Buyers about furniture "

Furniture dowels have long been used by furniture makers in their production. True, not all of them are used for their intended purpose - creating strong and reliable connections between parts. And it’s not a matter of laziness or lack of knowledge, it’s all about the difficulty of ensuring accurate drilling of holes for installing dowels. But let's talk about everything in order.

In the last publication, I told you about what good quality furniture it is. And just in this article it was already mentioned about the accuracy of the additive when drilling holes for connecting fittings. Today I want to discuss this issue in more detail, since, in my opinion, every buyer should have a clear idea of the quality and strength of furniture joints.

As you probably guessed, today we will be interested in the reliability that a furniture dowel . What's really going on? How do dowel connections behave in practice?

Hole depth and width

When assembling furniture, confirmat size 6.4*50 is usually used. Because the thread diameter is 6.4 mm, and the diameter of the confirmation body is 4.4 mm, then for high-quality fastening of parts, the hole diameter must be in the range of 4.5-5 mm and a depth of at least 50 mm.

Read also: Water aerobics for weight loss

If the thickness of the hole is greater than the specified one, the confirmat will not hold the parts well; if it is less, its thickness can tear the chipboard.

For drilling, use a confirmat drill with a diameter of 4.5 mm, which is equipped with an additional head for drilling an enlarged hole for the neck of the confirmat, which also makes a countersink for its head.

Of course, you can use a regular drill with a diameter of 5 mm, but for high-quality fastening in the hole you will additionally need to make space for the neck of the confirmat and its head.

Reviews

This product is recommended by 25% Show first Indeed, the diameter is less than 6 mm. I bought a Ø5.9 drill for them - they fit with a slight interference fit, maybe I should have taken a Ø5.8. Leroy is fooling customers by selling such a product. Advantages: There are no advantages. Disadvantages: Does not fit into the 5mm hole, splits the block. And in the 6mm hole it doesn’t just dangle, but shakes. In the holes made through the jig! Wolfcraft dowelmaster with a drill of the appropriate diameter, the dowels go in freely, generally dangle ( Disadvantages: Do not fit tightly in the hole, go in freely, dangle I recommend this product!

What is a dowel, its main dimensions

Modern cabinet furniture, sold by retail chains in flat packs, requires self-assembly by buyers or specialized workers. This is a good opportunity for the common man to get acquainted with dowels. They are small wooden or plastic cylinders with small chamfers at the ends. Usually they do not have a smooth, but a corrugated surface, represented by shallow longitudinal, helical or annular grooves.

As a rule, in places where round insert tenons are installed, the furniture manufacturer pre-makes mounting holes of the appropriate diameter. The linear dimensions of the dowels used vary greatly and depend on the size of the parts being connected and the type of connections. Joinery connecting elements have a diameter from 4 to 10 mm and a length from 15 to 100 mm.

Compliance with the rules

The minimum permissible distances between the axes of the dowels depend on their material. Such distances are calculated based on the diameters of the dowel. To accurately calculate the load-bearing capacity of a dowel, it is necessary to pay attention to many factors. First of all, this relates to compressive and bending stress. This calculation is complex and cumbersome. For practical use, this formula has been simplified. A number of assumptions were introduced during the calculation, but it was found that:

- maximum deformation of dowel connection - 2 mm;

- the dowel is considered as a beam of low bending rigidity on an elastic-plastic base, which is wood;

- frictional forces are not taken into account due to the possibility of a gap appearing between the elements being connected when they are dried across the fibers.

The correct calculation answer will ensure a quality connection. If it is difficult to make such a calculation yourself, contact a specialist and describe the problem.

Dowel diameter

Installation methods

Such products are inherently designed for the most durable connection of different furniture elements. However, their installation is not as simple as it might seem. One important nuance must be taken into account - fastening will not succeed if the holes prepared in advance are displaced.

Before making or assembling furniture using dowels, you need to familiarize yourself with the proven diagram:

- At the end of the canvas, points are marked where the holes for the rods will be located.

- Using a drill, drill a hole in the furniture half the length of the dowel. The same must be done in the covering tabletop.

- A rod is inserted into the end - its upper part should protrude to a distance that corresponds in depth to the hole in the covering element.

