| Rice. 23-24. Adjustable canopies right and left white |

We attach awnings to the sides of kitchen cabinets

We attach the canopies using self-tapping screws to the side walls; select the length of the screws so that they do not come out on the other side of the chipboard side wall.

When fastening, we retreat from above by the thickness of the chipboard, and align the front edge of the hinge along the inside of the groove.

| Rice. 25. Adjustable canopy attached to the side of the cabinet |

Determine the height at which we will fix the mounting rail

To determine the mounting height of the slats, so as not to bother with calculations, first apply the slats to the bottom of the protruding hooks of the canopies. We take a tape measure, hook it to the bottom of the cabinet and determine the distance from the bottom of the cabinet to the axis of the through holes in the mounting rail.

In our example, we ended up with a value equal to 740 mm (Figure 26). We tilt 10 mm so that the cabinets slide onto the tile apron and measure 730 mm up from the edge of the tile, this will be the mounting axis of our rail.

Source

Mounting methods

Using dowels is the easiest way to install cabinets on structures made of different materials. In earlier times, corners were used for this purpose. Today this method has lost its relevance. It was replaced by a mounting rail. If the question of how to hang a kitchen cabinet on the wall is being decided, a specific device called a wall mount is also considered.

Mounting rail

The use of such fasteners increases the reliability of the structure. Cabinets are hung on a horizontally oriented strip, which is called a mounting rail. It has several holes. The main task is to mount this element on the wall. All that remains is to secure the cabinets with screws. The advantage of this solution is that there is no need to regularly use a building level to control the position of furniture.

The use of self-tapping screws for point installation of individual cabinets does not provide a long service life. If you fix the furniture using a mounting rail, you can not only quickly mount the set, but also get a structure that will be used for a long period. However, to ensure that the cabinets are level, you will need to carefully check the position of the mounting rail.

Loops

This type of fastener allows you to adjust the position of furniture in the horizontal plane. Installation instructions:

- A cabinet is placed between the previously drawn marking lines. It is held to mark points for installing the dowel.

- A hole is drilled in accordance with the markings.

- Then you need to take the cabinet again and hold it in its original position (between the lines on the wall). The point of the second fastening element is marked. You should first check whether the product is level.

- Install hangers for kitchen cabinets. After this, you can fix the product on the wall.

Hanging on a plasterboard wall

If you try to fix a fairly heavy structure on an unreliable partition, the furniture may collapse after a while. To avoid this, when it is necessary to hang cabinets on a plasterboard wall, the only option considered is mounting on a strip, which is an element of the partition structure. In this case, the weight of the upper part of the headset is transferred to the most reliable area, made of metal. Fixing pieces of furniture is carried out using special dowels.

If you are deciding how to properly hang kitchen cabinets, you should follow the instructions:

- A magnet is used to search for fastening elements in a sheet of drywall.

- Correlate the distance between the nearest screws inside the partition structure and the size that determines the location of the hinges on the cabinets. If necessary, use an intermediate strip for fastening. This method will allow you to redistribute the load across the entire partition.

- Heavy furniture is fixed to the gypsum board wall using anchors and long screws. The partition is drilled through to get to the supporting structure.

Simple universal hangings for cabinets

Types of simple hangings for cabinets:

Oval hinged eyelet

A hinge for cabinets, with the funny name oval hinged eye , is one of the most common ways of hanging cabinets and shelves on the wall.

Installation is carried out by screwing the hinge to the rear edge of the cabinet or shelf. It is necessary to make markings on the wall and drill holes for installing dowels, the heads of which will catch on the holes in the hangers.

During installation, the plate is positioned with the large hole down; the head of the self-tapping screw will be inserted into it, which will pass through the groove and lock in the upper part of the hinged oval eye. In Figure 1, it is upside down; when screwing it on, do not forget to turn it around.

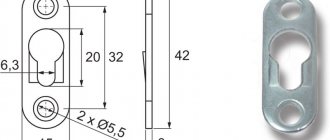

| Rice. 1. Drawing of an oval ear |

Hinged plate

The hanging plate or open hanger is made of galvanized steel 2mm thick. Functionally, this hinge corresponds to an oval eye, only the dowels will be visible from above.

For installation, holes for dowels are again drilled, hooks are screwed into them as in Figure 2. The plate itself is attached to the back of the cabinet, so that the through groove protrudes from above.

| Rice. 2. Mounting the hinge plate |

Pros and cons of hanging cabinets on the wall using an oval eyelet and a hinge plate

Pros of using simple attachments:

- low price

- ease of installation

- versatility.

