We save free space in a small apartment by making a transforming bed with our own hands

When arranging a bedroom or children's room in a small apartment, people spend a lot searching for a suitable bed model.

After all, such furniture should be compact, comfortable to use and aesthetically pleasing. An excellent solution for small rooms would be to choose a transformable bed. The cost of finished products in furniture stores is quite high. Therefore, we suggest making a transforming bed with your own hands. This way you will not only save your own savings, but also make furniture that will suit you in terms of the type of design, dimensions and appearance.

Advantages for a small apartment

The main advantages of transformable furniture include:

saving free space . These designs are ideal for small apartments where it is not possible to install massive furniture;- functionality . During the daytime, they turn into a wardrobe with additional furniture items, and at night, they are transformed into a spacious sleeping area;

- variety . Transformer furniture, depending on the type of design chosen and materials of manufacture, will fit into classic and modern interiors. Their facades can consist of mirror surfaces, visually increasing the space.

Features of Transformers

So, if you decide to install a sofa in your home, you should consider the best option for folding models . The most ideal solution would be to install a sofa bed.

During the daytime, the furniture will not take up much free space, and you can spend your leisure time on it in front of the TV or with family and friends. And at night, such furniture will completely replace the bed.

Making a sofa bed is quite easy on your own. This way, you will acquire original and exclusive furniture, and will not spend your personal savings on buying a sofa.

A special feature of the sofa bed is the presence of a folding mechanism, which allows the furniture to be used both as a sofa and as a bed. This sofa can come in various shapes, designs and sizes. With your own hands you can make a small sofa for one person or a spacious piece of furniture that can comfortably accommodate two or three people.

The advantages of a sofa bed include:

Ease of use. The use of modern transformation mechanisms allows you to unfold the sofa with a simple movement of the hand.- Spacious sleeping area. When using orthopedic slats, sleeping on the sofa will be pleasant and beneficial.

- Equipping a piece of furniture with additional drawers for linen will allow you to store personal belongings and bedding.

- Compact sizes. When folded, the ergonomics of the product allows you to install sofas in any corner of the apartment.

Tip : the use of various upholstery materials will allow you to make furniture to suit any interior style.

Design

According to the type of design, a transformable bed can be:

vertical . This product is a two-meter-long wardrobe, the head of which is fixed to the wall, and the sleeping place is hidden in the closet during the day;- horizontal . Such models are equipped with a single bed attached to the wall on the side;

- roll- out These are the most common models in which the lower built-in part slides out and forms a spacious sleeping area. Such models are suitable for arranging children's rooms and adult bedrooms;

- lifting _ This product is equipped with a pneumatic mechanism that easily allows you to remove the bed into a niche in a wall or cabinet.

In addition, the transformable bed can be a folding pouf. That is, when folded, the product is a regular pouf, and when unfolded, it is a small sleeping place. Round transformable beds are also popular, ideal for small children. They are safe because they have no sharp corners.

Help : children's models are often equipped not only with a sleeping place, but also with a sofa, chest of drawers and a work desk.

If there are two children in a family, it is recommended to install a transformable bunk bed in the room.

This design has one mechanism by which the product folds and unfolds. As for additional features, transformable beds are unique and versatile:

- beds for adults can be transformed not only into wardrobes and sofas, but also tables, chests of drawers, closed shelves;

- children's models are equipped with: changing tables, chests of drawers, drawers. Such products can be supplemented with lighting or a canopy.

Necessary materials

The set of necessary materials will directly depend on what type of furniture the home craftsman chooses. However, there is a list that is present with any choice.

MaterialMain parametersWhere it is usedLDF boards with a thickness of 10 to 22 mmManufacture of cabinets and shelves with high bending strength

DecorationMDFStrong sheets

Increased moisture resistance and density Tabletops, bench seats, kitchen facades Wood Solid wood, timber Any products Foam rubber Soft, comfortable, inexpensive For padding upholstered furniture Glass Thickness from For decorating cabinets and shelves Furniture fasteners Various types For all products Furniture accessories Various configurations and purposes For decoration

When decorating cabinet doors, drawers

Mechanisms

According to the transformation mechanisms, transformable beds can be equipped with the following lifting mechanisms:

manual _ This is the simplest and most affordable option. The bed is raised and lowered manually using physical force. This device has no shock absorbers or springs;- spring . Thanks to the use of twisted springs, the service life of the lifting mechanism is more than half a century. But this mechanism makes unpleasant sounds over time due to stretching of the springs;

- on gas lifts . This is the most convenient, but at the same time expensive option. To raise or lower the bed, you do not need to use force, since the mechanism will do everything itself.