- The dowel is lubricated with glue, then tightly fixed in the required position. Experts advise pouring glue directly into the hole and only then installing the fastener. This will allow the composition to be distributed more evenly over the entire surface.

- The top part is carefully placed on the protruding dowel. For the best fixation, it is recommended to lubricate the second hole so that the glue secures both sides of the rod.

Preparing holes for dowels

Dowels must be driven in as carefully as possible

Additionally, you can attach the part with glue

Subtleties of fastening dowels made of wood

How is the beam fastened with dowels? You can also do it yourself, without using the services of professionals. The procedure is extremely simple. Using wood tenons will first require finding the middle of the plane being used. At this point it is necessary to make the appropriate markings. This is where the hole will be created later.

Now you need to drill a hole using a drill. It is in this that you will then need to attach the dowels

That is why it is very important to choose the drill diameter correctly. Its dimensions must be identical to the same parameters of the spike. As for the depth, this is 1.5 timber

The question of what dowels for 150x150 timber turns out to be quite simple. Here you can see how this procedure is performed

As for the depth, it is 1.5 timber. The question of what dowels for 150x150 timber turns out to be quite simple. Here you can see how this procedure is performed.

In this case, the task itself disappears: how to drill the timber for the dowels. Of course, the best option is a modern drill. It is much more important to ensure that the hole is processed correctly. The entry angle depends on the position of the drill. It must be strictly perpendicular to the base itself. Competency in performing this step will allow you to avoid problems with the installation of fragments in the future. It is also worth remembering that if the dowel is located extremely loosely in the timber, this will deprive the structure of all the advantages of this type of fasteners. You should also avoid excessive density. The length of the dowel should not be greater than the established dimensions. Protrusion of a part above the surface leads to problems during the inevitable shrinkage of the structure.

Furniture dowel - production and parameters

External simplicity does not mean that this fastener is made using a handicraft method. Woodworking machines are used for turning dowels; there are even special dowel cutting machines. The fact is that their sizes are clearly calibrated in mass production, and for those cases when urgent minor furniture repairs are needed, a metal template is used, which has many diameters. Having chosen the one you need, you punch a wooden blank through it, thus making dowels with your own hands. As for plastic fasteners, they are cast in special molds.

To ensure that such a cylinder holds better in the hole, corrugations are applied to its surface. They can be longitudinal, transverse, helical or complex (mixed). You can also find such corrugations on plastic. The diameter of the dowel can be 4-30 mm, and the length can be 1.5-20 cm. You can, of course, make the product yourself at home according to the given parameters, but this is quite a troublesome job to get a round cylindrical piece of wood. All sizes are available for sale, and the price, of course, is quite affordable. It’s another matter if you need more exotic types of this mount, we’ll talk about that below.

Fastening log beams with wooden dowels

Fastening the log house with wooden dowels #8212; no alternative solution in wooden architecture. All wooden structures of this kind are fastened with wooden nails, which have the construction name of a dowel. Birch, oak and other hardwoods #8212; they are designed to tie the entire beam into a single structure and not allow the crowns of the log house to move and shift in the horizontal plane. According to their shape, dowels come in square and round sections. Such formats are easier to produce. Other sections of these wooden nails did not take root due to the complexity of production and high cost.

My bath #8212; not an exception. I will also secure the timber with wooden dowels. If I'm lucky, I'll get oak ones. The point is not that oak is very strong. Important properties of dowels should be as follows:

- durable (rot resistant);

- be amenable to machining and maintain linear dimensions;

- do not contain knots and have low causticity (do not crack when impacted);

- maintain the cross-sectional size for as long as possible

As a rule, wooden dowels are made on planing machines. Manufacturing accuracy must be quite high. The cross-sectional size must be precisely adjusted to the specific hole into which the dowel will be driven. And here I will go into more detail.

Some manufacturers of dowels are presented here

Making holes for fastening dowels

In order to simplify subsequent installation on the construction site and reduce construction time, the holes for the dowels were made in stationary conditions. An ordinary vertical drilling machine was used for this. Since the dowel must pass coaxially through two or three #8212; It is necessary that the holes for wooden nails be located on the same axis. This is why a template is used to mark the holes for the dowel.

The template for determining the center of drilling the hole for the dowel is made along the width of the mounting bowl of the timber and allows you to mark the drilling location at the same distance from the center of the bowl (lock).