Disadvantages of using simple attachments:

- precise marking is required for drilling for dowels

- not aesthetically pleasing

- no adjustments

- unreliable, cannot withstand heavy loads.

Press-fit cabinet hanging

The press-fit cabinet hanger can withstand a load of 20 kg. Since you need two pieces per cabinet, you can hook up a cabinet weighing up to 40 kg.

The suspension is pressed into a hole with a diameter of 30 mm in the chipboard. To do this, the cabinet design must have a longitudinal drawer or a back wall made of chipboard at the rear.

| Rice. 3. Cabinet hanger |

| Rice. 4. Suspension installation diagram |

Pros and cons of hanging cabinets on the wall using a round mortise hanger

Pros of using a round pendant:

- low price

- ease of installation of the finished product

- versatility

- It is allowed that the markings for drilling for dowels are not accurate

- reliability

- hidden from view, nothing spoils the appearance of the cabinet

Disadvantages of using a round pendant:

- it is necessary to change the design of the cabinet so that it has a back drawer or a back wall made of chipboard

- no adjustments

- To press the attachment in, you need to make a hole with a diameter of 30 mm, and for this you need a cutter of this diameter.

Useful drilling tools

Many home craftsmen have encountered the problem of the drill moving from the intended point due to the heterogeneity of the walls. This leads to the fact that the exact horizontal line is lost and it is not possible to hang a shelf or other piece of kitchen furniture straight.

In such a situation, craftsmen recommend that you independently prepare a sheet of plywood with a hole (a jig) through which the drilling will be carried out. To prevent it from moving when applied to the wall while the drill is operating, double-sided tape or sandpaper is glued to the surface oriented to the plane being drilled. For versatility, you can make several holes of different diameters. If you provide one edge with a plate attached at a right angle, then the dust will not fly away, but almost all of it will settle on this shelf.

To secure cabinets, it is often necessary to prepare holes with a specific distance. Here the conductor will also come to the rescue, on which precise markings are made, and two holes are prepared. Further actions will be aimed at drilling the first socket for the dowel in the wall, in which one side of the conductor is attached with a self-tapping screw. All that remains is to level it using a building level and drill a second hole.

Material and tool

In order to carry out fastenings efficiently and in the shortest possible time, you should worry about tools and consumables in advance. This list consists of the following items:

- building level;

- measuring tape;

- plumb line;

- hammer;

- knife;

- a spatula, but only when it becomes necessary to level the walls;

- screwdrivers;

- screwdriver;

- drills;

- open-end wrenches.

As for the headset itself and the materials for it, these will be:

- components of a set of cabinets;

- screws for hinges;

- screws and nails;

- hinges on which façade doors are hung;

- ties for connecting all sections;

- tires and attachments;

- bases for fastening boxes.

Once everything has been purchased and delivered to the work site, you can begin the process itself.

Marking the wall for installing cabinets

Method 3. Plastic and metal wrap-around dowels

This is the fastest option for hanging a cabinet from a plasterboard wall. The downside is a significant limitation on the maximum load. The video below demonstrates what load different types of dowels can withstand:

For fastening, special roll-up dowels for DRIVA plasterboards are used. They come in metal and plastic, with or without a drilling tip, and have large external threads and a cross slot for screwing into drywall with a screwdriver. In contrast to previous methods, these fasteners should not get into the metal frame profiles.

DRIVA is simply screwed into the plasterboard sheet in the right place, its end is flush with the plane of the wall. The force when screwing should be controlled so that the dowel does not “fall” through the gypsum board. To fasten hanging furniture, self-tapping screws or self-tapping screws are screwed into DRIVA.

The declared maximum load on DRIVA fasteners is 25 kg. At the same time, we should not forget about the additional dynamic loads that arise during operation. Craftsmen recommend using DRIVA for attaching small cabinets, shelves, plasma panels and paintings to drywall.

Another innovative solution is the use of the Fischer DuoTec self-aligning dowel. The principle of its operation and installation technique can be seen in the video:

Why mount the cabinet to the wall and how to do it. Part 1

We are often asked if wall mounting is included with our cabinets. Based on the number of these questions, we can conclude that the topic is popular and it is better to answer it in detail once.