As for the choice of materials, you can make a transformable bed on your own from:

- natural wood . This is the most expensive option. This product will delight owners with a long service life, beautiful texture, naturalness and environmental friendliness. But keep in mind, natural wood is quite difficult to work with. In addition to special equipment and tools, working with wood requires experience;

- Chipboard . This lumber attracts buyers with a wide range. Laminated chipboard has a rich color palette, various textures and textures. He is easy to work with. Laminated chipboard is suitable for those who have not previously had experience in making furniture;

- MDF . This material is environmentally friendly, easy to use, and durable. It is easy to process, and MDF furniture is aesthetically pleasing.

Drawings and diagrams

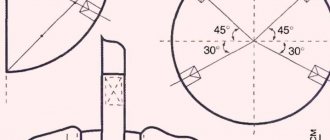

Before you start making and assembling a transforming bed, consider its dimensions, design, and materials of manufacture. All this must be put on paper with a pencil, not forgetting to indicate the connection points with fasteners.

You can make a drawing of a bed in different ways :

- independently, armed with a pencil and paper;

- using special computer programs that can be downloaded on the Internet;

- in a specialized company that manufactures furniture;

- download a ready-made diagram from the Internet and improve it according to your personal wishes.

Advice : if you order the production of a drawing from a specialized company, you will also receive product details along with it, which will simplify the manufacturing and assembly process.

Project preparation

It is difficult to imagine the manufacture of a complex set of three pieces of furniture without a clearly developed drawing.

The design and height of the elements must be compared with each other, correlated so that they can be modified without problems and complement each other. There are many ready-made sketches on the Internet with dimensions on how to make a set of transformable furniture. It is better to develop your own drawings according to the dimensions of your room. For example, a closet may be more voluminous and take up more space than provided for in finished projects.

When drawing up a project, pay attention to details:

- Indicate the general dimensions of the cabinet wall, show the location of the shelves, the height of the open niches, and set the dimensions of the doors. For each element, drilling locations and indentations from the edges of the parts are indicated.

- The sofa frame is drawn in detail, the joining areas and the dimensions of the frame sides are shown. Set the dimensions of the mattress, its base, and calculate the volume of foam rubber and fabric upholstery.

- The bed drawing should show the dimensions of the frame, taking into account the entry into the central part of the closet. The places where the legs are attached are marked, and the dimensions of the false panel are shown, which, after being lifted, will be a decorative part of the facade.

The depth of the furniture wall is calculated so that the bed is completely hidden there, taking into account the thickness of the headboard. The sides of the sofa should be hidden under the base of the unfolded bed (high legs) or remain on both sides of the mattress.

Andrey Peregubsky

Furniture handyman

Ask a Question

If ready-made furniture designs are used, they are carefully checked, all dimensions are calculated so as not to spoil the material. If the drawings are made correctly, they can easily be used to calculate the amount of wood, chipboard panels, and required upholstery footage. If there are changes during the manufacturing process, they are shown on the sketches.

Tools

To make a transforming bed you will need the following materials :

MDF 2 cm thick;- plywood 1 cm thick;

- fittings and guides;

- PVC edge for trimming;

- lifting mechanism;

- self-tapping screws;

- glue;

- safety belt;

- magnetic buttons.

Tools that will be useful:

- meter;

- pencil;

- sandpaper;

- drill and drill bits;

- screwdriver;

- circular saw;

- perforator;

- anchor bolts;

- metal corners.

Table-bed

Let's consider the design and manufacture of a transformer consisting of a desk and a single bed.

Table details (chipboard, laminated chipboard, MDF):

- table cover 618 x 1810 – 1 pc.

- backing 900 x 1810 – 1 pc.;

- support 58 x 1810 – 2 pcs.;

- front panel 48 x 1810 – 1 pc.;

- rear table drawers: 25 x 1810 – 1 pc.; 76 x 1810 – 1 pc.);

- rear drawers: 212 x 1810 – 1 pc.; 264 x 1810 – 1 piece;

- table sides: 611 x 954 – 2 pcs.; 126 x 646 – 2 pcs.;

Frame details:

- sidewalls 988 x 1336 – 2 pcs.;

- sidewalls 972 x 1336 – 2 pcs.;

- shelves 150 x 1874 – 2 pcs.;

- shelves 292 x 1930 – 1 pc.;

- top 426 x 1962 – 1 piece;

- drawer 98 x 1930 – 1 piece;

- front panel 68 x 1874 – 1 pc.;

- bottom 394 x 1874 – 1 piece;

- rear panel 1234 x 1930 – 1 pc.