The template is installed in the bowl and along its edge you can draw the center of drilling the hole. This method is used only with the use of factory drilling. It is most suitable for making through holes in walls for electrical wiring. The template allows you to accurately mark the axes of the holes for the dowel.

When drilling holes for dowels in places other than the frame assembly, it is important that the axes of the holes coincide. If the axes do not coincide, when driving in the dowel, the beam may shift. And this is #8212; is fraught with getting crooked log walls

When drilling holes on a construction site #8212; Strict vertical drilling is desirable, but not required! The dowel can be driven in at a slight angle #8212; along the inclined hole. The strength of the connection is not reduced

And this is #8212; may result in crooked log walls. When drilling holes on a construction site #8212; Strict vertical drilling is desirable, but not required! The dowel can be driven in at a slight angle #8212; along the inclined hole. This does not reduce the strength of the connection.

What should be the size of the hole for the dowel? Experience in the manufacture of wooden log houses suggests that 30-40 mm is absolutely sufficient. For my bathhouse with timber 120 mm thick, a 30 mm drill was chosen. Section side of wood dowel #8212; 23 mm.

The dowel should fit tightly into the hole. Best way #8212; try driving in test dowels. A dowel with a square cross-section should pierce the walls of the hole with its ribs. But it shouldn't go in too tight #8212; this can lead to splitting of the timber, especially thin ones. The timber must be able to settle along the dowel.

The round dowel completely fills the hole; there is less play during its installation. A slight drying weakens the fastening of the dowel in the hole. It's more difficult to make. But he is no less popular.

Making holes for fastening log beams with wooden dowels in the factory allows you to significantly speed up the assembly of the frame of an outdoor bathhouse, which means protecting the wooden structure from rain, sun and premature damage to the crowns by biological factors.

What is a lamella?

There is another interesting option for such fasteners in construction - a flat dowel. In wide circles it is more often called lamella, which is how it can be found in stores. Its essence is that it is not cylindrical, but really flat, it is also attached using specially made grooves, and often sits on glue. The holes are made, of course, not with a drill, but with a special router. It is used in cases where the possibility of twisting of parts relative to the axis of the dowel cannot be allowed.

Furniture dowels in factory designs

Factory furniture is a vivid example of the correct and effective use of dowels in connecting parts. It is in the “factory” that the dowel will fit tightly into its hole and, even without glue, will ensure a reliable connection of the parts. This is what connections involving dowels in factory furniture look like:

As you can see, factory furniture does not use connecting parts exclusively using dowels. Here the dowel is paired with a minifix. Even in factory furniture, dowels are used in conjunction with confirmations and other connecting fittings. This is exactly how dismountable furniture connections should be made. The dowel is not “set” on the glue, but simply driven into the hole drilled for it. This ensures the strength and rigidity of the structure. And the confirmat or minifix serves as a screed.

That is why the buyer of factory furniture can easily disassemble his structure and, if necessary, transport it to any place.

Why don't garage workers make such connections? And they can't do that. To ensure accurate drilling of holes in parts, industrial drilling machines are needed, which garage workers do not have. But with a hand drill, alas, you can’t drill like that. That is why garage workers simply do not have the moral right to put dowels where they can put a minifix or a furniture corner. Alas, some “craftsmen” continue to make complete “shkanto-slag” instead of furniture in their garages. We hope that the time will come when the defectors will curtail their work, and only conscientious furniture makers who, first of all, think about their clients, will remain on the market.

Common mistakes

Errors when using dowels in assembling furniture occur mainly among beginners. They can be avoided by considering the main difficulties:

- The planes of the structural elements do not coincide, while the edges of the connections themselves are located at the same level. To correct this, you should align the drill along the base planes of the two blades being joined, focusing on the central part of the edges.

- The holes in different elements do not match. This may make it difficult to secure the dowels properly. To ensure that all the holes are made exactly opposite each other, special markers are used. First, holes are drilled in one sheet and markers are inserted into them. After this, the two elements are pressed tightly against each other the way they should be assembled. On the second part, the markers will leave marks at the points where you need to drill holes so that the blades fit together as much as possible.

- Furniture dowels do not fit into the holes. It also happens that they simply fall into them. The correct fastener should fit tightly into the intended hole, so you should check that the diameter of the dowels matches the size of the holes. Factory-produced parts may not match the parameters of the technical documentation, both due to mass production and due to high or low humidity (products may swell or lose volume).

If the diameter of the dowels corresponds to the declared one, the problem is in the drill, namely in the drilling jig, due to wear of which the drill deviates. You should change the bushings or purchase a new tool.

These are the main problems that can arise with the installation of furniture on dowels. In order for the assembly to be successful, you also need to take into account a number of rules:

- It is better to mark with a sharpened pencil (an unsharpened one will not give accuracy) or a knife.

- Use straight drills with the point pointing down. If the sharpening is spiral, then strong versatile deviations are possible, and the direction of the hole made will be incorrect.

- A retaining ring is used to create a hole with the same depth. It is fixed on the drill and does not allow you to drill more than necessary. The optimal depth in this case should be 2–3 mm greater than the length of the rod itself.

Tips for painting furniture yourself, choosing a composition, stages of work

For high-quality assembly of cabinets, sofas and other structures, you can use special fasteners - furniture dowels of various sizes and configurations. It is best to give preference to wooden elements, for which holes are created in the canvases, and the rods themselves are attached with wood glue. You should first measure all furniture elements and parts, check the equipment and apply approximate markings. This will allow you to use fasteners as accurately as possible with the smallest error.

Installation and removal methods

Furniture dowels make it possible to significantly increase the strength of connections. But this is not as simple a method as it might seem at first: the connection cannot be secured if any hole is displaced. Depending on the size of the offset, the result will be unsatisfactory.

As a rule, tabletops on dining tables and desks are secured with a dowel. Put them in working position like this:

- The parts are first marked on the end side, and then holes are drilled to the required depth. The same holes are made in the countertops. They must match;

- A cylindrical fastener is installed in the end hole, the upper end protrudes at a distance equal to the depth of the hole in the covering part;

- To strengthen the dowel in the hole, it is generously lubricated with glue, fixing it in the desired position. Sometimes glue is poured into the holes, where the fastener is then inserted - this will completely cover its ribbed surface with glue, improving the adhesion strength of the elements;

- The second part of the design is superimposed on the installed dowel.

Drilling the material

Hammering the dowel

Connect with glue

The work is ready.

There are 3 main problems in assembling furniture using dowels:

- It is possible to assemble an edge-to-edge connection, but in this case, the planes of the structural parts do not coincide. Solution: The drill guide holes were not aligned with the center edges of the parts. The device must be constantly aligned with the reference planes of the two parts being fastened. Even in the absence of a central location of holes in the connection, no shifts or sagging are formed;

- Holes in one part do not line up with another. Solution: to align the holes, use special markers designed specifically for connections. Initially, holes are made in one part with a drill. A marker is then inserted into each hole and the two pieces are pressed together as they should be when assembled. This way, the second part will have marks with markers in the places where you should drill;

- The holes are made in the right places, but the installation of the dowels is disrupted: the fasteners do not fit through or, on the contrary, fall out. Solution: It is important to make sure that the diameter of the fasteners matches the diameter of the holes. Factory fasteners are mass produced and may have a diameter slightly larger or smaller than stated. In addition, wood can swell or shrink with changes in humidity. When the diameter is verified and it is identical, then the problem is the wear of the drilling jig and, as a consequence, the deviation of the drill. This leads to deformation. It is enough to change the bushings or purchase a new device.

To correctly assemble furniture parts onto a dowel, you will need to learn three basic rules:

- To mark, use a sharp pencil or knife. A pencil with a thick lead will not make marks accurately;

- When drilling holes, you need to use drills with a central point. Twist drills with conical sharpening can deviate to the sides during work, setting the wrong direction;

- To ensure uniform hole depths, a locking ring is placed on the drill and firmly fixed. The depth of the hole is made 2 - 3 mm greater than the length of the dowel.

We mark with a pencil

Use center point drills

Use a retaining ring

You can make cylindrical mounts yourself. Here is a short instruction on how to make dowels: To do this, take birch logs and split them into many pieces - you get square blanks. Next, they need to be trimmed by hand or on a lathe to give them a cylindrical shape and the required diameter. Fasteners can also be made using a circular saw.

It happens that the dowel breaks off and one half remains in the hole. The first thing you want to do is take a drill and drill out the fragment. This is incorrect, since the hole will be larger, and choosing a new mount will be more difficult.

The correct solution is to take a drill of a smaller diameter and drill in the center of the fragment. Then, using a screwdriver, chisel or chisel, break up the remaining debris and remove it from the hole. If difficulties arise, you can use photo instructions - there are a lot of them on the Internet.

So, when used correctly, a furniture dowel is a universal fastening that guarantees reliability. It is used for assembling different types of furniture in combination with other types of fasteners.

Varieties and sizes

Dowels come in wood and plastic. The latter are rarely used, but can still be found in stores. In cases where maximum strength is required, metal dowels can be used, but this happens even less frequently.

Wooden dowels can be divided into five main types depending on the notch:

- with a straight vertical texture. They are used everywhere and are the most affordable type of such fasteners;

- with a helical texture. Pins of this type are protected from loosening by means of a notch located at an angle from the vertical axis;

- with a complex texture. It has both transverse and longitudinal notches, allowing you to reliably hold structures subject to high loads;

- with horizontal texture. It is used for final assembly, as it creates a tight, often permanent connection;

- without invoice. Designed to protect against shear, usually used only with the horizontal joining method.

In this case, dowels are those fasteners that can be used to assemble vertical elements, that is, they have high tenacity and create a permanent connection. These, for example, include dowels with horizontal and complex textures.

Depending on the thickness of the material, the size of the dowels also varies. On the open market you can find dowels with a diameter of 4 to 30 mm, with a length of 15 to 200 mm. A correctly made dowel has no flaws and is resistant to temperature and other influences.

Wooden fasteners

Design of dowels and their varieties

The wooden dowel is perhaps the oldest type of fastener. Pins are wooden pins that are driven into pre-drilled holes and secure parts due to the natural elasticity of the material.

Square bars for connecting logs

Today, a variety of types of such parts are used in construction:

| Sign by which classification is carried out | Varieties |

| Wood species | Typically, dowels are made from hardwood. The following parts are used in construction:

|

| Part shape | To connect logs, as a rule, two types of products are taken:

|

| Size | Traditionally, the minimum diameter of the dowel is 25 mm. At the same time, when connecting large beams or logs, fasteners with a cross-section of 50 mm or more can be used. |

Dowels of different shapes and sizes

Installation sequence

When assembling furniture, dowels allow you to create strong connections. But the main problem is the exact alignment of the holes on individual parts. Otherwise, they simply will not be able to connect, so measurements must be taken with special care.

The most common use of dowels is to secure a tabletop to a table base. If we take this as an example, we get the following sequence of actions:

- Holes are made at the end of the base parts. With exact matching they perform drilling and table tops, to a depth of approximately 2/3 of the total thickness of the material. The dowel axes must completely coincide; it is recommended to check this before starting to connect the elements.

- A dowel is installed in the base part, and its length is selected in such a way as to fully correspond to the depth of the hole in the tabletop. If it is larger, the material will either not come together or damage will occur at the contact point. With a shorter length, the reliability of the fastener decreases.

- If you plan to create non-separable furniture, wood glue is used at the time of joining. It can either be applied to the dowel itself, or pre-filled into the holes.

- The tabletop is placed on the base and fixed with a weight while the glue hardens.

How does the pipeline material affect the solution to the problem?

Metal pipes are distinguished by their enviable resistance and durability. Almost their only drawback is their susceptibility to corrosion. This is often what causes a leak in the circuit.

Less commonly, other pipelines also fail: plastic, polypropylene (mainly in places of threaded or fitting connections).

It is enough to compress the plastic pipe in the problem area, and all manipulations can be carried out under water pressure. The main thing is not to overdo it with the screed, otherwise the plastic will crack, and then you will have to replace the entire pipe.

A polypropylene pipeline can be easily repaired by soldering a separate fragment; a metal-plastic pipeline requires inserts. In the latter case, if the damage is not extensive, wrapping with electrical tape or treating with an adhesive (polyurethane, epoxy) will be sufficient.

Varieties

In fact, a dowel is a small spike - it is a hidden type of furniture fastener. In appearance, it resembles a cylinder-shaped rod, with slightly rounded or simply truncated ends on both sides. Sometimes, to assemble furniture on dowels, not only wooden elements are used, but also plastic ones. They have slightly different purposes:

- Wooden ones are needed for positioning and connecting furniture parts made of MDF, chipboard, plywood, and solid wood;

- Plastic ones mainly connect parts when installing prefabricated panel furniture.

Wooden

Plastic

There are also metal products. They have improved strength characteristics; they are also called dowels or dowels. But the most commonly used are wooden dowels measuring 30 by 8, that is, the length is 30 mm and the diameter is 8 mm. There is also a smaller diameter - 6 mm. You can purchase different types in construction stores or markets. If you wish, you can make dowels yourself.

There are different grooves on wooden dowels:

- Straight vertical;

- Helical – located at a slight angle to the vertical axis;

- Complex ones - there are transverse and longitudinal recesses - they also allow you to make the adhesive joint stronger;

- Horizontal – help to make the adhesive joint as strong as possible;

- Smooth - do not have corrugation.

Corrugation helps air pass during the installation of dowels, improving the adhesion of the glue with the “glue” method of connecting parts.

Vertical straight lines

Complex

Smooth

Description

A furniture dowel is a wooden fastening element used in the manufacture of furniture. It has a cylindrical shape with longitudinal corrugation of the surface. Here you can buy dowels with a diameter of 6 and a length of 30 mm in small packaging of 50 pieces. The price of these products is much lower than metal fasteners, which in some cases they can replace. Advantages: — ease of use; — exact geometry and dimensions of the product; — fairly high connection reliability. The value of ready-made dowels lies in the fact that you will not have to spend time, which is also money, on making small parts. They can simply be purchased from us in any required quantity.

Some rules for laying timber

Image 4. Technology for assembling a log house using dowels.

You need to start laying timber in larger sizes (compared to the walls). Waterproofing made of 2 layers of roofing material is installed on the foundation. Laths about 15 mm thick are laid across it in increments of 20-25 cm. The length of the laths should be equal to the width of the foundation. The initial crown is made of timber with a cross-section of 20x20 cm. There is no need to attach it to the foundation, but it must be leveled. All gaps between the slats, foundation and beams are treated with polyurethane foam.

Insulation must be laid on the laid crown. It can be:

Jute in the form of a ribbon is a very convenient material. It is unfolded and placed on top of the beam, secured with a construction stapler. The material is reliable and practical.

Tow is sold in bales. Before use, it must be rolled up and timber laid. Attaching it is a little worse than jute tape, but tow costs much less than jute fabric.

In last place among insulation materials is moss, which can be found in any swampy place and collected for free. Moss or tow should be placed so that the edges hang 15 cm behind the beam. They will later be used for caulking the walls. The walls are caulked after they have settled.

The next rows are made of 15x15 cm timber. This is where our dowels come into use. You can sometimes use metal pieces of reinforcement with a diameter of 8 mm. The holes are made with a drill to a depth of one and a half thickness of the timber. After drilling all the holes, the top beam is removed, a dowel is inserted, and a heat insulator is laid.

Then the holes are aligned and the top beam is placed on the dowels. Openings for windows and doors can be left immediately, or can be cut out later. The top 2 rows of beams are not attached. After the frame shrinks, they are removed for laying the ceiling. The assembly of the log house is carried out quite quickly (image No. 4).

This way you can build a good house to live in. It will stand and delight you for many years. This building does not require any special finishing. You should choose wooden dowels.

Confirmat

This is a screw of a special design with deep and coarse threads and a wide “secret” head, at the end of which there is a hexagonal recess for a socket wrench. This type of fastening is widely used in furniture manufacturing. It is mainly used when tightening two sheet parts of the case perpendicular to each other, fastening fixed shelves, bottoms, cabinet lids.

The cap can be covered with a plastic plug in the color of the chipboard, which has a protrusion with which it is driven into the hexagonal hole of the confirmat. However, if the plug is installed carelessly or is touched during operation, it often falls out. More reliable in this regard are round flat stickers matching the color of the chipboard.

The confirmat can only be screwed into a specially prepared hole. It is made with a prefabricated drill, the design of which takes into account the length of the confirmat, the diameters of the head, threads, and the shape of the head. Available in several standard sizes.