It is clear that, first of all, these articles will be useful for those who are designing a wall cabinet or shelf, but in this note we will also indicate why it is necessary to mount cabinets to the wall, even if they are securely on the floor:

STRENGTHEN AN UNRELIABLE STRUCTURE

Sometimes our clients order cabinets and shelving without a back wall. If the cabinet is small, then this is not a problem, but as the dimensions increase, the risk that the cabinet will fold like a house of cards or will wobble also increases. To avoid this, it is usually enough to secure the cabinet at at least one point in the upper part of the structure

REINFORCE LONG SHELVES

We do not recommend using long shelves. We wrote a separate article about the length of the shelves in more detail. Long shelves can be strengthened using the back wall of the cabinet, or the load can be distributed using additional fasteners.

PROTECT AGAINST TIPPING

There is a lot of news on the Internet about how even the most famous companies were forced to withdraw their furniture from sale due to tipping due to customer complaints. Moreover, it is usually not the companies that are to blame, but their clients. The fact is that usually all large companies play it safe and write in the instructions about the mandatory fastening of any cabinets and chests of drawers to the wall, especially in rooms where children may be. Children are a common cause of troubles with cabinets tipping over, and sometimes incidents end tragically (an example with a death, followed by a huge payout). The fact is that children can use your closet or chest of drawers as a playground. Adults often don’t understand that a closet can be used as a ladder, and a chest of drawers as a great place to hide. In this case, the load is distributed unevenly, and the structure may tip over on the child. Even the simplest fastening to the wall can protect against this.

We hope that these points will help maintain peace in your home, since a couple of extra neat holes in the wall are much more harmless than the possible consequences.

Source

Other types of fasteners

To hang several rather heavy cabinets on self-tapping screws already screwed into the wall, you can attach a strip to their back surface. This flat piece has a slot that resembles a keyhole in configuration. It is selected so that the diameter of the widest part of the hole is slightly larger than the head of the screw. The narrow part of the hole should be slightly larger than the diameter of the thread. When hanging the cabinet, the head of the self-tapping screw enters the wide part of the slot, and then moves under weight into the narrow zone, ensuring reliable fastening.

If you need to fix a fairly heavy object on the wall, made with plasterboard sheathing, then you can first make a hole with a diameter of ≈ 3 cm in the area of the fastening room, through which a solution can be introduced into the empty space, allowing you to create a strong bridge to the wall.

You can simplify the process if you correctly calculate the length of the screw. In order for the kitchen wall cabinet to be firmly fixed, several values are added up: the thickness of the drywall, the gap from the finish to the wall, the layer of plaster, the depth of the hole in the wall itself.

Cabinet hanging mechanisms

Initially, furniture was mounted on the wall using nails or screws. The disadvantage of fasteners is their fragility and fragility. The cabinet could collapse at any moment. This is especially dangerous for glass doors on modern headsets. But such canopies are still used today.

Classic hinges

This is a pendant in the form of metal plates 1.5-2 mm thick. They are attached directly to the wall using a regular or L-shaped self-tapping screw (crutch) screwed into a dowel.

There are several types of loops available:

- Simple pendants differ in the location of the mounting hole: at the top and in the center. The most aesthetically pleasing devices are those with a pear-shaped groove in the middle. They are not visible after installation. But this complicates the installation: when hanging a cabinet, you have to aim for a long time to get onto the suspension. Attached to vertical racks, designed for cabinets with a small load. When the groove is located at the top, it is easier to install furniture. The number of holes for self-tapping screws can reach 5, versus 2 for hinges with central fastening. They can withstand furniture with greater load. Screw to the sides of the cabinet.

- The corner canopy is non-adjustable - bolted to the top shelf of the box and to the wall. There are no installation problems, but the suspension is visible from both sides. The shape allows the cabinet to be hung close to the wall or moved away.

- P-shaped - screwed onto the box with self-tapping screws in 2 places: the upper horizon and the vertical post. This allows you to strengthen the structure through screeding. The time required to draw markings is reduced, since the horizontal position of the cabinet can be adjusted.

It is impossible to combine aesthetics and ease of installation of furniture hinges. Either they attach easily and stick out on the wall, or they are not visible, making them difficult to hang.

Mounting strip

Modern suspensions are easy to attach and easily move in the horizontal and vertical plane. The adjustment block is attached to the side panel of the cabinet through 2 through holes. There are mechanisms designed for different capacities. The maximum load on weak suspensions is 35 kg, on reinforced ones - 130. A fixing hook comes out of the block. To attach it, you need a strip that is mounted directly to the wall.

Advantages of adjustable hangers:

- a single strip on which the cabinet is supported is more reliable than a point fastening with screws;

- Possibility of hanging alone;

- adjusting the cabinet relative to the wall and floor;

- no strict requirements for marking - an error of 1.5 cm is allowed;

- Possibility of attaching to a kitchen apron.

Euro hangers have no disadvantages, except for their high price compared to furniture hinges. They are stronger and more reliable than self-tapping screws screwed into the wall.

Table of popular canopies

Below are the manufacturers of accessories. The most valued are Italian, German and Japanese companies.

| Manufacturer | Description | Price in Moscow (RUB per set) |

| Camar (Italy) |

When describing the company, the cost of the cheapest and most expensive kit was taken into account. We will separately tell you about specific models that differ in price and quality from their analogues.

| The company produces suspensions, full-fledged systems, as well as all accessories for fasteners separately. There are models of various sizes, load levels, and designs. | 200-1500 | |

| Hettich (Netherlands) | ||

| Produces strips, fastening fittings and components for them. There are currently no ready-made kits offered. | 350-6000 | |

| Samet (Türkiye) | ||

| The manufacturer offers individual spare parts and a complete set with rack and hangers. The maximum load per element is 40 kg. Movement relative to the wall and floor – 1.5 cm. | 160-700 | |

| Bloom | ||

| The company produces a small line of products, which includes all the components. Load capacity for 2 canopies up to 130 kg. Adjustment in 2 planes: horizontally up to 12.5 mm, vertically – 7-11 mm. | 600 | |

| Name | Characteristics | Price in Moscow (RUB per set) |

| cam0029.L |

The price for hangers is for 2 pieces. The weight of each component (mechanism, tire, plug) does not exceed 80 g. This does not play a role during installation, so the indicator was not considered.

Rules for wall preparation

Before installation, the working surfaces (rough) are put in order. The most important points:

- The walls are checked for distortions. In this case, you should use a level or a long-length building level.

- Assess the condition of corner areas. The walls here should make an angle of 90°C.

- Installation of sockets, chiselling of rough surfaces - these actions are completed before the process of attaching kitchen cabinets to the wall begins. The same should be the approach to the distribution of water supply communications and sewerage.

- Finishing work is in progress. Cabinets in the kitchen are installed after finishing the wall cladding, otherwise the joints between the pieces of furniture and the finishing material will be visible.

If the walls are wavy, it is recommended to remove the old layer of plaster down to the brick/concrete. Then the partition is finished from scratch. If cabinets are hung on wavy surfaces without eliminating the defects, the furniture will be positioned unevenly. This will negatively affect the interior.

Sophisticated adjustable closet awnings

Types of complex hangings for cabinets:

Press-in mounting for wall-mounted cabinets Traser-6

Traser-6 wall cabinet mount is designed for attaching a wall cabinet to a wall. Mounted on the side wall of the cabinet.

The hitch has the following adjustment options: vertically (18 mm), horizontally (16 mm), front (25 mm). The canopies are suitable for cabinets with a height of 600-1000 mm and a depth of 300-350 mm. One suspension can withstand a significant load of 65 kg.

| Rice. 5. Press-fit mounting for Traser-6 wall-mounted cabinets |

| Rice. 6. Adjustments for hinges for Traser-6 wall-mounted cabinets |

The concealed mounting bracket is located behind the rear wall after installation. To access the adjusting screw, a through hole is made in the rear wall.

To hang cabinets, in addition to the hangers, you need a counter strip or rail, which is attached to the wall at the required height using dowels.

Method number 1: on a wooden beam

In cases where you install plasterboard partitions yourself, you can mark out your future kitchen in advance and lay a wooden beam at the location of the mounting rail before finishing work. Choose a beam of medium width, about 8-10 centimeters, so that later you can slightly adjust the height of the cabinets. The timber is laid in the spaces between the vertical guide profile to a width equal to the width of the kitchen unit, and is attached to the main wall of the room. Subsequently, choose the fasteners for your cabinet so that its length is enough to sew through the plasterboard sheet and secure it in a wooden block. This method is usually chosen in cases where main walls are leveled with sheets of plasterboard.

Useful drilling tools

A jack of all trades always needs certain tools to work in a private house, on a summer cottage, in an apartment, or when building his own house. Many of them are not even worth purchasing if they do not require constant use. For example, for drilling, there are many different attachments that will greatly increase the functions of your drill and significantly expand them.