Drawings with dimensions

Sleeping area

Table

Frame

Materials and accessories

In addition to the main material (chipboard, laminated chipboard or MDF), to make a table-bed you will need:

- chrome lamps 20W – 3 pcs.;

- thrust bearing button – 4 pcs.;

- PE416 chrome – 1 pc.;

- mortise switch – 1 pc.;

- euroscrew: 6 x 50 – 21 pcs.; 7 x 70 – 18 pcs.;

- dowel 8 x 30 – 10 pcs.;

- screw 4 x 30 – 17 pcs.;

- bed clamp – 2 pcs.

Tools

To make a transformer, you need the following tools and hardware:

- pencil, pen or marker;

- regular or electric jigsaw;

- electric drill;

- square, tape measure;

- hammer;

- screwdriver;

- nails and screws.

Important! When manufacturing a transformer, special attention should be paid to the safety of the product in order to eliminate any possibility of injury during assembly and disassembly of the structure. Sharp edges and protruding metal elements are not allowed.

How to do it yourself?

After all the materials and tools are prepared, you can safely begin making a transforming bed:

First, a special box is made and a special platform is installed for the base of the bed, which is attached to the wall with anchor bolts. For the frame, we take two boards 2 meters long and one board 1.1 meters long.- We connect the boards with screws and furniture glue . We wait until the structure dries, and attach the transverse one to the back side of the vertical boards. We fasten the board on the front side in the same way.

- At the end of the box we fasten the side trim with screws and glue. We attach a crossbar to the top of the box . Now we proceed to the construction of the folding part. Before laying the mattress, the box should be reinforced with transverse and longitudinal slats, on which plywood will later be laid. This will prevent the plywood from sagging and give the box strength.

- The folding part of our bed will consist of plywood with triangular crossbars on the sides, fastened with a horizontal board. We fasten the structure with a special mechanism , with the help of which the product will unfold and fold.

- Now we move on to installing the fasteners and designing the box . To do this, we attach a loop at the top of the product through which the safety belt will be pulled. We place magnetic clasps in convenient places that will prevent the product from opening when lifted. We lay the mattress on the base and attach it to the plywood with glue.

- The final touch will be the installation of the legs .

Attention : the depth of the box must be equal to the thickness of the future bed. To be on the safe side, the box can be made deeper.

That's the whole process of making a transforming bed with your own hands.

Manufacturing stages based on the model

First you need to decide on the location of the future product. The space should not interfere with the operation of the folding mechanism. In this case, an acceptable passage must remain. It is better to choose a design that is calm but laconic, so it is more likely to suit the interior. Drawings and diagrams must be made to a strict scale and clearly correspond to reality.

How to make a doll closet yourself, tips for beginners

You can design a product on a computer using a special program. Three most popular options:

- T-FLEX Furniture. One of the best applications for three-dimensional design of interior items of any complexity, from details to detailed assembly.

- Project Volumetric. When drawing up a diagram, the program suggests choosing ready-made variations of furniture parts, thereby speeding up the process.

- SketchUp. Suitable only for experienced artists, since the drawing must be created independently.

There are many specialized companies that provide furniture design services.

Before you start assembling a table or transformable bed, you need to prepare materials and tools. It is better to use laminated chipboard panels for the product, which are distinguished by their quality and durability. You can choose ordinary wood, but you need to take into account that it is sensitive to temperature changes and high humidity. It is necessary to select well-dried raw materials, otherwise the furniture parts may become deformed after assembly.

How to properly arrange furniture in a room, designer tips

Necessary tools for a product made from chipboard:

- drill;

- ruler;

- saw;

- roulette;

- screwdriver;

- several different screwdrivers;

- pliers;

- level;

- sanding paper.

T-FLEX

Project Volume

SketchUp

Transformable bed

To make transformable furniture with your own hands, you need a drawing with accurate measurements of the product being designed. All dimensions should be clearly defined in advance. Taking into account the measured data, a bed assembly diagram is drawn up. It will help you carefully plan all the elements:

- base attached to the wall;

- stock frame;

- fixing basic parts.