The main diameter of the confirmat head is 6 mm. Length - 50-70 mm. The disadvantage of this fastener is the impossibility of disassembling the furniture and reassembling it. Although this operation is allowed, it is better not to do it due to the risk of destroying the threads cut during the first tightening.

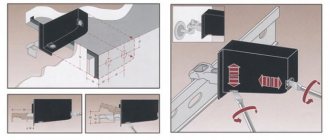

Eccentric coupler

An eccentric coupler is often used in the factory production of furniture. The reason for this is the difficulty of drilling holes. An eccentric coupler consists of two parts: a pin and an eccentric. The pin is installed in one part, and the eccentric in another.

Increase

Fig.7.

The main advantage of this type of fastener is that this fastener is hidden and therefore does not spoil the appearance of the furniture. In addition, this type of fastener, unlike confirmat, allows you to repeatedly assemble and disassemble furniture, which is important, for example, when moving. Also, using an eccentric coupler, you can connect parts at different angles.

When making furniture yourself, it is not often used due to the difficulty of drilling holes and the inability to correct the joint during assembly. The main difficulty in drilling holes lies in the hole for the eccentric. This hole is not through and requires the use of a special drill - a Forstner drill.

Increase

Fig.8.

Increase

Fig.9.

Increase

Fig. 10.

In this case, the sampling depth is about 12 mm, and the thickness of the chipboard is 16 mm. The remaining wall thickness is only 4 mm. There is a risk of drilling more than necessary, thereby damaging the piece of furniture. Therefore, when drilling holes for an eccentric tie, it is necessary to use drilling depth limiters.

This tie is a screw and nut with which two sections of furniture are pulled together, for example, two cabinets. To tie cabinets, 2 - 4 intersectional ties are used. Depending on the thickness of the chipboard, there are intersection screeds of various sizes.

Increase

Fig. 12.

Considering that the intersection screed is used to tie cabinets, and the cabinets, in turn, are made of laminated chipboard with a thickness of 16 mm, an intersection screed with a length of 32 mm is most often used. However, there are ties up to 50 mm long, which are used to tighten parts of greater thickness.

Increase

Fig. 13.

Corrugation of the side surfaces of the dowel

Dowels (either wooden or plastic) can have longitudinal grooves on the side surface - grooves, either straight, located along (parallel) to the cylinder axis, or helical.

The riffles serve to allow air to escape when installing dowels into the part. Since wooden elements are most often placed on glue, this improves adhesion and speeds up hardening.

Types of corrugation on the side surfaces of dowels (in the figure on the right - from top to bottom):

| Corrugation of the side surfaces of dowels |

- straight corrugations - corrugation for dowels for universal use. The most common option.

- helical riffles - located at an angle from the vertical axis. Makes it difficult to loosen.

- complex corrugations - (in this case, screw and transverse corrugations) corrugations for dowels intended for reinforced adhesive connections. Designed for structures subject to high loads that require a strong connection.

- transverse riffles - secures different parts as much as possible. Not recommended for use in cases where furniture may need to be disassembled.

- smooth dowel - made completely without corrugation and allows you to resist the shift of structural elements due to exposure to moisture and temperature.

Some types of plastic dowels have “roughness” on the side surfaces, i.e. they are equipped with projections. This surface prevents the dowel from falling out when disassembling furniture, securely fixing it in the main fabric.

Making dowels

You can make dowels at home quite simply. They will have a horizontal helical cross-section applied to them, which will allow such fasteners to reliably fix the parts being connected. A minimal set of tools is used for this; the process does not look labor-intensive.

As a form, you can use dies for cutting threads, called dies. The set usually has several diameters, which will allow you to choose the most suitable one. A wooden blank is pre-made, made in the form of a rod with a diameter slightly larger than the future dowels.

The die is fixed in a vice, and the workpiece is fixed in a conventional drill. The limitation of the dowel diameter is the maximum capabilities of its cartridge. It is not recommended to make workpieces that are too strong, as they may break from twisting during the grooving process. The workpiece is completely passed through the lathe, which leads to its turning to the required diameter and the application of a notch.

After this, it is enough to cut it using a hacksaw or jigsaw into fragments of the required length and the wooden dowels for the timber, made by yourself, are ready. The process is quite fast and allows you to save a lot of money, since you can use wood scraps and trimmings to make them.

Classification of tools

Before you buy a ready-made conductor or make it yourself, you need to decide what problems you will solve with its help and only then you need to select the appropriate option in terms of design and functions.

There are a number of categories of devices that differ in their design and functional features. Here are some of them:

- overhead - such devices are applied to a part that can be processed, then it is attached to it or simply fixed manually. With their help, holes are made in various flat parts, MDF boards or chipboard;

- rotary - these templates are used when processing cylindrical parts. They are equipped with horizontal and vertical axes of rotation, so holes can be made at different angles;

- universal - such devices are suitable for small serial furniture manufacturers, where sometimes quick readjustment of the equipment used is required, they have all the functions necessary for this;

- tiltable - used when the technological procedure is carried out in several planes at once;

- sliding - such conductors do not need to be attached. Simply attach them to the surface area of the workpiece where you want to make a hole;

- fixed - they are more convenient to use, but they limit freedom of action, which is very critical when working with machines where there is only one spindle.

How to arrange a connection between furniture parts

Types of furniture pipes, nuances and tips for their use

The procedure for attaching parts to a wooden nail is not complicated. By following the instructions below, you can connect the parts and assemble the furniture without much effort. The assembly diagram looks like this:

- Holes are drilled in the parts to be joined if they were not made at the factory. The diameter of the recesses should be slightly larger than the diameter of the chopper, and the length should be 1-2 mm longer than the dowel. The presence of gaps in this case is by no means a disadvantage. They prevent fasteners from jamming and help compensate for temperature and humidity deformation.

- The protruding part is filed down if necessary.

- Using a mallet, hammer a dowel into the hole so that its surface is slightly below the plane of the part. If you need to connect the furniture frame, then the dowel is driven in half. The protruding part of the wooden furniture chopper is smeared with glue and, having laid the end part of the furniture or facade on top, it is seated on the mount.

At first glance, it seems that this technique does not provide reliable fixation of the structure, but in practice it turns out that when using high-quality, well-dried dowels, furniture, log houses and timber are durable and stable.

Dowels, dowels, choppers, metal fasteners are types of fastening elements used for reliable connections. Without their use it is impossible to imagine the house-building industry and the furniture industry.

How to make a wooden dowel with your own hands

If necessary, dowels and dowels can be made at home, but production will require a lathe. The process of making wooden fasteners is as follows:

- For work, take a harvest of wood of the selected species. The block must be of high quality, without cracks, wormholes, knots, or irregularities. Use quality seasoned wood. When drying, the parts can become deformed and crack, as a result of which the cross-section of the wooden furniture chopper changes.

- Place the workpiece on the lathe and begin removing chips, gradually reducing the diameter.

- Having reached the required section, remove the chamfers and cut the workpiece.

Note! In factory conditions, the length of the dowels is up to 200 centimeters. After processing, the workpiece is removed and cut into fasteners of the required length

Characteristics

Product type Dowel Weight, kg 0.028 Country of origin Russia Quantity in set 50, 50 Color Beige Length (mm) 30.0 Diameter (mm) 6 Width (mm) 6.0 Color palette Beige Main material Wood Product weight in individual packaging (kg) 0.028 Product width individually packaged (cm) 10 Height of individually packaged product (cm) 16.1 Individually packaged product depth (cm) 2

Prices and availability may vary. Please check the exact cost and availability of goods in stores.

How it's done

Before you start working with the frames, make a simple sled device from slats with a cross-section of 19x25 mm and a piece of MDF board or birch plywood.

Then you will need already glued frames and some test miter joints on which you can practice. To make overlays for frames with a part width of 50 mm, spread cuttings measuring about 120x200 mm across the thickness to obtain thin pieces at least 50 mm wide. The scraps can be from a single board or glued together from different types of wood. Raise the disk to a height of 50 mm and adjust the longitudinal (parallel) stop so that the distance from the cut to the outer edge of the trim is slightly greater than the depth of the future folds at the corners of the frame. For safety and better control when cutting short pieces, use a comb and pusher. Turn the scrap over and make a second cut, leaving a spacer of about 12mm in the middle so that the trim blank remains on the scrap (Photo A). Then separate this workpiece using a band saw or hacksaw.

Link on topic: Veneer finishing - veneering: technology, instructions for surface production