Let's look at some devices for auxiliary potential.

To obtain precise holes of significant diameter in different workpieces, a device such as a drilling and milling attachment will help to carry out individual milling work.

Make a milling machine out of a drill.

The next device worth mentioning is very expensive, but has the highest versatility. You will sharpen all the tools that you have on the farm, be it knives, shovels, axes, hoes, various drills, effortlessly with the universal sharpening device.

When purchasing drill attachments, be sure to check their compatibility.

Holder with clamp. With its help, you can fix the drill anywhere, use it with various kinds of devices, use it as a mini-lathe, sharpening, milling or grinding and polishing machine.

The drill holder allows you to quickly secure the drill.

All kinds of attachments are also designed for drills. These can be stops that limit the depth of drilling, platforms with which you can drill at a certain angle or perpendicularly. There are nozzles that are adapters and extensions of different designs: offset, angled, flexible.

The angle drill adapter is designed for hand and electric drills.

Metal cutting attachments turn your drill into a one-of-a-kind tool. Some resemble sheet metal shears, while others have a different feature, such as roller shears. The nozzle, called the “Cricket,” seems to cut through the metal.

The main advantage is that they do not damage the polymer coating of the metal.

There are also other attachments designed for monotype work.

- For installing aluminum rivets. There are types for both the same size and those with interchangeable bushings for different calibers.

- Tape-shaped attachment for self-tapping screws. With its help, you will significantly save time when working with plasterboard partitions or when you need to secure other materials with self-tapping screws.

- A belt sanding attachment will completely replace a sanding machine, and it will be much cheaper in cost.

- An attachment with which you can turn your drill into a hammer drill will not be superfluous.

- Using the corner pruner attachment, you can cut various cables, as well as tree branches.

- Using a variety of attachments, the drill will replace your jigsaw, circular saw, pump, and you can polish surfaces and sharpen drills.

- There are unusual attachments.

Whatever attachments we use, the main thing is that the work is enjoyable.

Furniture #10. Dear Customer. And I don’t know what’s next.

With kitchen sets there were problems not only with delivery. A lot of interesting things happened during assembly.

An ordinary apartment, a little more than 150 sq.m., half on one floor, the other half on the floor above, connected by an internal staircase. Such an ordinary two-story apartment.

Without much controversy, we ordered a set 6-7 meters long and priced accordingly. Good built-in technology. Everything arrived complete and on time. The owner really asked for it to be delivered faster, since his wife was in her 9th month and was about to give birth. And they would not want the work to be carried out after the birth of the child.

Our office accommodated us, found a “hole” in the schedule, and set it for the very next day. We arrive, deliver, pick up, and assemble. The owner does not sign the deed. I'm going to investigate, the same day in the evening after work. Remember about “circumstances”?

What is the headset on? That's right, on the floor. I check the floor. B-i-ingo! The slope, and what a slope, almost 12 cm over 6 meters of length. The steel ball, placed on the floor, immediately rolled towards the radiator.

Formally, we did our job perfectly. But it’s impossible to use. An adult woman will not provide a stool to rinse the cups in the sink.

There is a lot of work: dismantling, installation, adjustment, finishing the tile “apron” to a new level, moving sockets (planned, but then abandoned). And the Customer is understanding and agrees to additional expenses, as long as his wife feels good.

We agreed on a date, we are getting ready to leave, the owner calls. "Circumstances". He took his wife to the maternity hospital. He asks: can we do it in 3 days? Or in six months. And it only took us three days to assemble. And still do the dismantling. I talked to the assemblers and decided to do it. I added a couple more knowledgeable people to the team, and everything was ready for the owner’s discharge from the maternity hospital.

I don’t know what the future fate of the set and apartment will be. But sloping floors and ceilings in new buildings, when I started working in housing and communal services, no longer surprised me.

Mounting options

There are 2 methods by which fastenings for kitchen cabinets are made. Installation is carried out:

- One line, that is, the location of the fastener is equidistant from the ceiling;

It is considered the most common type of accommodation. This way you can easily secure the cabinets yourself.

This method is used much less frequently, since its implementation is much more complicated than a linear fastening scheme.

The first method is popular because you can use only your own strength to attach kitchen cabinets, without turning to outside help.

The choice of option is determined by the number, size and depth of wall cabinets.

The second option for attaching fixation items is less common among ordinary people. This is because the roof of this furniture is used as an additional surface.

Any of the proposed variations is perfect for both a room with a small area and a large one.

And all because they do not have any effect on the fullness or compactness of the room.

When choosing a method, only the interior and design change.

Hang cabinets on drywall

Often apartment owners have to solve the question: how to hang the kitchen on drywall.

As you know, such material is not durable, but we need guarantees of high-quality installation - who wants a cabinet to ever collapse on the floor?

The problem is still doable.

Fastening methods:

- Butterfly dowel. Only suitable for light wall-mounted modules weighing up to 5 kg. The dowel body is aluminum, made in the form of a collet (a hollow cylinder with longitudinal cuts). When the screw is screwed into the dowel, the antennae move apart and are pressed into the surface of the hole in the sheet.

- Mounting rail. It is attached to a sheet and a wooden frame - this ensures higher reliability of fastening. Knowing in advance that the cabinets will be hung, you need to, if possible, take care of a more durable base (mortgages) under the drywall in the form of timber.

- In order to secure very bulky furniture, they also use additional fasteners: decorative cable. It is attached to the ceiling. In addition, tubes coated with a layer of chromium are used. They are screwed to the floor and serve as a frame.

Basic requirements for bathroom furniture

Before making a cabinet in the bathroom, you should keep in mind that this room has its own special climate, which differs from the rest of the rooms in the house due to high humidity, sharp temperature changes and lack of space. Therefore, furniture made from ordinary materials may “not survive” here. In order not to throw away your product, you should carefully select the materials from which you are going to make a cabinet in the bathroom. There are a lot of options to choose from: you can make a bathroom cabinet from wood, chipboard, MDF, plastic, glass, metal. The main thing is to follow the basic requirements:

Among all the materials listed above, there are types that can be adapted to the conditions of the bathroom, and some themselves fully meet these characteristics, but a certain type of cabinet will help cope with the lack of space.

Advantages and disadvantages of the plank

This simple design has a number of advantages, which is why it has gained its popularity:

- Even non-professionals - people with basic construction skills - can cope with the installation.

- When installing adjustable awnings, there is no need to measure and drill holes for each wall hanging cabinet separately. The general level is reflected.

- Using anchor bolts you can adjust the position of the cabinets. They can be placed on the same level, regardless of the flaws of the wall.

- Unlike fastenings for wall-mounted kitchen cabinets with dowels, a design with a strip is considered more “durable” and reliable. Even if a couple of screws loosen over time, the rest will hold well even when the cabinets are as full as possible.

The system has no global shortcomings. The only thing you should keep an eye on when purchasing a bar is the quality of the material. Low grade metal will bend a lot and may even break during furniture installation.

The locking mechanisms of kitchen cabinets have to endure heavy loads.

Tips for performing work

To ensure long service life and reliability of the structure, preference should be given to fastening elements that fully comply with technical requirements. To achieve a uniform load, the cabinet must be fastened exclusively by level. In order to prevent damage to the gypsum boards, it is necessary to strictly control the tightening force of the anchor bolts. The height of fastening objects to a plasterboard wall is determined taking into account your own height and family members, the distance between the work area and hanging pieces of furniture.

Bolts, anchors or tires?

To ensure that the fastenings are reliable and the filled cabinet does not fall at the most unfortunate moment, you should take into account the material used to make the walls and furniture. Carefully consider the type of fastening.

How to fasten and what fittings are most optimal for a brick, concrete, wooden wall?

For a wooden wall of a country house, fastening with countersunk screws made of hardened alloy would be optimal. The most effective installation is with self-tapping screws with a large pitch and double-start thread.

It is better to attach shelves to a concrete and brick base using dowels, plugs, metal bolts, and plastic fasteners. You can strengthen the fittings in the holes after the drill with gypsum mortar.

Molly or butterfly screws will securely secure hanging furniture to a plasterboard wall.

For open shelves with light loads, decor, and lighting, you can use plastic butterfly dowels and drill dowels.

Hanging storage systems for dishes, food, and equipment should be mounted on classic metal fittings. For example, you can buy regular dowels made of durable alloy or molly (butterfly dowel in a metal version).

If it is impossible to reach the wall through the sheathing, you can use wooden bookmarks. The thickness of the embedded beam should be equal to the thickness of the transverse frame. If these numbers do not match, the structure may become deformed. The thickness of the timber is adjusted according to the profile sample. A metal butterfly screw is optimal for fastening hardware.

The attachment is attached directly to the bar made of bars. To enhance the load-bearing capacity, use the longest length of the plank: for example, along the width of the entire set of hanging furniture.

The two most proven types of fasteners are:

- mounting rail;

- classic bolts and screws.

Step-by-step instructions for 2 hanging options

Two methods of installing the upper block are used: in the first case, different types of fastening fittings (corners, hinges) are used, in the second case, a mounting canopy formed from a wall strip is used. Regardless of the chosen option, the fittings are first screwed to the furniture, then markings are formed on the wall for it.

Ordinary method

In the traditional hanging scenario, the corners and hinges are screwed almost identically:

- the fasteners are applied to the edge of the block and the entry points of the screws are marked with a pencil;

- If the hinges are fixed with self-tapping screws, holes are formed for them, the diameter of which should not exceed 2 mm. When using a furniture confirmator, you need to arm yourself with special drills with the same marking;

- the loops are screwed to the object being hung. Self-tapping screws used in relation to the side wall must be no shorter than 50 mm;

- When the hinges are securely fixed, it becomes possible to accurately measure the level of installation of fasteners that will be placed on the wall. It is important to fix the distance between working points;

- for hanging heavy modules, anchors with a diameter of at least 6-10 mm are used, light blocks are placed on metal hooks, similar in structure to self-tapping screws;

- when using powerful anchors, drill a hole into which the fasteners are placed; later it can be tightened after hanging the cabinet. A plastic dowel is hammered into the holes intended for light hooks and the fittings are screwed in.

Lightweight hanging blocks are mounted using hooks with a diameter of up to 5 mm.

Installation method

To properly secure kitchen wall cabinets, you need to select a tool in advance and strictly follow the installation technology. It’s easier to do the work with 4 hands, but 1 person can do it

Of course, this will take a little more time and will require extreme concentration, accuracy and caution.

An important factor is the reliability and quality of fastening of each part of the headset to the wall.

Preparatory stage

Before starting the process of drilling surfaces and direct installation, you need to perform the following steps:

- Cleaning and leveling walls. The easiest way to do this is with drywall. First, you need to secure a frame of profiles to the wall, on which the structure of the cabinets will be supported.

- For corner kitchens, the angle between the two planes should be maintained at 90 degrees. If the curvature of the walls is insignificant, you can simply plaster them.

- Applying basic markings. Using a perpendicular, a construction pencil and a level, you need to schematically arrange the attachment points and select the height of the structure.

- If the situation requires it, you must first install all sockets and lighting fixtures and attach all related elements.

- Before starting work on the installation of kitchen cabinets, the walls must be painted or wallpapered - no repair work should be carried out after installation.

Hanging height indicators

It should be convenient to use the set, so the height of the cabinets directly depends on the height of the owners and the anatomical features of their figure, and the features of the room.

Before you start assembling the set into a single “wall”, you need to decide on the height at which the furniture will be hung.

Main criteria and numbers:

- The drawers should be tactile and located at eye level. On average, the distance from the plane of the table top to the top cabinet is 55-65 cm. In this case, a person must reach the very top shelf without the risk of dropping the desired item and without the use of auxiliary objects (chairs, benches, etc.).

- If you do not plan to mount a table top or the lower part of the set, then the ratio of human height and fastener height should look like this:

- up to 165 cm – 175-180 cm;

- 165-157 cm – 185 cm;

- 175-190 cm – 200 cm.

To correctly carry out these manipulations, preliminary calculations must be made.

Required tools and materials

To carry out the work quickly and efficiently you will need:

- Drill or hammer drill with drills or augers. For brick and concrete, the impact mode should be used; for other surfaces, regular drilling will be sufficient. When working with tiles, you need to stock up on drill bits with pobedit tips.

- A screwdriver, which will be used to tighten the screws for attaching the holders to the cabinets.

- Construction pencil and tape measure.

- Level for marking the location of cabinets and adjusting awnings.

- Stable ladder.

Installing a cabinet in the bathroom

After the cabinet is assembled, the only remaining question is how to install the cabinet in the bathroom. In the case of a classic pencil case, there should be no difficulties - we just put it in a predetermined place. If you made a cabinet with legs, take care to equip them with adjusting mechanisms so that the installation of the cabinet in the bathroom is reliable, especially when the floor is imperfect.