To assemble the bed-wardrobe you will also need:

- set of materials for fastening;

- limiters and clamps ensuring safe use of furniture;

- swivel support for correct operation of the gas shock absorber mechanism.

The set of accessories depends on the selected product model. You need to think through everything in advance, make a list of the necessary elements for assembling the furniture.

Required materials and parts:

- laminated chipboard beam 50 x 50 mm;

- edged board 15 x 150 mm;

- fixing corners;

- freewheel joints.

First you need to make the frame of the product. To do this you will need to do the following:

- Cut the side plates (1120 x 440 mm) and the rear base (440 x 1700 mm). Depending on preferences, part parameters can be changed.

- Combine the resulting slabs into one box using screws. To avoid splitting the material, you need to pre-drill holes, the radius of which should be smaller than that of the screw.

- To strengthen the structure, you can attach bars to the inner corners of the box.

After the assembly of the frame has come to an end, you can begin to create the body of the product. Sequence of actions:

- The walls for the base are cut out, the dimensions of which should be comparable to the frame parts. The result is elements of a box with a solid bottom.

- The panels are connected with screws every 25-30 cm. This must be done carefully, since poor joints will affect the operation of the structure in the future.

- A beam is fixed around the perimeter, which will be the basis for the mattress pad. Mounting height – 30 mm.

- To place the mattress pad, an edged board is screwed to the created support.

- As an additional fixation, movement limiters are attached to the mattress pads.

Instructions for making furniture from chipboard with your own hands for beginners

All that remains is to assemble all the components of the product into one moving unit. The stock box is placed on a hinge mechanism. The movable legs are fixed on both sides on the structure bar.

Scheme

Design dimensions

Building a box frame

Finished frame with footboard

Base installation

Assembling the mattress box

Installation of hinges for fastening to a wall box

Folded

Unfolded

Table transformer

For a small room this element is an indispensable thing. A compact bedside table that easily turns into a dining table for a large company will not leave any person indifferent . A diagram for assembling furniture can be found in the public domain in specialized resources.

Transformable tables can be made from a variety of materials:

- Tree. The most standard option. You can choose MDF, chipboard, fiberboard or just an array.

- Metal. Its durability and increased strength attract many lovers of modern design.

- Glass. Despite the beauty and aesthetics, it will be extremely difficult to make such transforming furniture with your own hands without any skills.

Wood is suitable for self-assembly; it is a good furniture material, pliable and comfortable.

As parts for furniture you need to prepare:

- 2 wooden slabs 550 x 800 mm;

- 1 plate 300 x 700 mm;

- a mechanism that will ensure transformation;

- furniture corners;

- 4 bars, 50 cm each;

- bolts, screws and washers.

Furniture assembly process:

- all parts of the product must be cut out with maximum precision so that problems do not arise during transformation;

- the table legs can be combined with a tie, which will increase reliability;

- before fixing the transformation device, markings should be made;

- connect the fastening parts to the mechanism with bolts;

- secure the tabletop to the holder using the corners.

The smaller panel is subject to initial fixation. After securing it, you can test the furniture transformation mechanism to ensure the accuracy of the assembly. Seashells and sea stones are perfect table decorations. Using sandpaper, you can age the product by first coating it with varnish. For decoration, it is recommended to choose a mosaic from glass pieces of various colors, which will add originality and unusualness to the table. There is also a special varnish that, when dried, creates the effect of cracked furniture. Glitter and confiture go well with it.

Prepare tools

Decide on the material

Assembly is carried out according to the diagram

It is better to purchase a ready-made transformation mechanism

The tie will increase reliability

Ready table

Finishing

If desired, the inside and outside of the box can be covered with a special material that does not allow moisture to pass through.

To make it decorative, a wooden product can be coated with stain, varnished or painted .

To make the transforming bed look believable and resemble a real closet when folded, fittings are applied to the outside.

The end sides are decorated with PVC adhesive tape , which is applied to the product, heated with a hair dryer and pressed firmly.

Advice : if you are serious about saving space in your apartment, try making a lift-up bed, a wardrobe bed, an armchair bed or a loft bed. In addition, you may be interested in a folding or folding table.

Such furniture is not only functional, but also beautiful: