. Patina treatment . For this process, various methods and materials can be used to achieve the desired effect. For example, sanding with foam rubber or steel wool, scraping with a spatula, scratching with emery cloth, and the like.

6. Coating the patina with varnish . Since the patinated surface of the facade is easily vulnerable to mechanical damage, it should be protected and secured with a layer of polyurethane varnish. Moreover, to achieve the desired effect, you can use either matte or glossy varnishes.

The most popular patination techniques for MDF facades are the classical method, contrast patination and the crackle technique.

Patina varnish using the craquelure technique is applied either by spraying or using a swab or brush. At the same time, various patterns and cracking effects can be obtained on different parts of the façade surface.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

I’m new to decoupage, so I took very thin rice paper, diluted PVA glue with water and, having first attached the pictures to the right place with a drop of water, covered it all with glue. If you want to clarify something, please contact me!

Peeling off

Film facades are quite sensitive to the atmosphere - they can peel off under the influence of excess humidity and elevated temperature.

The varnish, with the help of which the aging effect is created, becomes an obstacle to any negative factors, be it moisture or heated objects. This prevents the film from peeling off and deformation of the product. But at the same time, you should carefully consider the back side of the facade, since it is not subject to varnish treatment. Therefore, you should not exert any mechanical, temperature or other influences on the inner surface, otherwise no film or varnish will be able to save it from deformation.

Veneered facades are quite reliable, but incorrect pasting, faulty production technology or low quality materials can lead to rapid peeling.

Patination technology for MDF facades – MDF Workshop

I'm ready for criticism in advance, since this is my first master class, it may be a little clumsy. But its purpose is only to share information.

In addition, this is also my first experience in decoupage. I searched for a long time on the site for similar master classes for dummies, but never found them. A little earlier there was a master class on decorating a chest of drawers, but my technique is slightly different, although the idea is similar.

I indicated the time based on the fact that it is necessary to leave the product to dry. The net working time on the bedside table is about two hours, including patination, and on the trough, about 30 minutes.

So, we have a small wooden bedside table, which previously lived in the bathhouse, and now has settled in a bright bathroom. The task was to fit it into the interior. The idea to make a master class did not appear immediately, so the photo is not of very good quality. Therefore, I replaced the bedside table with a wooden trough. Actually, it was decorated using the same method in conjunction with the bedside table.

– primer, acrylic paints, brushes, pictures for decoupage, varnish.

First of all, we sand the surface of the trough to remove everything that was previously covered with it. You can do this with sandpaper, I was lucky, I found a sanding machine in the garage.

After this, the most interesting part begins - patination with paint. I spent a long time searching on the Internet for the best way to do this, and read about patina and wax, but everything turned out to be much simpler.

Here we need to go back a little to the priming process. I specially primed the surface with a wide brush with stiff bristles - this way I got a slightly uneven surface with grooves. And now we use this in the patination process.

For patination, I chose gray acrylic paint - it matched the color of the stains on the tiles in the bathroom.

So, we are ready for patination. It is better to immediately prepare several pieces of an old rag and preferably it should be clean.

Take a brush, dip it a little into the paint and spread it heavily over part of the surface. The brush should be almost dry. Let it dry for 10 seconds, then take a dry, waste cloth and wipe off the paint. At first it seems that the surface is simply smeared with paint, but the more you rub, the less paint remains on the surface, mainly in those very grooves.

Thus, the structure of the tree gradually appears.

It is best to leave a little more paint in the corners. In general, how your imagination will fly. I made the recesses on the door a little darker than the rest of the surfaces.

How to patina wood: application technology, review of materials and tools

The simplest and safest way to age furniture is to rub dark wax into its surface. This gives it a natural appearance, associated not with careless care, but with time, contamination.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

Modern patination technology makes it possible to age wooden surfaces, furniture elements and products in general, which significantly increases their decorative value. If you want to clarify something, please contact me!

Advantages of patinated furniture

The undoubted advantages of furnishings processed in this way include practicality, durability, uniqueness and accessibility.

Since the colors of the headset are not uniform, the appearance itself will look harmonious with minor abrasions and minor flaws that inevitably arise during use.

There is no need to worry, the beauty of the furniture will not suffer from external unfavorable factors. This is a question of practicality.

As for durability, the composition with which the furniture is treated has protective properties, makes it moisture-resistant and resistant to temperature changes (which, as you know, is not uncommon when cooking). The patinated set will look luxurious for many years and will invariably delight all family members with its impeccable appearance.

Regarding uniqueness, hand-made patination will add a special atmosphere to your home. As you know, antiques are accessible to select segments of the population, so the achievements of modern technologists in terms of artificial aging of objects make it possible for a wide range of lovers to purchase antique furniture.

Features of processing large parts

The patination technology is slightly modified when working with large parts, such as door leaves, furniture facades, and wall panels. The preparatory stage is completely repeated without changes, but priming is carried out with a special primer, which is based on polyurethane or acrylic compounds.

When the primer dries, one thin layer of paint is applied. The part, completely dry after painting, is sanded with a metallized sponge called Scotch Brite. Then the surface is wiped dry and coated with a colorless polyurethane, acrylic or nitro varnish. The shade of varnish is selected based on the natural color of the wood being treated.

For birch, walnut and linden furniture, light, yellowish varnishes are used. For oak and alder, darker varnishes are used.

Types of patina, consistency and compositions

How to make a patina with wood stain? Staining is ideal for furniture made in a classic style. The color of the products will be darker than it was originally.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

This material is water-based, but makes it possible to create a stable coating that has excellent adhesion to surfaces. If you want to clarify something, please contact me!

Easy to clean

One of the main advantages of film facades. Dirt, grease stains, even a marker - all this will not leave marks on the surface of the furniture. Many of them just need to be wiped with a cloth or sponge, but the product can easily withstand cleaning with both soap and water and cleaning liquids.

Patination varnish in combination with film creates a very durable structure that perfectly withstands the effects of cleaning agents. But their use may be necessary only in exceptional cases, since almost any dirt can be easily wiped off the surface with a cloth or sponge, sometimes moistened with water.

Veneer is resistant to moisture, so it can be washed without problems. But the peculiarity of this material allows you not to use it too often: most stains and dirt can be quickly removed by wiping with a slightly damp cloth or sponge.

Sets

- Acrylic patina for wood. It's acrylic paint. The least complicated in practice and ideally suited for apartment conditions. Acrylic patina is applied with a brush. The advantage is the large number of colors that can be used to tint the product. If necessary, repainting is done to achieve the desired shade.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

Variability

Products with film will delight you with a huge variety of colors, shades and textures. It is possible to order a product with a film that imitates expensive materials: valuable wood, leather, precious metals. It is possible to apply images and emboss.

Patination of the facade is aimed at creating the effect of antique furniture. There are two options for this design - wood effect and metal effect, but the shades, texture, and “natural” pattern are individual and very diverse. At the same time, using processing, you can make the color of the film brighter or, on the contrary, more muted.

Veneered facades look as if they are made of solid wood - solid, solid. They harmonize perfectly with wood products: MDF panels, tables, cabinets and others. For greater savings, you can not cover the entire surface with veneer, but use it as an accent on certain elements. The combination of veneer and enamel deserves special mention: this combination creates a luxurious image of furniture, emphasizing the sophistication and value of the product.

It is also possible to perform milling in each of the proposed options.

The most inexpensive are film facades. In second place are patinated ones. And the most expensive of those considered are veneered ones.

In all of the above there was not a word about safety. We considered it unnecessary to include this in a separate discussion, since the basis for the facades is tiles of compressed wood chips - one of the most environmentally friendly materials. Additional materials have similar characteristics - the film and varnish used in patination are non-toxic and do not emit harmful compounds. And veneer surpasses them in these properties.

Each material has both advantages and disadvantages. The choice in favor of any depends on the aesthetic preferences and financial capabilities of the customer. The main thing to remember is one thing - don’t skimp, then the facades will fit perfectly into the image of the furniture and will last a very long time.

What's the result?

Brief summary: if you look at things realistically, it becomes clear that natural wood is an expensive and impractical material to maintain, which requires careful handling and constant maintenance. Glass and ceramics are poorly studied exotics: not every buyer is ready to experiment with materials at his own expense.

We have noticed that when buying a kitchen, our customers strive to solve several problems:

find a solution that can be used for many years, without the need for repairs;

choose materials that can withstand daily use;

do not overpay for unobvious advantages (it’s just beautiful - not an argument when the budget for repairs is limited within reason).

The logical choice is a kitchen with facades made of MDF coated with PVC film or plastic. We are confident in the quality of manufacturing and assembly, so we provide a 24-month guarantee on all kitchen furniture. It's up to you: all you have to do is choose a kitchen in a classic or modern style and rely on our craftsmen who will carry out high-quality installation.

And let the new kitchen create comfort in your home and promote any culinary experiments.

LiveInternetLiveInternet

–Categories

- (0)

- +++Hobbies (3604)

- PERGAMANO (1)

- costume jewelry (92)

- Beads (64)

- rope (22)

- embroidery (2)

- Crochet (317)

- Knitting needles (333)

- newspapers. straws (40)

- Clay Porcelain Gypsum (67)

- Decoupage (1249)

- jute (46)

- cardboard (12)

- kinusaig (1)

- Rugs (61)

- Beauty from nothing (137)

- macrame (28)

- New Year's (189)

- origami paper quilling (72)

- papier-mâché (44)

- Easter (61)

- PLASTIC dishes (65)

- patchwork (1)

- Miscellaneous (218)

- christmas (10)

- scrapbooking (1)

- soutache filigree (16)

- spot painting (315)

- foil (1)

- TATTING (3)

- Sewing beauty (162)

- joke (12)

- boho (30)

- VERA (14)

- hair (19)

- education (38)

- games (14)

- presentations (1)

- psychology (2)

- geography (44)

- House 6)

- painting (918)

- animals (108)

- LAW (3)

- Health (91)

- diet (1)

- charging (17)

- leather (22)

- herbs (6)

- interesting (19)

- interior (71)

- curtains (10)

- Art (13)

- cinema (21)

- books (93)

- computer (39)

- Cooking (1231)

- sandwiches (5)

- second (151)

- baked goods (154)

- desserts (84)

- Jewish (2)

- blanks (126)

- Snacks (87)

- candy chef (122)

- multicooker (7)

- meat (74)

- drinks (17)

- fish (35)

- salads (85)

- sauce (43)

- Liquor (8)

- soups (29)

- cheeses (19)

- phyllo dough (2)

- cakes pastries (134)

- medicines (1)

- lyrics (31)

- makeup (1)

- mathematics (5)

- prayers (10)

- music (145)

- soap making (3)

- nails (3)

- politics (157)

- parable (17)

- draw (94)

- Russian language (23)

- Gardening (215)

- Samodelkin (187)

- repair (12)

- funny (54)

- tips for housewives (187)

- fashion (20)

- tables (7)

- dancing (8)

- dish decoration (39)

- flowers on the window (48)

- quotes (56)

- sewing (354)

- alterations (90)

- bags (23)

- SLIPPERS (3)

- sewing machine (1)

- SCHOOL (4)

- Esoterics (29)

- etiquette (22)

- lawyer (9)

What interior style should you choose for a kitchen with patina?

Patina is applied in order to artificially age the furniture, give it a more antique look, and create the illusion that it is many years old. This means that patina should not be used in any modern interior design.

Ideal design solutions that go well with a touch of antiquity on furniture - kitchen interiors in country style, Provence, shabby chic. Patina would look quite appropriate in a classic interior, but in this case it is necessary to use more expensive shades of coating - gold, bronze, copper.

Facades with patina look chic and create a classic style.

Thanks to patina, you can create a unique atmosphere in the room, giving the interior originality and uniqueness.

Varieties and advantages

Today there are several types of mixtures for this type of processing on sale:

- Shellac varnish. When processing the varnish mixture, use a brush or soft sponge. The color can vary from transparent red to golden.

- Acrylic based patina. The easiest to use and perfect for decorating an apartment. Such mixtures can be applied with a brush. The advantage of acrylic compositions is the wide choice of colors for tinting the product.

- Bitumen composition. The surface of the furniture is covered with a bitumen-based varnish mixture; its remains can be easily removed with white spirit. The mixture penetrates into the pores of the material, creating an aging effect. This type of patina results in a dark color. With the help of an additional layer of shellac varnish, you can preserve the result for a long time.

- Wax based patina. Such compositions help not only to patina the wood, but also to tone the material, and also to emphasize its structure. Wax mixtures harden for a long time, which makes self-application easier. It is advisable to use this type of patina in cases where you need to highlight the structure of the wood. Often used for small elements made of ash and oak.

- A patina based on an oil mixture is similar in performance properties to a wax patina, but is considered more universal.