For a wall cabinet, you need to proceed differently. Before you make a bathroom cabinet, you need to decide whether to do it using a mounting strip or ordinary furniture hinges.

Selecting the height of the cabinet

Before you start attaching wall cabinets to the wall, you need to choose the right height for hanging them. It is determined based on the main criterion - the height of the owner. On average, the distance is approximately 50-60 cm from the countertop to the bottom of the wall cabinets. According to GOST, this value is 45 cm.

Methods for assembling hinged elements

Any disassembled kitchen is a set of parts made of chipboard and MDF, fittings, and fasteners. Using all this, you need to assemble the cabinets. The kitchen is mainly equipped with upper and lower cabinets.

Methods for assembling a kitchen set:

- In pairs. The master assembles the upper and lower cabinets and then installs this pair.

- First, assemble the upper cabinets, and then the lower ones.

- The lower elements are assembled first, and then the upper ones. Many people find it more convenient to hang the upper elements while standing on the countertop.

If you collect everything at once and then install it, you can clutter the entire apartment, but sometimes this is not possible, especially if the apartment is one-room or heavily cluttered with furniture.

How to place it correctly?

There are a few simple rules:

- accessibility of food, dishes and other kitchen utensils stored in the closet - to ensure this possibility, it is recommended to place pieces of furniture at a given distance from the countertop, and not under the ceiling;

- cabinets should not interfere with air circulation, so they are installed next to the ventilation grille, and it is prohibited to close the entrance to the duct;

- pieces of furniture in the kitchen are placed so that they do not spoil the geometry of the room.

The distance is enough to place all kitchen appliances on the table. Moreover, more often they choose an option within 45-50 cm. A distance of 65 cm and above in most cases determines the position of the hood (from the countertop to its lower edge).

You should also focus on the growth of the residents of the house. Possible options:

- If a person's height is between 155-160 cm, the recommended height from the floor to the top shelf is 175 cm.

- If your height is 160-170 cm, the top shelf should be located at a height of 190 cm.

- For tall home owners (height 170-190 cm), a suitable option is when the top shelf is at a height of 200 cm.

If you do not follow these recommendations, it will be difficult to freely use dishes and kitchen utensils located in cabinets. You will have to use a stool for this purpose. In addition, you need to check at the installation stage that the hanging furniture is level. Any distortions can lead to the collapse of part of the kitchen equipment. In this case, the appearance of the interior also deteriorates. A building level should be used to check the position of the cabinets.

Almost always, wall-mounted and floor-standing pieces of furniture are placed so that they are on top of each other. Otherwise, the set will not look organic and symmetry will be lost. If necessary, cabinets are positioned higher or lower than existing standard values. However, before you finally drill holes in the wall, you should make sure that a person can easily reach the top shelf. Recommendations for calculating the installation height of cabinets:

determine the height of all residents of the apartment, take the average value - if you focus on only 1 family member (the tallest or shortest), then the rest will be uncomfortable using the furniture; take into account the dimensions of the upper cabinets; The most harmonious look is the set, which occupies most of the wall, for this reason, when choosing, you need to focus on the height of the ceilings of the room; sometimes it is important to make the apron high enough (for example, when installing specific decorative elements, the upper cabinets are raised additionally); The style direction in which the set is made is also taken into account (sometimes it is necessary to place cabinets at some distance from each other)

Installation instructions

- After completing the preparatory work, you can begin assembly. After screwing the screws, you need to align the hooks in one position and make sure that they are at the middle level. Canopies must be secured in one position. The protrusion of the fastening part (has a hook configuration) should be 2 mm in relation to the rear of the wall.

- If you planned to cut the tire, then it’s worth taking care of the preparations.

- Holes are made on the pre-marked wall for fixing the tire.

- The body of the hanging furniture must be mounted on a tire. The reference point is the plane of the wall. The next fastening of wall kitchen cabinets is carried out based on the previous one.

- The next step is the sequential fixation of installation objects using fasteners. A clamp is used for this. To prevent the surface from being damaged, a thin layer of insulating material must be laid.

- Next, you need to drill holes in the housings. To avoid cracks or splinters, use plywood or wood overlay. After preparing the apertures, the elements are connected with ties.

- After hanging and fixing the drawers, the doors should be screwed on. To do this, they must be laid out on the floor in such a way as to attach the loops to special niches. After this procedure, installation to the housing occurs.

Installation of doors and opening mechanisms

|